Nylon 12 GF Powder 6 kg

Engineering

SLS

Stiff & Strong

38 MPa

56 MPa

36 J/m

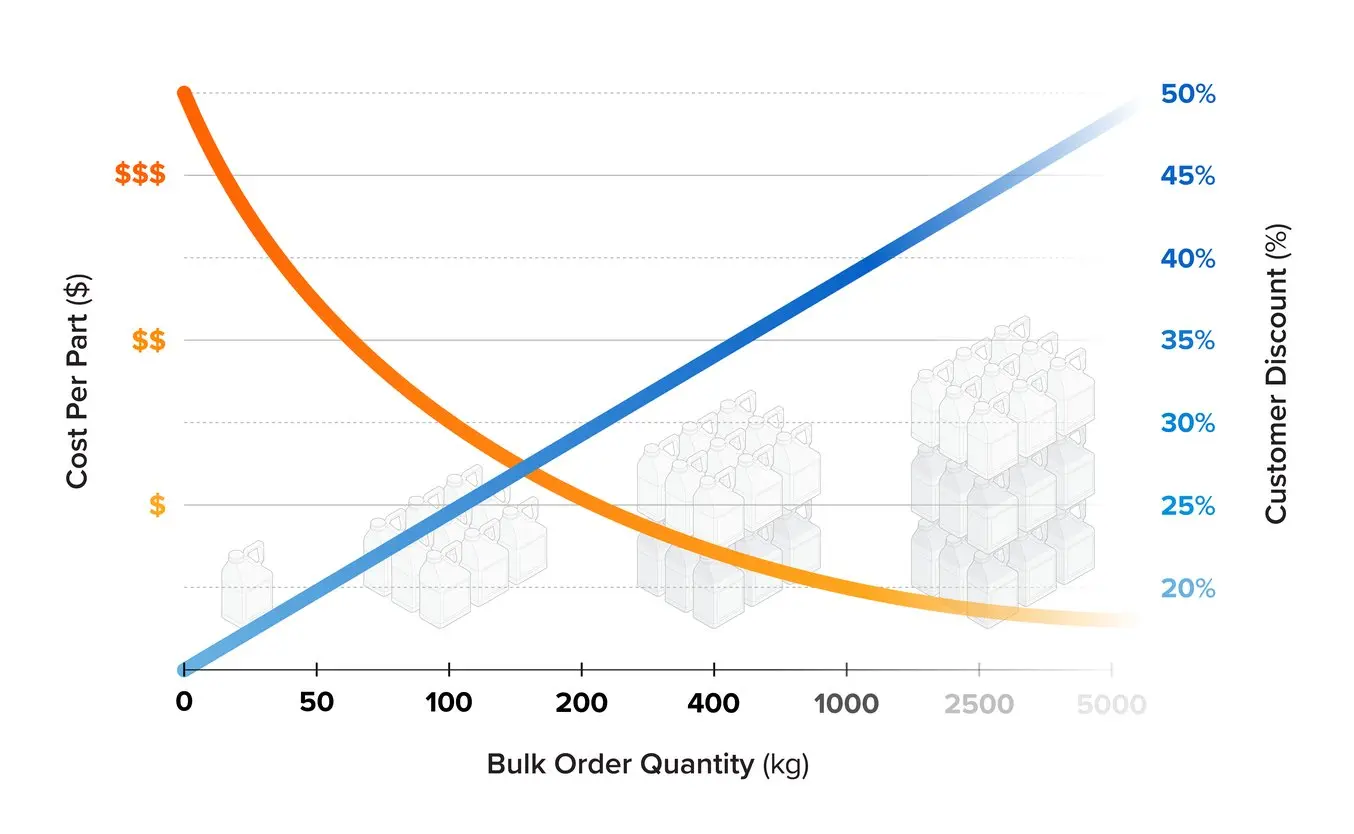

| Bulk order quantity (kg) | SKU Qty | Discount % |

|---|---|---|

| 10 | 1 | 0% |

| 50 | 5 | 20% |

| 100 | 10 | 25% |

| 200 | 20 | 30% |

| 400 | 40 | 35% |

| 1,000 | 100 | 40% |

| 2,500 | 250 | 45% |

| 5,000 | 500 | 55% |

Nylon 12 GF Powder 6 kg has been added to your cart.

Why Choose Nylon 12 GF Powder

Nylon 12 GF Powder is suitable to produce high-performance functional prototypes or robust end-use parts that need to maintain dimensional accuracy.

High Stiffness

Produce end-use parts that need to endure sustained loading.

Thermal Resistance

Prints that will remain dimensionally stable at elevated temperatures.

Dimensional Accuracy

A high-precision material with low warpage.

Environmental Stability

Nylon 12 GF Powder prints absorb very little moisture and are resistant to light, heat, and chemicals.

Applications

With its high Modulus and thermal stability, Nylon 12 GF Powder is the high-performance alternative to create functional validation prototypes for composite materials or stable end-use parts that will endure demanding conditions.

* Material properties may vary based on part design and manufacturing practices. It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.

Explore Material Properties

Compare Printability of SLS Powders

| Nylon 12 (Recommended) | Nylon 12 Tough | Nylon 12 White | Nylon 11 | Nylon 12 GF | Nylon 11 CF | TPU 90A | |

|---|---|---|---|---|---|---|---|

| Air/ Inert Recommendation | Air | Air | Nitrogen* | Nitrogen** | Air | Nitrogen | Air |

| Refresh Rate | 30% | 20% | 30% | 30% | 50% | 30% | 20% |

| Printer Compatibility | Fuse 1 Fuse 1+ 30W | Fuse 1+ 30W | Fuse 1+ 30W | Fuse 1+ 30W | Fuse 1 Fuse 1+ 30W | Fuse 1+ 30W | Fuse 1 Fuse 1+ 30W |

| Dimensional Accuracy | Best | Best | Good | Good | Best | Good | Fair |

| Surface Finish | Best | Good | Good | Good | Best | Good | Fair |

| Print Speed | Best | Good | Fair | Fair | Fair | Fair | Good |

| Fine Feature Resolution | Best | Best | Good | Fair | Fair | Fair | Good |

| High Aspect Ratio Parts | Best | Best | Best | Fair | Good | Good | Fair |

| Large Cross Section Parts | Good | Best | Good | Fair | Good | Good | Fair |

* Nylon 12 White Powder is recommended to print in nitrogen to maintain the most consistent white appearance. Printing in air has been correlated with yellowing of powder over time. Powder yellowing has little to no impact on the ability and efficacy of dyeing printed parts.

** Nylon 11 Powder is recommended to print in nitrogen environment. Printing in air is possible, but will compromise material properties and lead to powder degradation at a faster rate.

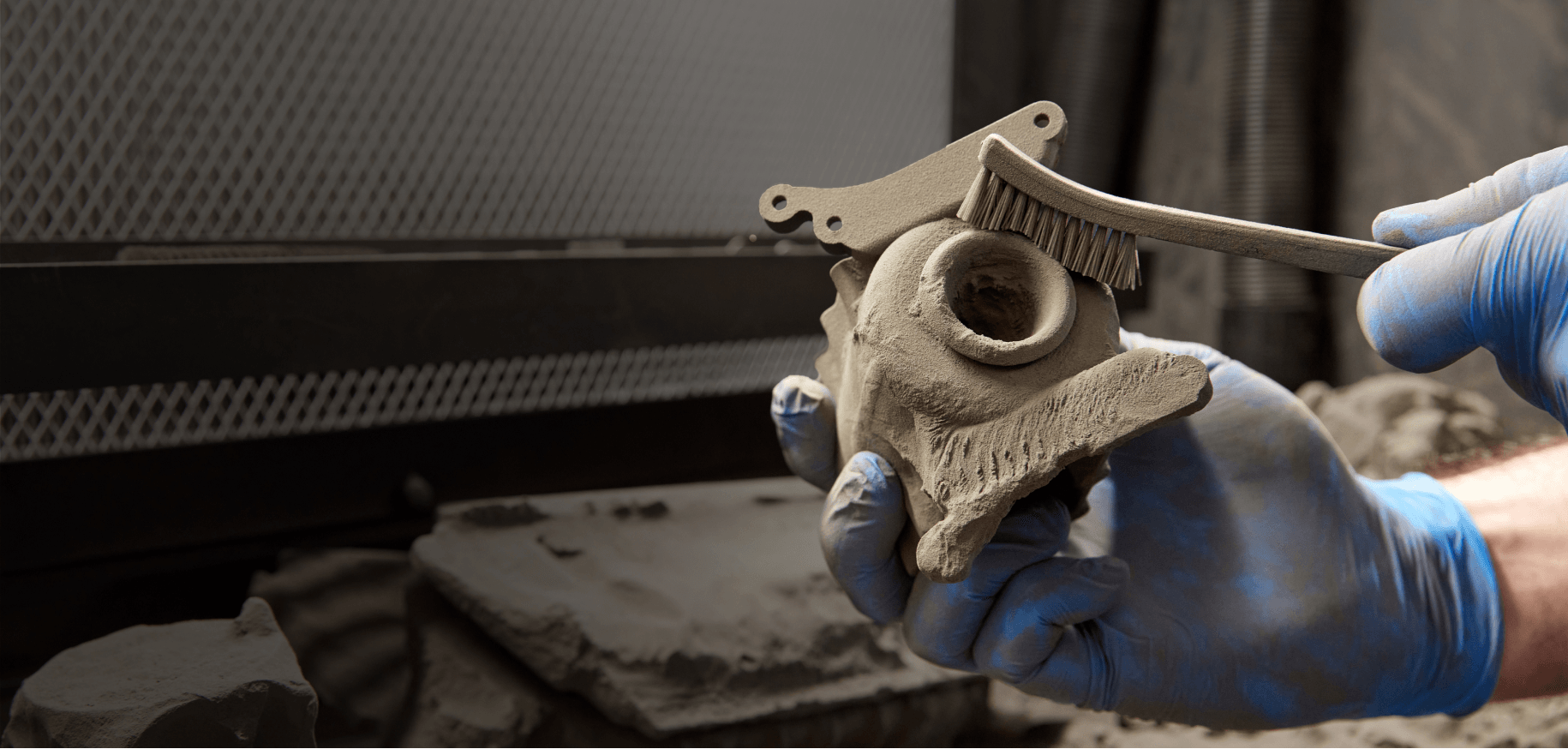

Post-Processing

Post-processing with the Fuse Sift powder recovery station and media blasting is necessary. To learn more about post-processing Fuse 1 prints, download our workflow guide.

Bulk Powder Pricing for Your Lowest Cost Per Part

3D printing is now cost-effective even at higher volumes thanks to substantial volume discounts for our SLS Powders. Discounts start at 20% for customers purchasing 50 kg of powder in bulk and prices can reach as low as $45 per kilogram.