Before the Form Wash L and Form Cure L were released, the options for large volume post-processing of stereolithography (SLA) parts were limited. Customers had started printing with Formlabs Form 3L and Form 3BL large-format SLA printers, but still needed a post-processing solution. The pressure was on to design and manufacture accompanying washing and curing machines.

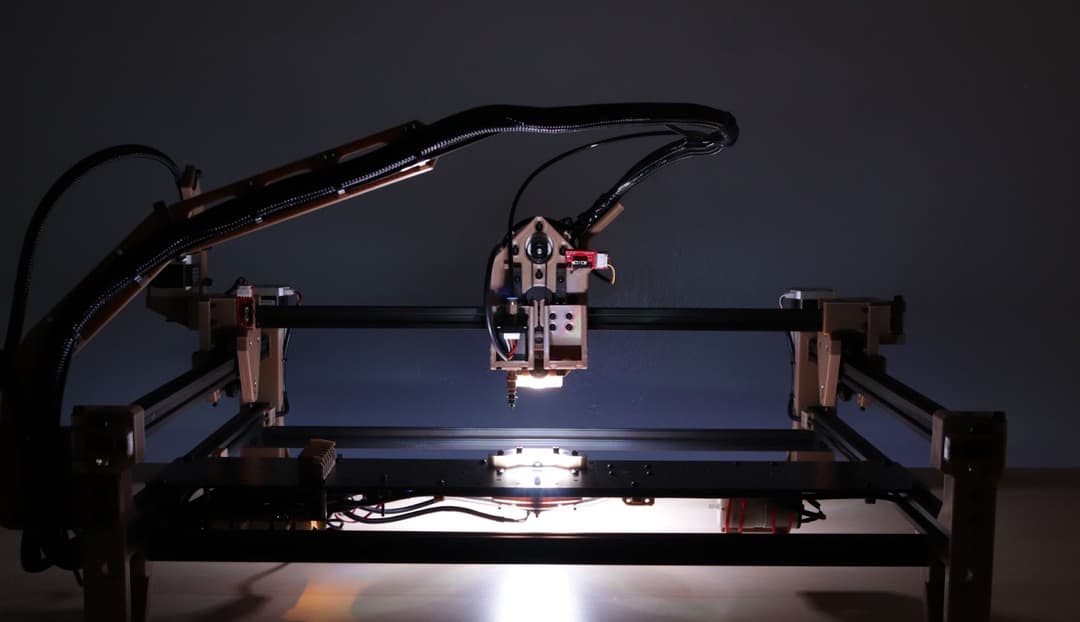

The engineering team at Formlabs needed an agile and high-quality prototyping solution as well as the ability to produce rugged, end-use parts for designs that were still evolving. The answer was right under their noses—Formlabs’ own Fuse 1 SLS printer and Nylon 12 Powder.

Read on to learn how Formlabs used the Fuse 1 printer to both prototype and manufacture end-use parts that are part of the Form Wash L and Form Cure L post processing units being shipped to customers today.

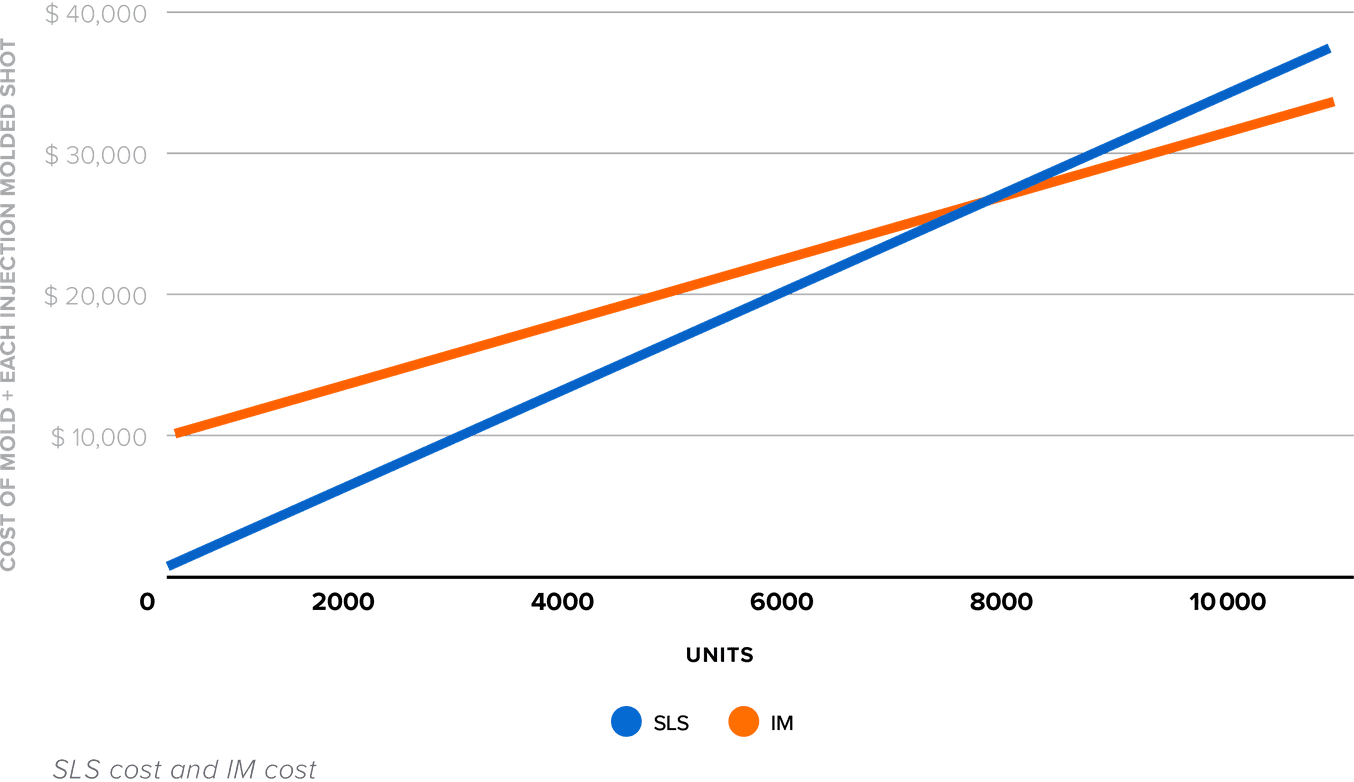

SLS 3D Printing vs. Injection Molding: When to Replace Molded Parts With 3D Printing?

This white paper showcases the cost-dynamics for real-life use cases, and presents guidelines for using SLS 3D printing, injection molding, or both.

A Complete Large-Format SLA Workflow

In September 2020, Formlabs had begun shipping the Form 3L, our flagship large format SLA printer. After years of telling customers that the only solution for large parts was to slice their CAD file in half, print it piece by piece, then glue the whole thing together, the Form 3L finally made it possible to print large parts without sacrificing the accuracy, surface finish, or range of material properties they could achieve with their standard Formlabs SLA 3D printers.

The Form 3L made an immediate impact for customers in every industry—orthodontic labs were able to print up to 120 full arches a day, product development companies like Black Diamond could print full-sized helmet prototypes, and hospitals could print an adult ribcage anatomical model for preoperative study.

However, each of those customers were also feeling the pain of an incomplete workflow–the delay of accompanying large-format post processing machines meant that customers were purchasing third party options, or creating DIY solutions that produced inconsistent results.

Prototyping the Wash L and Cure L With The Fuse 1

The basic premise of the new products was clear, simply create larger versions of the Form Wash and Form Cure systems. But sourcing certain parts became problematic as global supply chain issues combined with the COVID-19 pandemic to delay delivery on many of the materials the team needed to prototype.

“We definitely ran into challenges. We were on a tight timeline and it made getting the materials ready for development builds very tricky. There were supply chain issues and we had to match up with a delivery schedule that was pretty aggressive”, says Formlabs Supply Chain Engineer Megan Liu.

Fortunately, the team had an industrial quality solution right down the hall for both prototyping and production. The Fuse 1 SLS system allowed the Wash L/Cure L team to quickly run through multiple iterations of each part of the design for the two machines, even when certain traditional manufacturing processes were out of reach due to cost or lead time. Six of those parts continue to be printed on the Fuse 1 and are part of the end products’ final phase manufacturing build.

Manufacturing Form Cure L Parts With The Fuse 1

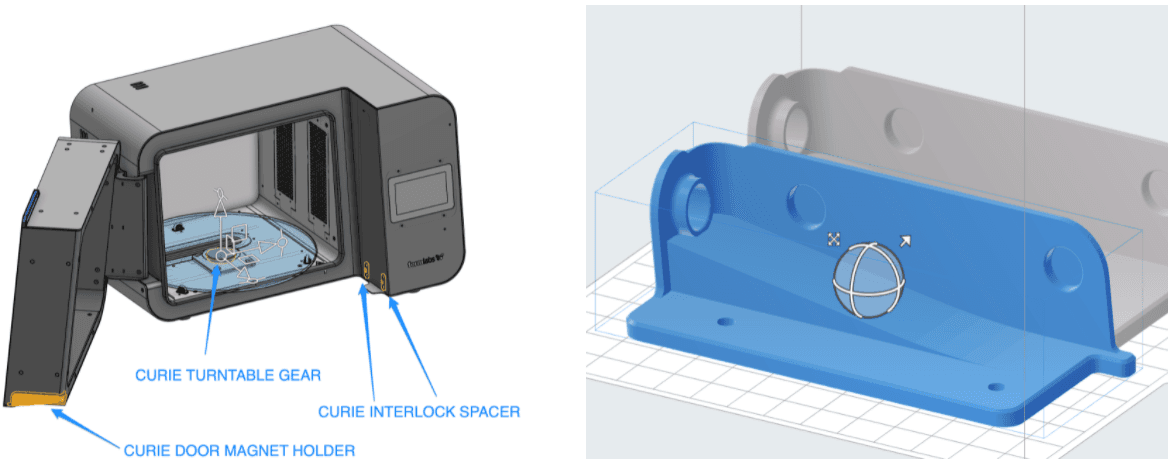

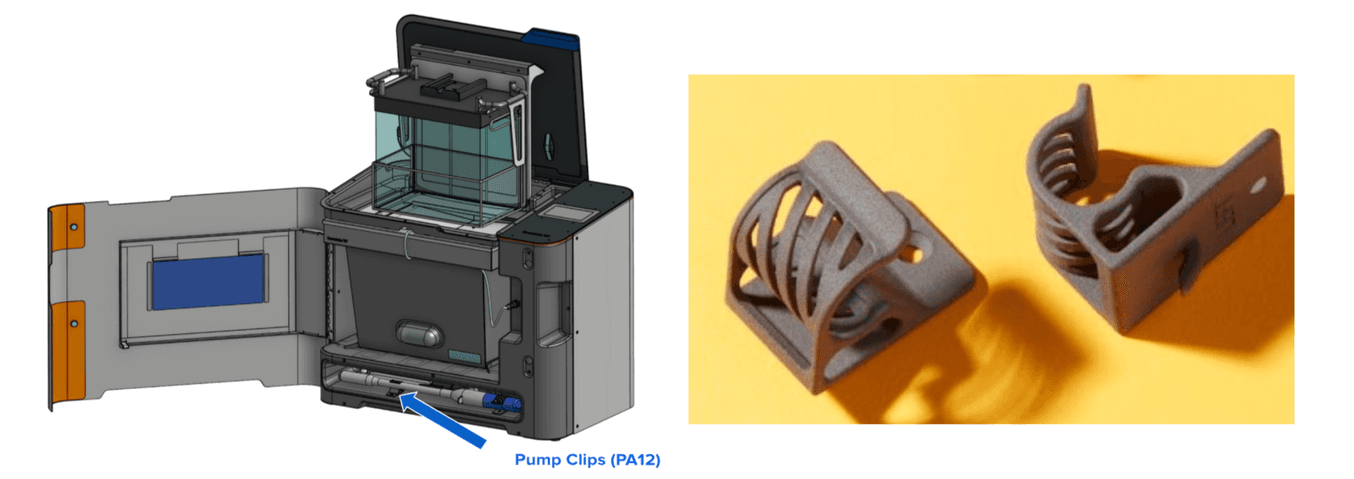

The Form Cure L units shipped to customers have three parts printed on the Fuse 1: the turntable gear, door magnet holder, and interlock spacer. Form Wash L units have two different pump clips printed with Nylon 12 Powder on the Fuse 1, and the first round of production units also had a small magnet cover. This isn’t the first time our global sourcing teams have used Fuse 1 printers to produce end-use parts for Formlabs products–there are actually parts on production units of the Fuse 1 itself that were printed at the Formlabs fabrication hub on existing Fuse 1 units.

To design the Form Cure L’s turntable gear, the team had to iterate multiple times to make sure the chamfered hole in the center could grip the turntable tightly, and generate enough force to revolve the table. After several designs and prototypes, they settled on 3D printing the final part instead of injection molding, due to the core in the center. An injection mold would require two parts to achieve that core, but SLS printing allowed the designers to consolidate the design into one part.

“If the size of the gear hole wasn’t conforming, we could change it immediately. We were able to adapt really quickly, stop what wasn’t working, and try something new. The changeover process between iterations was much easier because we knew we wouldn’t have to change tooling or suppliers for a new iteration,” says Liu.

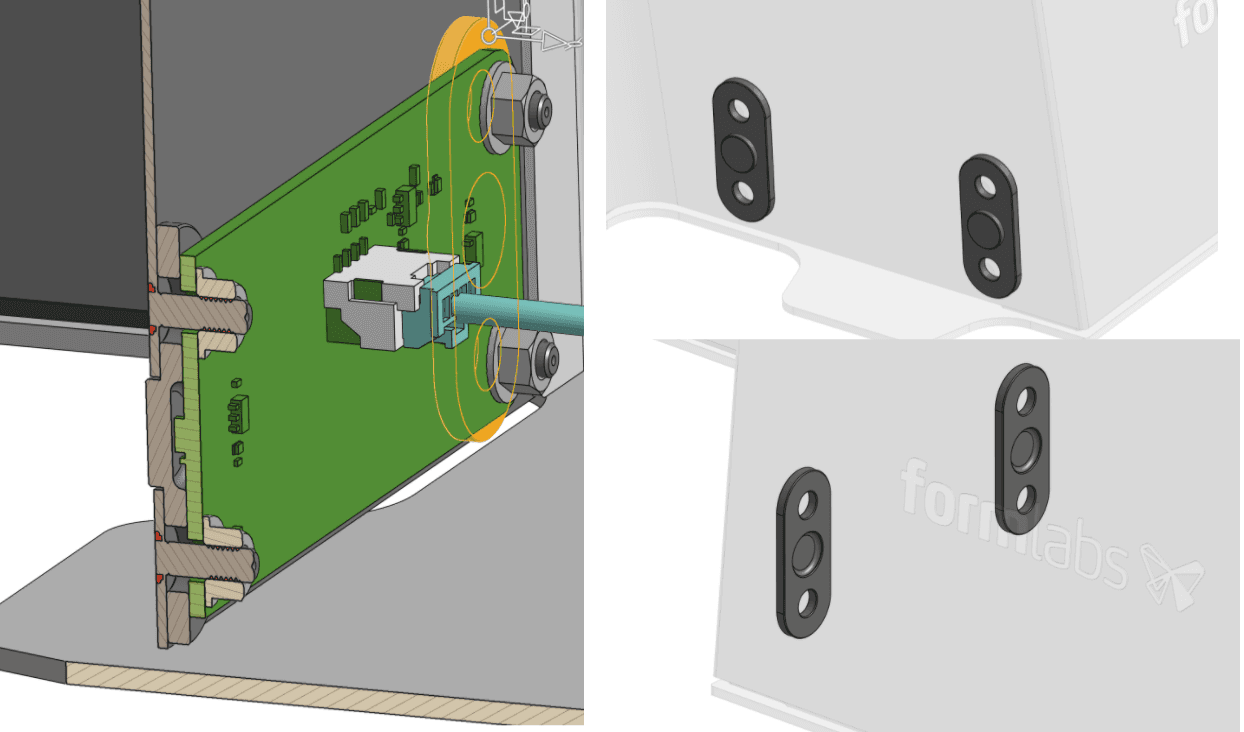

For the Form Cure L interlock spacers, the team prototyped with the Form 3 SLA printer, then printed the final part on the Fuse 1. The team needed to use plastic because interlock sensors work best when there is no metal between magnet and sensor. This part cosmetically seals the exterior, allows for a minimum of plastic in front of the actual sensor, and sets the sensor distance by acting like four insulating standoffs. The team was able to cut time and costs by moving from final stage prototype to production test all in-house, with no lead-time to account for with tooling.

The Form Cure L interlock spacer parts, rendered in CAD.

The last Form Cure L parts made on the Fuse 1 are two door magnet holders, suspending the magnets that hold the Form Cure L door closed and making it ‘click.’ The parts needed to be plastic, for magnet interference reasons as well as tactile reason–a metal part would scratch the powder coat and make unpleasant scraping noises when shutting the door. Because this part has both objective criteria (does the door close?) and subjective criteria (how does the door feel to close?) it was difficult to pin down a design until every other component was finalized. If the team had then needed to outsource the part to an injection molder, it would have added weeks to the production schedule. Printing in house kept them on track for their aggressive timeline.

The Form Cure L has three parts printed on the Fuse 1, left, and a close up of the door magnet holder, right.

Manufacturing Form Wash L Parts With The Fuse 1

The two pump clips hold the battery powered solvent pump in the storage compartment of the Wash L. They had to be custom sized to fit around the pump, and were designed specifically for material efficiency. The unique design with spiraled sides means they wouldn’t be able to be traditionally manufactured. Throughout the iterative process, the team was able to make design changes without having to redo tooling. Because the part was completely redesigned through the development cycle, this gave the team much more wiggle room in their budget.

In the Form Wash L, a magnet holds the solvent monitor in place inside the washing bucket. To protect that magnet from rust or scratching the engineering team designed a small magnet cover. Printing these for the first few hundred production units of the Wash L was a stopgap option, and the part is currently manufactured through injection molding. While lead times were high, it made sense to print these on the Fuse, as the small part was easily able to fit nested inside other parts, thanks to the improved Fuse 1 packing algorithm.

Shortened Timelines, Broken Supply Chains

The production timeline of the Form Wash L and Form Cure L coincided with the COVID-19 pandemic, as well as supply chain issues that affected the team’s ability to source materials and communicate with contract manufacturers.

Liu and the rest of the supply chain engineering team at Formlabs has developed relationships with a variety of vendors over the years, and can usually rely on finding the parts they need from one vendor or another. With shipping ports backlogged, Chinese supplier factories shut down, and transportation companies dealing with union strikes and employees sidelined by COVID-19, every option for prototyping materials was a dead-end.

“Having the printers in house enables us to be very flexible, even when we’re waiting for samples to come in that we’re going to eventually manufacture with traditional methods—we used 3D printed parts as a stopgap to make efficient use of our time.”

Megan Liu, Formlabs Global Sourcing

Due to these materials delays, the Form Wash L and Form Cure L team had their typical ramp scheduled drastically compressed. Instead of six weeks to produce 600 units, the team had half that—they needed to produce 200 units each week to meet their deadline. The Formlabs print farm at the materials production facility in Ohio didn’t have the capacity, so the Formlabs engineering team printed them at headquarters in Somerville.

“We could immediately double capacity by having those printers on hand. If we had been outsourcing and the contractor had shut down, you couldn’t just transport that tool to a new contractor, but with the printers we were able to decentralize manufacturing and add capacity immediately so we could stay on schedule,” says Liu.

Moving to Injection Molding: When and Why?

Once the team successfully produced those 600 units, they had the opportunity to assess their options for full production with established timelines and demand. Though some parts, like both pump clips, the interlock spacers, and turntable gear still make sense to produce on the Fuse 1, other parts, like the magnet cover, have been moved to an injection molding workflow.

We’ll take a look at two parts, the turntable gear and the magnet cover, to show how that decision gets made, and when it makes sense to switch the workflow from direct SLS 3D printing to traditional injection molding.

Part 1: Saturation Sensing Magnet Cover (Form Wash L)

The mold for the saturation sensing magnet cover would cost $3,700, and it took over a month to complete from the start of the production schedule, which would have delayed the final iterative stages and early production runs of the Form Wash L.

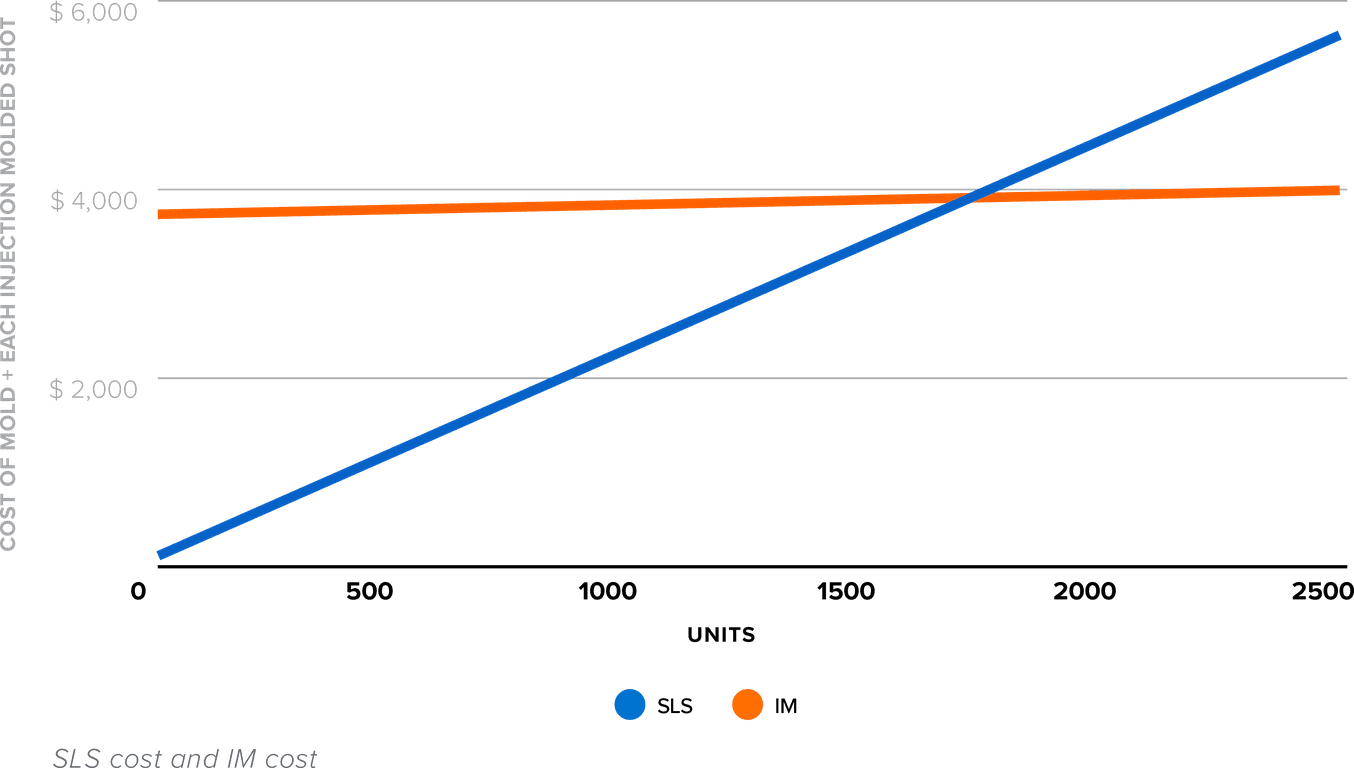

The per part cost, including labor, of printing the magnet cover on the Fuse 1 was only $2.20–a cheaper alternative at quantities fewer than 2000 parts. The Global Sourcing team decided that SLS 3D printing was a great interim manufacturing option, but once the mold was made, realized it would be cheaper to move forward with injection molding.

| SLS | IM per part | IM tooling cost | |

|---|---|---|---|

| Saturation Sensor Magnet Cover | $2.20 | $0.11 | $3700 |

Part 2: Turntable Gear

This part has a chamfered hole in the center in order to grip the turntable peg tightly and generate enough force to revolve the Form Cure L platform.

To create an injection mold for that design would require two parts to achieve that core, and a two part mold is more expensive. The estimated cost from the injection molding contract manufacturer was $10,000.

| SLS | IM per part | IM tooling cost | |

|---|---|---|---|

| Turntable Gear | $3.50 | $2.20 | $10,000 |

SLS 3D printing the Tuntable Gear allowed the designers to consolidate the design into one part, and the cost per part was only $3.50, meaning that the breakeven point for injection molding was at quantities close to 8000 units. The team decided to print the part on the Fuse 1, saving thousands of dollars, and lowering the cost of the final product. Working up to that production level will give the Global Sourcing team ample time to plan, order molds, and switch to injection molding when it becomes most economical. SLS 3D printing these parts for the time being allowed them to speed up launch time, and focus on other parts of the product.

Can You Replace Injection Molding With 3D Printing?

The Fuse 1 printer fleet is a complementary part of the supply chain. While it did replace traditional methods of production for some of the parts, conventional tooling, casting, molding, and machining are still necessary parts of a product life cycle. Being able to rely on industrial quality 3D printers brings a larger portion under the control of the manufacturer, and protects them from external variables such as delayed raw materials or long lead times for tooling.

The Fuse 1 SLS printers allowed Formlabs engineers to deliver two products on a tight timeline, while overcoming hurdles posed by the COVID-19 pandemic and supply chain disruptions. The Form Wash L and Form Cure L production units each have multiple parts printed on Formlabs’ own technology, proving that the Fuse 1 is an end-to-end product development and manufacturing solution. In the SLS 3D Printing vs. Injection Molding whitepaper, we took a deep dive into each application possible for end-use parts on the Fuse 1 SLS printer, from replacement parts, to customized prosthetics, to after-market engine parts.