At Formlabs, we get excited about all types of 3D printing. At the 2016 Hackathon—a 2-day event where employees could build anything—one team wrote a slicer for DLP resin 3D printers. This slicer is a web-based tool that accepts an STL file and turns it into a set of bitmaps representing individual layers. It’s completely client side and uses WebGL to do slicing quickly.

Formlabs is happy to release the slicer as an open source tool: the source code is hosted on GitHub and released under the MIT license. Although this program is not an industrial-strength tool, you can try it on your own DLP printer. Customize it by editing values in printer.js, or load your own models into the demo below.

Looking for a Slicer for Formlabs SLA 3D Printers?

PreForm is the free print preparation and slicer software for Formlabs 3D printers. Get your model ready in minutes, upload to your printer, and let it build.

Looking through 2D slices of your 3D model can be confusing, but with a bit of practice, you can start picking out patterns and structure. Below are sliced versions of the five platonic solids. Can you tell which is which? Here’s a hint: the unchanging square is a cube.

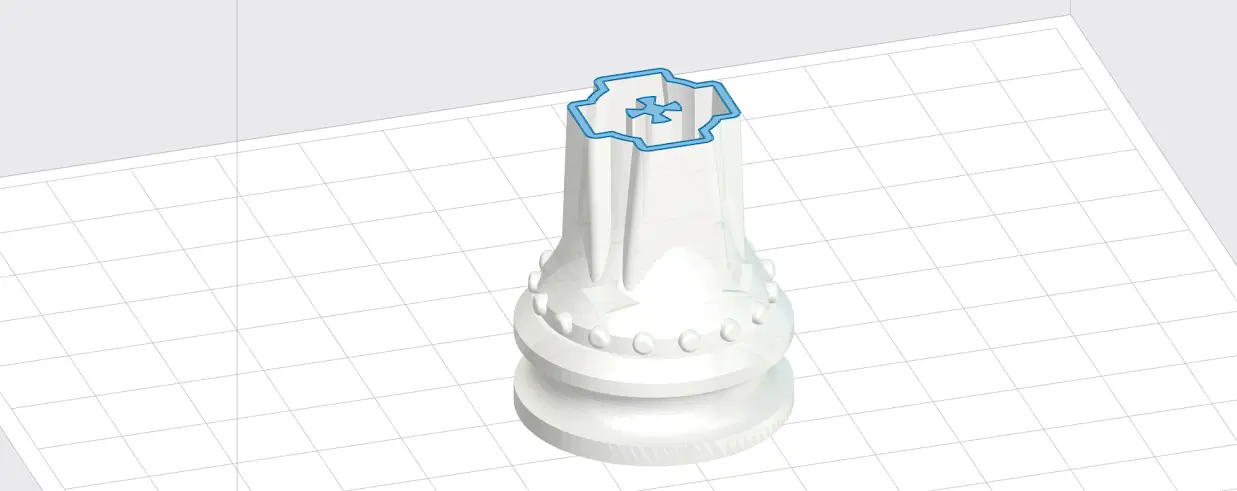

Examining slices can also reveal details that aren’t immediately obvious. The chess piece in the demo below has internal structures that can’t been seen from the outside (but would look great in Clear Resin).

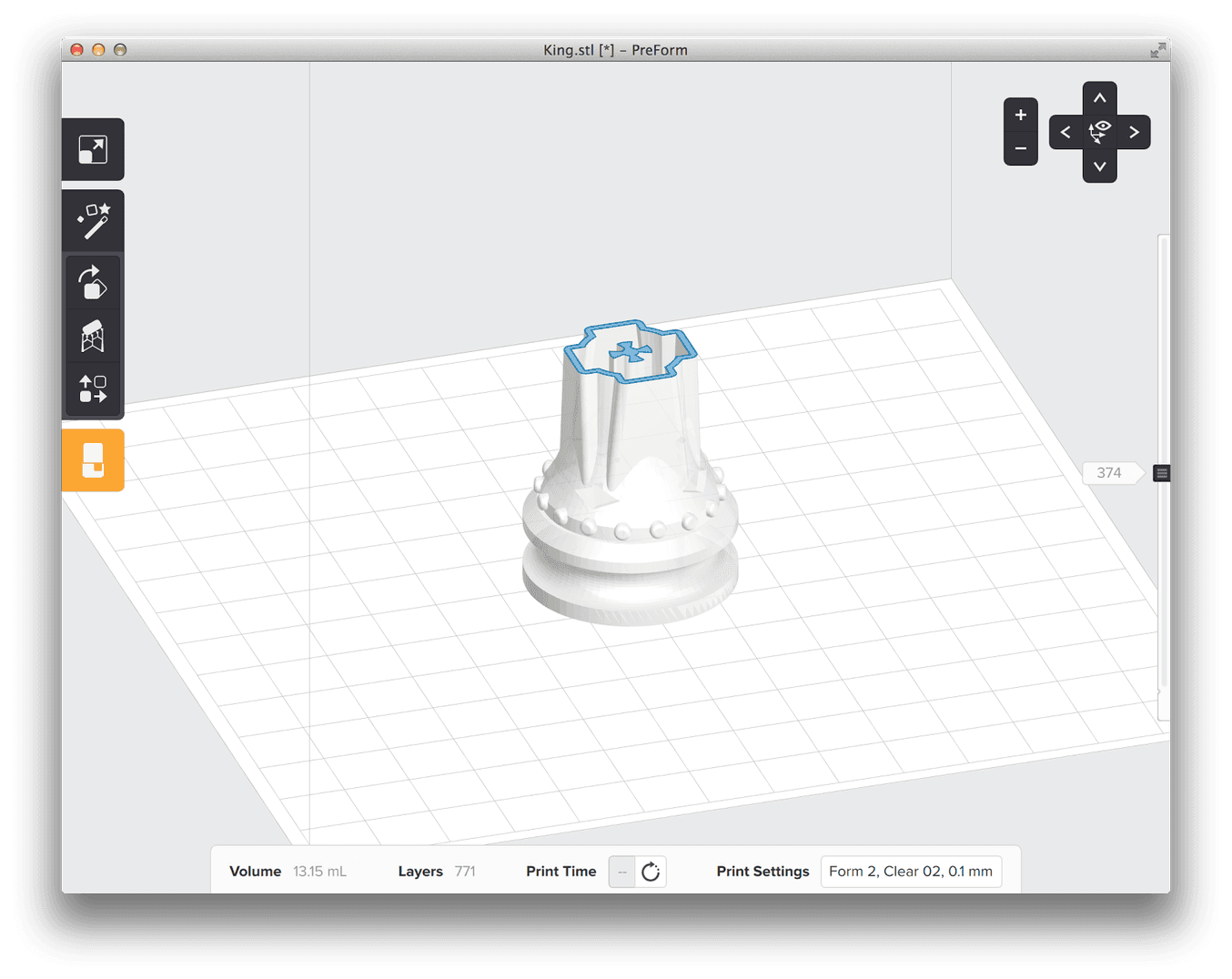

A similar examination is possible in PreForm, the desktop software package for Formlabs printers. Here’s the same model sliced halfway up, revealing an internal cross-shaped pillar:

It’s not always obvious how a model should be sliced, especially in cases with nested and overlapping meshes. For a deeper dive into slicing algorithms, check out Matt’s blog post.

Request a Free Sample Part

See and feel what you can create with a Formlabs SLA 3D printer. We’ll ship a free 3D printed sample part to your office.

Thanks to Matt Keeter and Martin Galese for creating and sharing this tool!

Want to learn more SLA and DLP 3D printing? Explore the differences between the two technologies, and what that means for final prints.