Masking, or the strategic covering of certain areas during a processing step such as painting, media blasting, or metalizing, is traditionally a labor-intensive step in manufacturing processes with a low margin for error. 3D printing presents a cost-effective means of creating customized masking parts that can fit complex geometries and be used repeatedly, reducing the need for hours of manual labor during post-production workflows.

Both stereolithography (SLA) and selective laser sintering (SLS) 3D printing technologies can be used in the manufacturing of masking tools, and each presents unique advantages. In this guide, we will outline the considerations to take when creating masks, how to evaluate which 3D printing technology is right for your workflow, and provide examples of customers successfully finishing their parts with the help of 3D printed masks.

What Is Masking?

Masking is the strategic covering of certain areas on a part that need to remain free of any coating, painting, metallizing, or other surface finishing processes. Those areas may need to remain untouched for various reasons — because they will become an attachment area for an assembly, for electrical conductivity reasons, or because they might need to be coated in some other material or color, among others. Masks are therefore manufacturing aids that can be customized and made to correspond to each final part, or created once and used as each part goes through the finishing process individually.

Even in industries where much of the finishing process is automated, like in the automotive industry, masking is still often done by hand with tape and paper. Photo credit: mirka.com

Overview

Coating, painting, or metallizing processes can vastly improve both the functionality and appearance of parts used in any industry, but these processes often involve extra steps, one of which is masking. Masking is the strategic covering of certain areas on a part that need to remain free of any coating. That area may need to remain untouched for multiple reasons — because it will become an attachment area for an assembly, for electrical conductivity reasons, or because it might need to be coated in some other material or color, among others.

Traditional masking workflows include manually measuring and cutting masking tape, machining metal or plastic masks, or sometimes coating an entire part and then machining or scraping away the coating from the designated area. Taping workflows, though they use cheap materials, are extremely labor-intensive, and can add minutes of labor time per part on a production line. Machined masks can be repeatedly used but are expensive to manufacture, and the machining process confers some geometric limitations.

Masks are an ideal application for 3D printing — they are often needed in low-volume production quantities and with very specific geometries to ensure they only cover certain areas at the center, on the edges, or in a specific pattern across a larger part. There are many types of coatings that are compatible with 3D printed masks including Cerakote, airbrushing, spray paint, low-temperature and UV powder coating, vacuum metallization, and even subtractive processes like media blasting, where the mask covers a designated area to preserve the coating or surface finish it already has. 3D printed masks can be produced with less labor, offer more repeatability, and simplify many complex masking jobs. The technology can also be used to prototype and test a mask design before moving to machined metal masking if absolutely necessary for temperature tolerances.

3D Printing Masking Considerations

There are a few factors to consider when selecting a material option for producing masks. These factors are mechanical and chemical requirements, part fit, and production requirements.

-

Temperature: The largest limiting factor for 3D printed masking is temperature. Some coatings, such as powder coatings, cure at temperatures above 238° C. To select the most appropriate 3D printing material for an application, consult the Technical Data Sheet to find the heat deflection point before using it in a coating process. For many lower-temperature powder coating processes, High Temp Resin can withstand up to 238° C.

-

Abrasiveness: Some finishing processes, like media blasting or vibratory tumbling, are subtractive, so the use of masking tools is to keep the coating of certain surfaces protected, rather than bare. These processes are more abrasive, and the masks need to be made from materials that can withstand the forces of the media used, like ceramic pellets or walnut shells. For these instances, use a harder material such as Rigid 10K Resin for SLA parts or Nylon 12 GF Powder for SLS parts.

-

Solution Use: Many coatings require solutions, both basic and acidic. If an acidic or basic solution is part of the processing workflow, make sure to compare the TDS with the chemical requirements. Some Formlabs SLA resins perform better than others when submerged in different solutions. If an acidic solution is a part of your workflow, consider using Tough 1500 Resin or Rigid 10K Resin. The full set of Formlabs materials’ TDS can be found on our website.

-

Part Fitment: Both Formlabs SLA and SLS materials offer a range of compliance and stiffness. Creating masks traditionally limits options for trying out new materials, because machining or molding parts is cost-prohibitive for one-off test runs. Having a 3D printer expands material possibilities for masks — you can try multiple materials at a very low cost per part.

For Formlabs SLA, press-on fitment can be easily achieved with a material like Tough 1000 Resin. For SLS printers, Nylon 11 Powder is a good option for parts that have to flex very slightly and be used repeatedly. For masks that require a higher flexural modulus, Rigid 10K Resin or Nylon 12 Powder are excellent options. The accessibility of the Formlabs SLA and SLS platforms enables businesses to try multiple materials and find the one that best suits their particular workflow. Then, when the end part changes and a new modulus is required, businesses can switch masking materials again, without having sunk thousands of dollars into tooling. -

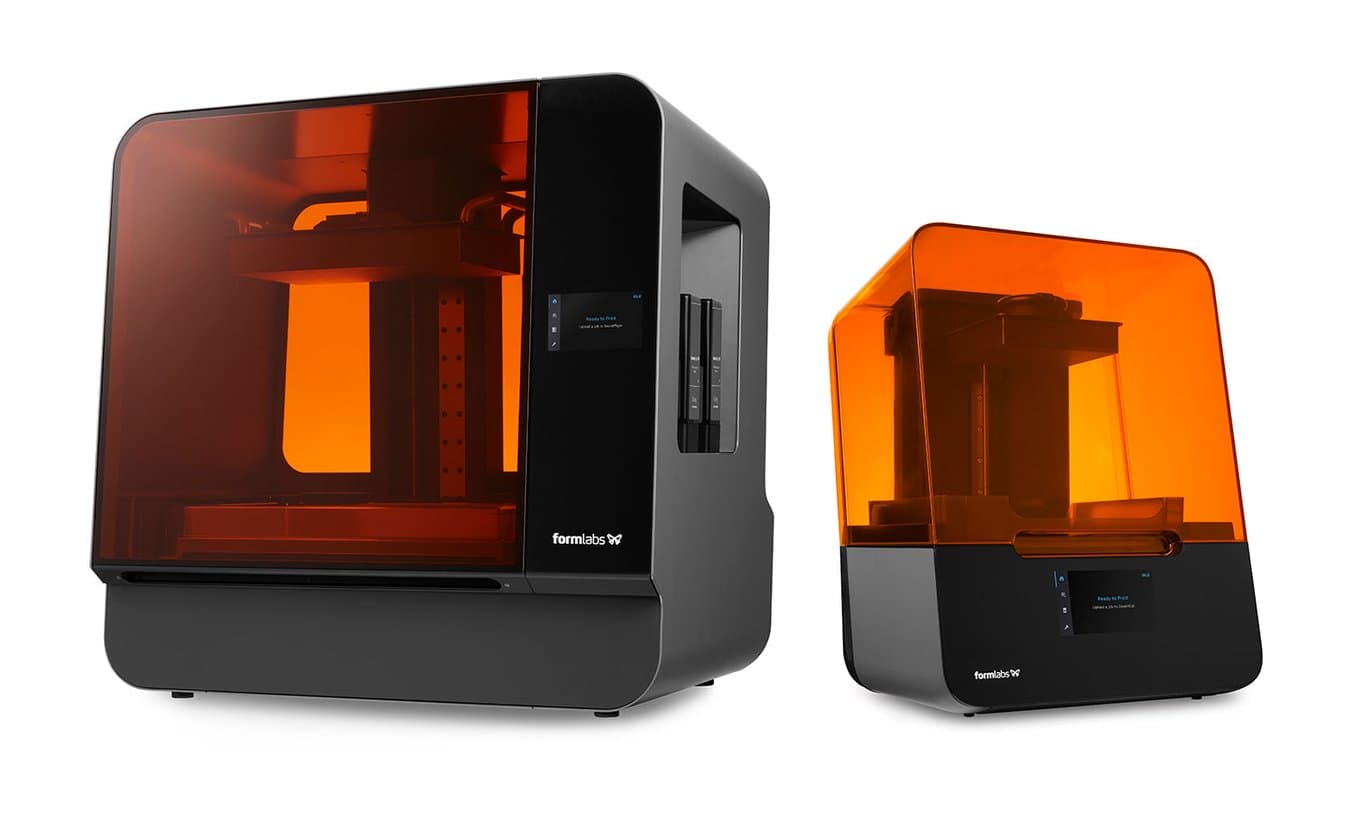

Production Requirements: Some masking applications require only one or two masks, while others need to match the volume of masks to the volume of parts. Formlabs’ SLA printers, both Form 3+ and Form 3L, are great choices for low volumes of masks, such as subtractive processes that can only be done a few at a time. The Fuse 1+ 30W SLS printer is better suited for higher volumes of masks given its ability to vertically stack multiple parts within the same build. For applications such as automated painting or Cerakoting with a Cerakote robot, where tens or hundreds of parts can be finished at once, printing masks at a higher volume on an SLS 3D printer is a better option.

SLA and SLS Technologies for Masking

SLA: Form 3+ and Form 3L

Formlabs SLA printers, the Form 3+ desktop and Form 3L benchtop units, offer a broad range of material options, quick turnaround time, high resolution, and large-format capacity.

The versatility of the Formlabs SLA printers is another advantage — with over 40 resins to choose from, users can select a material uniquely suited to their material property needs. The resins range from soft, compliant materials like Elastic 50A Resin for a mask that simulates silicone, to Rigid 10K Resin for stiff, rigid masks. For masking process considerations like temperature or conductivity, the Formlabs materials library offers specialized materials as well. ESD Resin effectively dissipates electrostatic discharge and protects electronic components from damage during assembly and manufacturing processes. High Temp Resin can securely attach to parts without deforming even at temperatures up to 238 °C.

| Resin | Key Strength | HDT |

|---|---|---|

| Draft Resin | Very high print speed. This resin is a great choice for quick turnaround when tolerance is not a primary concern. | 57 ℃, 135 ℉ |

| Durable Resin | Compliant and high impact strength. A good material choice when looking for snug fits, press fits, or flex/conformity around features. | 41℃, 106℉ |

| Tough 1500 Resin | Stiffer than Durable Resin while still maintaining compliance. | 52℃, 126℉ |

| Rigid 10K Resin | Very stiff resin, great choice for masking applications where slide fittings or sharp edges are desirable. Can also be a good selection for abrasive processes. | 218℃, 424℉ |

| High Temp Resin | Formlabs’ highest temperature resin, High Temp Resin is an option for any processes requiring temperature cures. | 238℃, 460℉ |

| Elastic 50A Resin | Lowest durometer material. Elastic 50A is a good option when compliance is the primary concern. | N/A |

The high resolution possible on Formlabs Form 3+ and Form 3L printers makes tight tolerances achievable, so masks fit correctly and stay snug to the part during any finishing process. Many masking parts are designed to fit along a narrow edge or trace organic shapes on a part that requires high dimensional accuracy. Formlabs SLA printers have a 25-micron layer height setting, and tolerances of +/- 15 microns for multiple materials. If sharp features, corners, and crisp lines are required, SLA printed masks are the best option.

SLS: The Fuse Series

The advantages of printing masks with the Fuse Series SLS printers are their batch production capacity, the durability and ruggedness of SLS powders, and the lack of post-processing necessary. Vertical stacking in the Fuse Series build chambers allows for tens or hundreds of parts to print at one time, making these masks ideal in applications such as Cerakoting where robotic arms can coat hundreds of parts at once.

Formlabs SLS Powders, which include four types of nylon and one TPU powder, are well known in manufacturing disciplines, and can be relied upon for durable strength and ruggedness.In general nylon materials have good chemical compatibility performance. Due to its semi-crystalline structure, Nylon materials have good resistance to petroleum, acetone, and silicone-based greases, and are less susceptible to environmental stress cracking.

Read more about the specific solvent compatibility of nylon here.

| Powder | Key Strength | HDT |

|---|---|---|

| Nylon 12 Powder | Lowest price SLS material option with a high refresh rate, stiffer and higher HDT under force than Nylon 11 with better flexural strength. If the masks require a stiff component or to minimize production costs, select Nylon 12 Powder. | 171℃, 340℉ |

| Nylon 11 Powder | High performance material with great impact strength, good performance on thin features, and a high degree of ductility. Nylon 11 is a great choice for SLS compliant masks or masks requiring very fine features. | 182℃, 360℉ |

| Nylon 11 CF Powder | Superior material properties. If producing a stiff mask with high impact strength along with high HDT especially under force Nylon 11 CF Powder has lots to offer. | 188℃, 370℉ |

| TPU 90A Powder | An elastomeric SLS material, allowing for flexible components with a high degree of design freedom. TPU can be used for gasketings, plugs, and compliant masks. | 94℃, 202℉ |

The self-supporting nature of the Fuse Series powder bed eliminates the need for supports, making material usage more efficient and removing the need for laborious manual post-processing and support removal. Printing without supports also enables complex geometries, such as overhangs, lattice shapes, or internal channels that cannot easily be produced by other means.

Case Study: NIC Industries (Cerakote) SLS Printed Fixture and Mask Combo

NIC Industries, the manufacturer of Cerakote, has been coating 3D printed parts and using 3D printed masks for a long time, and find them especially useful when deploying their robotic Cerakoting machine for high volume production.

For a batch production run of sample parts, they worked with Formlabs to produce 1,000 units, using SLS 3D printed masks to quickly and efficiently mask certain surfaces. Masks were printed using Nylon 12 Powder on the Fuse 1+ 30W SLS printer, and served to cover the inside of the two-part final product assembly to prevent overspraying and ensure clean delineation between colors. The masks also serve to fixture the part to the robotic applicator assembly, allowing for high throughput, and consistent coating.

SLS 3D printed mask and fixture (left), 3D printed masks fixtured to allow for robotic coating (center), and two-piece SLS 3D printed sample part, finished with Cerakote H-Series (right).

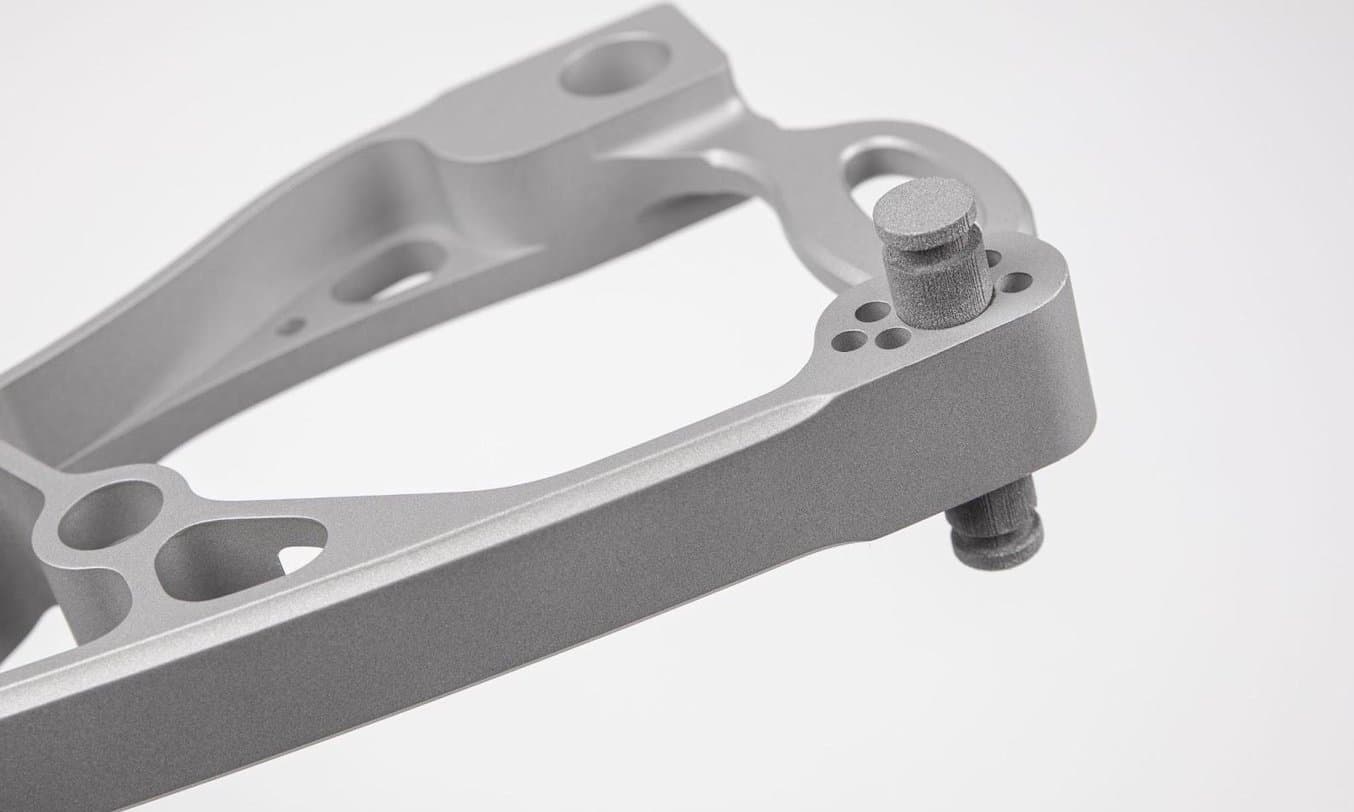

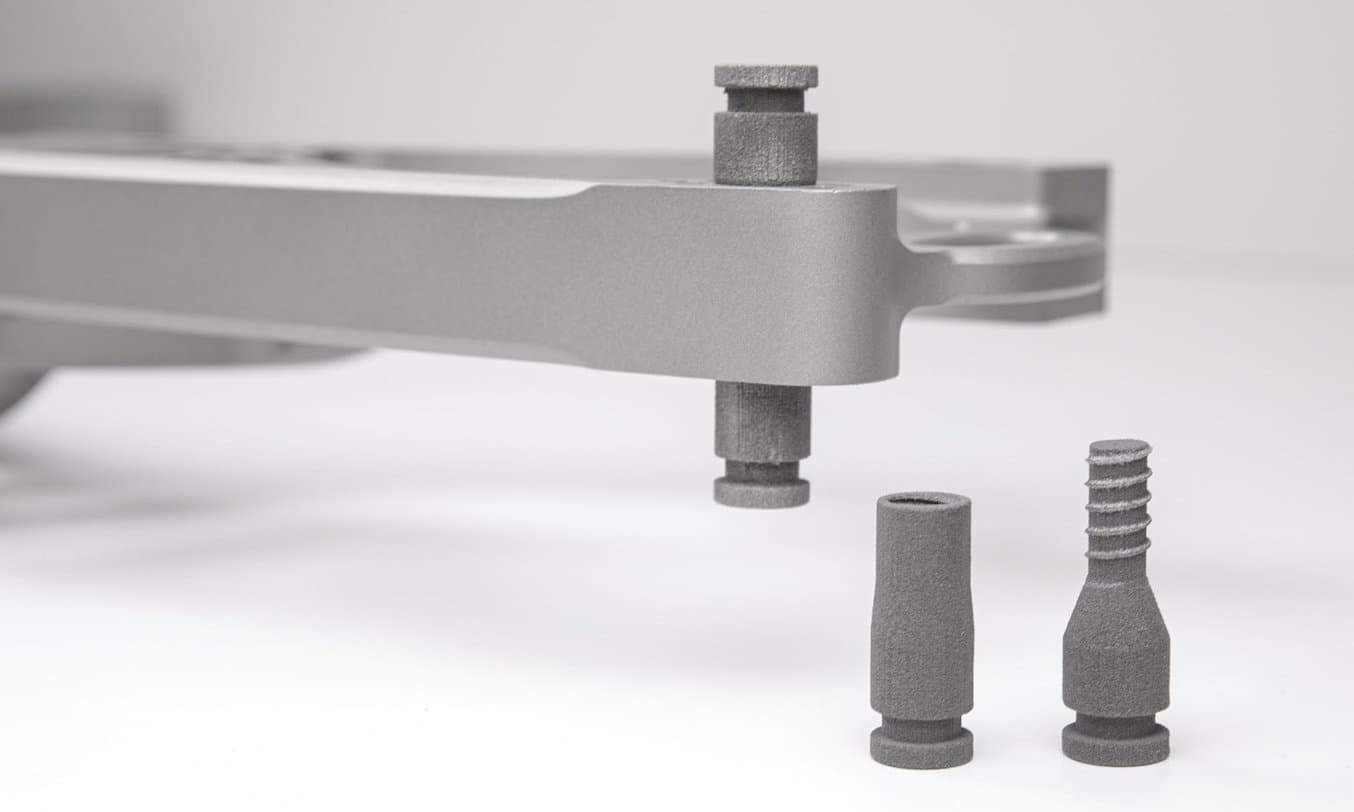

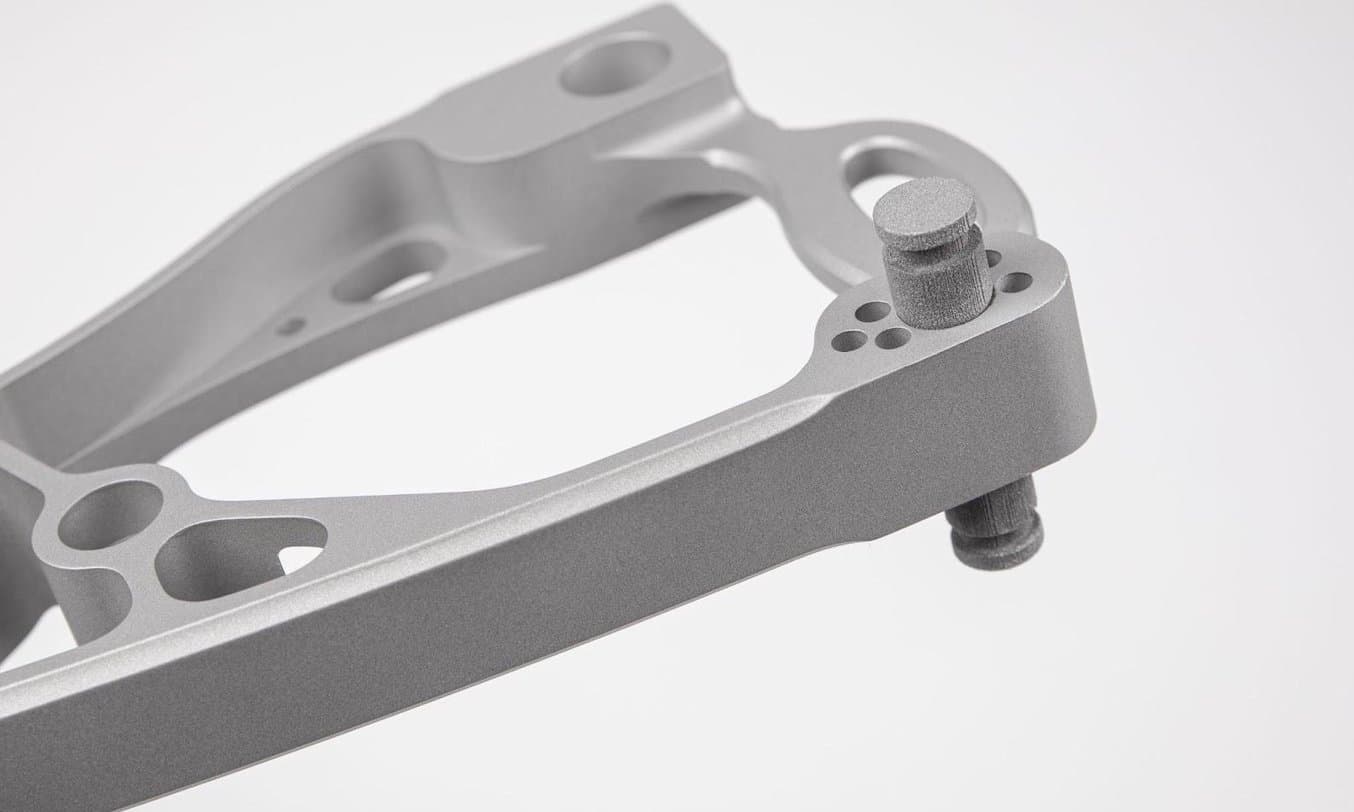

On another part, NIC industries needed to post-process this bow riser, but protect the inner channel of a screw thread during the coating phase before final assembly. Prior to having Cerakote applied, NIC Industries designed and 3D printed a mask to protect interior surfaces of this bow riser. They designed a plug-style mask that fits into the screw thread and prevents any coating material from entering the cavity to ensure a smooth threading in the final assembly. The plugs can be easily removed, flex slightly to pop in and out of the cavity, and are durable enough to be used for hundreds of coating applications.

Nylon 12 Powder two-piece 3D printed mask for bow riser

Bow riser and 3D printed mask assembled

Case Study: Productive Plastics: SLS Printed Stencil Guide

Productive Plastics is an industrial thermoformer that uses Fuse Series SLS printers for a variety of manufacturing aids on the factory floor. During the painting process, they use tape to cover a critical copperized surface and protect it from paint. They needed to cut the rest of the tape away, tracing the outside of the copper surface, which took several minutes to do accurately.

With a 3D printed mask that perfectly fits over the copperized surface, they can quickly stencil around the mask and remove the unnecessary tape, without worrying about damaging the copper.

In the first step, tape covers a large section of the part. In the second, the 3D printed part acts as a stencil around which a technician will cut the rest of the tape away, ensuring that the copper-coated part remains free of paint, while the rest of the surface is painted black.

3D Printed Masks Improve Costs and Throughput

The following example of a 3D printed mask for a small pump housing demonstrates the costeffectiveness of 3D printed masking parts, on both SLS and SLA printers. The pump housing (grey) requires masking on the interior surfaces prior to coating. The interior surface is masked with a Nylon 12 Powder part (black) printed on the Fuse 1+ 30W SLS printer. This part has features that enable easy alignment as well as fixturing and protects the interior of the pump while the outside is coated. SLS printing was a good choice for this component due to the lack of supports required for the complex alignment pins and fixturing features. The top-facing circular feature is masked with a cap printed in Durable Resin (white) on the Form 3+. Durable was a good choice for this component as it could be printed flat on the build platform and the compliance of durable allows it to press fit into the outlet hole of the pump housing ensuring a snug fit.

| PRODUCTION SYSTEM | FUSE 1+ 30W | FORM 3+ |

|---|---|---|

| Material | Nylon 12 Powder | Durable Resin |

| Parts Per Build | 168 | 85 |

| Material Cost Per Part | $0.94 | $0.15 |

Conclusion

3D printing masks in-house can reduce labor costs, improve the look and performance of final parts, and streamline validation processes. The use of 3D printed parts in end-use applications is growing, and coating, dyeing, and painting are often necessary steps. Masking tools are necessary for both these 3D printed parts, and for many traditionally manufactured items. The advantages that 3D printing provides for the part itself (customization, design freedom, affordability of low volume production) also apply to the fabrication of the masks. Leveraging the speed, efficiency, and material versatility of Formlabs SLA and SLS printers can streamline inhouse masking fabrication and reduce bottlenecks in your supply chain.

To learn more about which Formlabs 3D printer and material are best suited to your application for masking, contact our sales team.