Formlabs’ new software update, PreForm 3.37.0 provides unparalleled access to print customization for all Formlabs stereolithography (SLA) models. The new PreForm version unlocks Open Platform, including Open Material Mode for the Form 3 Series printers and Print Settings Editor for Form 4/B.

No two customers or applications are alike, and Formlabs Open Platform creates new opportunities for every unique workflow. By combining the speed, dimensional accuracy, and reliability of Formlabs printers with new levels of customization through Open Material Mode and Print Settings Editor, this update can help users unlock entirely new ways of approaching their parts and processes.

Open Material Mode

Open Material Mode (OMM) empowers expert users and researchers to push the boundaries of 3D printing with custom resins. Currently available for the Form 3 Series, OMM allows users to experiment with any 405 nm photopolymer resin, unlocking unprecedented possibilities for material innovation and advanced applications.

To print with OMM, create a custom print setting with the PreForm Print Settings Editor. Learn more about using Open Material Mode here.

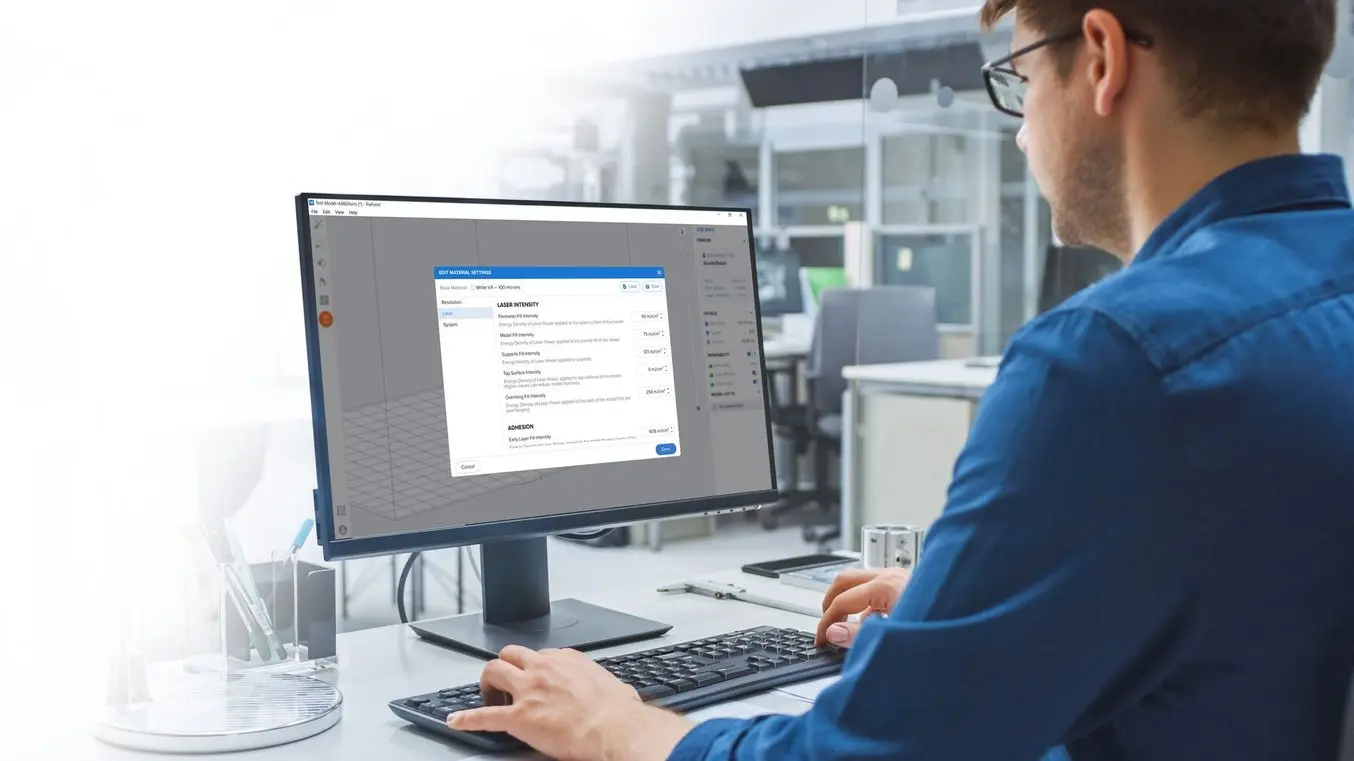

Print Settings Editor

Print Settings Editor is a feature within PreForm that allows users to adjust certain print process settings in order to achieve certain characteristics in their printed parts. Unlike OMM, which enables third-party resins to be used on Formlabs printers, Print Settings Editor works only within the Formlabs ecosystem, and is a great tool for Form 4 and Form 4B users to customize their workflows while maintaining the advanced material properties Formlabs resins are designed to offer. Restrictions may apply when using biocompatible materials, as divergence from regulated and approved workflows can impact the biocompatible status of the finished part.

Print Settings Editor grants greater control over:

- Exposure time

- Layer height

- Resolution

- Heating

- Wiping

- Interlayer motion

Continuous Improvement to Enable Innovation

Since the first version of PreForm and the first Form 1 3D printer, Formlabs users have pushed the boundaries of what’s possible. From creating new product categories to improving processes in every industry, our 3D printers have been leveraged as powerful tools that help bring ideas to life. Though iterating and improving our hardware ecosystems is a big part of that, software and firmware have made some of the biggest differences in customers’ day-to-day operations.

Faster printing speeds, increased build volumes, surface finish add-ons, and more — a software or firmware update can have a huge, tangible impact on what kinds of parts are possible. PreForm 3.37.0 is an example of our commitment to continuous improvement. Enabling Open Materials License for the Form 3 Series and Print Settings Editor for Form 4/B puts more power in the hands of the user.