3D Printing Resources

Hone your skills with our library of in-depth 3D printing guides, step-by-step tutorials, white papers, webinars, and more.

All Applications

3D Scanning and Reverse Engineering

Anatomical Models

Blow Molding

Composite Part Manufacturing

End-Use Parts

Injection Molding

Investment Casting

Manufacturing Aids

Medical Devices

Metalworking

Models and Props

Orthotics and Prosthetics

Patterns for Casting and Pressing

Rapid Prototyping

Rapid Tooling

Sheet Metal Forming

Silicone & Rubber Parts Production

Thermoforming

All Industries

Aerospace

Architecture

Art and Design

Audio

Automotive and Transportation

Education

Engineering

Entertainment

Jewelry

Manufacturing

Medical Device Manufacturing

Point of Care

All Products

Form 2

Form 3+

Form 3B+

Form 3BL

Form 3L

Form 4

Form 4B

Form 4BL

Form 4L

Form Auto

Form Cure

Form Wash

Fuse 1+

Fuse Blast

Fuse Sift

Software

All Materials

Alumina 4N Resin

BioMed Amber Resin

BioMed Black Resin

BioMed Clear Resin

BioMed Durable Resin

BioMed Elastic 50A Resin

BioMed Flex 80A Resin

BioMed White Resin

Black Resin

Castable Wax 40 Resin

Castable Wax Resin

Ceramic Resin

Clear Cast Resin

Clear Resin

Color Kit

Color Resin

Draft Resin

Durable Resin

ESD Resin

Elastic 50A Resin

Fast Model Resin

Flame Retardant Resin

Flexible 80A Resin

Grey Pro Resin

Grey Resin

High Temp Resin

Model Resin

Nylon 11 CF Powder

Nylon 11 Powder

Nylon 12 GF Powder

Nylon 12 Powder

Nylon 12 Tough Powder

Nylon 12 White Powder

Open Material Mode

Polypropylene Powder

Rebound Resin

Rigid 10K Resin

Rigid 4000 Resin

Silicone 40A Resin

Surgical Guide Resin

TPU 90A Powder

Tough 1000 Resin

Tough 1500 Resin

Tough 2000 Resin

True Cast Resin

White

White Resin

All Resource Types

Case Studies

Guides

News

White Papers

Basics of 3D Printing

White Paper

Comparing Surface Finish: Fuse Series SLS, EOS SLS, HP MJF, and Form 4 SLA

Blog

SLA vs. PolyJet (Material Jetting) 3D Printing: In-Depth Comparison

Blog

Building a Sustainable Future With 3D Printing

Blog

Methods for Measuring Toughness

White Paper

Additive Manufacturing as a Production Technology

Blog

When to Choose SLA vs. FDM 3D Printing

Blog

Advanced 3D Printing Techniques

Blog

Customize Parts and Increase Efficiency With New PreForm Features & Shareable Print Settings

Blog

FDM vs. SLA vs. SLS: 3D Printing Technology Comparison

Blog

How to Hollow Out 3D Models With Meshmixer & PreForm to Save Material and Time

Stereolithography (SLA)

Blog

Guide to Rapid Tooling

Blog

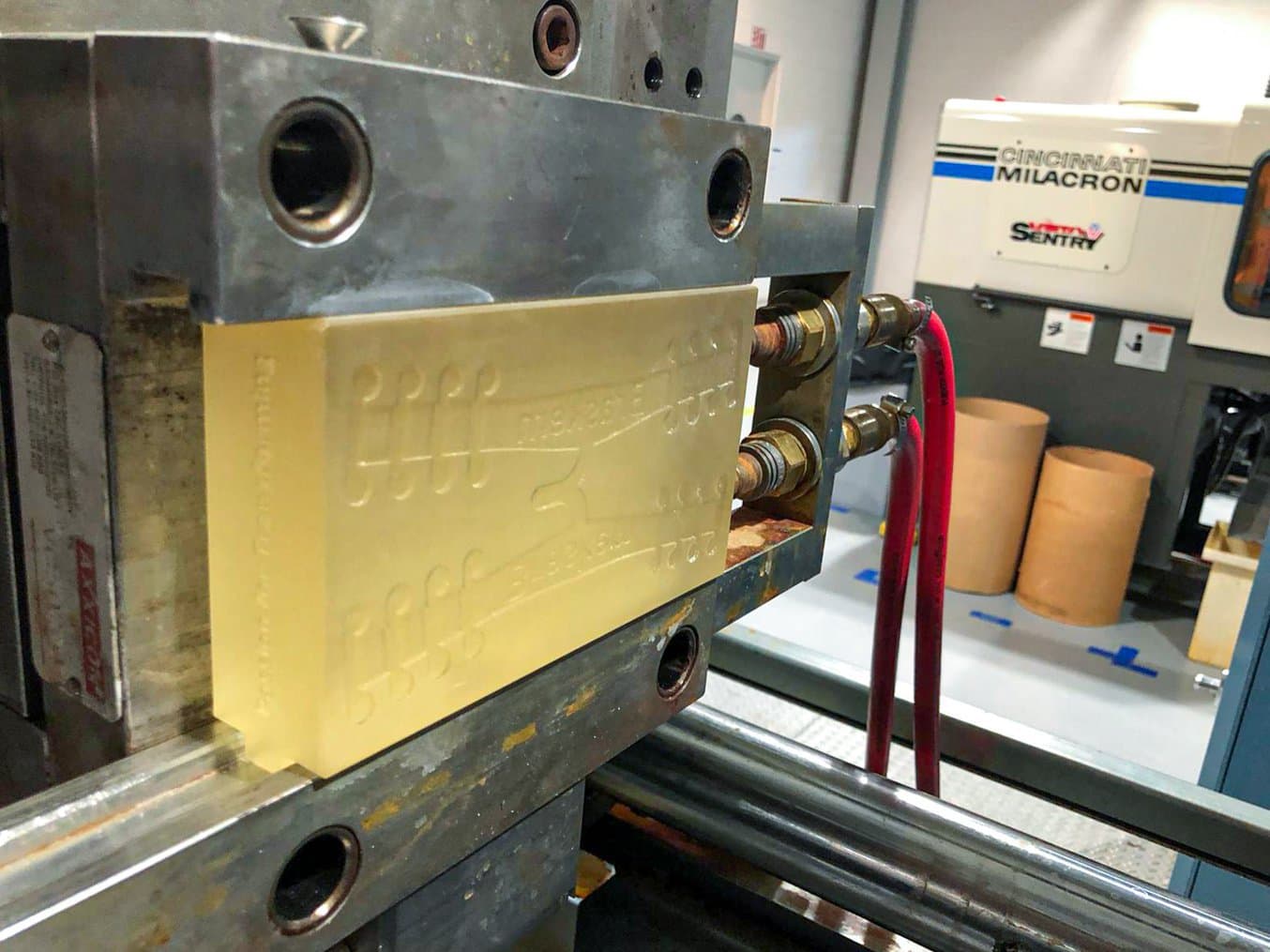

How Unilever and Serioplast Develop New Bottle Designs With 3D Printed Molds

Blog

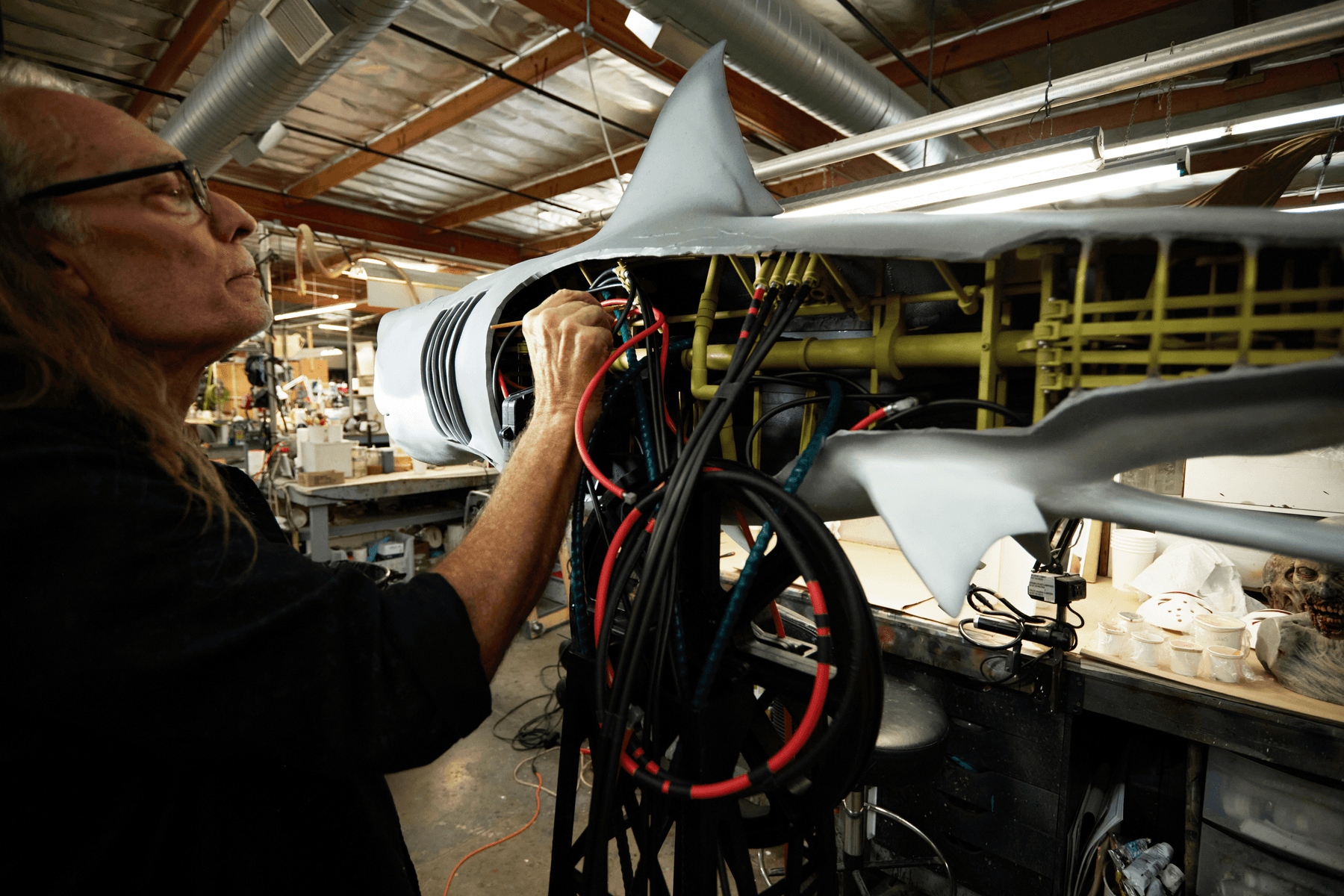

Perfect Replicas and Next-Day Props: How KNB EFX Melds Technology and Art

Blog

How to Use 3D Printing for Injection Molding

Blog

Rowing 9,000 Miles Across the Pacific With 3D Printed Parts: The Journey of the Maclean Brothers

Blog

Making the Zerømouse Blade “Indestructible” With Tough 2000 Resin and Form 4L

Blog

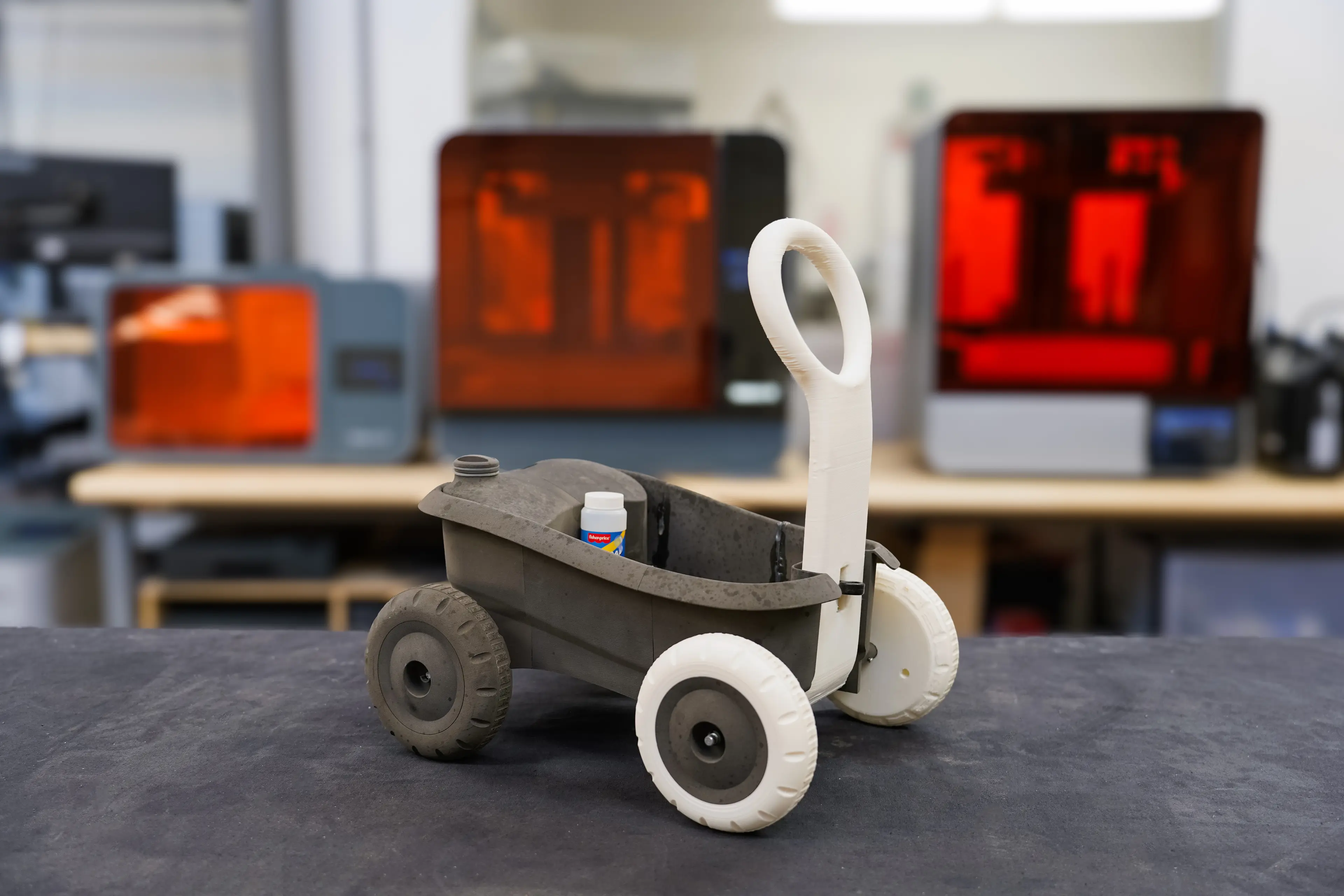

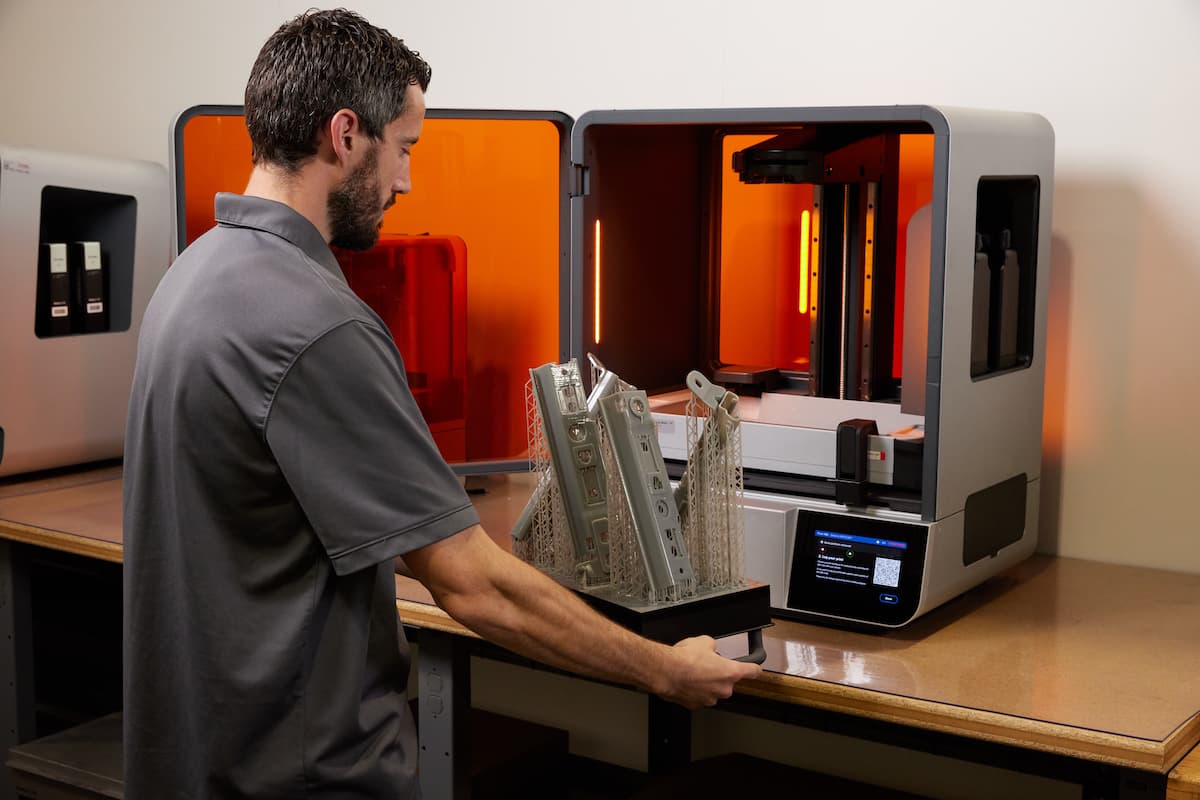

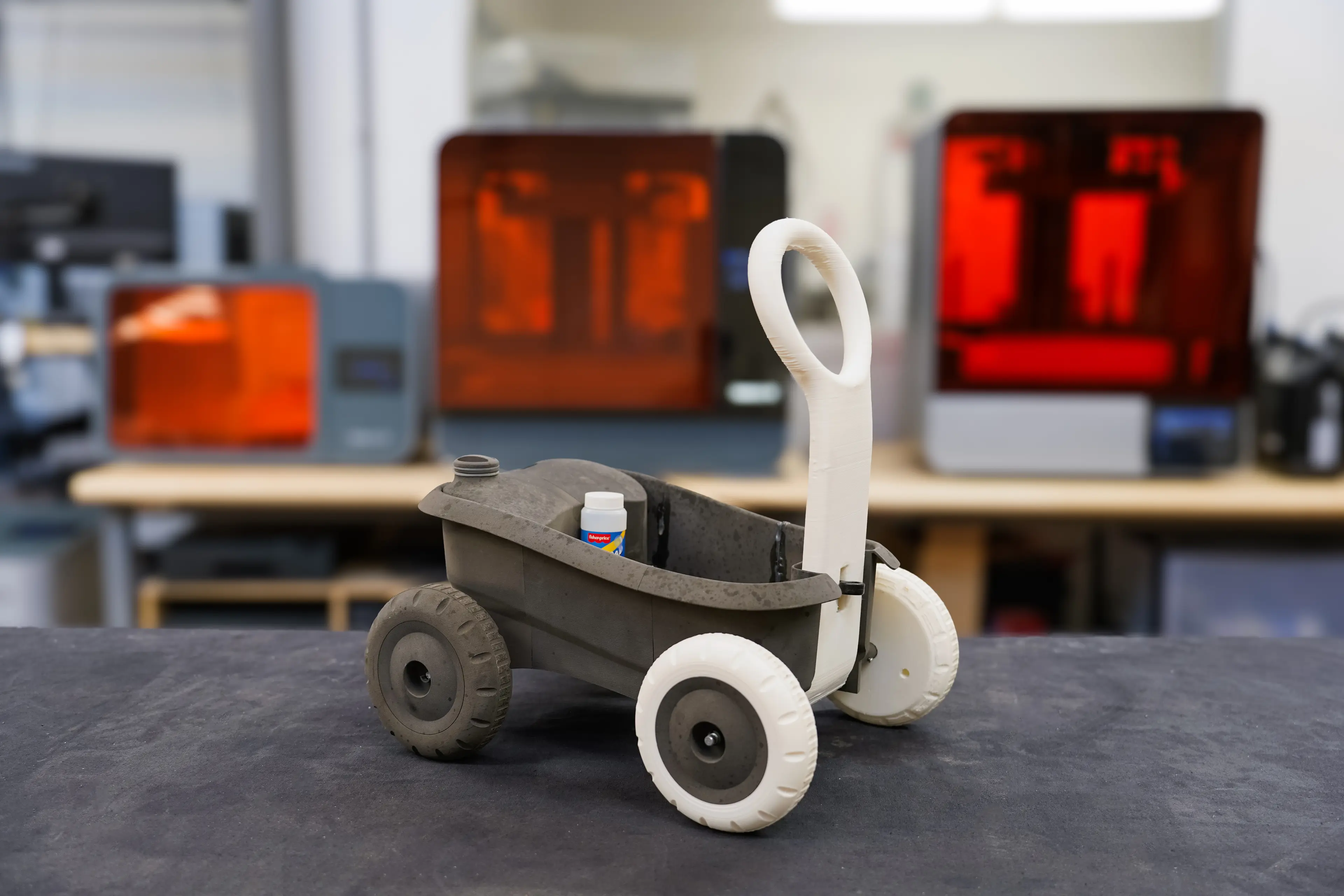

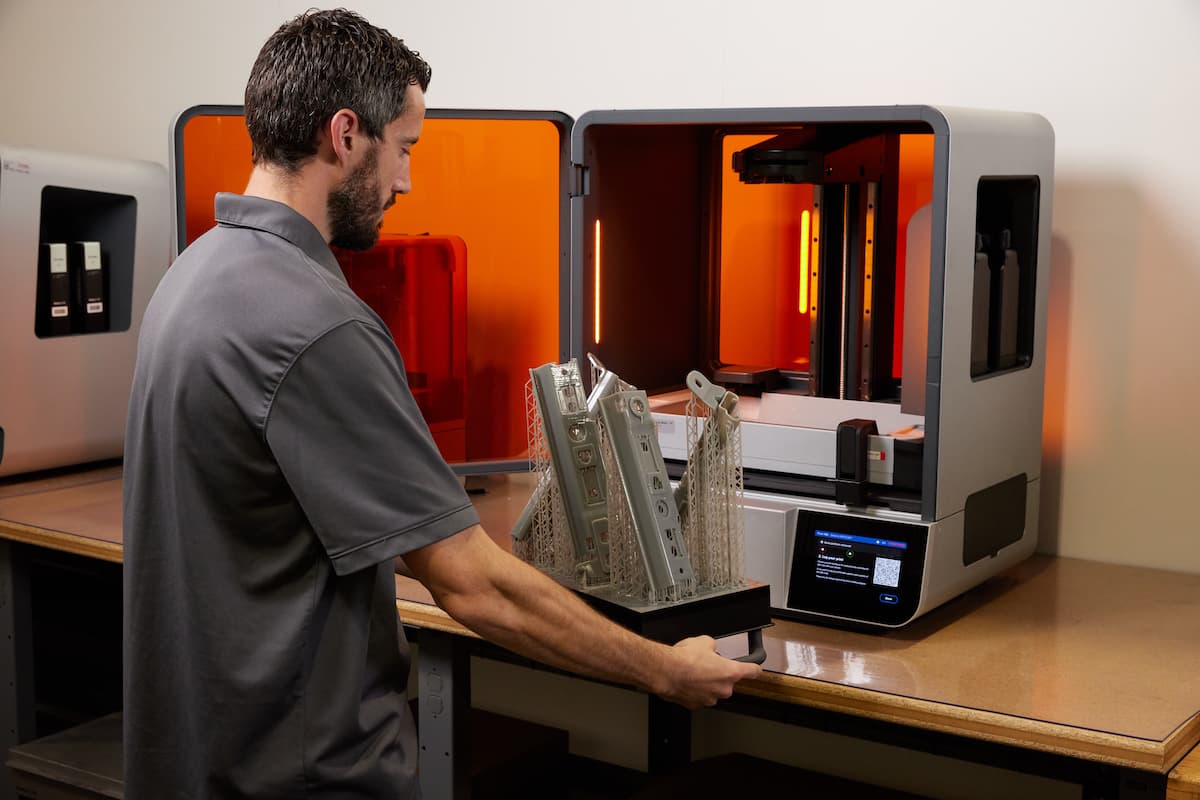

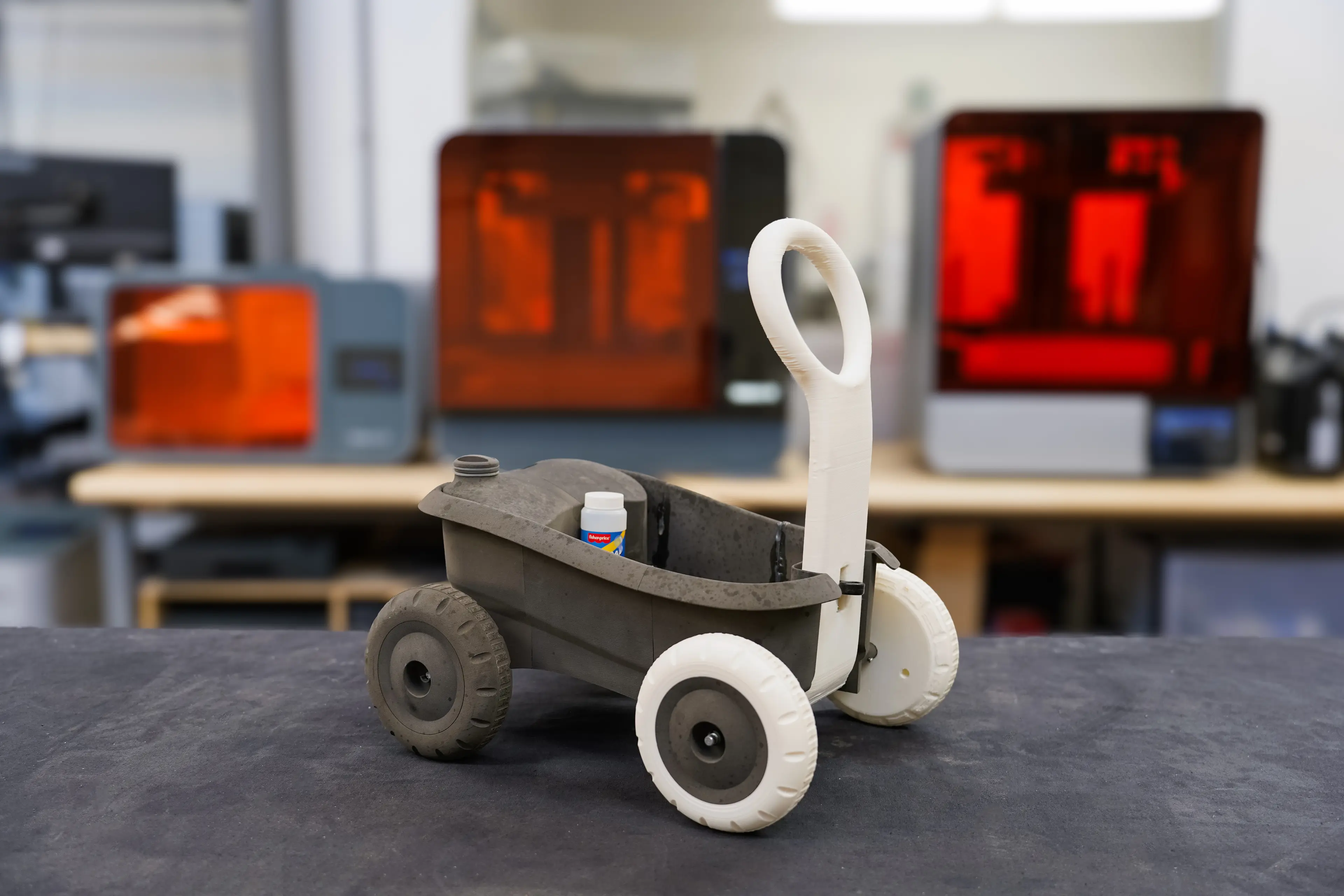

How Form 4L and the Fuse Series Support Innovation at Radio Flyer

Blog

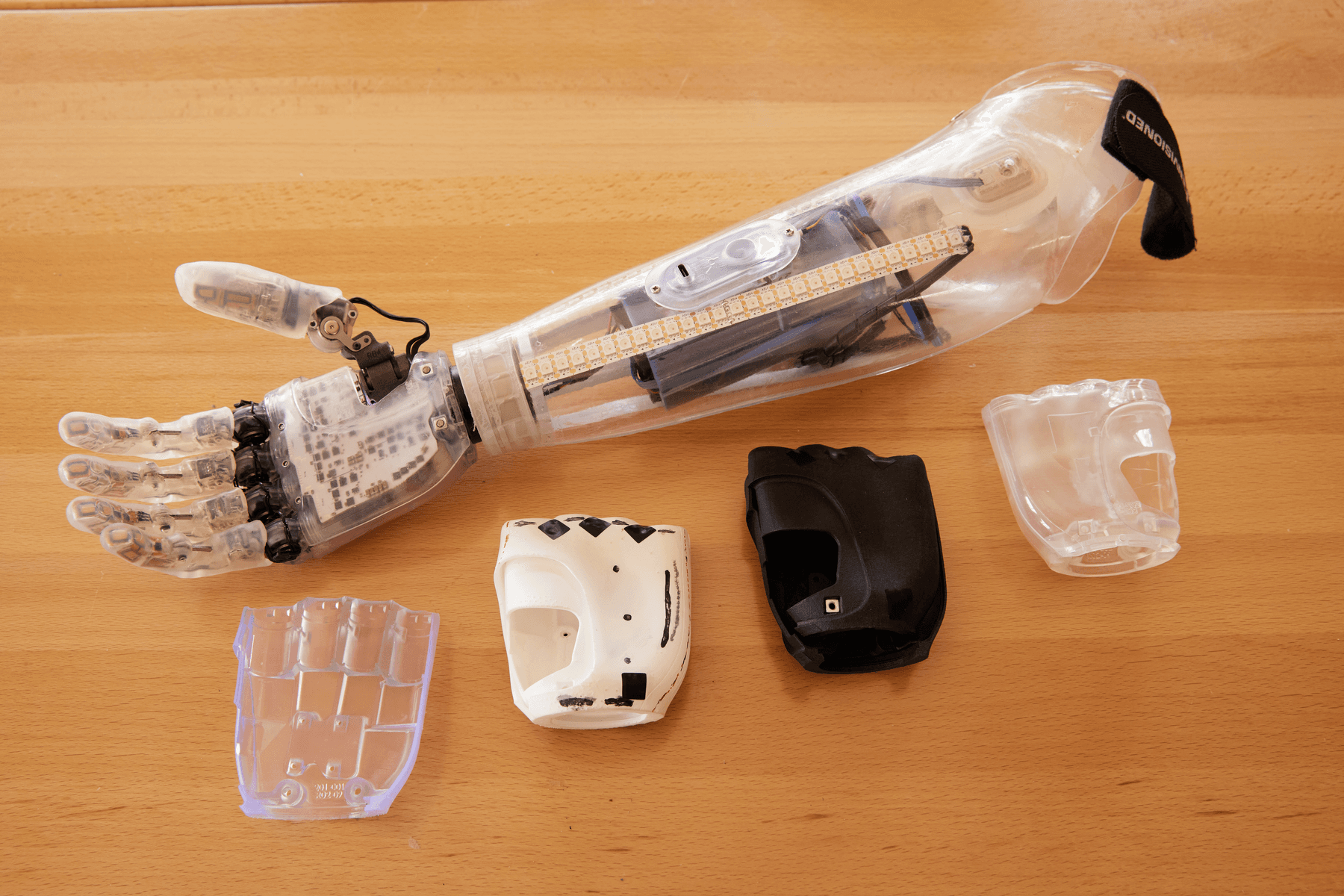

How PSYONIC Uses Agile Manufacturing to Build the World’s Most Accessible Bionic Hands

Blog

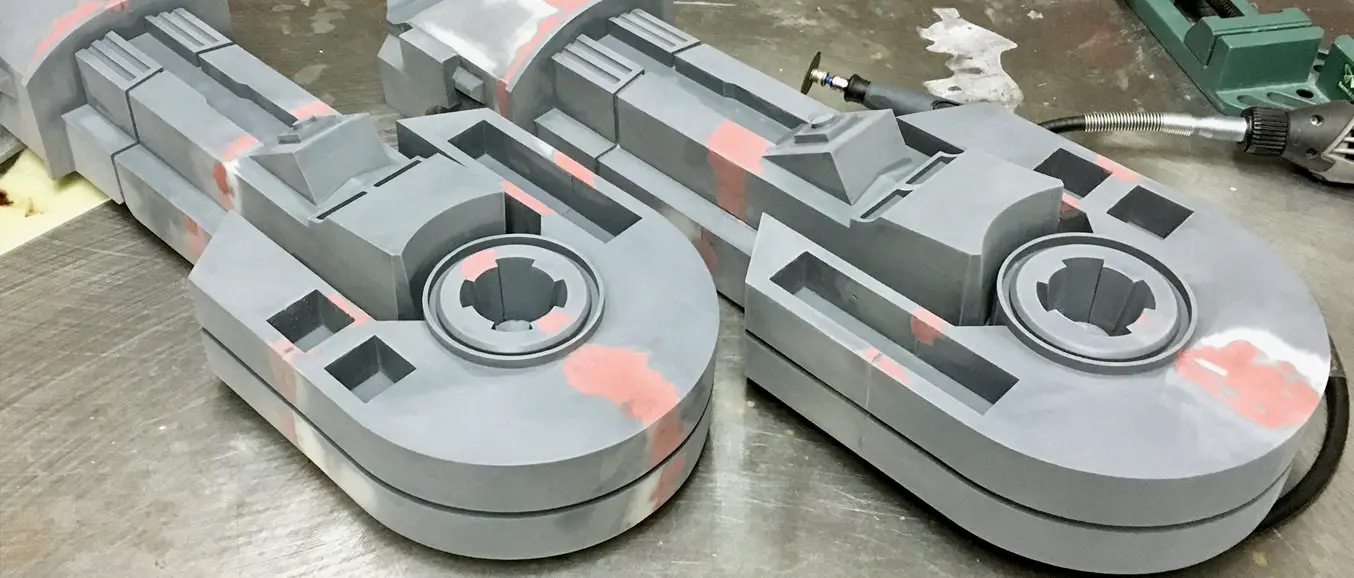

How Brose Leverages SLA and SLS Technology to Bolster Automotive Production

Blog

How Ford Developed the New Explorer Using Formlabs SLA and SLS 3D Printers

Selective Laser Sintering (SLS)

Blog

Printing Presses, Empowered by 3D Printing: Robotics Applications and Replacement Parts at HEIDELBERG

White Paper

Comparing Surface Finish: Fuse Series SLS, EOS SLS, HP MJF, and Form 4 SLA

Blog

Saving Charlotte: How 3D Printing Helps Sea Turtles with Bubble Butt Syndrome

Blog

One-Man Plastics Factory: Getting New Products to Market With the Fuse 1+ 30W

Blog

How Deutsche Bahn Uses 3D Printed Manufacturing Aids to Streamline Vehicle Maintenance

Blog

How Form 4L and the Fuse Series Support Innovation at Radio Flyer

Blog

How Police and Special Vehicles Are Produced With SLS 3D Printing

Blog

How Brose Leverages SLA and SLS Technology to Bolster Automotive Production

Blog

How Ford Developed the New Explorer Using Formlabs SLA and SLS 3D Printers

Blog

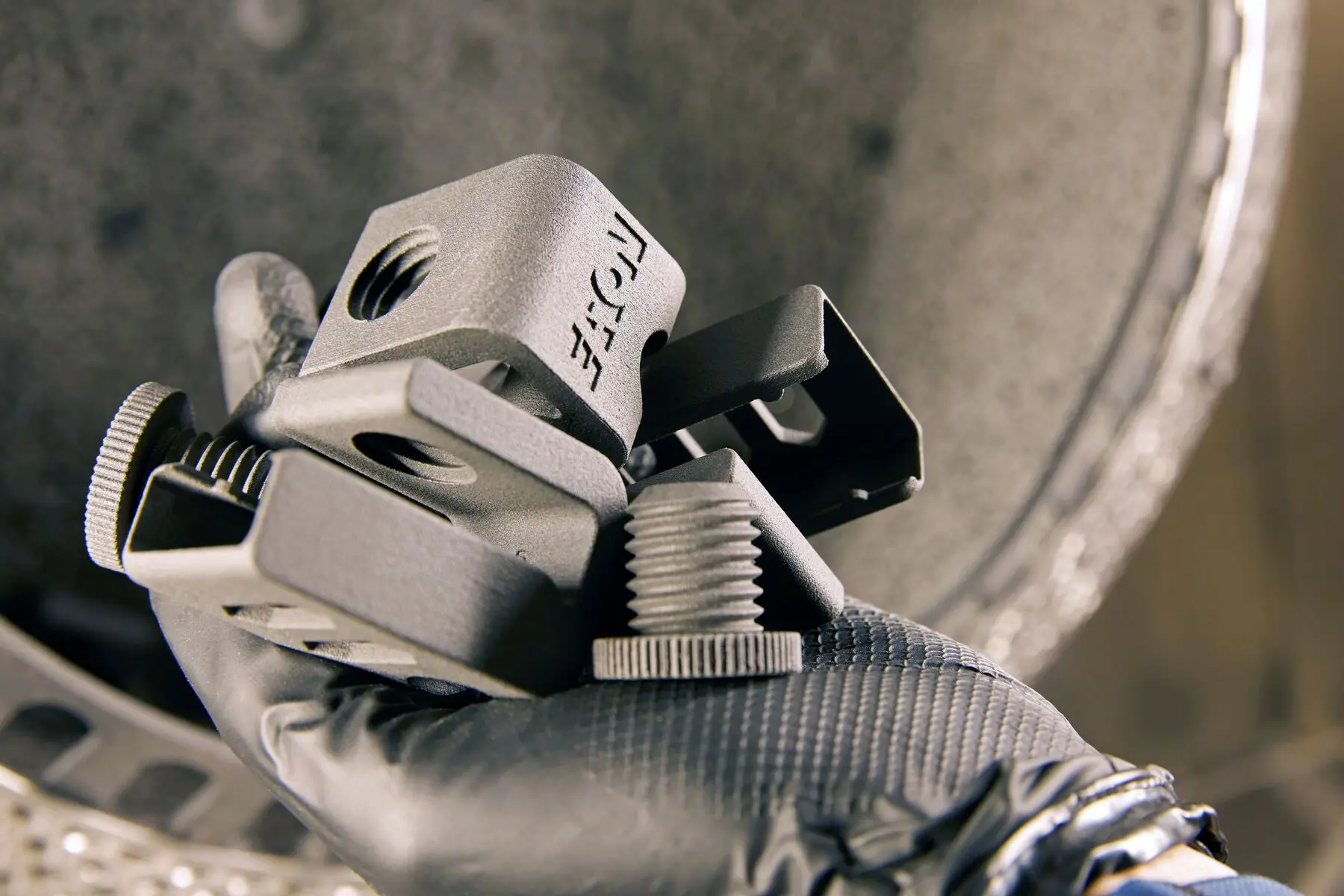

SLS 3D Printing Streamlines Single Piece Flow Manufacturing at Eaton

Design

Blog

How Form 4L and the Fuse Series Support Innovation at Radio Flyer

White Paper

Fuse Series SLS Design Guide

Blog

How to Design and 3D Print Snap-Fit Joints for Enclosures, Boxes, Lids, and More

Blog

How to 3D Print Interlocking Parts and Assemblies

Blog

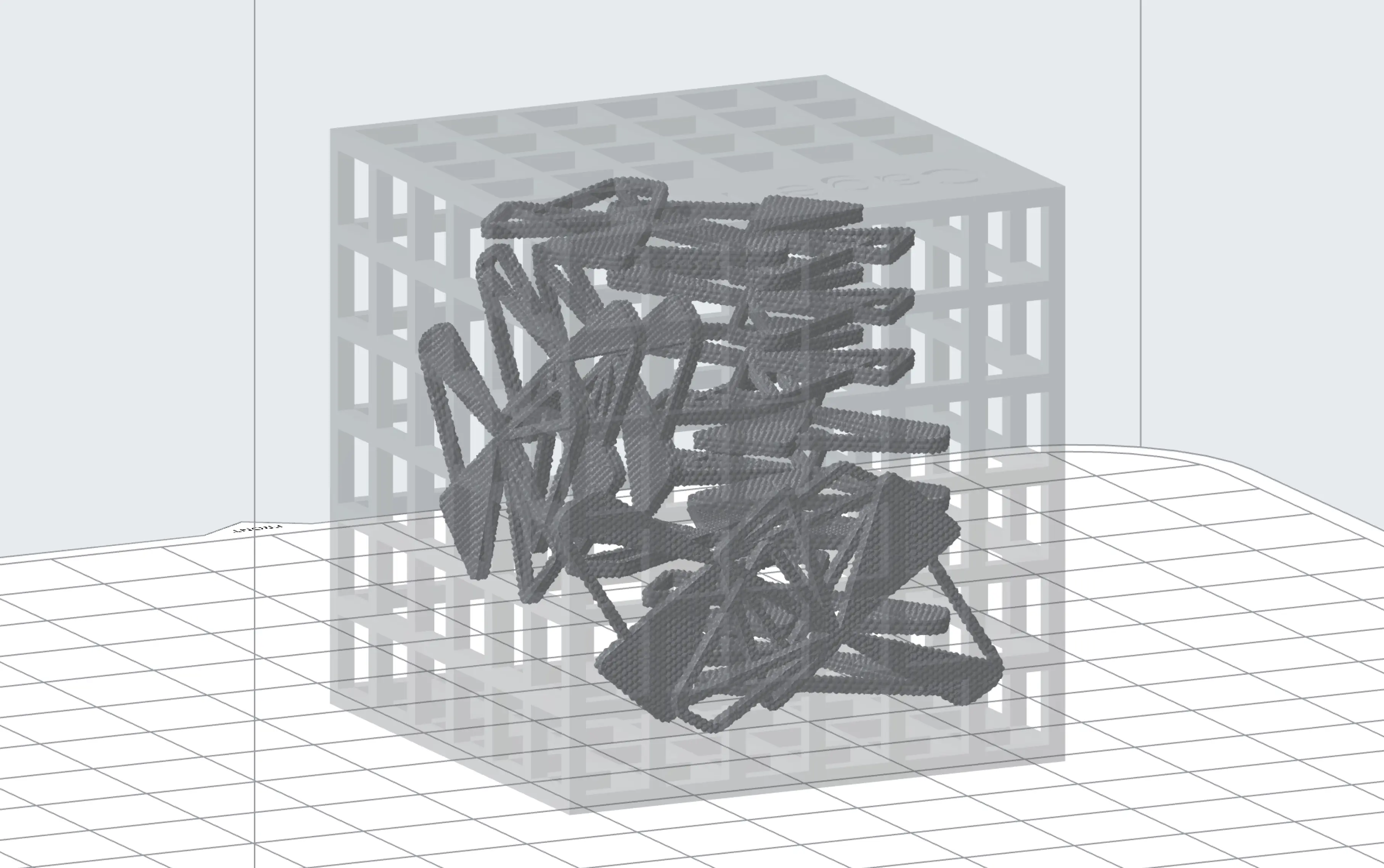

Advanced 3D Printing Techniques

Blog

Customize Parts and Increase Efficiency With New PreForm Features & Shareable Print Settings

Blog

How to Hollow Out 3D Models With Meshmixer & PreForm to Save Material and Time

Blog

How to Create Models Larger than Your 3D Printer’s Build Volume

Blog

How OXO Iterates Twice Before Lunch With Form 4

Blog

Introducing the Formlabs Texture Engine for Texturing 3D Models

Post-Processing

White Paper

Complete Guide to Cerakote: Ceramic Coating for SLA and SLS 3D Printed Parts

White Paper

Enhancing the Surface Quality of SLS 3D Printed Parts With Vapor Smoothing: A Collaborative Study by Formlabs and AMT

Blog

Vibratory Tumbling (Vibratory Finishing) for SLS 3D Printed Parts

Blog

Guide to Dyeing SLS 3D Printed Parts

Blog

Announcing the Non-Flammable, Next-Generation Formlabs Resin Washing Solution

Blog

Guide to Post-Processing and Finishing SLA 3D Prints

Blog

Heat-Resistant 3D Printing Materials Guide: Compare Processes, Materials, and Applications

Blog

Guide to Vapor Smoothing for SLS 3D Printing

Blog

Guide to SLS Post-Processing Techniques: Media Blasting, Smoothing, Coating, Coloring, and More

Blog

Alternate Wash Solutions for SLA Parts

Start Scaling Your Prototyping and Production Today

Explore our 3D printers to find the right solution for your business or contact a Formlabs 3D printing expert for a 1-1 consultation.