SLS 3D Printing vs. Injection Molding: When to Replace Molded Parts With 3D Printing?

In this whitepaper, we’ll discuss injection molding and its advantages and disadvantages, as well as introduce SLS 3D printing and the applications in which it can be leveraged as a complementary technology. Using two case studies from manufacturers who both use SLS 3D printing and injection molding for end-use parts, we’ll explain when it makes sense to move from one technology to the other for optimal efficiency.

SLS 3D Printing vs. Injection Molding: When to Replace Molded Parts With 3D Printing?

In this whitepaper, we’ll discuss injection molding and its advantages and disadvantages, as well as introduce SLS 3D printing and the applications in which it can be leveraged as a complementary technology. Using two case studies from manufacturers who both use SLS 3D printing and injection molding for end-use parts, we’ll explain when it makes sense to move from one technology to the other for optimal efficiency.

Introduction

Virtually every piece of plastic used in daily life, from phone cases to the knob on your car stereo, is manufactured the same way—through an industrial injection molding process. Originally invented in the nineteenth century, but modernized in the mid-1950s, injection molding refers to a process where plastic pellets are melted, then squeezed into a hollow mold, where they cool and harden to form their final shape. When the mold opens, the final product is removed, and the mold can be used hundreds or thousands more times.

Injection molding is currently the preferred method of plastic fabrication due to its repeatability, low cost per part, and tight tolerances, as well as the range of mechanical properties available by choosing different types of polymers for the pellets. Because the mold and the injection pressure stay the same, tolerances are tight, and consistent dimensional accuracy is easily achieved. The process is automated to reduce labor costs, and the time required to complete each cycle is short, so manufacturers can run the machines at optimal efficiency. The only major investment is the die, or master mold, itself.

Creating the mold, usually through a metal subtractive manufacturing process, is extremely costly — usually upwards of four or five figures. This means that the process is only cost-effective at higher volumes, when the costs get distributed among hundreds or thousands of parts. It generally takes around four to eight weeks to go from design to finished mold product. There is no room for a change in design once the mold is made, which can lock manufacturers into creating hundreds of thousands of the same part, even if the design could be optimized based on feedback from customers or manufacturing.

In recent years, some manufacturers have looked to rapid tooling to bridge the gap between prototyping and end-use parts, and make injection molding a viable option also for lower volumes of parts. New methods of rapid tooling, like 3D printed or aluminum molds, are being adopted for stopgap options while traditional molds are made, or for low-volume production runs. 3D printing is also increasingly being used to supplement or replace injection molding.

Historically, 3D printing has not been a solution for end-use plastics and has been relegated to the realm of prototyping and design. But as 3D printing materials and technologies advance, the optical and mechanical properties that can be achieved by 3D printed parts are now often able to match injection molding standards. With recent improvements to the selective laser sintering (SLS) 3D printing process, manufacturers are adding the technology to their wheelhouse to be used as a complementary method to injection molding.

Even after those improvements, the SLS technology available that could match injection molded plastics was out of reach for all but the largest, most well-capitalized manufacturers. It typically required a mid-six-figure investment and a huge footprint, and came with stringent facility requirements. With the release of the Formlabs benchtop SLS printer, the Fuse 1, and its accompanying post-processing machine, the Fuse Sift, industrial-quality 3D printing finally became accessible to manufacturers of all sizes. Now, with the upgrade Fuse 1+ 30W printer and the addition of an accessible media blaster to the ecoystem - the Fuse Blast - affordable production is within reach for manufacturers of all different sizes.

SLS 3D printing uses a high-power laser to sinter distinct plastic particles, one thin layer at a time, into a fused whole. The high mechanical strength of the finished parts makes SLS technology a valid method for manufacturing end-use parts. Because of the self-supporting nature of the Fuse Series powder bed, complex geometries are easy to print, and parts can be designed with features that are difficult to create with traditional molding processes.

The Fuse Series printers make it economical to print short runs of parts, because there is no expensive master tool to be made first. Though the material is more expensive than injection molding per part, for manufacturers that change their product design frequently, or require only a small number of parts to be made at once, the Fuse Series is now often be the most viable option. Additionally, bulk powder discounts are available for manufacturers doing higher volume production runs, making volumes of tens of thousands of parts more economical to produce with the Fuse Series than through traditional metal tooling.

As production volumes increase to true mass production, injection molding can still be the right solution, but the range of applications and the production volumes where SLS 3D printing is more efficient has grown significantly over the last few years, empowering manufacturers to save time and costs compared to traditional tools.

This white paper showcases the cost-dynamics for real-life use cases, and presents guidelines for using SLS 3D printing, injection molding, or both together. If you would like to receive an analysis of the cost comparison between SLS 3D printing and injection molding for your own parts, contact our SLS experts.

Book a Consultation

Get in touch with our 3D printing experts for a 1:1 consultation to find the right solution for your business, receive ROI analyses, test prints, and more.

Applications

Though 3D printing is firmly entrenched in manufacturers’ toolboxes as a prototyping solution, the adoption of it for end-use parts is still on the rise. Innovators in every industry are looking for ways to utilize the power, utility, and agility of SLS 3D printing in a variety of applications. We’ll take a look at how several manufacturers are utilizing the technology as a complement to their traditional processes.

Short Run Production

Though the vast majority of current consumer products are mass-produced, some products are still manufactured in small batches and have short-run production cycles. When there is uncertain demand or just a small customer base, producing parts in small batches mitigates the risk of overproduction and of overspending on tooling before the business establishes a strong revenue stream.

ZapWizard is a one-man manufacturer of accessories for Leatherman products, like customizable holsters for their advanced multi-tools. In just seven months of owning the Fuse Series ecosystem, ZapWizard owner Joshua Driggs designed, manufactured, and delivered 3600 end-use products to his customers. 3D printing end-use parts with the Fuse Series instead of injection molding enables ZapWizard to:

- Manage an entire design-to-manufacturing operation in a retrofitted residential garage

- Spend just three hours a day on the business

- Deliver customized products without having to work with outside vendors or change expensive tooling

- Get a one-man manufacturing operation up and running without extensive infrastructure or equipment purchases

- Avoid committing to a single design to respond better to changes in customer demand

Before bringing the Fuse Series in-house, Driggs evaluated other fabrication options, like overseas contract manufacturing for injection molding, but it would have limited his ability to make changes to the design. A big part of ZapWizard’s success is the breadth of products he offers, and his ability to make changes on the fly, something that only SLS 3D printing can make cost-efficient. He offers over 300 variants and models of the Leatherman Holsters, and for customers who reach out with a specific request, he often designs something unique. “I might tweak something 15 times before I settle on a final holster design, changing something by just 0.1 or 0.2 mm. That’s only because I had SLS 3D printing available, to react that fast and be proactive," says Driggs.

ZapWizard relies on the Fuse Series ecosystem to print hundreds of parts each month. The in-house SLS 3D printing workflow enables the business to stay agile and respond to new customer requests, rather than commit to one design with expensive injection molding tooling.

Customization

A growing trend in both the consumer product industry and healthcare is customization. A customer purchasing a product is more likely to invest more money if that product is tailored specifically to them. Common examples are items like snow goggles for competitive snowboarders and skiers, surgical guides used in everyday prosthodontic surgery, or custom-built earphones made to perfectly match a user's ear.

Both performance and patient outcomes can be improved when the equipment is designed specifically to respond and adapt to someone’s unique needs. This concept is felt nowhere more acutely than in the prostheses industry. Every device and part must be as unique as the patients themselves. To ensure a snug fit that helps correct the imbalances of weight, posture, or injury, prostheses and orthoses must be made to order and based on scans or impressions from the patient’s anatomy.

At Custom Precision Technology (C.P.T), CEO Marco Garano developed a new workflow for SLS 3D printed prosthetics to provide an unmatched level of performance, comfort, and functionality to customers who need prosthetics. NOVA Foot is composed of multiple sections for the forefoot, midfoot, heel, and ankle. Each segment of the foot can be customized based on a patient’s needs. These highly customizable sections are printed on the Fuse 1+ 30W printer. Additional soles at the toe and heel, also printed on Fuse 1+ 30W, are completely waterproof and offer traction and stability in wet environments, such as a shower.

The cost of an injection mold to manufacture all the NOVA Foot parts can be estimated at €50,000-60,000 per size, with a minimum of six sizes. This would put molds alone for the six sizes at a minimum of €300,000, which is prohibitively expensive. In-house 3D printing also offers supply chain resilience, decreasing risk, and quick turnaround times for both prototyping and production. Additionally, powder refresh rates with SLS minimize waste. Currently, a single NOVA Foot takes about five hours to print in Fuse 1+ 30W, and up to four prostheses can be included in a single build.

“We chose 3D printing to produce NOVA Foot parts because we have full control of the production process. Furthermore, if we need to modify the parts to customize them based on patient needs, we can do it without having to incur the costs of modifying molds," says Valentina Garano, the Sales & Marketing Manager at Protosystem, the C.P.T. spinoff producing the NOVA Foot.

NOVA Foot has been tested in gyms as well as normal life, with users remarking on the fluidity of walking up a ramp. The ability to customize each component without additional cost keeps the prosthetic affordable yet highly functional for each individual user.

Stop-Gap and Bridge Manufacturing

Stop-gap manufacturing, or bridge manufacturing, refers to a transitional or short-term strategy used to manufacture parts while a company puts its intended or eventual production methods on hold. The reasons for this strategy could be a supply chain disruption, a change in a customer's order, or an issue with capital readiness. As 3D printing technologies become more adept at producing functional, aesthetically pleasing, end-use parts, their suitability as stop-gap options is being brought to the forefront for major manufacturers.

Because injection molding tooling typically requires significant up-front investment and a commitment to part geometry, material selection, and production schedules, many manufacturers now use 3D printed parts in end-use products while they defer commitments to tooling on components that might need more design changes, have uncertain demand, or where the supply chain may be disrupted.

Brose, the international automotive components manufacturer and supplier, relies on 3D printing for stop-gap manufacturing of end-use parts when an order from a customer like BMW, Volkswagen, or Mercedes has components that require extra time before going to injection molding. When an OEM requests a part — or a change to an existing part — that cannot be tooled and mass-produced fast enough, the additive division at Brose evaluates if 3D printing is suitable.

For the BMW X7 seat assembly, the Brose team used their Fuse 1+ 30W SLS 3D printers and Nylon 12 GF Powder to 3D print over 250,000 seat clips, rather than wait for a new injection molding tool to be machined. "We decided to jump onto the Formlabs boat here. We did that because the material availability and the consistency of the prints were so much improved that the technology is now ready to be helpful in the automotive industry...We have proven that we can implement parts like we do on the current BMW X7," says Matthias Schulz, Manager, Seat Prototyping, Brose North America.

Brose printed over 250,000 of these seat clips to be used as end-use parts in their BMW X7 seat assembly, enabling them to hit delivery timelines despite a change in the design plan from the customer.

New Products and Scaling Up

When starting a company or releasing a new product, the variables of demand, supply, overhead, and price aren’t yet set in stone. The process of determining those factors is what keeps many

entrepreneurs out of the market. They can’t afford to take a gamble and invest in a tool for a production run without an accurate estimate of demand, but until now, injection molding was the only way to create plastic parts with the durability needed to be used in the field. Going through the mold design, creation, and offshore shipping timelines would delay the ability of these start-up manufacturers to get vital customer feedback. Without getting in front of customers, the product can’t be improved, or it might not reach the right customers at all, just languish in the development phase while funding is prioritized.

For these start-ups, entrepreneurs, and innovators, SLS 3D printing offers a way to produce end-use parts without the cost of tooling. While producing with SLS, they can court investors, gather market data, improve and iterate their product, and build up a customer base.

Ken Pillonel, engineer and founder of popular YouTube channel Exploring the Simulation, used SLS to help turn a common frustration into a popular new product: an AirPods case that would not only protect the headphones but make it possible to use a USB-C connector to charge them, instead of the old Lightning connector. The forced obsolescence of consumer products and the impediments to user repairability have frustrated Pillonel for years, and when an accessible solution like the Fuse Series ecosystem became available, Pillonel knew that it would be possible to get a business off the ground without taking on expensive debt and committing too early to a design with injection molding.

"The Fuse printers are still the most affordable on the market right now. The way I saw it was, it costs the same as a few molds. So, if I had to outsource a few molds, it would be the same price as my setup. But with in-house SLS, I have a way to make parts for years — and can make an infinite amount of new designs. So if this product doesn't work out, I can just try to make a new one and, hopefully, make back my investment later," says Pillonel.

With multiple components and slightly different designs, tooling would be prohibitively expensive, quashing any hopes of getting the business off the ground. With SLS 3D printing, Pillonel can introduce the product and bring in revenue without a high up-front investment in tooling, then make changes as the demand changes and customers make requests or suggestions.

Aftermarket Parts

Aftermarket manufacturers create end-use products that operate as components of additions to an existing product from the original equipment manufacturer (OEM). Their business models depend on knowing in advance when production changes, so that they can adjust their own products and ensure continued compatibility. This can lead to huge losses when an OEM releases an update or ends a product line. The aftermarket manufacturer is left with tooling that no longer creates a usable product and often a large inventory of already molded parts that’s destined for trash.

Terra X manufactures accessories for vans and off-roading vehicles. The success of their first few products drew the attention of one of the OEMs they designed for, Ram, and though they're official Ram dealers now, they still need to update their product line to fit new Ram models, as well as the changes from other OEMs.

SLS 3D printing gives them the opportunity to bring their entire process in-house, from concept to finished product. That vertical integration means that as soon as an OEM releases a change or a new vehicle, Terra X can make a design change and be ready with a new product in just a few days, ensuring their customers can always get the products they need.

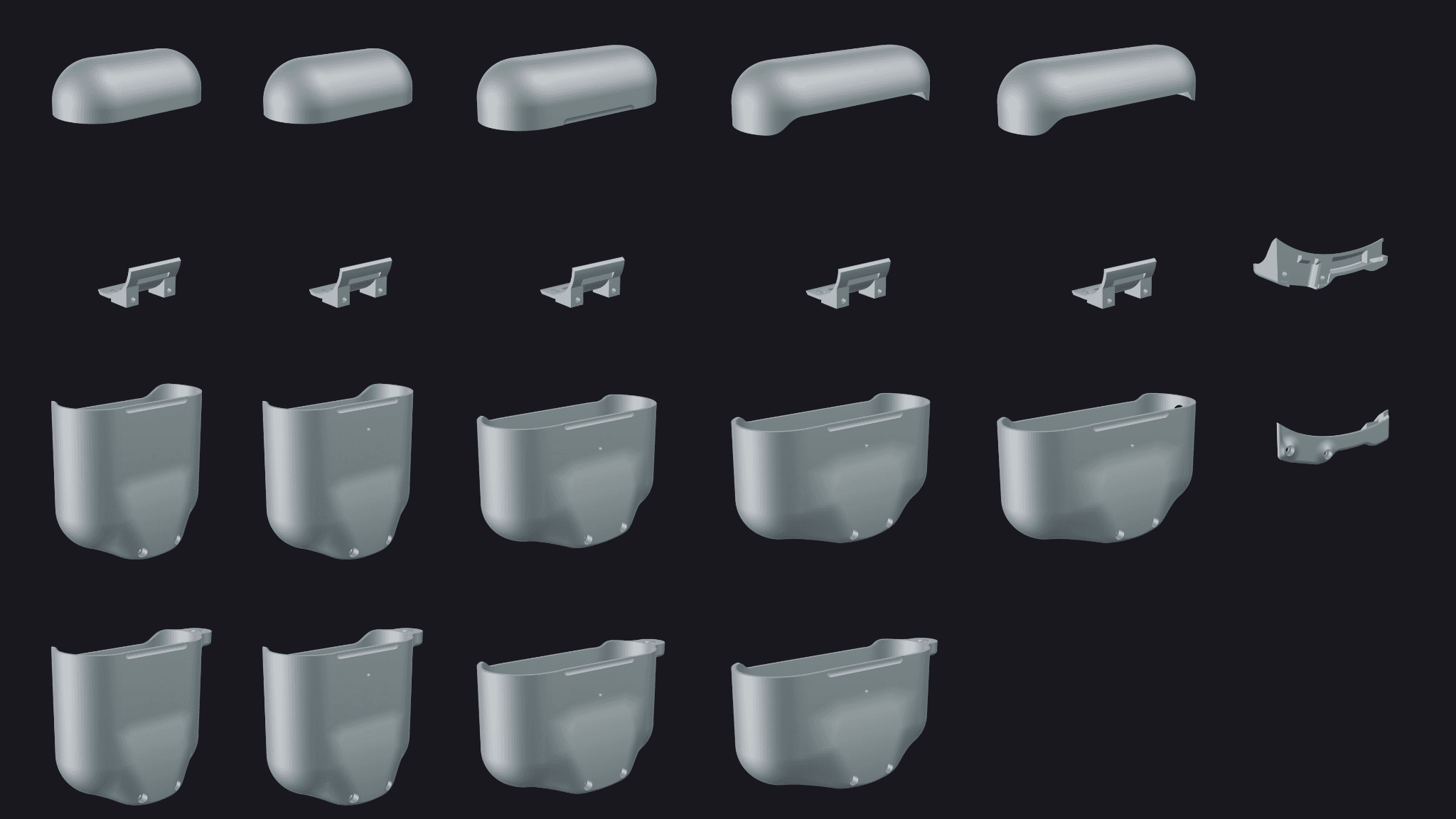

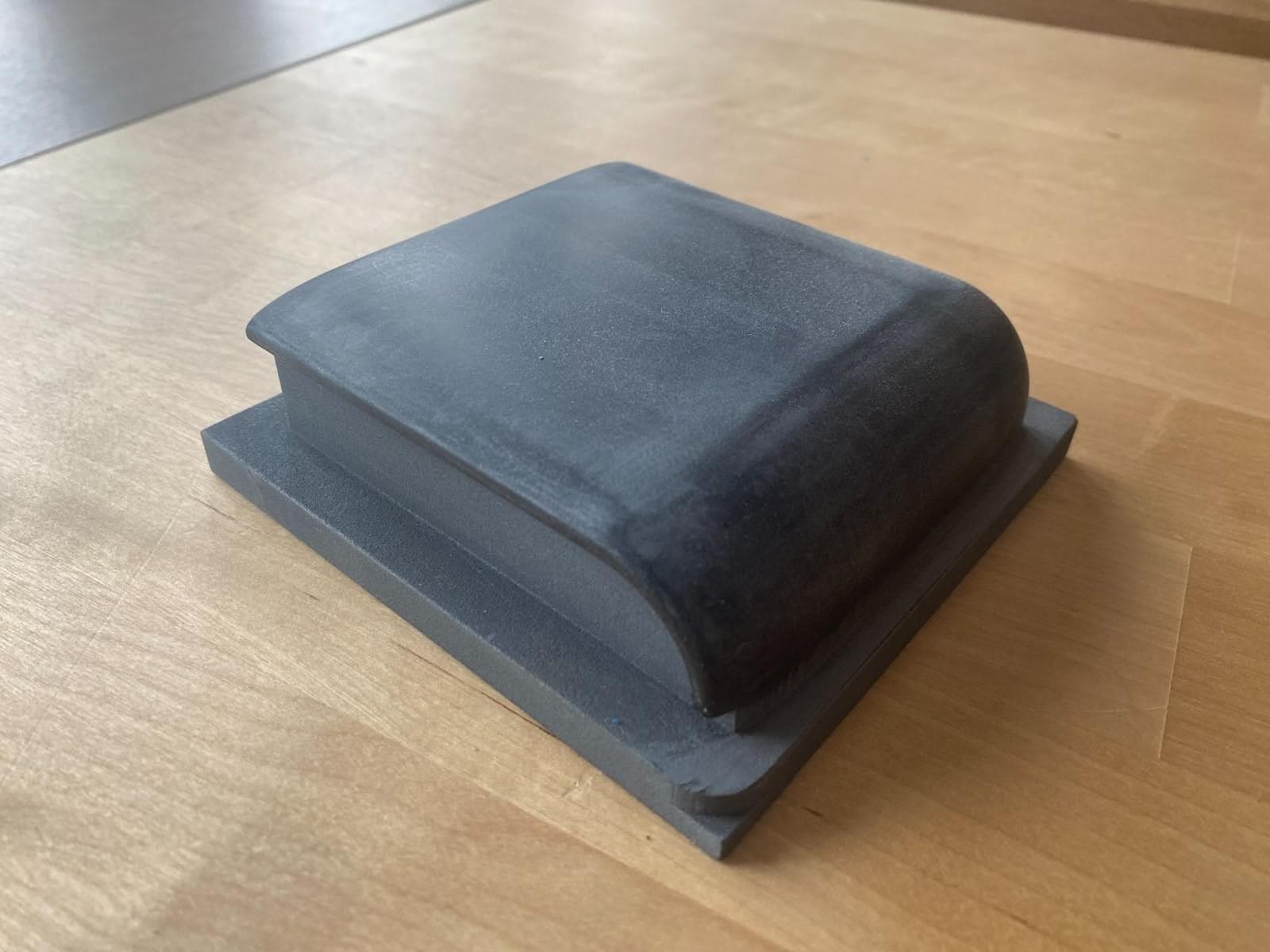

Terra X mount and holder, produced on the Fuse 1+ 30W in Nylon 12 Powder in-house.

Short Run Production

When an OEM stops production of a particular product or model, they have to continue to stock thousands of parts to service customers who have legacy products and need replacements or repairs. If the OEM doesn’t create and store enough of these extra parts, large groups of customers who still have those discontinued models are often left without solutions. It’s difficult for an OEM to calculate exactly how many parts to store—if they overestimate, they have to deal with waste and storage issues, and if they underestimate, customers become disgruntled. As product life-cycles speed up and customer demand for new models increases, the issue of how to create enough spare parts and where to store them becomes increasingly relevant.

The traditional molding or tool used to create those products can be used to create extras, but the manufacturer won’t be able to accurately predict how many to make. This can lead to problems with waste and a lack of storage space when overestimating the need for spare or repair parts. If the OEM underestimates, customers are left with irreparable items and no spare parts available. Because the tool has been disposed of, or the manufacturing process is no longer possible, there’s no way to perfectly respond to the market demand by creating more products.

At Eaton's Olean, NY location, 15,000 metal oxide varistors (MOVs) move through their single-piece flow every day, ushered along by a complex fleet of machines as raw material is compressed, painted, ground to parallel, welded, tested, and assembled into the final product: surge arrestors for utility poles and stations. With such high volume, the machinery and tooling often require replacement components, but waiting for a new part from the machinist or ordering one from the OEM could shut down production for days. Instead, Eaton produces manufacturing aids and tooling in high volumes to keep their production line running.

For one painting step in the assembly line, a paint scraper that keeps a rotating metal masking ring clean wears out quickly. With 3D printed replacements on hand, the team can remove the worn-down scraper immediately and keep the assembly line running, with no disruption to production. “Because we have so much product going through, they tend to wear out. That’s where production consumables become a factor,” says TJ Zurell, Senior Manufacturing Engineer at Eaton (Olean).

During glass collaring, paint builds up on this metal ring (mask) and needs to be cleaned so it doesn’t deposit paint onto the parts. A ring scraper keeps paint from building up.

Complex Designs

When creating products with complex designs, injection molding presents challenges in the mold design process. Because the master mold must have the right geometry to allow melted pellets flow through it uninhibited, and then be able to break apart to allow the part to release, possibilities are limited for the shape and flow.

The powder bed in SLS printers is self-supporting, so complex geometries can be built without supports. Certain characteristics, like organic shapes (often topology optimized parts or those that are generatively designed), those with overhangs, internal channels, and more, are only possible on an SLS 3D printer.

For Airion, their Advanced Inflight Relief Universal System (AIRUS) system was only possible to design with SLS 3D printing. The AIRUS system allows female pilots to relieve themselves during flight, keeping them safe and enabling them to hydrate for the entirety of their mission. The AIRUS is designed so that liquid collected in the custom-fit cup cannot flow back out and create any discomfort or mess for the pilots. This feature is made possible by an internal design feature that would be impossible to injection mold.

“We beat out huge names in defense contracting to win the AFWERX challenge, and we were able to deliver a better solution, the Advanced Inflight Relief Universal System (AIRUS), because of our ‘fly, fix, fly’ approach to design and testing. That approach was only possible because of our SLS 3D printers," says Colt Seman, AIRION co-founder and CEO.

Case Studies

In the following two case studies, we’ll examine how manufacturers can use SLS 3D printing as a complementary manufacturing technique to traditional injection molding, and when it is most advantageous to switch from one to the other.

Formlabs Wash L and Cure L Components

The Form Wash L is the large-format automated rinse machine designed to complete SLA workflows that produce very big parts or higher volumes of small parts. The Formlabs Global Sourcing team chose to utilize multiple manufacturing methods for the various components in the Form Wash L, and for some component,s changed from one method to another in response to sourcing costs, lead time, and part geometry.

Various parts of the Form Wash L and Form Cure L post-processing units, produced on the Fuse Series SLS 3D printers in Nylon 12 Powder.

Form Wash L Saturation Sensor Magnet Cover

For the Saturation Sensor Magnet Cover of the Form Wash L, the Global Sourcing team sent out files to be priced for injection molding. Due to a sourcing issue and shipping delay from Formlabs' usual contract manufacturer, the mold was both more expensive and would have taken much longer than usual to make. To make a deadline for production and customer fulfillment, Formlabs needed to get Form Wash L's in stock, fast, but injection molding the part through another vendor would take too long.

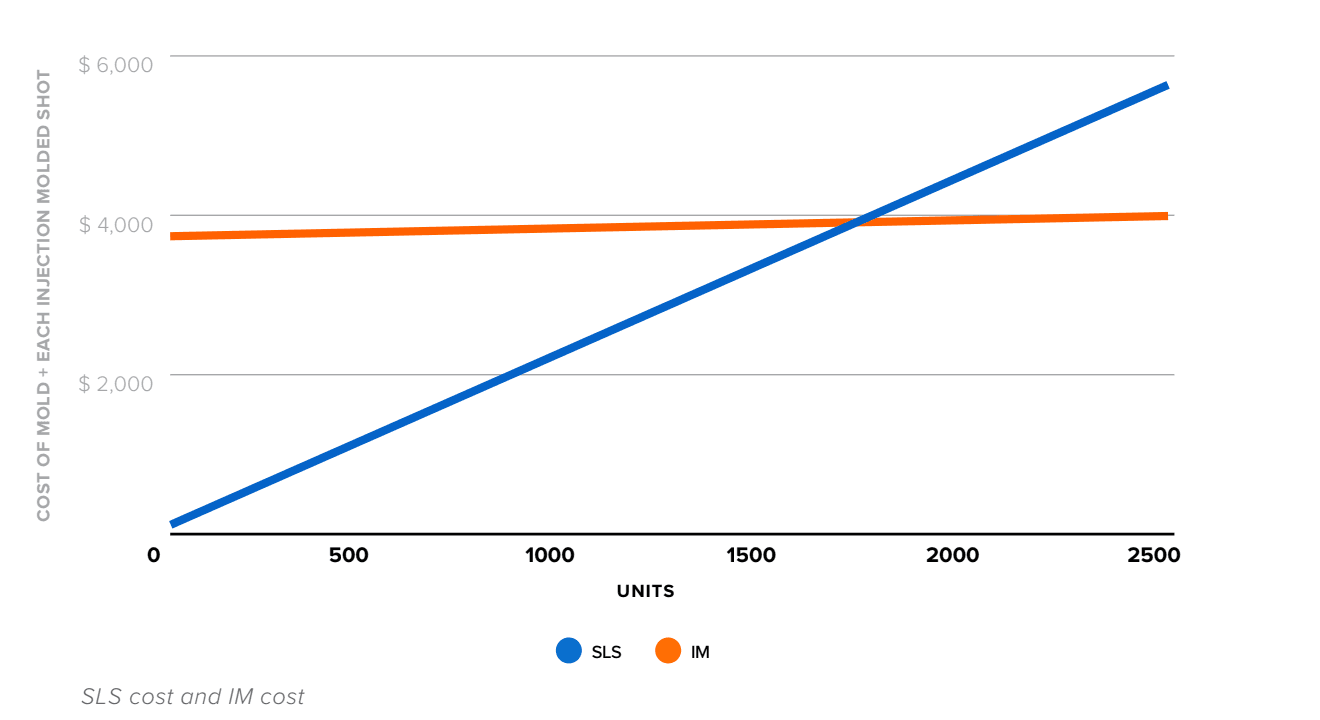

Though the mold for the Saturation Sensing Magnet Cover would cost only $3,700, it would take over a month to complete from the start of the production schedule, and possibly delay the delivery of the overall unit. The per part cost, including labor, of printing the magnet covers on the Fuse Series was only $2.20 – a cheaper alternative at quantities fewer than 2000 parts. Because only a few hundred production units were needed to fulfill the backlog of orders, the Form Wash L team decided to order the mold and also produce parts using the Fuse Series in the meantime.

| SLS | IM Unit Price | IM Tooling | |

|---|---|---|---|

| Saturation Sensor Magnet Cover | $2.20 | $0.11 | $3,700 |

Form Cure L Turntable Gear

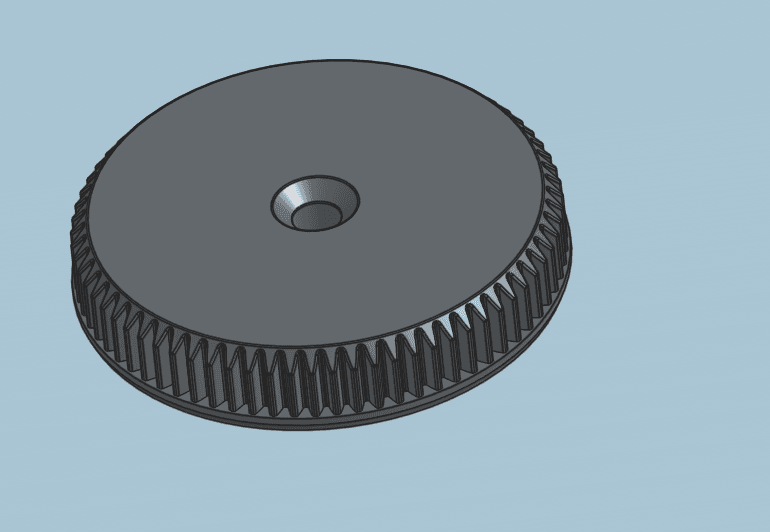

The Form Cure L Turntable Gear rotates the curing platform in the base of the Form Cure L. It has a chamfered hole in the center in order to grip the turntable peg tightly and generate enough force to revolve the platform.

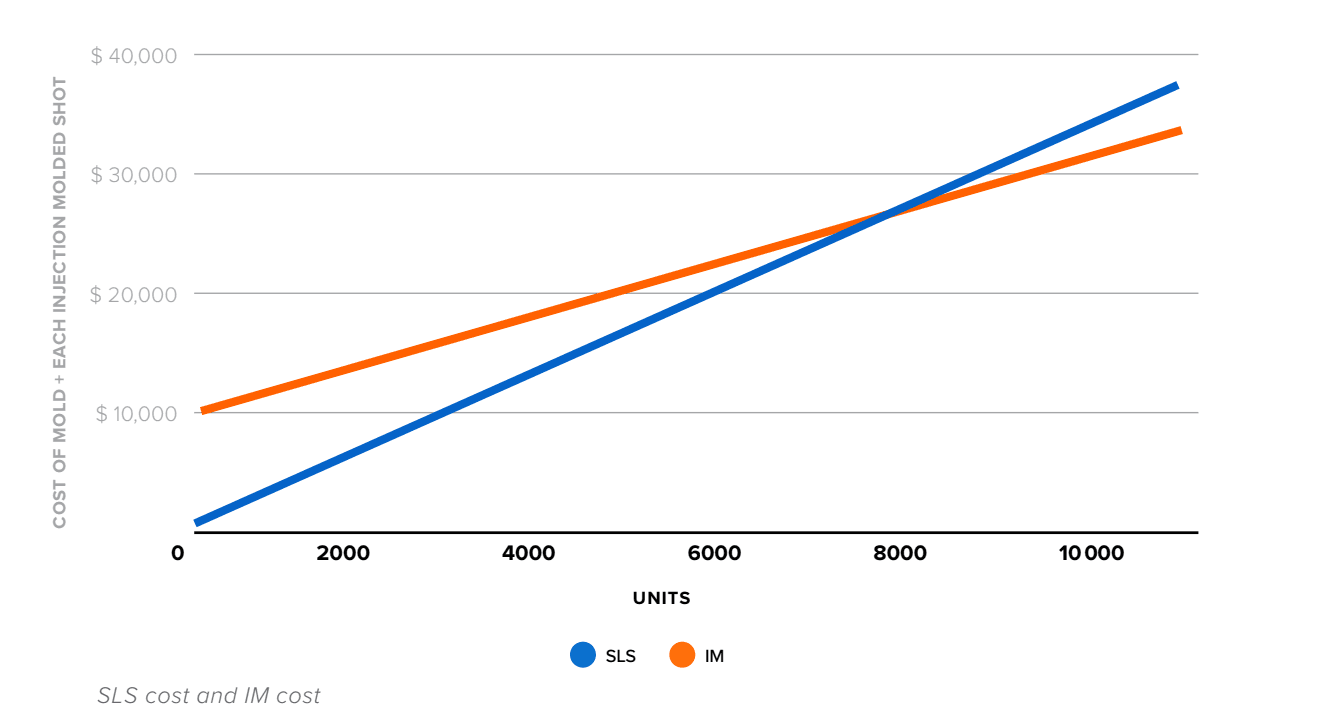

An injection mold would require two parts to achieve that core, and a two-part mold is more expensive. The estimated cost from the injection molding contract manufacturer was $10,000.

SLS 3D printing the Tuntable Gear allowed the designers to consolidate the design into one part, and the cost per part was only $3.50, meaning that the breakeven point for injection molding was at quantities close to 8,000 units. The team decided to print the part on the Fuse Series, saving thousands of dollars and lowering the cost of the final product.

SLS 3D printing made more sense and was more affordable than injection molding for the Form Cure L turntable gear component up to quantities of 8,000.

Haply Robotics

Haply Robotics designs and manufactures robotic consoles that help surgeons prepare for life-saving procedures. Haply Robotics’ products allow medical professionals to practice complex operations and receive real-time physical feedback, helping reduce the risk of the medical related errors that account for over 400,000 deaths a year. To create tools that require such extreme sensitivity and precision, Haply Robotics uses a variety of design and manufacturing tools, including SLS 3D printing on the Fuse 1 and traditional injection molding.

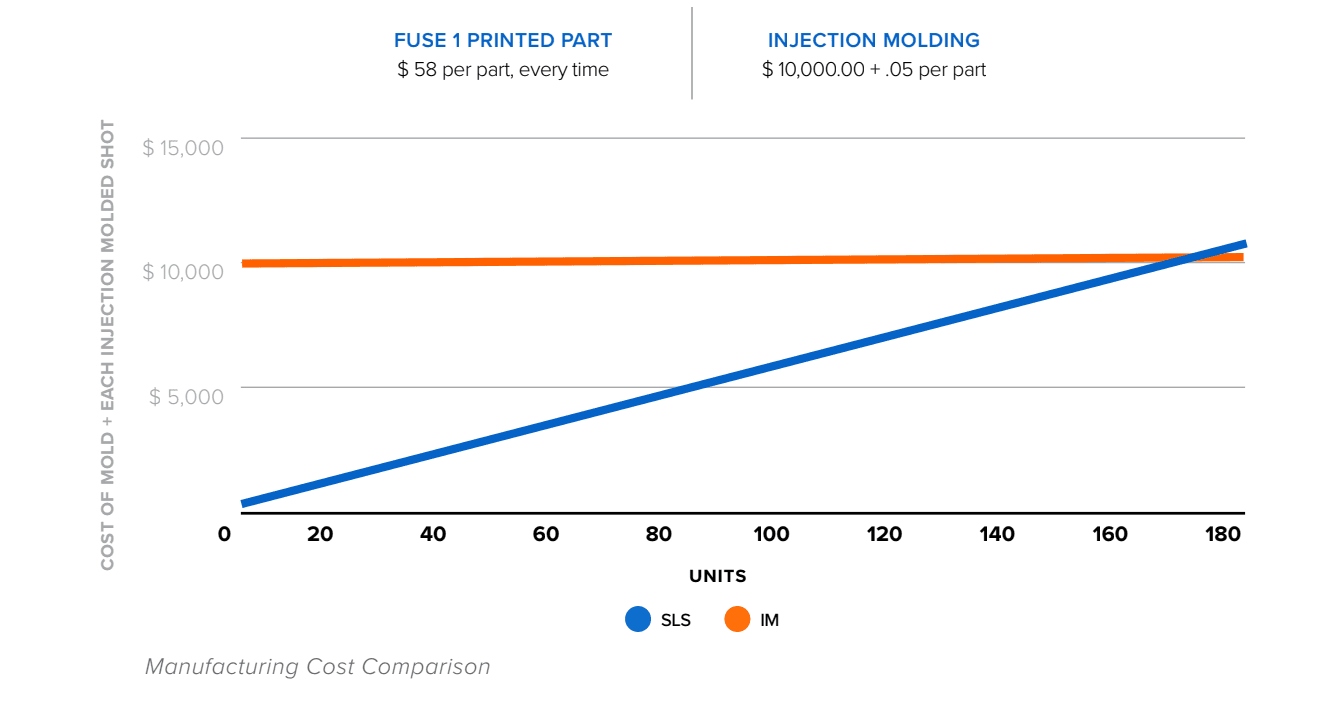

Though originally the team at Haply Robotics was using their Fuse Series SLS 3D printer solely for prototyping, they quickly realized that at their relatively low production volumes, it made sense for them to SLS 3D print certain end-use components as well. One part of their robotic system was produced first with the Fuse Series, for only $58 of materials and labor. To injection mold the part would have cost $10,000 in up-front tooling, and then $0.05 per part after that.

Taking these prices into account, it made sense to print the part directly on the Fuse 1, but only up to a quantity of ten units. While introducing their new robotic system to the market, SLS 3D printing certain components could drastically lower their production costs and allow them to spend their budget on other components. The decision accelerated their time to market and reduced their overall spend, giving them more time and budget to make changes to future iterations without wasting money tooling that might soon be obsolete.

The Haply team also found another solution for mid-level production volumes. They printed a mold in Nylon 12 Powder on the Fuse Series and poured silicone into it for the final part. The mold creation costs $178 in materials and labor and is only good for 20 shots of silicone, but the pour process is inexpensive and quick to complete. This workflow makes sense for volumes between 10 and 200 units and gives the team another option away from expensive industrial injection molding.

This Fuse Series SLS 3D printed mold (left) is used for silicone pours. The final part will look like this SLS 3D printed part (right), a prototype.

Should You SLS 3D Print or Injection Mold?

Making the calculations to determine when to use SLS 3D printing, injection molding, or both, can be difficult. External factors like the price of shipping fuel, or the availability of raw materials, and internal changes to design and workflow, can throw off your ROI determination.

Formlabs has created a customizable ROI Calculator to take some of the guesswork out of this process. By choosing a benchmark SLS part and customizing your labor time and cost, you’ll be able to see values for production cost. By comparing it to injection molding tooling estimates, you can see where it makes sense to switch from one technology to the other.

To have our team conduct an in-depth analysis of your part cost, including labor and bulk powder discount pricing, reach out to the sales team.