Familiar, industry-standard materials now possible on-demand, with an agile workflow that eliminates reliance on external machinists or tooling.

FuseSeries

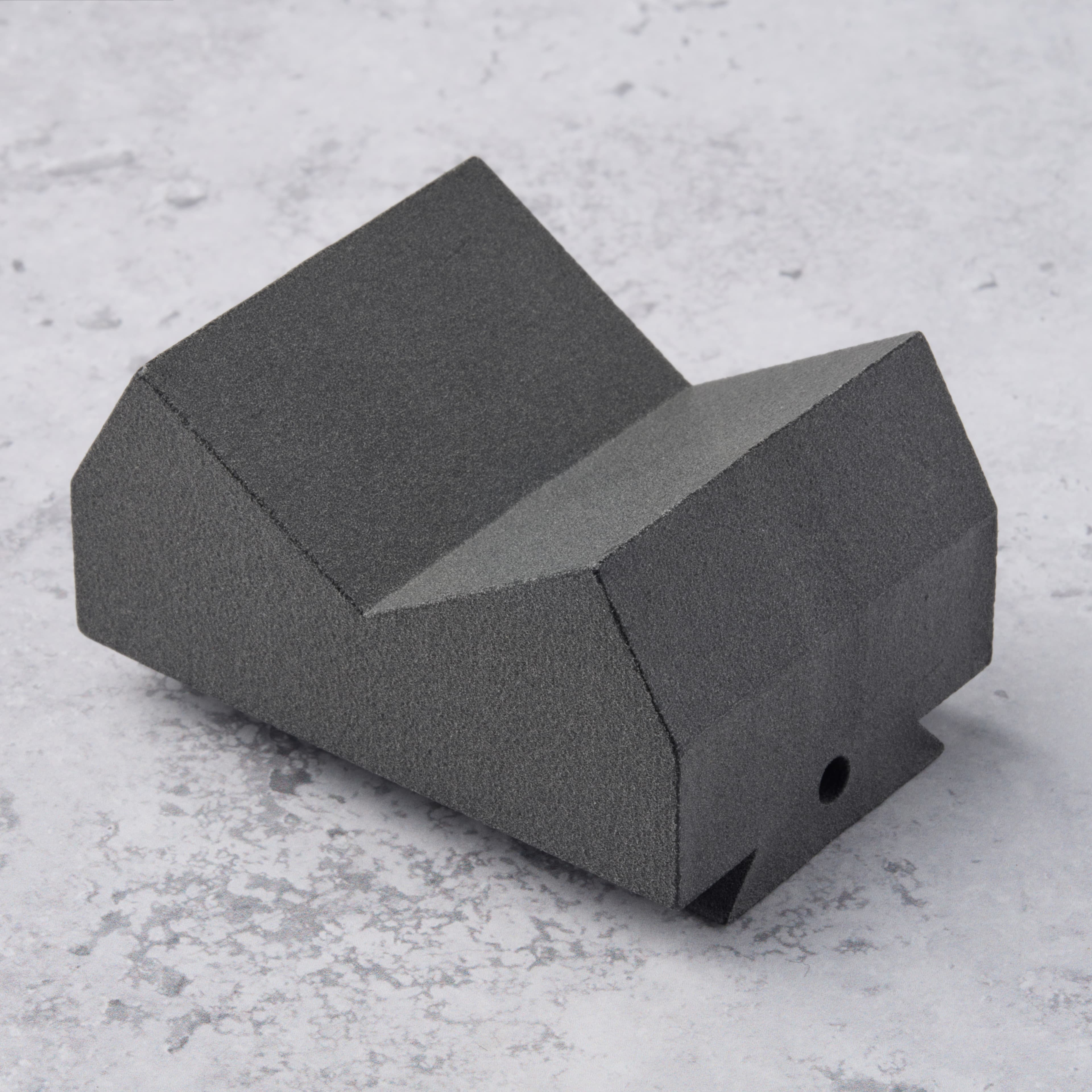

Replace and improve molded or machined plastics

Avoid costly tooling and shorten lead times

An easy and intuitive workflow from start to finish

Solve problems in your office and on the factory floor

Expand as the demand grows with agile manufacturing

FuseSeries

Explore Material Properties

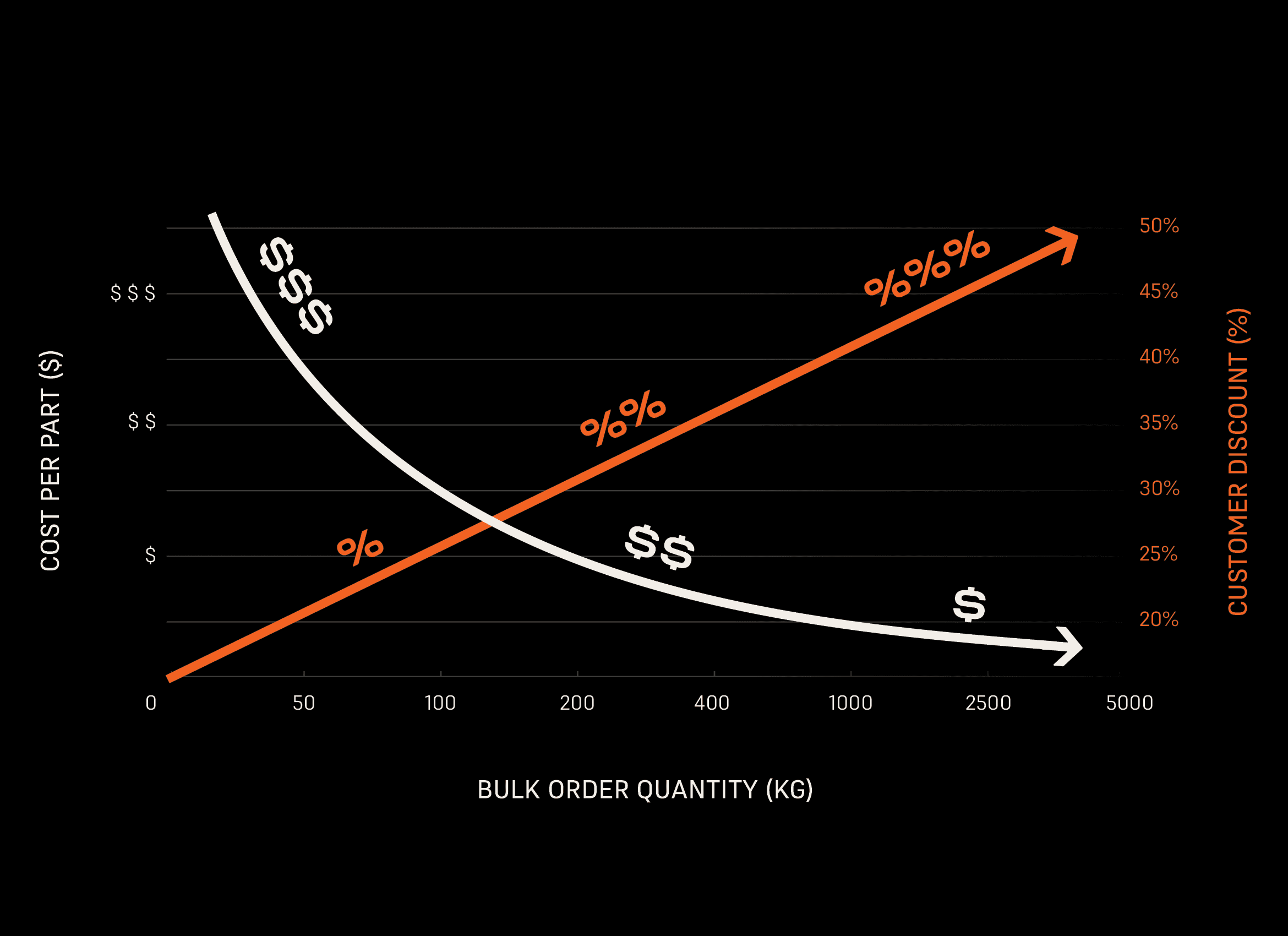

Bulk Powder Pricing for Your Lowest Cost Per Part

3D printing is now cost-effective even at higher volumes thanks to substantial volume discounts for our SLS Powders. Discounts start at 20% for customers purchasing 50 kg of powder in bulk and prices can reach as low as $45 per kilogram.

Lowest cost per part for up to tens of thousands of parts, faster than with any traditional manufacturing method.

- $10.7Fuse 1+ 30W*Nylon 11 PowderLead time 2: 2 day

$47.24Industrial SLS (Outsourced)Lead time 2: 10 day$192.01Machining Cost (Outsourced)Lead time 2: 13 day$4.99Injection Molding (Outsourced)Lead time 2: 5 weeks

$47.24Industrial SLS (Outsourced)Lead time 2: 10 day$192.01Machining Cost (Outsourced)Lead time 2: 13 day$4.99Injection Molding (Outsourced)Lead time 2: 5 weeks

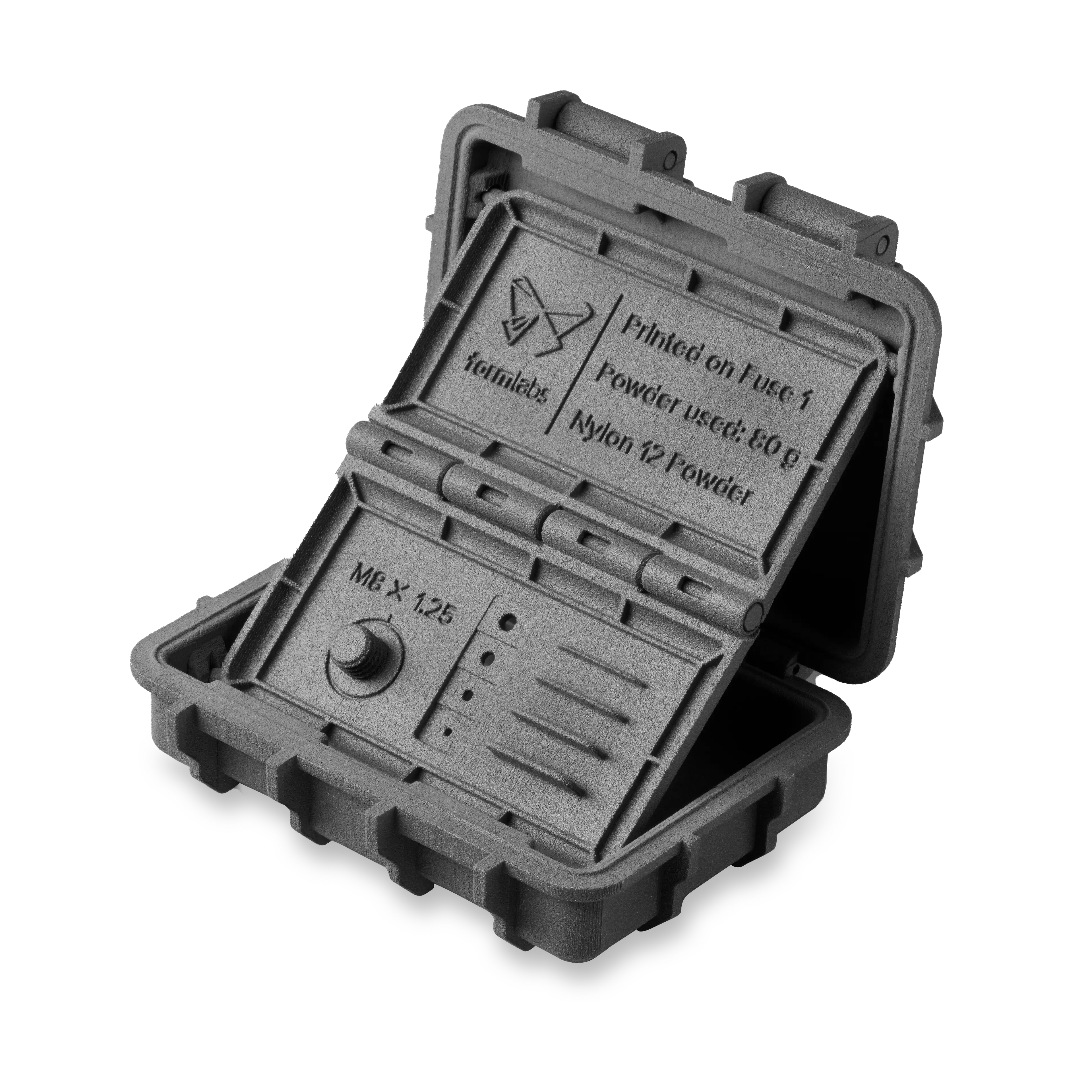

- $9.03Fuse 1+ 30W*Nylon 12 PowderLead time 2: 2 day

$40.25Industrial SLS (Outsourced)Lead time 2: 6 day$103.34Machining Cost (Outsourced)Lead time 2: 20 day$4.25Injection Molding (Outsourced)Lead time 2: 6 weeks

$40.25Industrial SLS (Outsourced)Lead time 2: 6 day$103.34Machining Cost (Outsourced)Lead time 2: 20 day$4.25Injection Molding (Outsourced)Lead time 2: 6 weeks

- $0.87Fuse 1+ 30W*Nylon 12 PowderLead time 2: 2 day

$30.4Industrial SLS (Outsourced)Lead time 2: 6 day$301.08Machining Cost (Outsourced)Lead time 2: 10 day$2.84Injection Molding (Outsourced)Lead time 2: 5 weeks

$30.4Industrial SLS (Outsourced)Lead time 2: 6 day$301.08Machining Cost (Outsourced)Lead time 2: 10 day$2.84Injection Molding (Outsourced)Lead time 2: 5 weeks

- $6.93Fuse 1+ 30W*Nylon 12 PowderLead time 2: 2 day

$37.35Industrial SLS (Outsourced)Lead time 2: 9 day$543.07Machining Cost (Outsourced)Lead time 2: 20 day$4.25Injection Molding (Outsourced)Lead time 2: 6 weeks

$37.35Industrial SLS (Outsourced)Lead time 2: 9 day$543.07Machining Cost (Outsourced)Lead time 2: 20 day$4.25Injection Molding (Outsourced)Lead time 2: 6 weeks

*Powder discount 10%

Scalable and Affordable: Expand Your Fleet As Necessary, On-Demand

Affordability & Ease of Use: Get Started

Industrial power, without the industrial infrastructure — add the Fuse Series into any office or workshop environment, without breaking the bank.

Add Redundancy For Low-Risk Manufacturing

Improve and adapt with agile SLS. Respond to requests faster and easier with a flexible fabrication solution. Create single prototypes or replacements on-demand, or free up your machine shop by 3D printing thousands of parts a week.

Scale With Your Demand

Scale incrementally and grow your fleet as demand increases. Offer versatile materials or increase throughput by scaling a reliable production workflow.

INDUSTRIAL POWER, WITHOUT THE INDUSTRIAL INFRASTRUCTURE

INDUSTRIAL POWER, WITHOUT THE INDUSTRIAL INFRASTRUCTUREAffordability & Ease of Use: Get Started

Industrial power, without the industrial infrastructure — add the Fuse Series into any office or workshop environment, without breaking the bank.

Add Redundancy For Low-Risk Manufacturing

Improve and adapt with agile SLS. Respond to requests faster and easier with a flexible fabrication solution. Create single prototypes or replacements on-demand, or free up your machine shop by 3D printing thousands of parts a week.

Scale With Your Demand

Scale incrementally and grow your fleet as demand increases. Offer versatile materials or increase throughput by scaling a reliable production workflow.

1 Printer:Getting Started IMPROVE AND ADAPT WITH AGILE SLS

IMPROVE AND ADAPT WITH AGILE SLSAffordability & Ease of Use: Get Started

Industrial power, without the industrial infrastructure — add the Fuse Series into any office or workshop environment, without breaking the bank.

Add Redundancy For Low-Risk Manufacturing

Improve and adapt with agile SLS. Respond to requests faster and easier with a flexible fabrication solution. Create single prototypes or replacements on-demand, or free up your machine shop by 3D printing thousands of parts a week.

Scale With Your Demand

Scale incrementally and grow your fleet as demand increases. Offer versatile materials or increase throughput by scaling a reliable production workflow.

2 Printers:Add Redundancy SCALE INCREMENTALLY AND GROW YOUR FLEET

SCALE INCREMENTALLY AND GROW YOUR FLEETAffordability & Ease of Use: Get Started

Industrial power, without the industrial infrastructure — add the Fuse Series into any office or workshop environment, without breaking the bank.

Add Redundancy For Low-Risk Manufacturing

Improve and adapt with agile SLS. Respond to requests faster and easier with a flexible fabrication solution. Create single prototypes or replacements on-demand, or free up your machine shop by 3D printing thousands of parts a week.

Scale With Your Demand

Scale incrementally and grow your fleet as demand increases. Offer versatile materials or increase throughput by scaling a reliable production workflow.

3+ Printers:Fleet Production

Simplified Workflow

- 1

Auto-Pack, Optimize, and Organize in PreForm

With automated packing, hollowing, orienting, labeling, and more, PreForm optimizes your parts and your workflow from the first step.

- 2

Print Quickly and Reliably on the Fuse Series

Set it and forget it. Print overnight and have multiple iterations or batch production parts ready in the morning.

- 3

Unpack and Recycle Your Powder in the Fuse Sift

Depowder parts in just 10 minutes with Fuse Sift to reclaim unused powder.

- 4

Clean and Polish Your Parts With Optional Automated Media Blasting

Leverage automation with Fuse Blast and Polishing System to achieve smooth, end-use quality parts, without added labor.

- 5

Add Color, Coating, and Sophisticated Surfaces With Advanced Post-Processing Techniques

Create high-performance, end-use parts with smooth surface finishes or vibrant colors through coating, dyeing, painting, smoothing, and more.

- 6

Easy, Quick Maintenance Keeps Your Focus on the Parts, Not the Printers

Maintain near-constant uptime with an on-screen checklist for your 10 minutes of between-print maintenance and cleaning.

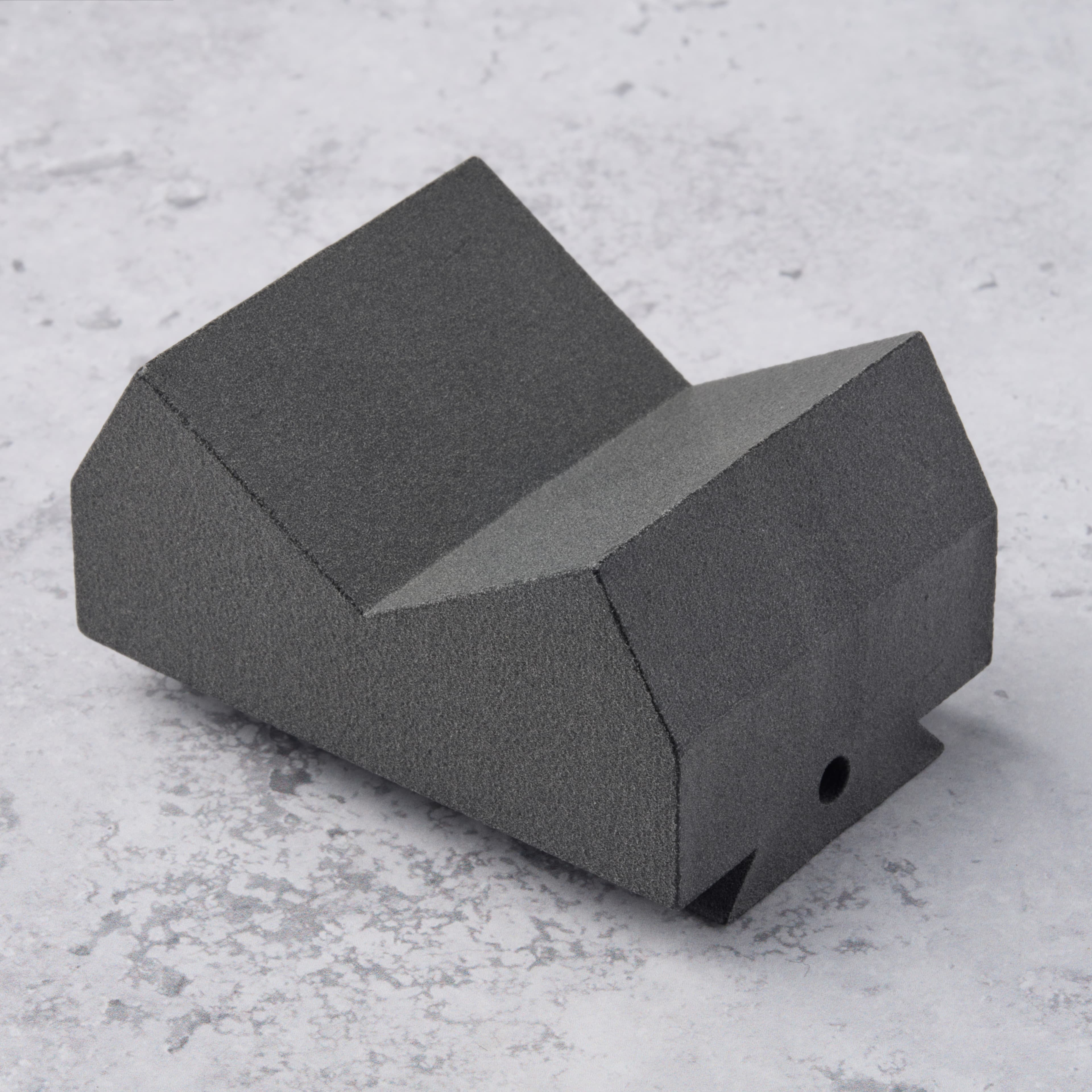

Solve problems, fast. Move quickly through iterative changes and eliminate production bottlenecks with strong, functional parts.

The proliferation of drone manufacturers and their success in gaining a foothold in a competitive field can be partly attributed to the accessibility and power of modern manufacturing methods, namely 3D printing.

The proliferation of drone manufacturers and their success in gaining a foothold in a competitive field can be partly attributed to the accessibility and power of modern manufacturing methods, namely 3D printing.

Manufacturing Aids, End-Use Parts

Eaton

“The Fuse is attractive because it's a price point that is easily adoptable. The build volume is right for what a factory generally needs, and so when you match the footprint size plus the cost, it makes it attainable to a lot of our factories. Then the ecosystem around it and the usability was a step change in the SLS category.”

Cameron Peahl,

Global Industry 4.0 Additive Manufacturing Strategy Manager

Rapid Prototyping

Ford

“The Fuse 1+ is much faster than the competitors. It's also very easy for our workers to operate the machine. At the end of the day, what really matters for us is that it’s very easy to deliver the parts faster.”

Bruno Alves,

Additive Manufacturing Expert and Tooling Specialist, Ford

End-Use Parts, Rapid Prototyping

Brose

“The material availability and the consistency of the prints were so much improved that the technology is now ready to be helpful in the automotive industry. The issue for us is that safety and durability concerns exist, especially with the OEMs. We’re trying to rule this out. And in collaboration with Formlabs, we have proven that we can implement parts like we do on the current BMW X7.”

Matthias Schulz,

Manager, Seat Prototyping, Brose North America

Manufacturing Aids, End-Use Parts

Heidelberg

“If we didn’t have access to this technology, especially SLS 3D printing with the Fuse Series, then the development processes would be enormously protracted. The machines allow us to achieve very large development steps in a very short time. We can test and reject or further develop ideas, and produce parts overnight to test at the customer's premises the next day. Without this access, the development process would be almost like conventional manufacturing.”

Joachim Krumma,

Management, CTS-3 GmbH

Manufacturing Aids

Deutsche Bahn

“We use Formlabs machines because the price-performance ratio is unbeatable for us. They are reliable and really plug-and-play, especially the SLS printers. This makes the job a lot easier when you’re continuously iterating parts. They run 24 hours a day, seven days a week, all year round."

Carsten Wolfgramm,

Manufacturing Engineer and Additive Manufacturing Expert, Deutsche Bahn

End-use Parts

Mosolf

“We use SLS technology and especially the Fuse 1+ 30W for different components, from the smallest, simplest designs to the complicated console that is installed on the vehicle. We have been using this technology extensively and the Fuse fulfills about 80% of our needs."

Tiberiu Morariu,

Prototyping, Design, and Technical Conception lead, MOSOLF

Orthotics

Kriwat

With Formlabs, the big advantage is of course also the financial aspect. As a medium-sized company, I can afford this investment, which would simply not be achievable for us with other manufacturers, and neither for other companies in our industry.”

Lais Kriwat,

Master Orthopedic Shoe Technician, Management at Kriwat GmbH

Manufacturing Aids, End-Use Parts

Rosenberger

"Our Fuse 1+ 30W ran for five weeks…" In the past, sample tools were made to produce very small quantities by injection molding. 3D printing lets us dispense with expensive metal tools, which makes prototyping much cheaper. The great thing is that you can now also produce sample parts using 3D printing that would not have been made before."

Manuel Kapsreiter,

Equipment Designer, Rosenberger

Rapid Prototyping

Hyphen

“I always do a comparison when I'm looking for maybe a semi-permanent part — can we 3D print it here or can we outsource it? Nine times out of ten, we end up 3D printing it in-house because outsourcing it is either three times as long or the cost is just so insanely high relative to doing it here for free.”

Jacob Boyer,

Senior Mechanical Engineer, Hyphen

End-Use Parts

Ken Pillonel

“The Fuse printers are still the most affordable on the market right now. The way I saw it was, it costs the same as a few molds. So, if I had to outsource a few molds, it would be the same price as my setup. But with in-house SLS, I have a way to make parts for years — and can make an infinite amount of new designs. So if this product doesn't work out, I can just try to make a new one and, hopefully, make back my investment later.”

Ken Pillonel,

Engineer and Founder, Exploring the Simulation

End-Use Parts

Savewo

“Traditional industrial manufacturing methods take a long time. With Fuse 1+ 30W, we can print directly, and when we need to make changes, we can immediately change the design and print it again. This can greatly speed up the entire development process, and the printed part can be placed on the robot for testing.”

Savewo R&D Engineer Mr. Feng

Explore SLS Webinars: User Stories, Tutorials, and More

Selective Laser Sintering

The Power Behind Fuse 1Selective Laser Sintering

The Power Behind Fuse 1The FUSe 1+ 30W Ecosystem

Complete Your 3D Printing Experience

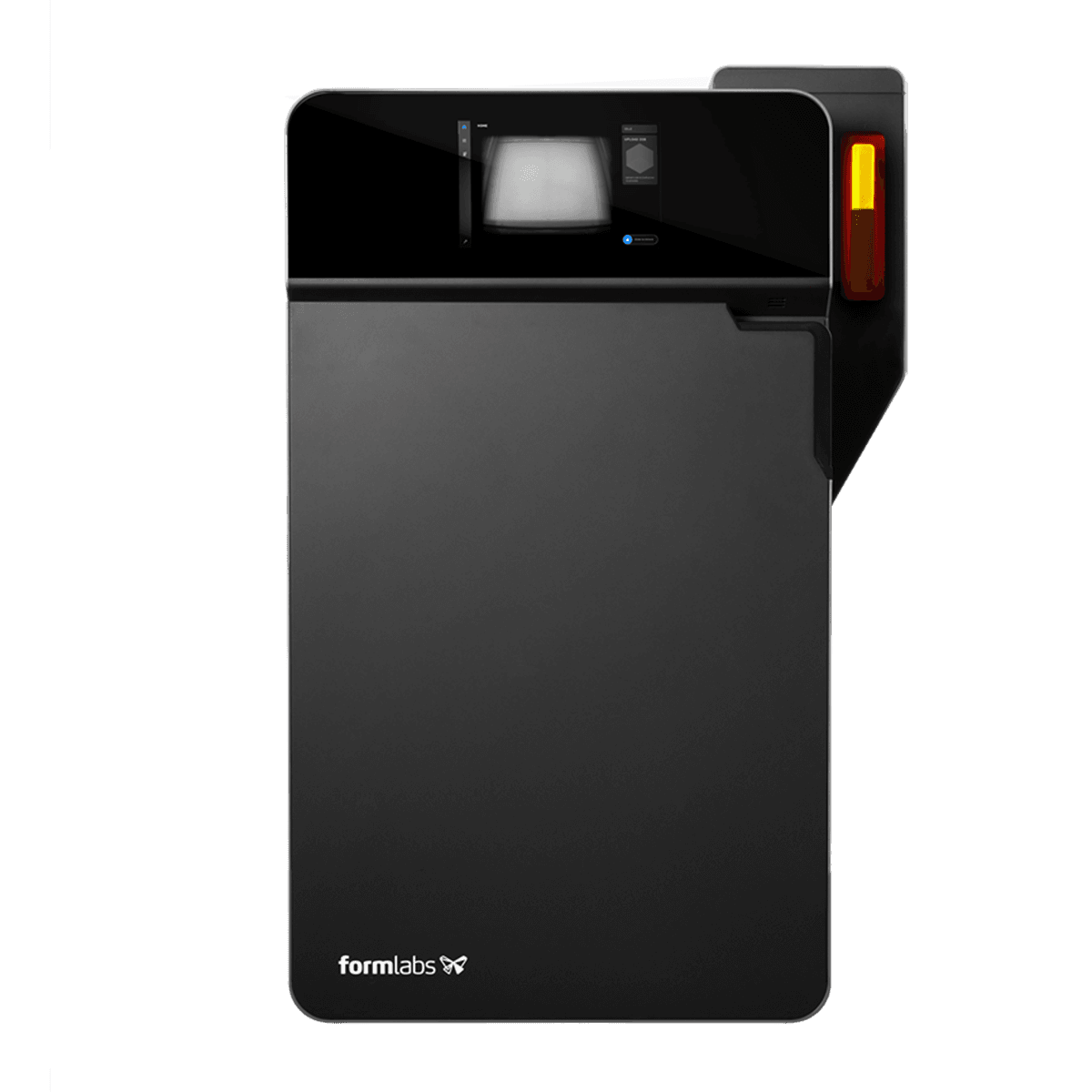

Fuse 1+ 30W

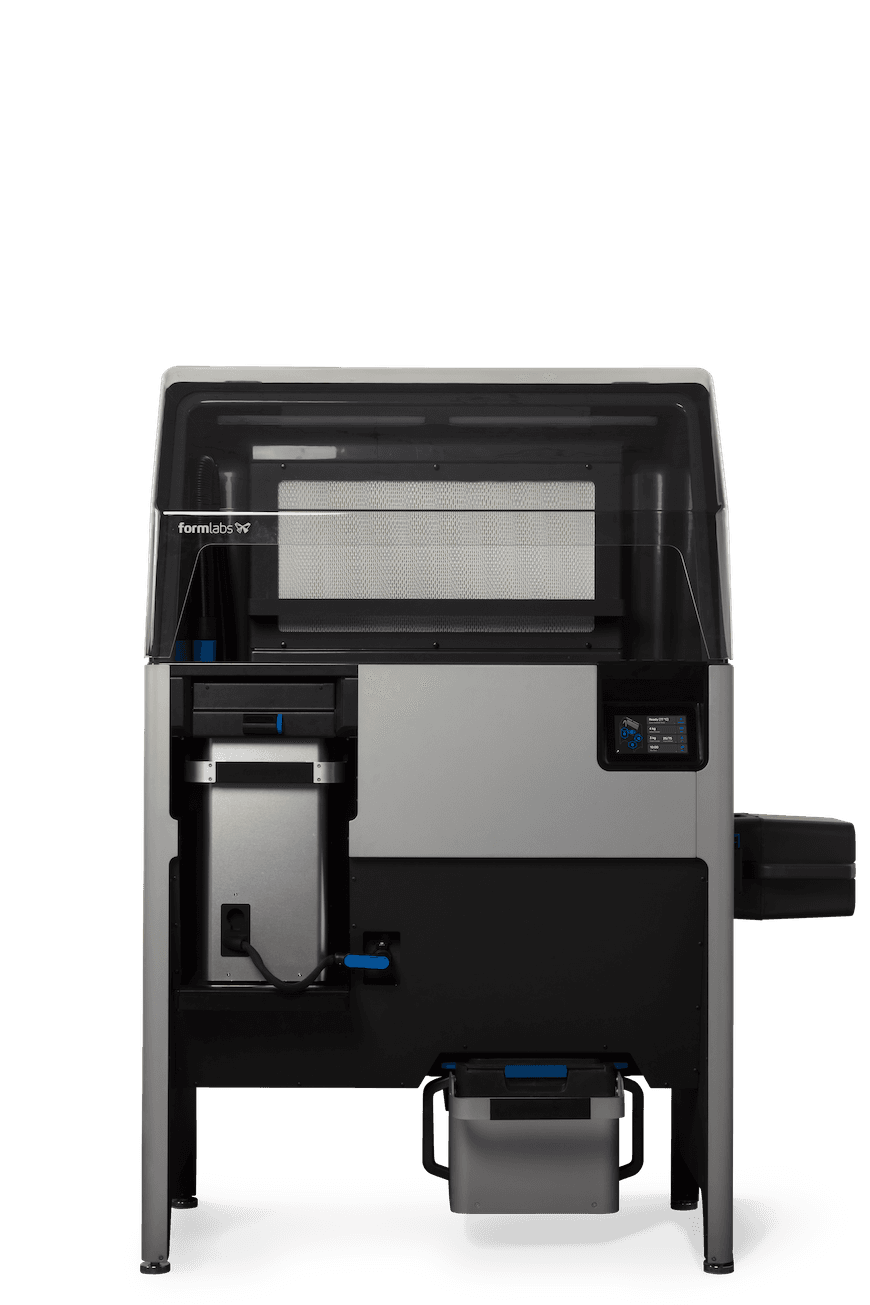

Fuse Blast

Fuse Sift

Formlabs materials