Low-Volume Rapid Stretch Blow Molding With 3D Printed Molds

Whether you are looking to design functional prototypes with end-use materials, fabricate parts during pilot production, or manufacture end-use parts, 3D printed rapid tooling combined with traditional manufacturing processes offers a cost-effective way to quickly produce parts in limited quantities.

For stretch blow molding (SBM), molds can be 3D printed for low- to mid-volume production, to prototype in the final material, or to enable multiple model testing and quick design modifications in pre-production.

This white paper provides methods and guidelines for using stereolithography (SLA) 3D printed molds in the SBM process to lower costs and lead time during pre-production. From design and workflow considerations to molding conditions, it details the feasibility study from two industry experts, Unilever and Serioplast, to establish a new innovative solution for accelerating product development with on-demand tooling.

Low-Volume Rapid Stretch Blow Molding With 3D Printed Molds

Whether you are looking to design functional prototypes with end-use materials, fabricate parts during pilot production, or manufacture end-use parts, 3D printed rapid tooling combined with traditional manufacturing processes offers a cost-effective way to quickly produce parts in limited quantities.

For stretch blow molding (SBM), molds can be 3D printed for low- to mid-volume production, to prototype in the final material, or to enable multiple model testing and quick design modifications in pre-production.

This white paper provides methods and guidelines for using stereolithography (SLA) 3D printed molds in the SBM process to lower costs and lead time during pre-production. From design and workflow considerations to molding conditions, it details the feasibility study from two industry experts, Unilever and Serioplast, to establish a new innovative solution for accelerating product development with on-demand tooling.

Introduction

Blow Molding

Blow molding is a group of long-established manufacturing processes for producing hollow plastic products such as food and beverage containers, cosmetic packaging, medical packaging, and more. It is a rapid mass production method for high-quality, thin-walled parts. Blow molding has very short cycle times, typically between one and two minutes, and is extremely costeffective for high-volume production. It is usually employed for producing millions of identical parts at low unit costs.

Blow molding is the forming of hollow plastic parts by inflating a heated plastic tube, called parison or injected preform, inside a mold until it forms into the desired shape. There are three types of blow molding processes: extrusion blow molding (EBM), injection blow molding (IBM), and stretch blow molding (SBM). This report considers SBM, which is commonly used to produce high-quality glass clear PET containers such as water bottles.

SBM molds are traditionally made out of metal by CNC machining, which requires specialized equipment, CAM software, and skilled labor. The production of metal tooling is generally outsourced to service providers offering four to eight weeks lead time and costs anywhere from $2,000 to $100,000+ depending on the complexity of the part and the number of parts per mold. As a result, blow molding parts in low volumes has traditionally not been economically feasible.

Rapid Tooling With 3d Printed Molds

3D printing is a powerful solution to fabricate tools rapidly and at a low cost. It requires very limited equipment, freeing up CNC capacity and skilled operators’ time for other high-value tasks. With in-house 3D printing, manufacturers and product designers can introduce rapid tooling into the product development process to validate design and manufacturing steps before transitioning to mass production. 3D printed molds are already used in processes such as injection molding or thermoforming to iterate quickly, accelerate product development, and bring better products to market.

Stereolithography (SLA) 3D printing technology is a great choice for molding. It is characterized by a smooth surface finish and high precision that the tool will transfer to the final part and that also facilitates demolding. SLA 3D printed parts are chemically bonded such that they are fully dense and isotropic, which makes it possible to produce functional molds at a quality not possible with other common plastic 3D printing technologies, such as fused deposition modeling (FDM). SLA 3D printing also offers unmatched design freedom to create complex and intricate molds. Desktop SLA printers, such as the Form 3+, can integrate seamlessly into any workflow as they are easy to implement, operate, and maintain. While being compact enough for an office, the large format Form 3L enables the fabrication of large-scale parts and molds. Additionally, Formlabs offers a wide range of engineering materials with mechanical and thermal properties that pair well with tool manufacturing.

Get Started with 3D Printing

Formlabs' complete, easy-to-use ecosystem makes it simple to get started with 3D printing. Explore our 3D printers and materials to find the right fit for your needs.

How Unilever and Serioplast Accelerate Pilot Testing

Reduce Lead Time And Costs With Modular Tooling

As one of the world’s largest fast-moving consumer goods (FMCG) companies, Unilever is constantly developing new products for everyday use, from personal care to home care, nutrition, and more. Serioplast Global Services is one of their major partners for producing rigid packaging for the home and personal care market in PET, PP, and PE bottles through stretch blow molding (SBM), extrusion blow molding (EBM), and other injection and blowing technologies (ISBM, IBM).

To stay ahead of the competition in this fast-moving industry, the two partners have been exploring innovative ways to accelerate prototyping and pilot testing. With this in mind, Stefano Cademartiri, CAD & Prototyping Owner at Unilever R&D Casalpusterlengo Italy, and Flavio Migliarelli, R&D Design Manager at Serioplast Global Services, worked hand in hand to test the viability of 3D printed molds for low-volume stretch blow molding. This white paper reports their process and findings.

Industrial blow molding machines in Serioplast’s facility in Bergamo, Italy.

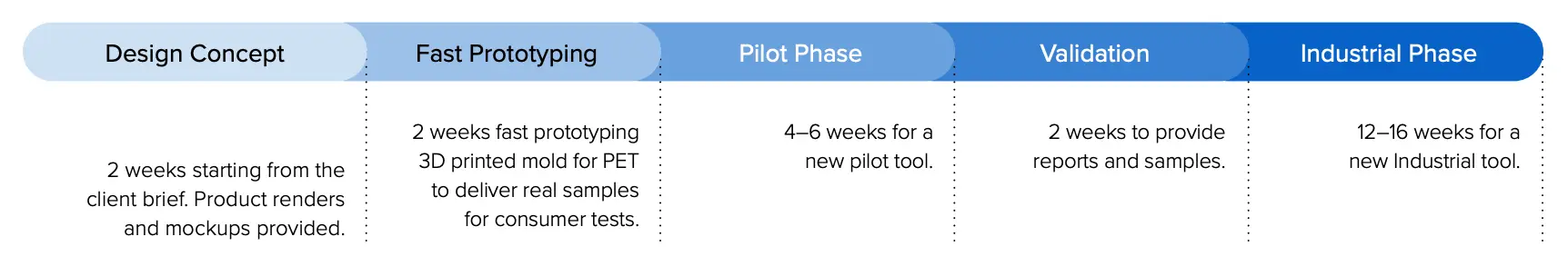

The goal of Unilever and Serioplast’s research was to develop a modular SBM tool to speed up product development by enabling the quick and cost-effective fabrication of high-fidelity prototypes and pre-production parts for pilot testing. A pilot run usually requires about 2,000 to 5,000 units of a product, complying with the aesthetic and functional specifications. These samples are deployed in consumer testing, process validation, and line testing.

Production Quality Parts For Consumer, Process, and Line Testing

Typically, Serioplast would either directly 3D print mockups for prototypes or produce them through blow molding. Traditionally, 3D printed mockups didn’t represent the right feel or transparency and were not reliable enough to be sent to consumers. However, building production-quality samples through SBM requires expensive metal tooling, adding six to nine weeks of lead time to a typical pilot testing phase due to the complexity of the process and outsourcing the production of the mold. Even machining a metal mold in house normally takes six weeks as it requires several steps: lead time for material order, CAM and machine setup, manual polishing, and waiting time for machine availability.

Serioplast’s tool manufacturing factory is equipped with CNC machines (top) to fabricate pilot and production tools in metal (bottom).

With 3D printing, a mold can be built in two days. 3D printed molds reduce the lead time to start pilot testing from six to two weeks while achieving realistic pre-production parts that are very close to production quality and molded using the same material and machinery as the eventual production units. Additionally, 3D printed molds allow operators to pilot-test multiple designs simultaneously.

Project timeline to fulfill a typical order.

For one client seeking to test four different designs, Serioplast was able to produce 200 units of each design in only one month. Running such extensive testing with traditional methods is almost impossible. They would need to invest in a metal mold for each design without the benefits of economies of scale and would never recover tooling costs.

Primarily, the 3D printed tools are employed to produce samples for consumer testing. They are representative of the final product in terms of feeling, aesthetics, and usage, and are perceived as the real product in the eye of the consumer.

A secondary use of the modular mold is to validate the SBM process as well as the PET preform that will be blown, looking at the process windows, stretch ratio, and material distribution achievable. Serioplast produces the preforms in-house through injection molding. While some preforms are custom-made for a specific bottle, they usually work with standardized items that users can’t modify. The Serioplast team wanted to understand the range of capabilities available through this stock preform. Knowing this information helps them determine if a given preform is suitable to blow mold a specific bottle before going into production.

The third application for producing rapid molds is to test some aspects of the production line early on. Because the bottles formed with 3D printed molds are so close to the production units, they can be employed to carry out some primary validation of the filling line such as the movement of the line, the operation of the star wheels for the bottle-filling machines, the capping, or the action of the robotic case packer. Pilot testing the manufacturing line early allows factories to anticipate spare parts, prepare the line for mass production, and accelerate their time to market.

Book a Consultation

Get in touch with our 3D printing experts for a 1:1 consultation to find the right solution for your business, receive ROI analyses, test prints, and more.

Method

Polymeric 3D printed tools are intended for low-volume production as they show reduced longevity and dimensional accuracy compared to a production metal tool. However, with the right preparation, 3D printed SBM tooling can produce hundreds of parts with a quality close to what is achievable with traditional metal molds.

To optimize the dimensional accuracy, lifetime, and dimensional stability of a 3D printed mold, three parameters should be considered:

- The thickness of the mold: a thicker part tends to deform more during printing.

- The supports placement and orientation of the mold while printing: the print preparation influences the dimensional accuracy of the print.

- The 3D printing material: the tool needs to withstand the pressure and temperature of the SBM process while maintaining the critical dimensions throughout the cycles.

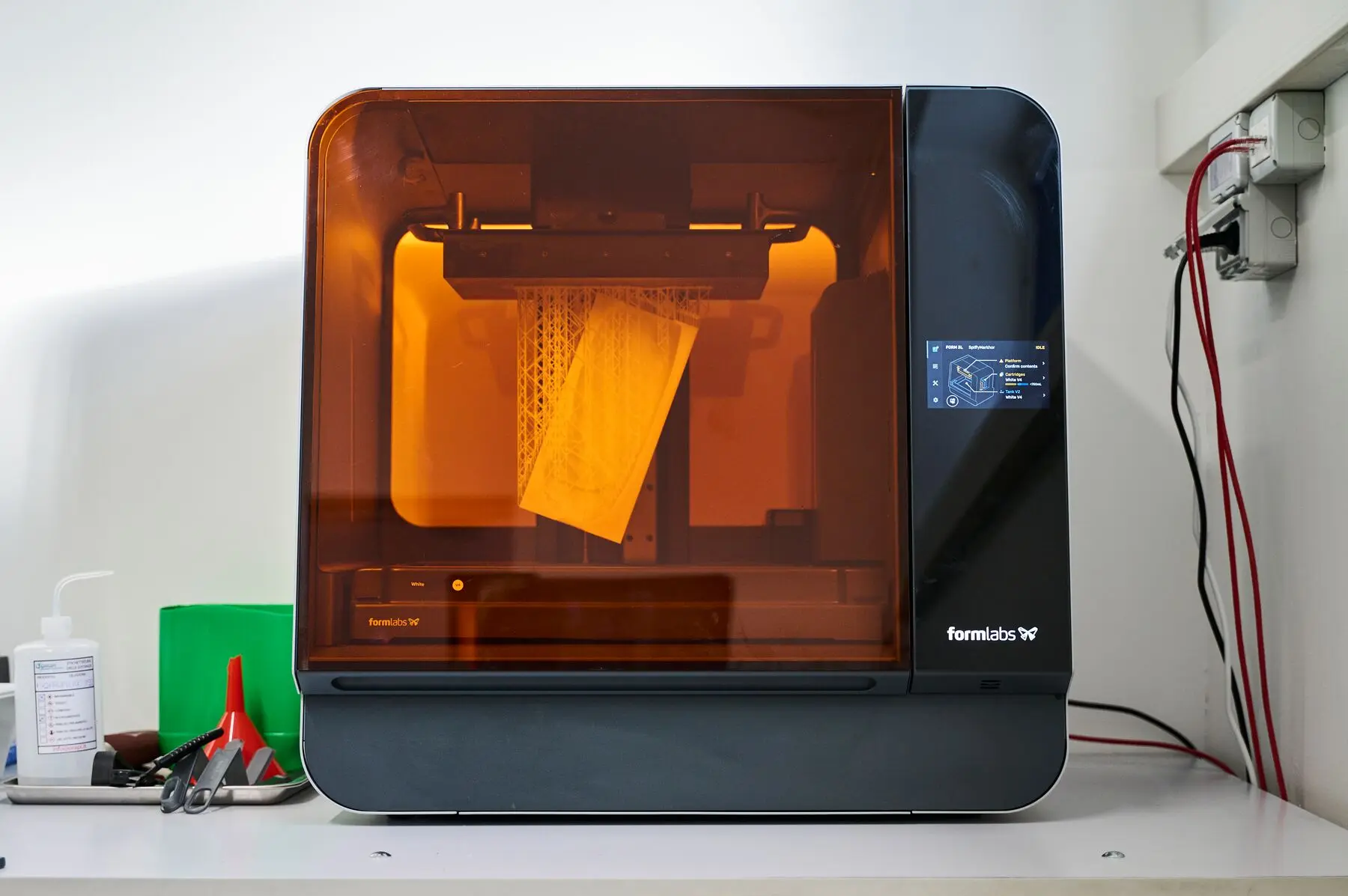

Both Unilever and Serioplast teams used the Formlabs Form 3L, Rigid 10K Resin, and PreForm print preparation software for this research project. The next sections share their feasibility studies and best practices. Formlabs manuals, product setup, and 3D printing instructions are available on Formlabs' support page.

Process Overview

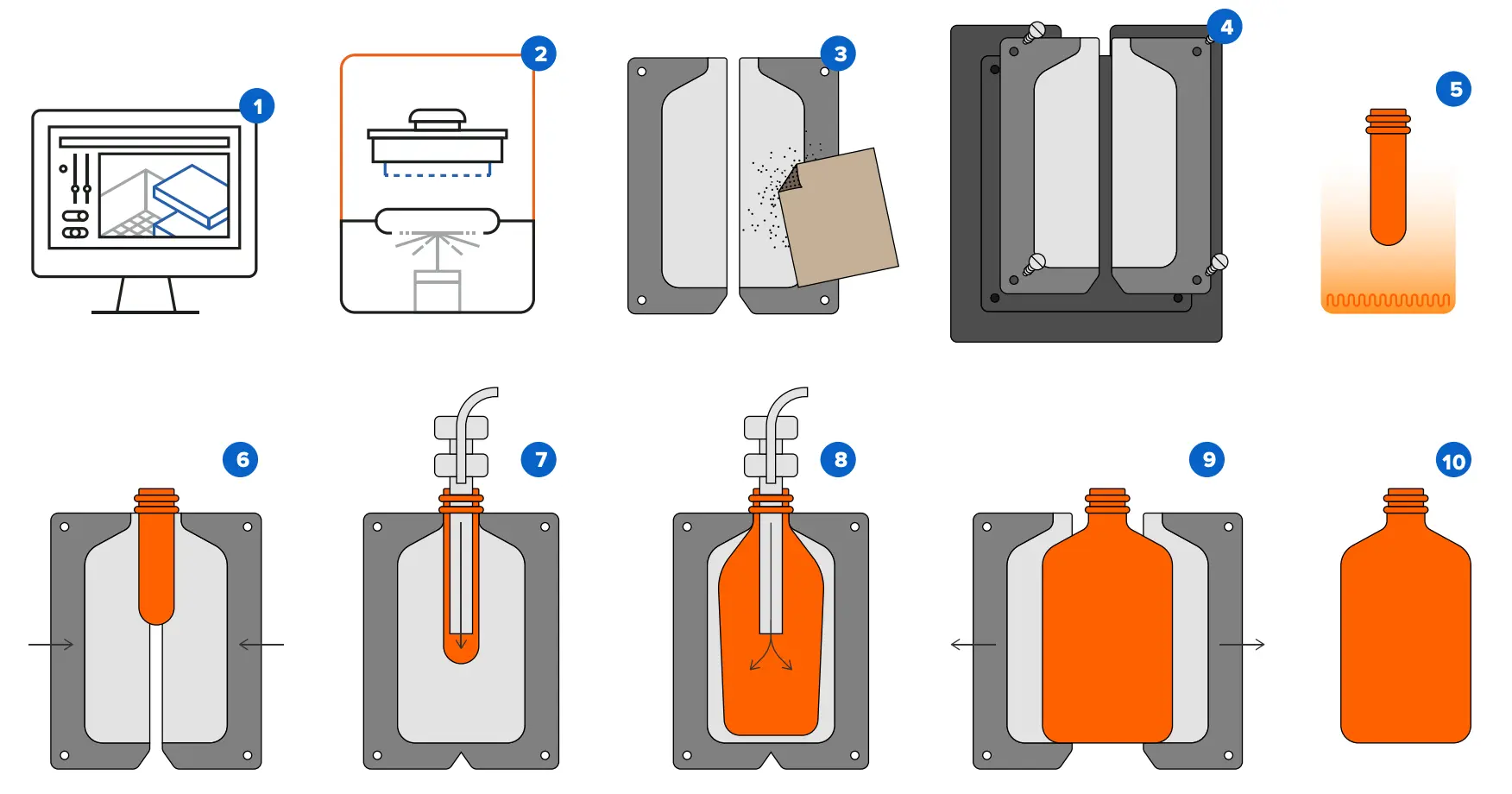

1. Mold design

2. Mold 3D printing

3. Mold post-processing

4. Mold assembly

5. Injection molded preform heated

6. Preform secured into blow mold

7. Preform stretched with core rod

8. Compressed air is blown in and preform inflates to mold

9. Product is removed from mold

10. Finish product

Designing The Mold

Serioplast did multiple SBM trials with 3D printed molds, testing about 15 different designs, mostly on new products. The following report displays the results of trials done on a 3D printed mold for a Unilever Slice 750 mL bottle already on the market.

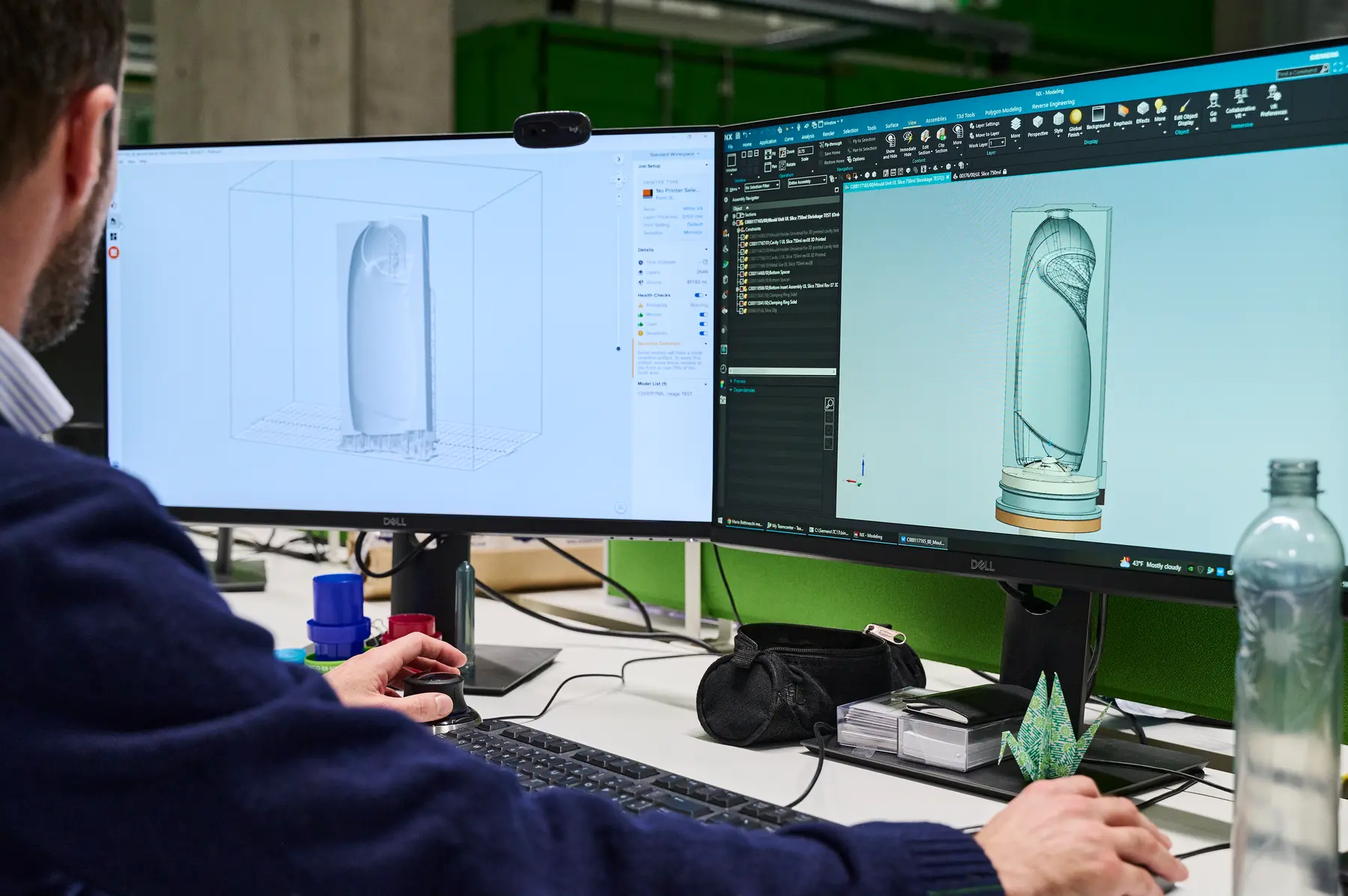

CAD model of the mold and STL file loaded in PreForm software

A dimensional accuracy study of the bottle is shown in the “Results” section. It is driven by two main parameters: the shrinkage behavior of the plastic inside a high-temperature mold and the dimensional accuracy of the printed mold.

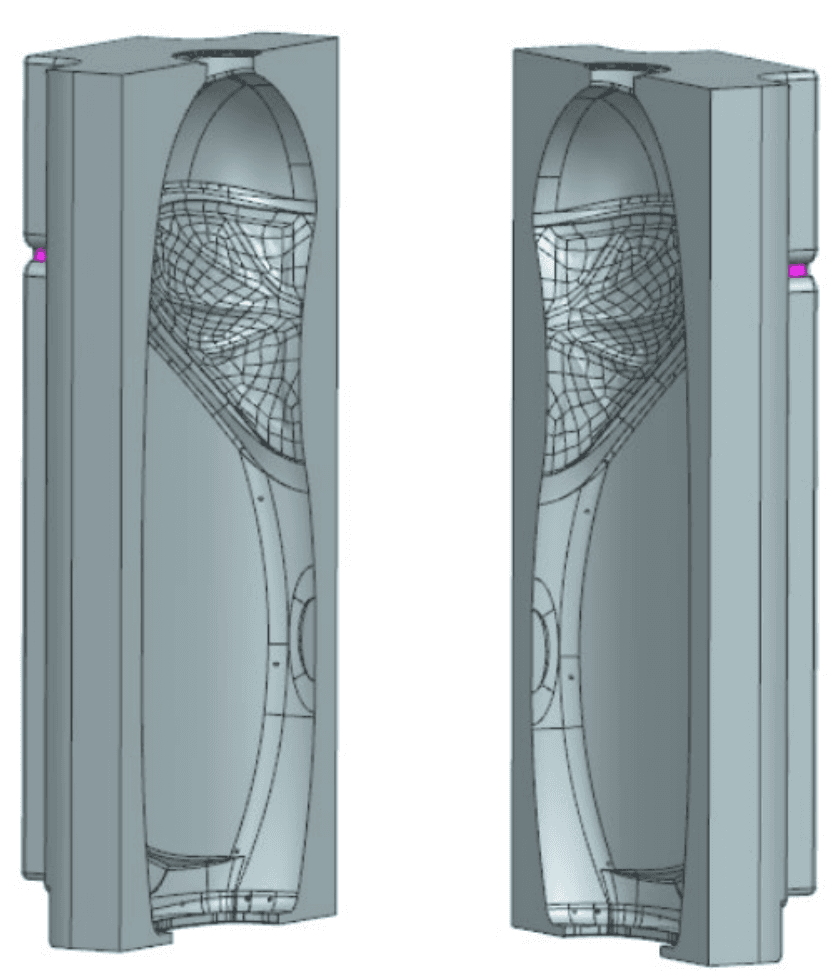

The team investigated the influence of the cavity design and print settings on the dimensional accuracy and planarity of the printed mold. In the first step of CAD design, they found that removing material on the back of the cavity reduces the risks of deformations, material cost, and printing time.

CAD design of the 3D printed mold assembly with the cavity back (left) cavity operator side (right), and bottom insert (bottom).

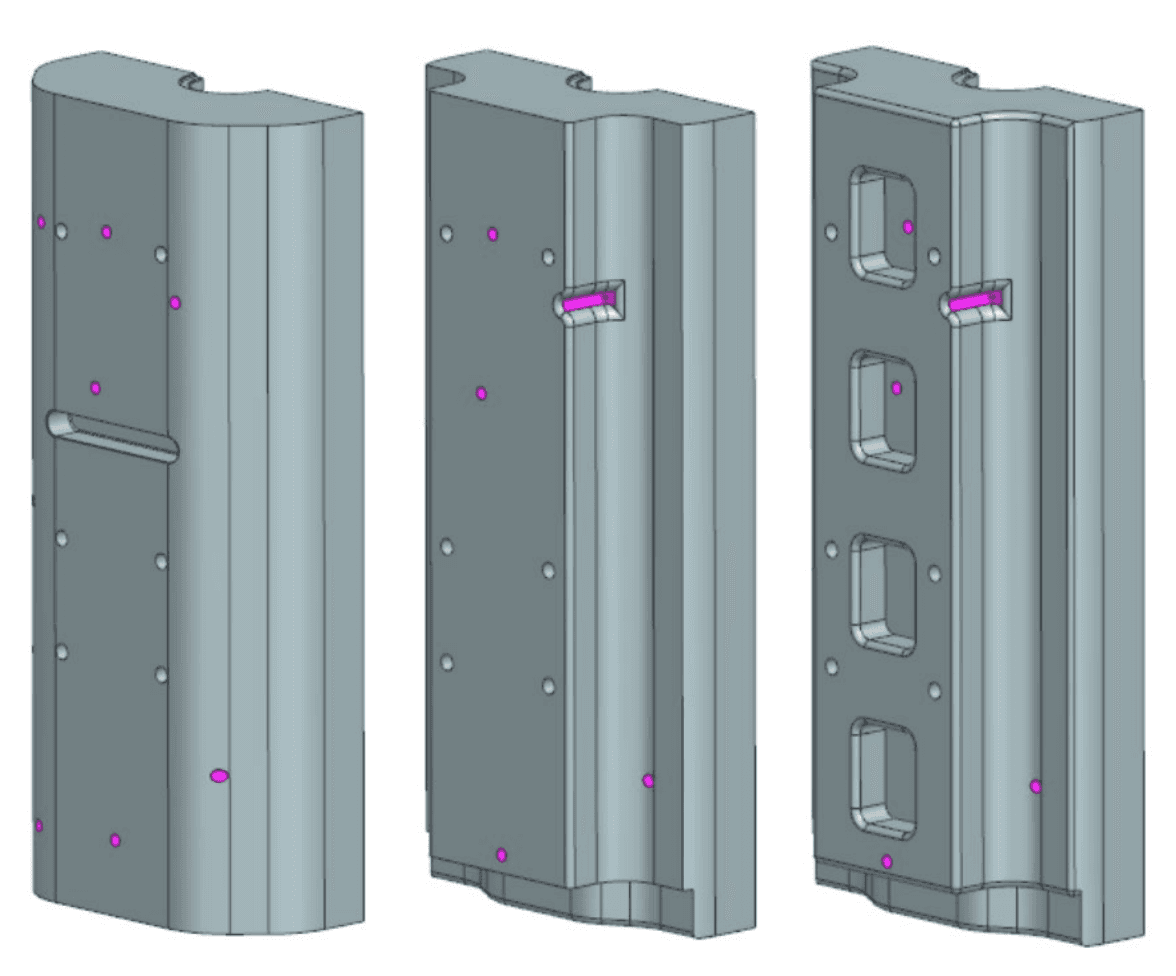

Iterations on the CAD design of the mold starting from a solid block to guarantee robustness (left), to a block with removed unnecessary area not in contact with the shell holder (middle), to the final design with further slots added to decrease weight and material distortion (right).

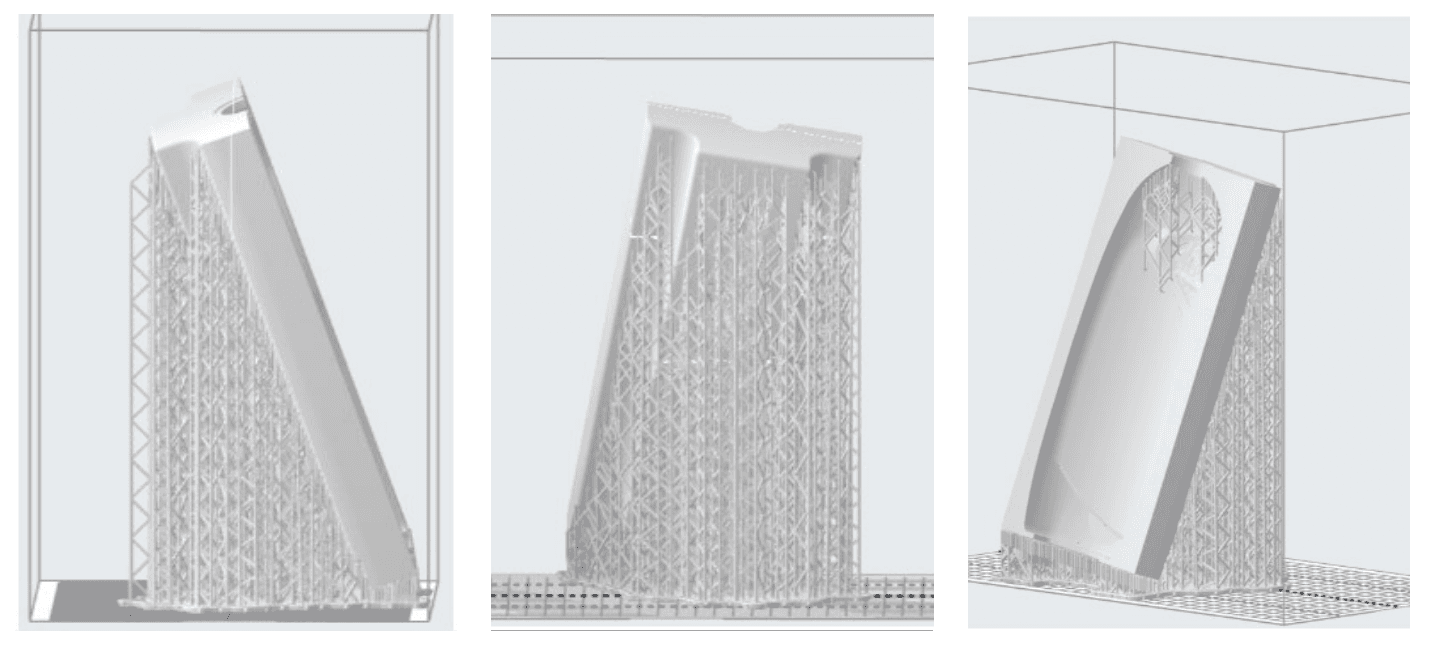

The print preparation in PreForm software is key to the success of the 3D printed mold. By finetuning the print settings, it is possible to maximize dimensional accuracy and planarity. For this project, they tilted the part by 30° along the z-axis, 20° along the X-axis, and 10° along the Y-axis. The orientation is optimized to minimize supports inside the cavity, avoid laser printing parting lines on the figure, and keep enough strength in the supporting.

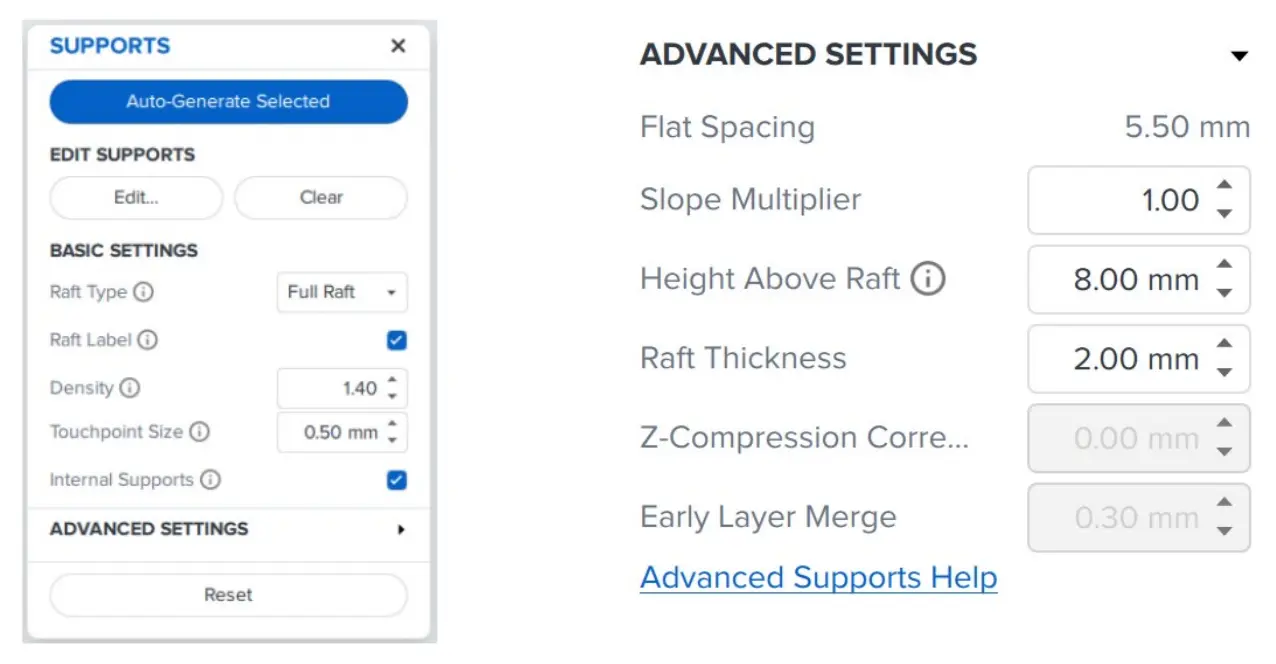

Print settings used by Serioplast in the PreForm print preparation software.

A mold half in PreForm print preparation software

Once the Serioplast team has a standard mold design and print preparation they only need to modify the cavity for each new bottle design. It takes at most two working days to prepare, whereas designing a standard metal mold can take more than two to three weeks. Textures and surface finish can also be directly implemented in the CAD model.

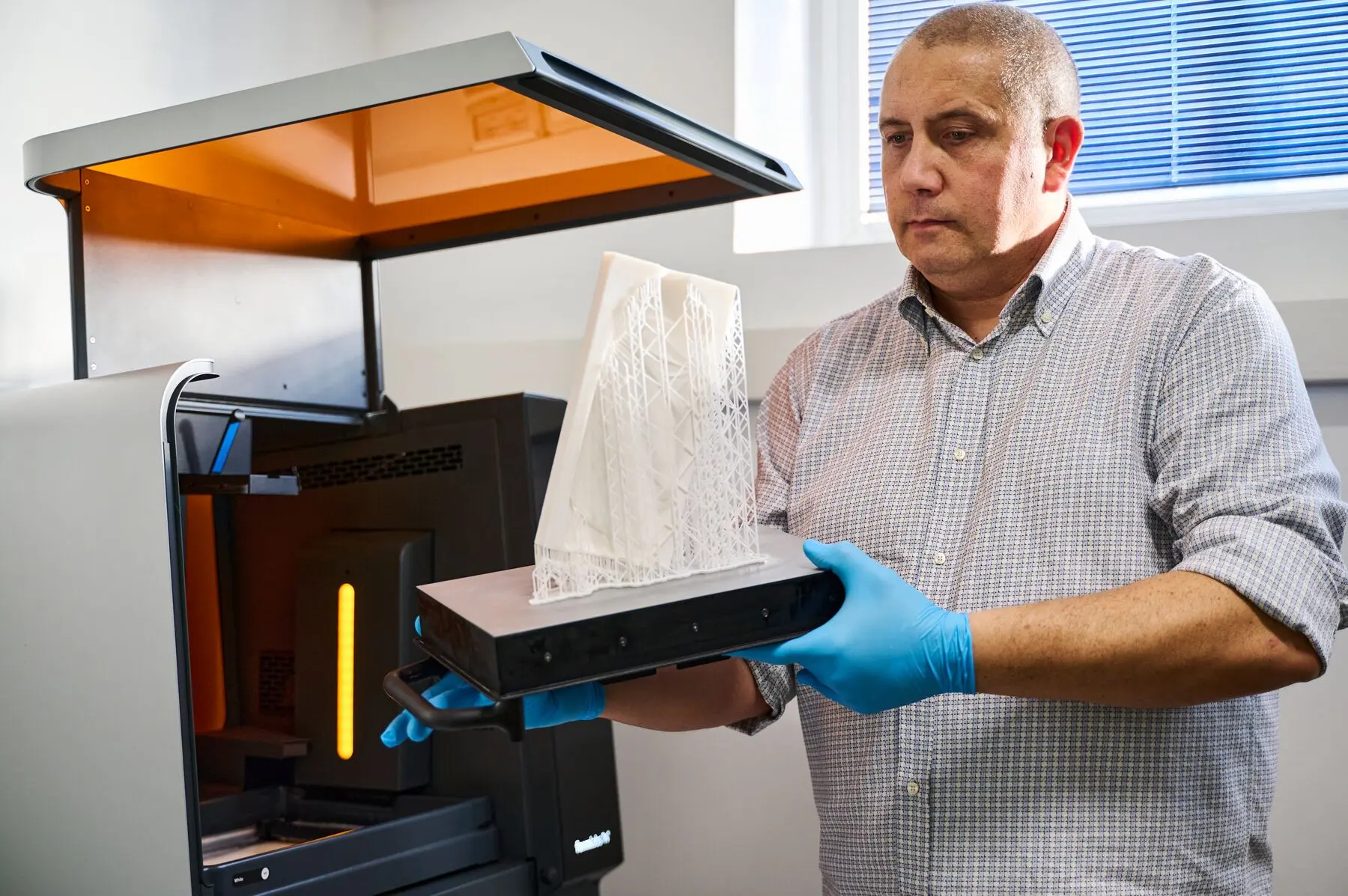

3D Printing the Mold

The next key step is choosing the right resin for 3D printing. The Serioplast team needed a material that could withstand the internal pressure and the temperature of the SBM process while showing good dimensional accuracy and stability. Rigid 10K Resin is Formlabs' recommended material for SBM as it combines strength, stiffness, and thermal resistance. It is an industrialgrade, highly glass-filled material with an HDT of 218°C @ 0.45 MPa and a tensile modulus of 10,000 MPa. Tooling printed with Rigid 10K Resin has good dimensional stability and is suitable for hundreds of blow molding cycles with high repeatability.

With Unilever’s 750 mL bottle design, one mold half requires 776.54 mL of resin and 25 hours to print at 100-micron layer heights. Each cavity is built separately to limit the deformation.

After printing, the parts are washed in IPA twice for 10 minutes, dried with compressed air if available, and post-cured at 70 °C for 60 minutes following Formlabs instructions. Alternatively, the parts can be heated in a non-food oven at 90 °C for 125 minutes for a higher HDT.

Rigid 10K Resin prints can be wiped with mineral oil to remove any excess powdery glass particles, and media blasted to improve the surface quality and mechanical properties.

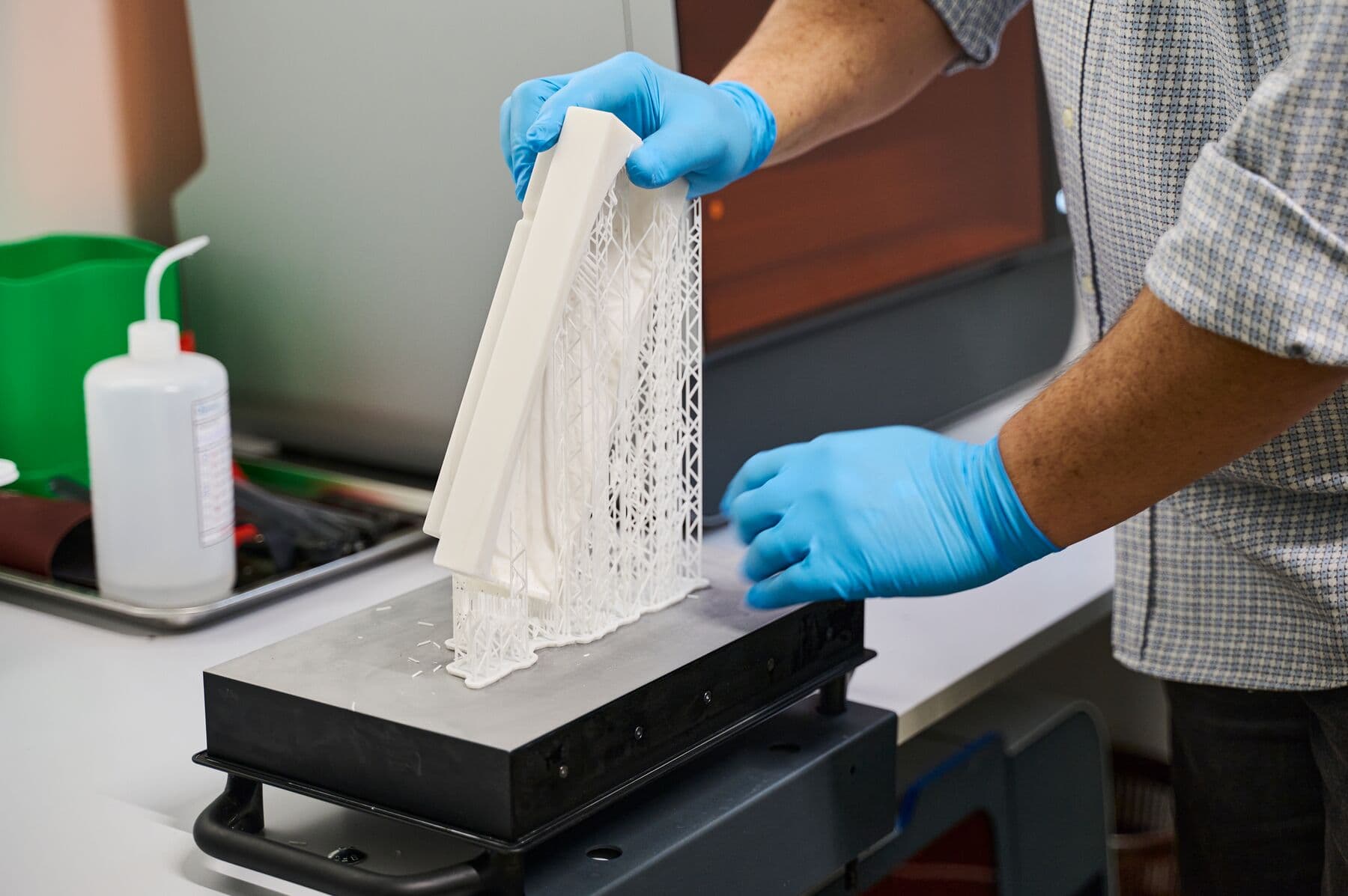

The mold is 3D printed on the Form 3L with Rigid 10K Resin. After washing, the supports are removed and the mold is post-cured.

By using Rigid 10K Resin, Serioplast obtained precise molds with smooth surface finish, capable of integrating fine features, including holes as small as 0.5 mm. They post-processed the tool with a polishing machine or manual sanding to meet the critical dimensions. Textured surfaces were incorporated in the CAD of the mold cavity.

The final dimensions differ slightly from the theoretical dimensions; further study might help to predict the printed plastic’s behavior in order to match the project specifications.

| MOLD DIMENSIONS | THEORETICAL | 3D PRINTED | VARIATION |

|---|---|---|---|

| Height (mm) | 247 | 247.15 | 0.15 |

| Diameter (mm) | 115.6 | 115.73 | 0.13 |

| Shape major axis (mm) | 92.8 | 92.94 | 0.14 |

| Shape Minor axis (mm) | 27.1 | 27.08 | -0.02 |

| Neck diameters (mm) | 25.3 / 32.65 | 25.25 / 32.65 | -0.05 / 0.0 |

Planarity can be a minor issue, as there is a tendency to have a deformed arch in the middle of the cavity plane.

Serioplast also conducted tests with Formlabs White Resin. This material is more affordable and easier to post-process than Rigid 10K Resin, it can be easily smoothed and groomed manually with a polish card to adjust the dimensions. However, it is less stiff and thermally resistant than the Rigid 10K Resin, making it only suitable for limited cycles as the cavity will quickly deform during the process. White Resin is a good alternative for users looking for a low-cost material to produce a few parts without tight tolerances.

Blow Molding With a 3D Printed Mold

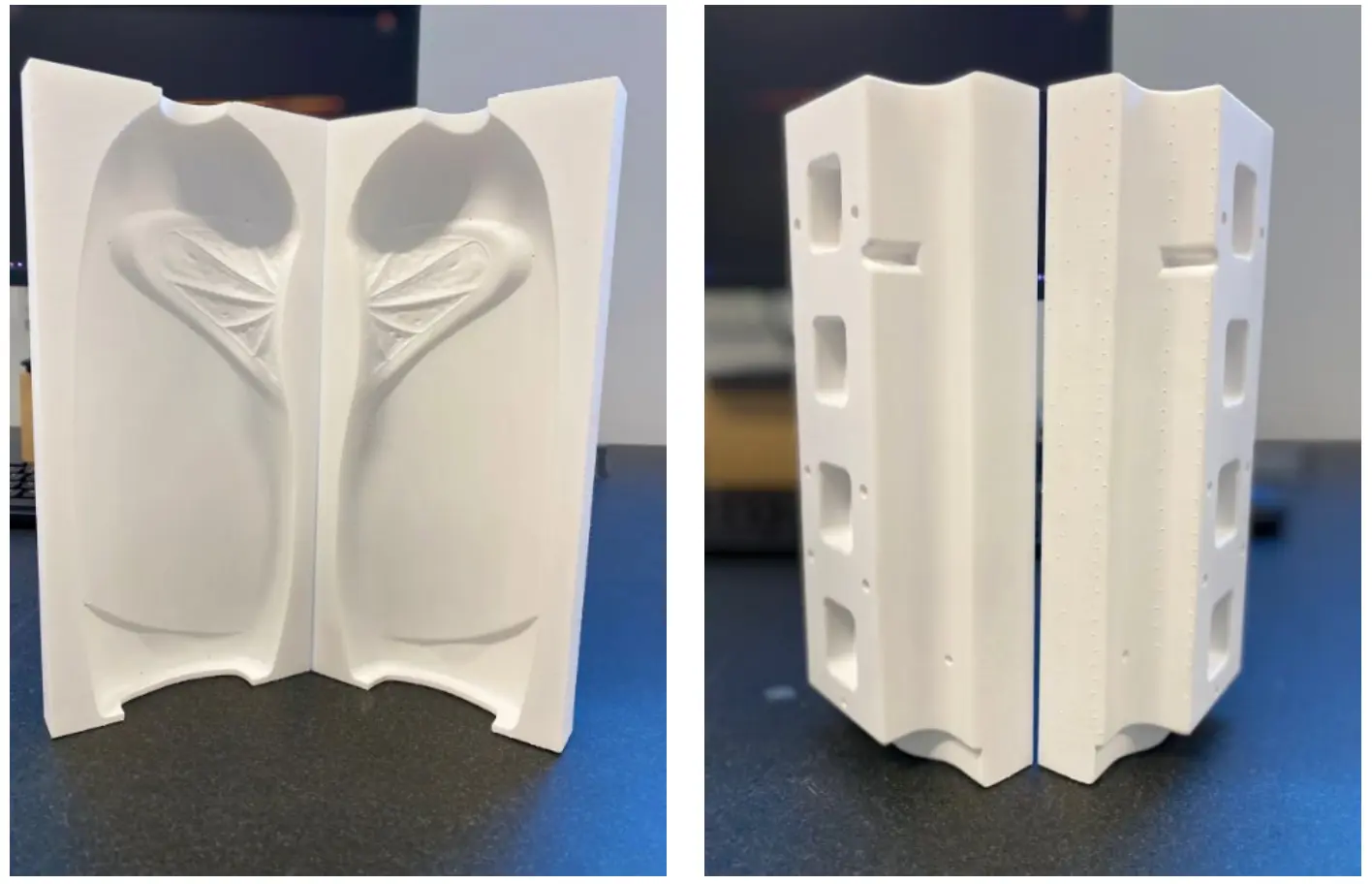

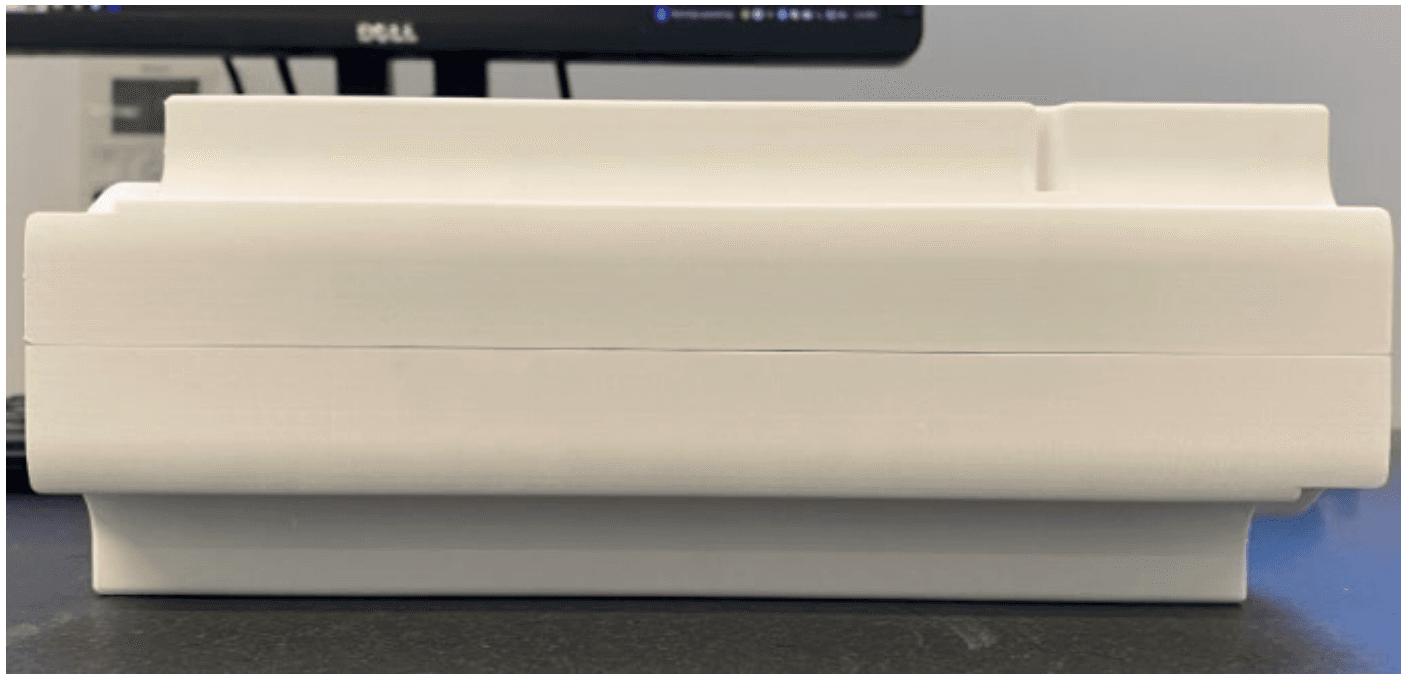

Once the cavity is printed and post-processed, it is assembled into a metal frame and then placed inside a shell holder that is already installed on the machine for a quick changeover. This metal frame was custom-made for 3D printed molds and can now be reused for each new cavity, it permits the reduction of the amount of resin needed on the 3D printed tool and it also helps absorb the forces in play.

The mold 3D printed with Rigid 10K Resin is manually polished and then assembled into a metal frame.

With this tool assembly, Unilever and Serioplast have a solution for producing a modular SBM mold, that can accept different shapes as their product portfolio evolves. They ran the trial on their Seriomac UNIX 4 Cavities industrial SBM machine, which is the model they use for production.

Pressure is a critical factor in SBM — the higher it is the more accurately the bottle replicates the cavity, forming even fine details. Typical internal SBM pressure is around 30-32 bar. The team ran the trials on the 3D printed molds at normal pressure without observing any defects. After blowing, the machine opens and the part is automatically removed from the system without any adjustments compared to the normal use.

The temperature is another parameter to consider. With 3D printed molds, Serioplast processed mostly PET, from virgin to up to 100% recycled, which is usually blown at 100 °C. While this temperature does not threaten the integrity of the printed mold itself, it can alter the transformation of the preform and compromise the final bottle. If the temperature of the mold is too high, then the bottle may shrink in an unpredicted way and not meet the dimensional specifications. In a traditional metal mold, water cooling channels usually cool down the cavity to avoid that.

In 3D printed polymeric tools cooling channels require extra time for design and cleaning and are not as efficient as in a metal tool because heat transfer occurs slower. It is the user’s choice to increase the time for design or cooling. For reference, the Industrial Technical Center IPC studied the impact of adding a regulation system on a 3D printed thermoforming tool in a previous report.

Instead of adding cooling channels, Serioplast operated trials while monitoring the mold temperature. They found that letting the mold cool down for at least four minutes between each shot was a simple way to maintain the temperature to about 40 °C. Compressed nitrogen can help speed up the cooling process but they found that for large series it is not worth the manual work.

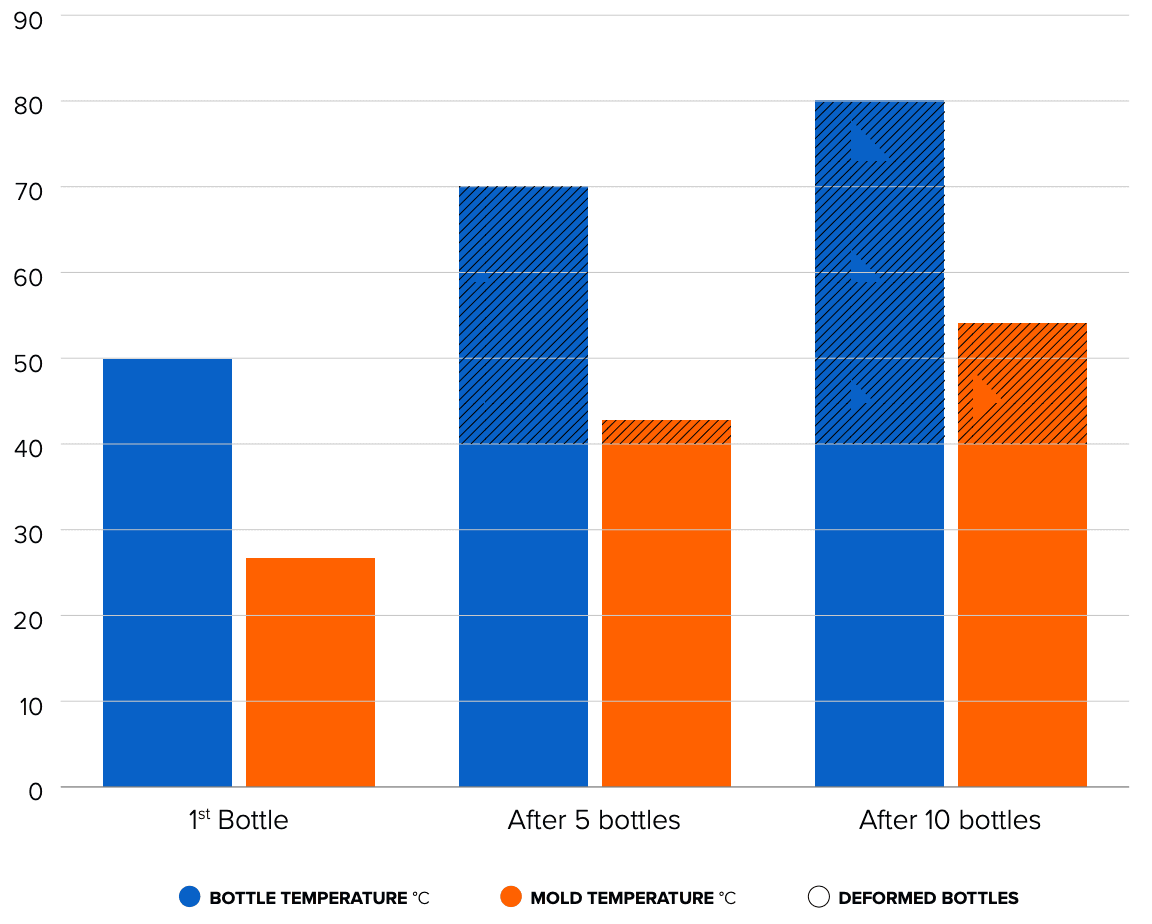

Evolution of the 3D printed mold temperature with increasing the number of cycles. The team made some trials during which they measured the temperature of the mold cavity after each cycle with a thermal scan. The bottle temperature started at 50 °C at the first cycle, after five cycles the temperature rose to 70 °C and the bottles started to deform, and after 10 cycles the temperature reached 80 °C.

Seriomac UNIX 4 Cavities SBM machine from Serioplast in their production facility in Italy.

Serioplast blew one preform on the machine every 48 spindles in order to increase the cooling time and maintain a 10-15 bottles per hour output. The table below reports the SBM configuration Serioplast used with 3D printed molds:

| PARAMETER | VALUE |

|---|---|

| Machine | Seriomac UNIX 4 cavities |

| Material | PET (virgin and up to 100% recycled) |

| Blow temperature | 100 °C |

| Stretching rod speed | 1,100 mm/s |

| Pre-blow pressure | 3.5 bar |

| Blow pressure | 24 - 30 bar |

| Cooling time | 1.7 s |

Results

Serioplast tested about 15 different models of bottles, working on two to three design iterations for each. With one mold 3D printed with Rigid 10K Resin, Serioplast stretch blow molded about 200 units without breaking the mold. They did not observe any sign of breakage and they don’t expect the mold to crack under more cycles at these molding conditions. The cavity would most likely show more wear over time than a metal mold, but they did not perform any dimensional stability study at this point.

The bottles produced with the 3D printed mold were not as transparent as the ones formed with a metal tool because the metal mold goes through mirror polish finishing. However, the overall quality of the bottles was very close to production in terms of aesthetics and functionality, suitable to be considered as a final product for consumer testing.

From left to right: the two-part mold 3D printed with Rigid 10K Resin, a bottle produced with the mold 3D printed with Rigid 10K Resin, a bottle produced with a metal mold, and a labeled prototype bottle for customer testing.

The bottles produced with the 3D printed mold are going through some of the same testing procedures used for production. In these pictures, Stefano Asnaghi, R&D Lead technologist at Serioplast, is conducting a section weight analysis, cutting the bottle with a hot wire cutter bottle to ensure the uniform distribution of the material in all the sections of the bottle. The results are comparable to a production bottle.

Dimensional Accuracy Analysis

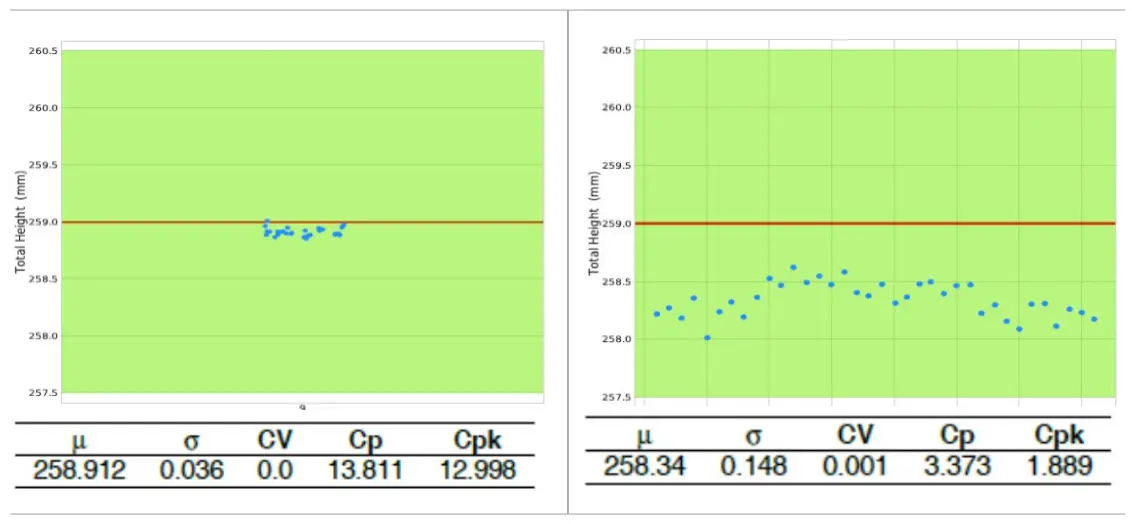

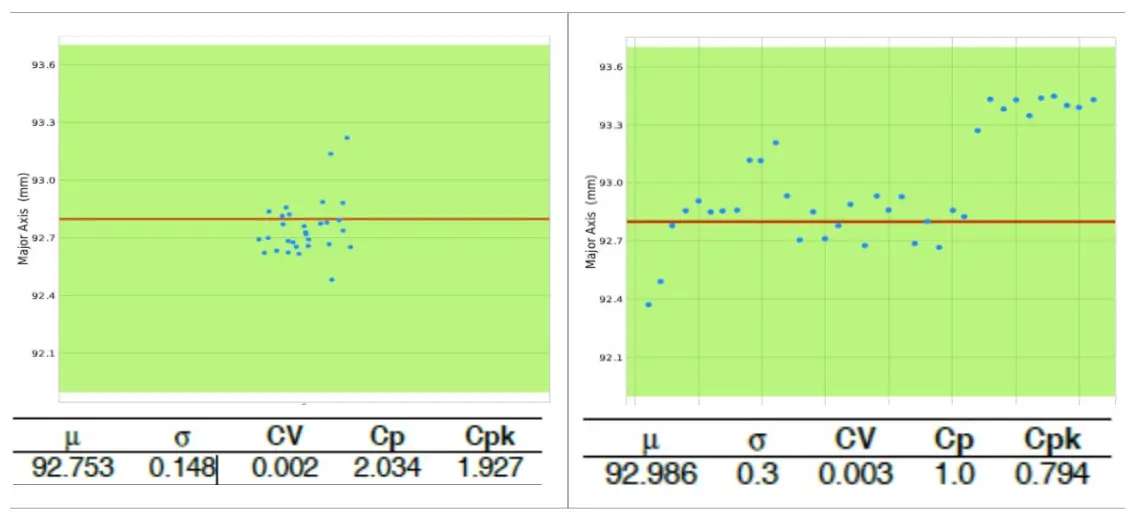

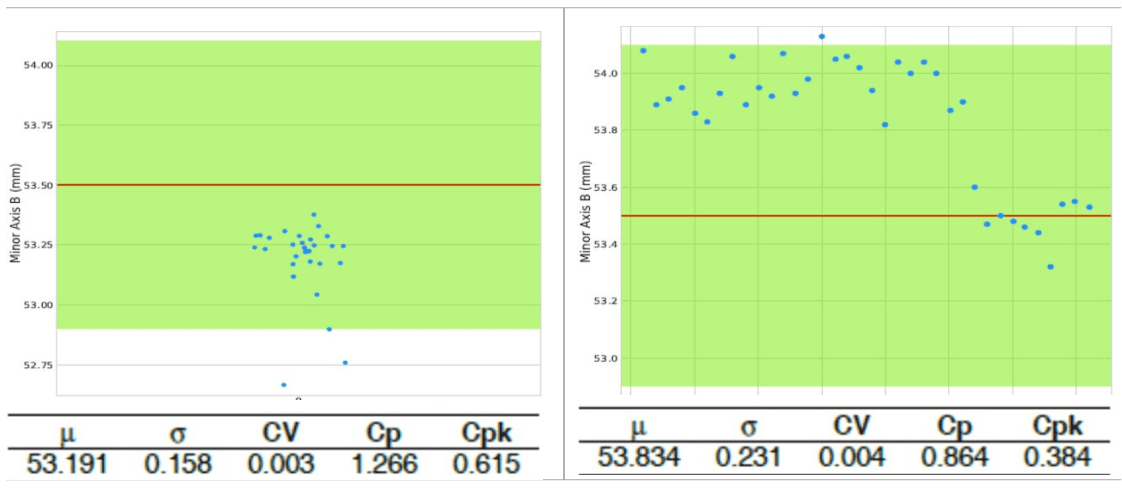

The team measured the dimensional accuracy of bottles blow molded with a 3D printed mold and compared it with the results from a production mold. The measurements were done with a coordinate-measuring machine (CMM) on a sample of about 40 bottles. The graphs below show the following parameters for the principal dimensions of the total height, major axis, and minor axis:

- µ: mean

- 𝜎: standard deviation

- Cv: coefficient of variation

- Cp, Cpk: process capability index

- Δ: variation from production tool to 3D printed tool

BOTTLES BLOWN WITH A PRODUCTION TOOL

BOTTLES BLOWN WITH A 3D PRINTED TOOL

Total height

Major axis

Minor axis

Evaluating the results:

- The total height is the most controlled dimension with σ = 0.148 mm for the 3D printed tool. The results with a 3D printed tool are quite close to the ones from a production tool (Δµ = -0,572 mm) and show that it is not particularly altered by this new process.

- The major axis is influenced by the bottle shrinkage driven by the mold temperature. The output with a 3D printed mold is variable because of the lack of cooling ( = 0.3 mm). More trials are necessary to predict the shrinkage behavior. (Δµ = 0.233 mm)

- The minor axis is mostly influenced by the tolerances between the shell holder and the mold planarity in the closing phase. Small gaps can make a difference in the final dimension. (Δµ = 0.724 mm, Δ = 0,073 mm)

Cost Analysis

For this specific project, the team used about 2.5 liters of resin to produce the 3D printed mold including three design iterations. They formed about 200 pre-production samples in two weeks. Unilever and Serioplast now have a new tool available to achieve pilot testing in two weeks from start to finish at a tenth of the cost of traditional methods.

| PRODUCTION 200 UNITS | MACHINED METAL MOLD | 3D PRINTED MOLD | SAVINGS |

|---|---|---|---|

| Equipment | In house CNC machine or outsourcing | Form 3L Rigid 10K Resin | |

| Pilot testing lead time | 6-8 weeks | 2 weeks | 66-75% |

| Tooling cost | $2,500-10,000 | $500-1,000 | 80-90% |

“A consumer goods company like Unilever must be on the market as soon as possible or before your competitors. You need to offer the best product at the best price in the shortest time possible to the consumers. 3D printing helps us speed up this process.“

Conclusion

This report shows that 3D printed molds can be used to produce rapid tooling for stretch blow molding for prototyping and low- to mid-volume production. Because it is a toolless fabrication method, 3D printing enables on-demand mold fabrication, quickly and cost-effectively while increasing design freedom. 3D printed molds can easily be integrated into traditional SBM processes to validate design and manufacturing steps before transitioning to mass production.

With Formlabs SLA printers and Rigid 10K Resin, Unilever and Serioplast were able to reduce lead times by up to 70% and tooling costs by up to 90% to produce pilot runs of 200 units in only two weeks. They were able to fabricate PET bottles with a quality close to production units in terms of aesthetics and functionality, that are suitable for consumer testing, process validation, and filling line testing. By developing a modular tooling system based on 3D printing, they are now able to assess multiple geometries at once, iterate and incorporate design changes quickly at no extra cost, and accelerate the validation and pre-production stages.

Do you have questions about using an SLA printer for blow molding or other engineering and manufacturing applications? Reach out to our solutions specialists to request a free sample part printed in Rigid 10K Resin.

Request a free sample part to see Formlabs 3D printed materials firsthand and contact our 3D printing specialist to find the right solution for your application.