Outsourcing vs. In House: When Does it Make Sense to Bring SLS 3D Printing In House?

In this white paper, we evaluate the value proposition of bringing selective laser sintering (SLS) 3D printers in-house, in comparison with outsourcing SLS parts from a service bureau. By providing an overview of the SLS 3D printing market today and conducting six case studies representing three applications, we will demonstrate the positive ROI of bringing the accessible, affordable Fuse Series SLS ecosystem in-house.

Outsourcing vs. In House: When Does it Make Sense to Bring SLS 3D Printing In House?

In this white paper, we evaluate the value proposition of bringing selective laser sintering (SLS) 3D printers in-house, in comparison with outsourcing SLS parts from a service bureau. By providing an overview of the SLS 3D printing market today and conducting six case studies representing three applications, we will demonstrate the positive ROI of bringing the accessible, affordable Fuse Series SLS ecosystem in-house.

Introduction

Selective laser sintering (SLS) refers to an additive manufacturing process in which a laser sinters one thin layer of powder on top of another, building a part vertically inside a build chamber. These 3D printers use plastic powder particles, but they are typically considered to be in the same family as other powder-bed fusion 3D printing systems, like multi-jet fusion (MJF) or metal laser sintering (DMLS or SLM) printers. The manner in which the parts are built offers several advantages.

First, the powder bed surrounds the parts during the print process, eliminating the need for support structures and enabling complex geometries like interlocking links, functional assemblies, and living hinges.

Another advantage is the materials themselves — SLS 3D printers can create strong, durable, temperature-resistant, and long-lasting parts for functional testing of prototypes or for end-use applications. SLS 3D printing materials, such as nylon, are already heavily used in the design, engineering, and manufacturing communities, whether through an injection molding process or additively manufactured.

Besides the advantages of producing parts with complex geometries and advanced material properties, bringing SLS in-house means businesses can control a greater portion of their manufacturing processes. Fuse Series printers are intuitively designed, have an accessible workflow, and a compact footprint, allowing businesses to integrate them into existing systems seamlessly. The Fuse Sift powder unpacking and reclamation unit and the Fuse Blast media blasting and polishing system take the complexity out of the post-processing stage. The Fuse Series’ multi-build chamber workflow allows for continuous production, all with minimal labor.

An in-house SLS production facility with Formlabs Fuse Series SLS printers.

Traditional SLS 3D Printing

Traditional industrial SLS 3D printers have been the only 3D printing option for parts meant to replace or simulate injection molded plastics, but utilizing them in-house has been out of reach for most manufacturers. Historically, the only SLS printers available were complicated to use, required special infrastructure, including HVAC and industrial power, and were prohibitively expensive, with a starting price of around $250,000, and well beyond that for complete solutions. As 3D printing has become more widely used, the demand for SLS parts has grown exponentially, especially in manufacturing and end-use applications where durability and functionality are of paramount importance.

SLS 3D Printing Through Service Bureaus: the Only Way?

Service bureaus and contract manufacturers have begun to answer the demand for high-strength, lightweight, durable parts by offering SLS as an option. Though most businesses couldn’t afford a machine themselves, they could afford to pay a couple hundred dollars for a part, especially when comparing that price to the many thousands of dollars they would spend on making a mold for an injection-molded version. Similarly, most companies weren’t able to accommodate the large-format machines in their facilities, but service bureaus and contractors had ample space and skilled labor necessary to operate these machines.

Part providers, however, are dealing with hundreds, if not thousands, of part requests every week. Depending on the order size and volume, the lead time to get a print back might take weeks, and if there is a consultation required, the process can extend far beyond that. For the requestors, who aren’t familiar with SLS design guidelines, they might require changes to the design, and that back-and-forth between designer and an external contractor via phone, email, or video, can further extend the timeline. The same design iterations can be done quickly in-house when the designer and technician both have access to and knowledge of the printing optimization.

At the end of the day, costs and lead times add up, chipping away at the benefits of why businesses would choose SLS 3D printing in the first place. The math stops making sense, and so manufacturers use SLS for fewer applications, missing out on its full potential.

Applications of SLS 3D Printing

The high demand for SLS parts from service bureaus is in part due to the growing range of applications for which SLS is the ideal technology. Bringing the capacity to meet that demand in-house allows manufacturers to differentiate themselves from their competitors, by being able to iterate more extensively, become more resilient in the face of supply chain disruptions, or respond with more agility to the need for replacement parts and repairs.

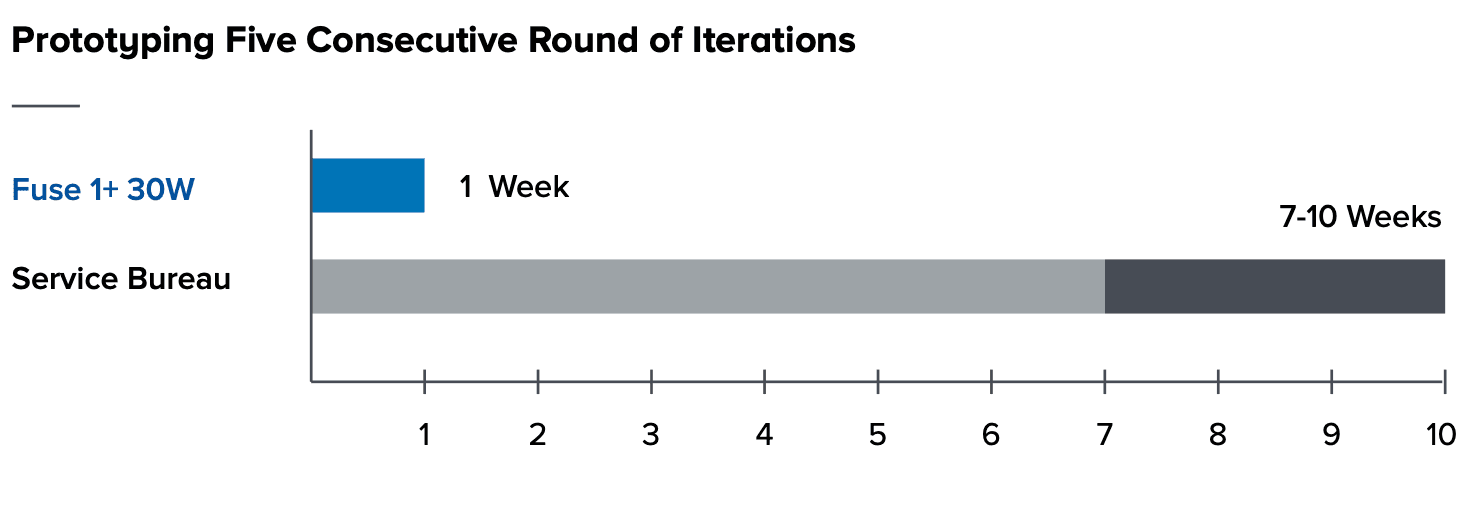

Rapid Prototyping

The most common use of 3D printing technologies is in the prototyping phase. Rapid prototyping, however, becomes much less rapid when the end user, designer, engineer, and technician are all in separate locations. Even if four different iterations are sent to a service bureau at the same time, it could still take a week or more to receive those parts back and begin testing them or getting internal feedback. That week of downtime is eliminated by bringing SLS in-house. Having a Fuse Series SLS printer centralizes the process — truly rapid prototyping is done best by in-house teams that are able to collaborate on design, testing, and implementation.

The flexibility and strength of Nylon 12 Powder make it ideal for functional testing of complex assemblies like multi-component snowboard bindings.

End-Use Parts

Though traditional methods of production are still most efficient in many cases, there are a few situations in which it makes sense to produce end-use parts with SLS 3D printers. In those situations, manufacturers gain a competitive advantage by producing in-house as opposed to going through a contractor or service bureau.

In aftermarket production, manufacturers have to respond to changes enacted by the OEM, a business model that requires agility and responsiveness in the design, testing, and production phases. For Terra X, a manufacturer of automotive accessories, outsourcing SLS 3D printed parts was a great way to get started with product testing as they built a customer base. Then, as demand grew, they brought production in-house with the Fuse Series to improve margins, reduce lead time, and shorten their development cycles.

These end-use automotive accessories are navigation mounts designed and produced by Terra X, who use three Fuse Series SLS 3D printers to manufacture all of their products.

In-house SLS part production became globally relevant as supply chain issues effectively halted traditional methods of manufacturing beginning in 2021. With customers facing months of product delays, the manufacturers that were able to find a stop-gap solution gained a competitive advantage. Since then, trade wars, tariffs, supply restrictions, and other events have continued to disrupt the global supply chain, making domestic production more attractive for small and medium-sized manufacturers.

Those that had SLS capabilities in-house have been able to dynamically respond to shortages and pivot to focus their 3D printing capacity on parts that otherwise would be traditionally tooled. Because of the simple workflow and high material efficiency of the Fuse Series printers, manufacturers could keep production costs low and deliver products to customers at a time when competitors were at a loss, waiting for parts to arrive.

In-house production capabilities help businesses to insulate their supply chain and avoid long lead times from contractors. Brose, an automotive supplier, prints hundreds of thousands of these seat clips for end-use in the BMW X7 model.

SLS 3D printing is a viable solution for production volumes, in terms of cost per part as well as lead time. For production scenarios like stopgap manufacturing, aftermarket customization, supply chain management, and in emerging markets, SLS 3D printing is more on-demand, and with the added benefit of having these printers in-house, manufacturers can be responsive, agile, and efficient.

For start-up companies that don’t have the funds to pivot back and forth between injection molding and 3D printing, utilizing the same methods of production as they already use for prototyping in-house is a great way to introduce a product and establish a revenue stream. By 3D printing their product in-house, the start-up can enter the market, gain customer feedback, collect revenue, and invest it back into their R&D or manufacturing, perhaps later switching to injection molding when the demand is readily apparent.

The Tension Square, a medical device prototyped and produced en masse on the Fuse 1 in Nylon 11 Powder.

Manufacturing Aids, Rapid Tooling, and Replacement Parts

Bringing SLS capacity in-house is never more relevant than when printing replacement parts for other machines. More and more businesses are creating a digital repository of possible 3D printed replacement parts for pieces of manufacturing equipment. If a machine needs a spare part, being able to 3D print it on demand saves days of lead time waiting for a part to arrive from the OEM or a service bureau. Every hour of down time for a machine can mean a loss in profit, and if that loss can be minimized by a quick SLS print from an in-house team, the business can mitigate losses.

For Formlabs customer Eaton, the Fuse Series has been a problem solver at their Olean manufacturing plant, which produces electrical utility equipment at high volumes. Using the Fuse 1+ 30W and Nylon 12 Powder, the Eaton Olean site has been able to replace almost all of the production consumables on their automated assembly lines. Their SLS 3D printed grippers, EOAT, spacers, fixtures, jigs, and housings have improved production outcomes, reduced costs, and made their maintenance, repair, and overhaul (MRO) operations more efficient.

This Eaton centering block was printed in two pieces with an optimized design on the Fuse 1+ 30W (left), which replaces the machined aluminum and machined delrin assembly on the right.

Manufacturing aids and tooling have typically been produced at a high cost through subtractive processes, often out of metal or plastic blocks of Delrin. It’s no surprise that 3D printing is providing a faster, more efficient alternative, but is there a need for in-house production of these tools? The advantage to fabricating your own tooling as compared to ordering from a service bureau lies in your ability to make changes and customize.

Tooling is often bulky, like the shaping presses, left, used by Swiss eyewear manufacturer Marcus Marienfeld. Marienfeld uses the Fuse 1 to create presses for bending titanium eyewear frames into a distinct shape. To order this press from a service provider, at higher cost and lead time would limit the number of different presses, and thus eyewear shapes, possible. Marienfeld has the ability to create multiple tools in one build chamber, and then press hundreds of different frames in a day, delivering the final titanium product in half the time it would have taken to rely on a service bureau.

Book a Consultation

Get in touch with our 3D printing experts for a 1:1 consultation to find the right solution for your business, receive ROI analyses, test prints, and more.

The Fuse Series Brings SLS Within Reach

With an affordable price point, and a small footprint that enables everyone from small studio designers to large corporate manufacturers to install a printer, the Fuse 1+ 30W enables industrial quality SLS 3D printing in-house, lowering per part costs for every application and speeding up production.

The Fuse 1+ 30W and Fuse Sift put SLS within reach for small and medium manufacturers to get started, and large manufacturers to scale production.

Ease of Adoption

Since the introduction of the Fuse 1 in 2020, Formlabs has sold more SLS 3D printers than any other 3D printer manufacturer. Businesses are able to get started so easily because the price is affordable, the compact size and low weight mean that the printer is easily installed, and the user experience is streamlined with the end-to-end ecosystem of printer, Fuse Sift, and Fuse Blast with Fuse Blast Polishign module. With industrial-standard materials like Nylon 12 Tough Powder, a true TPU powder, a white nylon powder that is easily dyed, and nylon composites for specialized applications, the Fuse Series is an easy way to bring manufacturing in-house.

Businesses can allocate funds for a Fuse 1+ 30W system as well as materials, service, and training, at a fraction of the price of traditional industrial SLS systems. There is no need to hire and pay a dedicated technician — anyone who has used 3D printers in the past will easily be able to get started with the Fuse 1+ 30W’s simple user interface and workflow. The price of the Fuse 1+ 30W opens the doors for small manufacturers that couldn’t previously afford in-house industrial equipment. They can scale up production, increase their prototyping iteration rate, and improve their product lines without paying service bureaus for each part.

Low Cost and High Throughput

With a starting price below $55,000 for the entire ecosystem (and under $27,000 for just the printer), the entry price point of the Fuse 1+ 30W is 5-10x lower than that of traditional industrial SLS systems. This means that cost analyses need to factor in a smaller fixed cost, enabling manufacturers with lower budgets to bring SLS in-house. They can then reach positive ROI faster and for a wider range of applications. Thanks to the lower cost, per-part costs are dramatically reduced, making lower-volume production more viable.

Curious to see how much you can save? Try our interactive ROI tool to calculate your time and cost savings when 3D printing on a Fuse 1+ 30W

The automated Fuse Blast reduces hands-on labor time by up to 80% and includes an optional Fuse Blast Polish module for parts that look and feel like injection molded plastics.

The modular workflow allows multiple build chambers to be run and post-processed continuously, facilitating a higher volume of parts without any downtime. One of the biggest contributors to lower per part costs is the powder refresh rate and improved packing density algorithm, which together create an optimal ratio of sintered powder to unsintered powder, improving the efficiency of powder usage and utilizing all the material in a more circular system. Thanks to the 30% refresh rate for the most commonly used materials, many Fuse 1+ 30W users are able to print with zero powder waste through optimized powder refresh rate and packing density. These users are able to use all of their non-sintered powder in their next print, eliminating powder waste and increasing the utility of each powder purchase. Additionally, bulk powder pricing tiers (as low as $45/kg) make higher-volume applications even more cost-efficient.

Get Started with 3D Printing

Formlabs' complete, easy-to-use ecosystem makes it simple to get started with 3D printing. Explore our 3D printers and materials to find the right fit for your needs.

Testing the Theory: Fuse 1+ 30W In-House vs. Outsourcing SLS Parts

To test the theory that in-house SLS is both faster and less expensive than ordering parts from a service bureau, we’ll cover six case studies. Six different builds, representing three applications — prototyping, end-use part production, and manufacturing aids — will be printed on Fuse 1+ 30W printers in-house and sent out to the four leading US service bureaus. Both per part costs (including labor, materials, and shipping) and lead time will be measured and compared.

The “Total Time” of Fuse 1+ 30W in-house builds will be calculated by adding the print time, cooling time, and labor time for post-processing the parts in the Fuse Sift and Fuse Blast. The “Total Time” for Service Bureau SLS parts will be calculated by taking an average of the delivery time from the service bureaus, from uploading the file and placing an order, to receiving the parts at our location.

The “Total Cost” of Fuse 1+ 30W in-house builds will be calculated by adding the materials cost and labor cost, assuming a powder price of $99/kg for prototyping, $75/kg for manufacturing aids, and $55/kg for production, and a $17 hourly rate for the in-house printing staff. The “Total Cost” for service bureau SLS parts will be calculated by taking an average of the quoted costs for each build and standard shipping from the four service bureaus.

Application 1: Prototyping

Practice makes perfect, and in product development, practice is rapid prototyping. The ability to design, make small changes, print, and test a physical model leads to true innovation and measured improvement. 3D printing has opened the doors to rapid prototyping across every industry, and SLS 3D printing even more so, with works-like prototypes made out of functional, strong materials. However, companies are still deciding between rapid prototyping in-house or through outsourcing to a service bureau. We’ll take two prototypes, one for the automotive industry, and one for a consumer product (construction hardware), and see whether the cost and speed of prototyping are comparable with SLS in-house and outsourced.

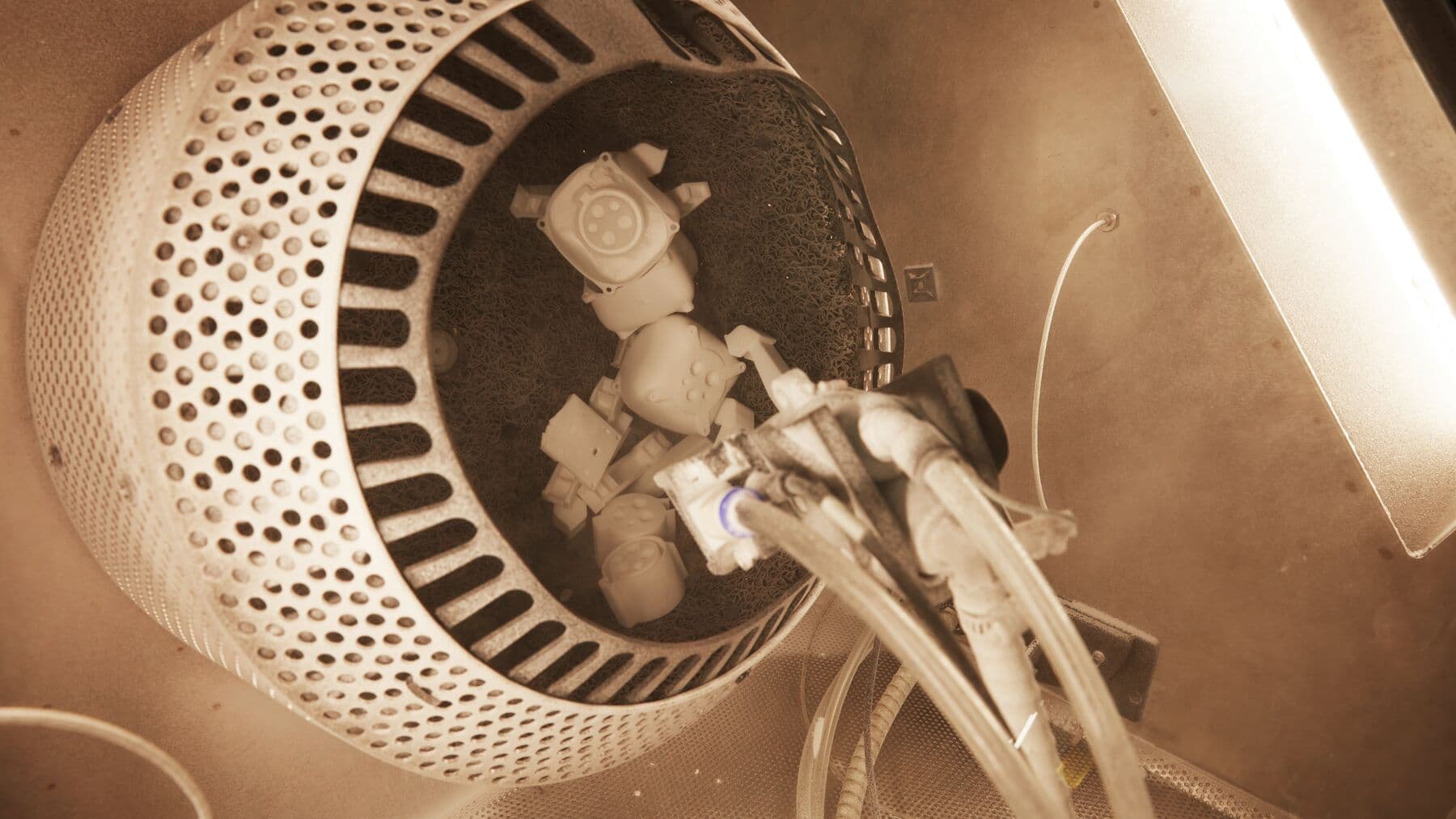

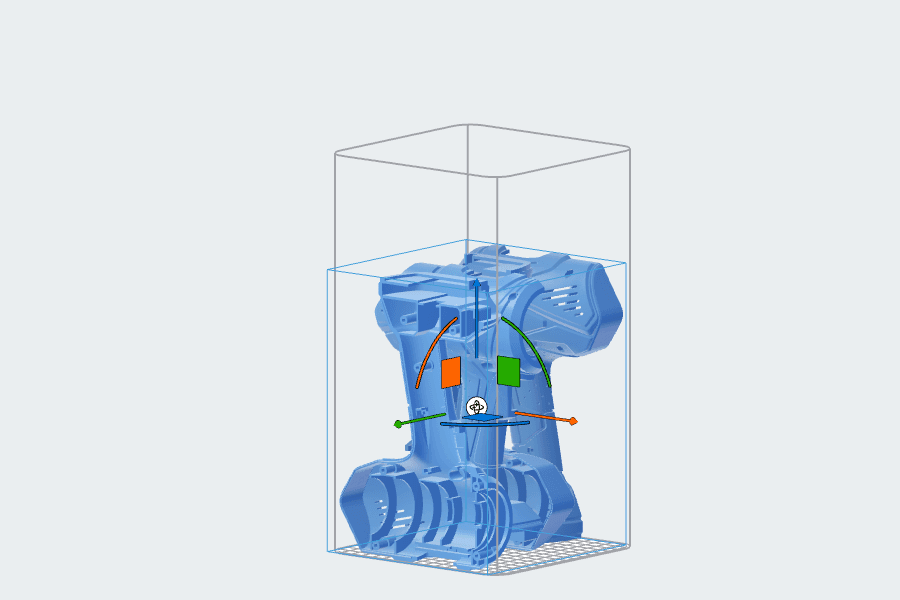

Each build has been optimized to fit as many models as possible — this exemplifies the iterative process. A design team may think of several different changes to make to a part, and want to try each out for functional testing and visual experience. Packing a build chamber as efficiently as possible gives them the ability to test multiple prototypes, use their powder more efficiently and cost effectively, without extending their wait time by too much.

Prototype 1: Automotive Manifold

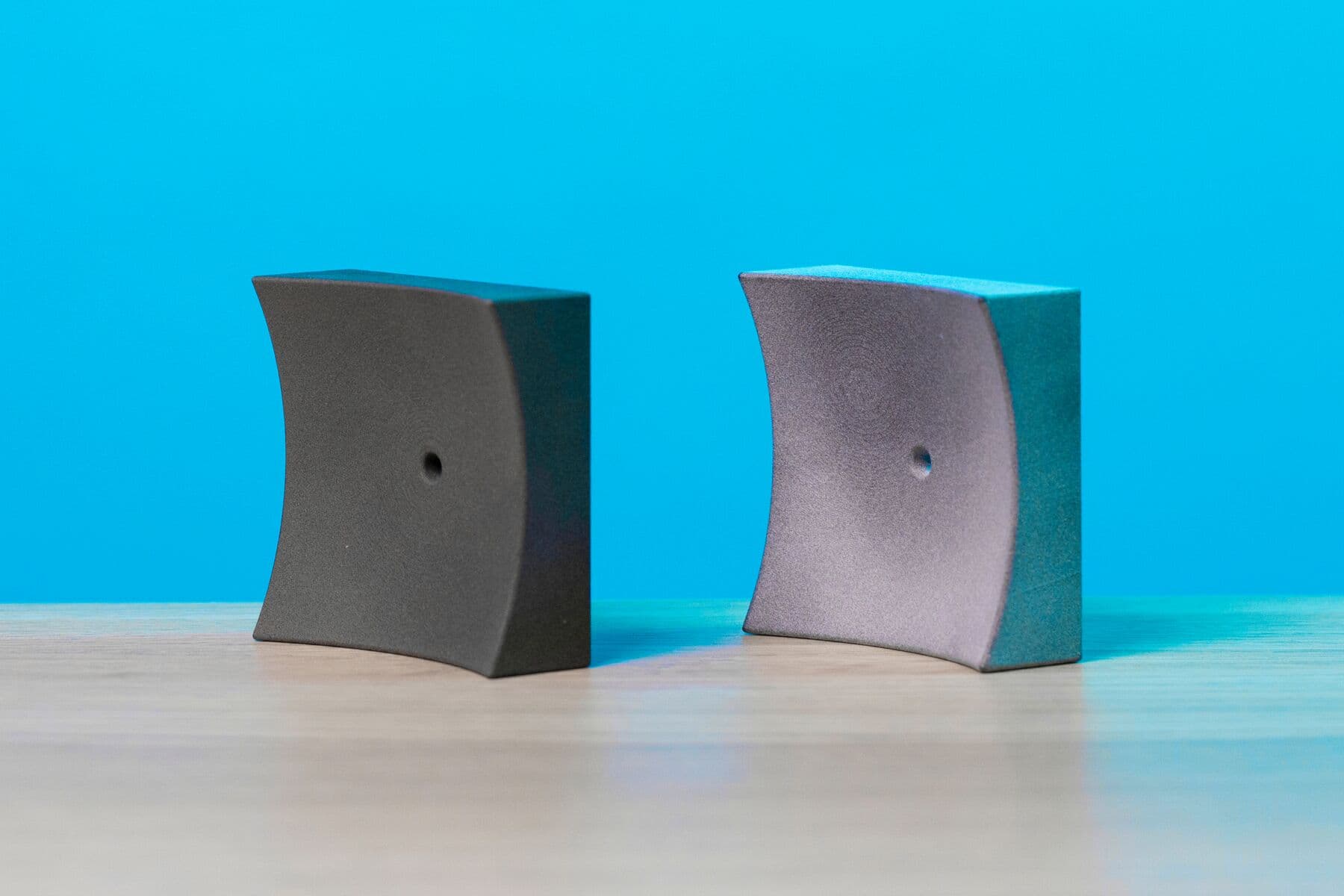

An SLS manifold 3D printed in-house on a Fuse Series printer (left) and an outsourced manifold printed on an HP MJF printer by a service bureau (right).

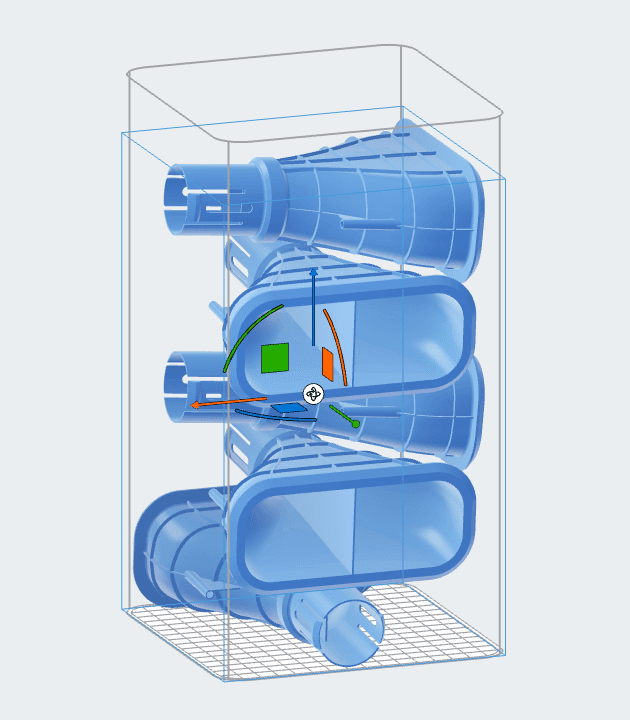

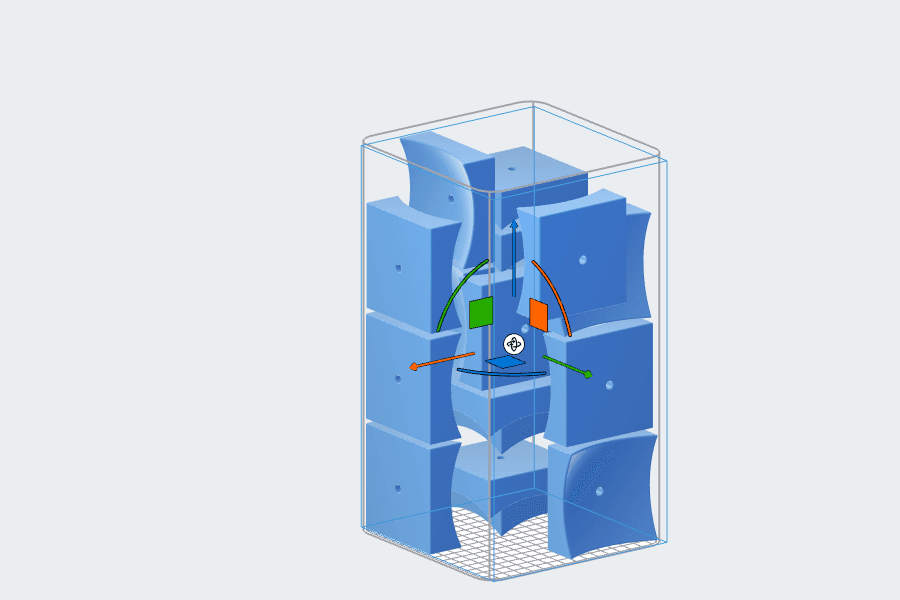

These five manifolds are stacked in PreForm and packed for optimal density and material use efficiency. The more densely parts are packed, the lower the cost per part.

| Fuse 1+ 30W In-House | Service Bureau SLS | |

| Print Time | 10 h 28 m | |

| Additional Cooling (in Fuse Sift) | 13 h 30 m | |

| Sift/Part Extraction (hands-on) | 10 m | |

| Blast Time (automated) | 15 m | |

| Total Time to Part | 24 h 23 m | 7 business days |

| Materials Cost* | $98.48 | |

| Labor Time (hands-on) | 43 m | |

| Labor Cost | $12.18 | |

| Total Cost: | $110.66 | $163.32 |

| Cost Per Part | $27.67 | $40.83 |

* Rapid prototoyping is not necessarily done in high volume, so here we used the standard powder cost of $99/kg to calculate cost per part. For those printing every day, bulk powder pricing is an easy way to drastically reduce cost per part.

** Fuse users can unpack build chambers in the Fuse Sift when the internal temperature reaches 50 °C, which is typically hours before the full ‘Additional Cooling Time’ time is fulfilled. For this example, when the user comes into work the next morning, the build chamber would be ready to be unpacked, having reached below 50 °C overnight.

In the space of one typical work week, a product designer could work through 25 different iterations of this manifold when printing in-house, rather than wait seven days to receive their first round of iterations from a service bureau. Though in typical prototyping scenarios lead time is more of a concern than cost per part, even with powder costs being set to their highest possible amount ($99/kg) and no bulk powder pricing discount, it is still less expensive to SLS 3D print in-house than outsource here.

Prototype 2: Power Drill Casing

An SLS drill prototype 3D printed in-house on a Fuse Series printer (left) and an outsourced drill prototype printed on an HP MJF printer by a service bureau (right).

PreForm's autopacking feature enables fast print preparation for your most efficient print set-up and the lowest possible powder cost.

| Fuse 1+ 30W In-House | Service Bureau SLS | |

| Print Time | 12 h 4 m | |

| Additional Cooling (in Fuse Sift) | 13 h 55 m | |

| Sift/Part Extraction (hands-on) | 10 m | |

| Blast Time (automated) | 15 m | |

| Total Time to Part | 26 h 14 m | 7 business days |

| Materials Cost* | $118.51 | |

| Labor Time (hands-on) | 43 m | |

| Labor Cost | $12.18 | |

| Total Cost: | $130.69 | $234.34 |

| Cost Per Part | $26.14 | $58.59 |

* As above, in-house SLS material cost set at its highest possible point, $99/kg to reflect low volume prototyping.

** As above, time to ‘appropriate cooldown,’ i.e. the 50 °C threshold, is typically hours before this estimate, meaning parts could be post-processed sooner and overall ‘time-to-part’ is even shorter than shown.

As with the first example, the total time required to produce these prototypes would allow in-house SLS users to run five full production runs each week, printing ten iterations of the two-part drill casing assembly. Compared to two iterations every seven business days when outsourcing, an in-house SLS printer opens up opportunities for true iteration. Each new model could have a different aesthetic, alternatives for the grip’s design, or screw threads placed in different spots, and then be presented physically to an approval team the very next day.

As with any prototyping application, iterative speed matters most. In this scenario, waiting seven business days for two prototypes when outsourcing could pose a significant challenge to the product development process. Meanwhile, with in-house SLS 3D printing, product designers could print four parts — two full drill enclosures, every day.

Application 2: End-Use Part Production

Once a design has been finalized and the consumer demand projected, production runs begin. For production runs, the typical question is not whether to SLS 3D print in-house vs. service bureau, but comparing 3D printing with other traditional manufacturing methods, such as injection molding.

As we explored in our white paper comparing SLS 3D printing to injection molding, there are several possible scenarios in which 3D printing makes sense for end-use production, including aftermarket parts, customization, supply chain stopgaps, and more. Cost per part and throughput are two of the most important factors when calculating ROI for different manufacturing methods. The Fuse 1+ 30W offers fast print speeds, interchangeable build chambers, a streamlined post-processing unit, and improved packing density that vastly improve the economics for end use production.

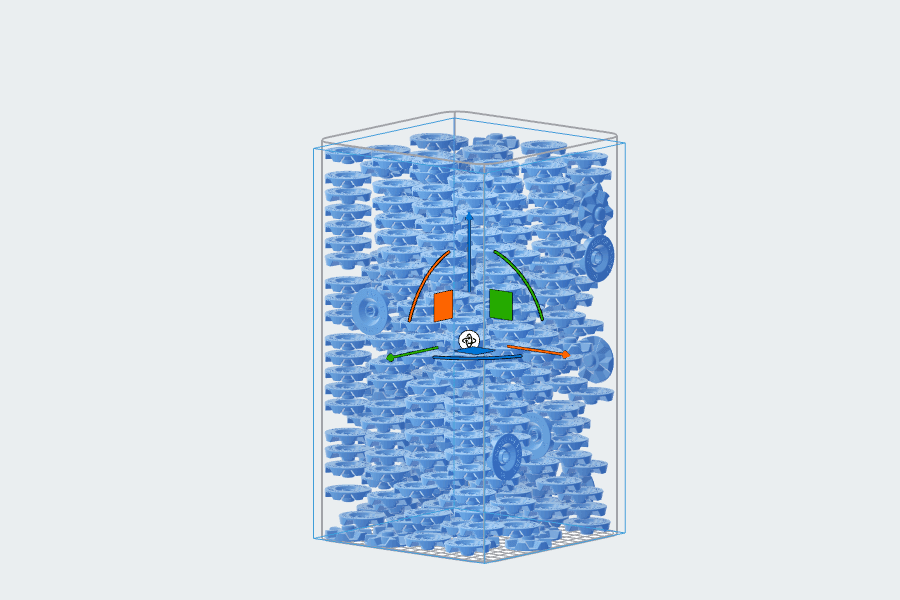

Now, we’ll look at how much extra cost is added by a service bureau, and how that shipping time affects overall production timelines by comparing in-house Fuse 1+ 30W production runs with outsourcing SLS 3D printing to service providers. These production scenarios are designed to maximize throughput by utilizing the PreForm packing density algorithm to optimize powder usage and refresh rate, as well as deliver the most end-use parts to the user.

End-Use Production Run 1: Bike Pedal

This close-up of a the bike pedal shows the detail and accuracy possible with the Fuse Series printers. The Fuse 1+ 30W produces end-use quality parts at an affordable price and with an accessible workflow.

Using automated packing in PreForm, Fuse Series users can find the optimal packing set-up for their production volume builds in order to reduce cost per part while increasing overall output.

| Fuse 1+ 30W In-House | Service Bureau SLS | |

| Print Time | 18 h 4 m | |

| Additional Cooling (in Fuse Sift) | 13 h 46 m | |

| Sift/Part Extraction (hands-on) | 15 m | |

| Blast Time (automated) | 15 m | |

| Total Time to Part | 32 h 20 m | 8 business days |

| Materials Cost* | $118.81 | |

| Labor Time (hands-on) | 43 m* | |

| Labor Cost | $12.18 | |

| Total Cost: | $130.99 | $278.38 |

| Cost Per Part | $4.23 | $8.98 |

*Material cost for in-house 3D printing has been calculated using bulk powder discounting tiers, with the smallest possible discount, 20% off when purchasing 50 kg of powder at a time.

**Labor time is taking into account only five minutes for print preparation (because production builds are often pre-determined/repeated from previous days), but more time for part extraction in the Fuse Sift because there are so many parts.

The bike pedal production case study shows that 31 pedals can be produced in a 33 hour period, or less when you take into account minimum necessary cooling times and a multi-build chamber workflow.

Starting a new build when the technician arrives each morning and post-processing it the next day allows for five rounds (155 parts) during a typical five-day work week, and at minimum 690 parts a month. At $4.23 per part, compared to more than double when outsourcing, SLS 3D printing in-house makes the case for stop-gap manufacturing, early stage design testing, and low-volume production. For small manufacturers looking to make limited edition runs or offer customization options, SLS printed Nylon 12 Powder can deliver on both material strength, durability, and cost.

End-Use Production Run 2: Form Cure Turntable Gear

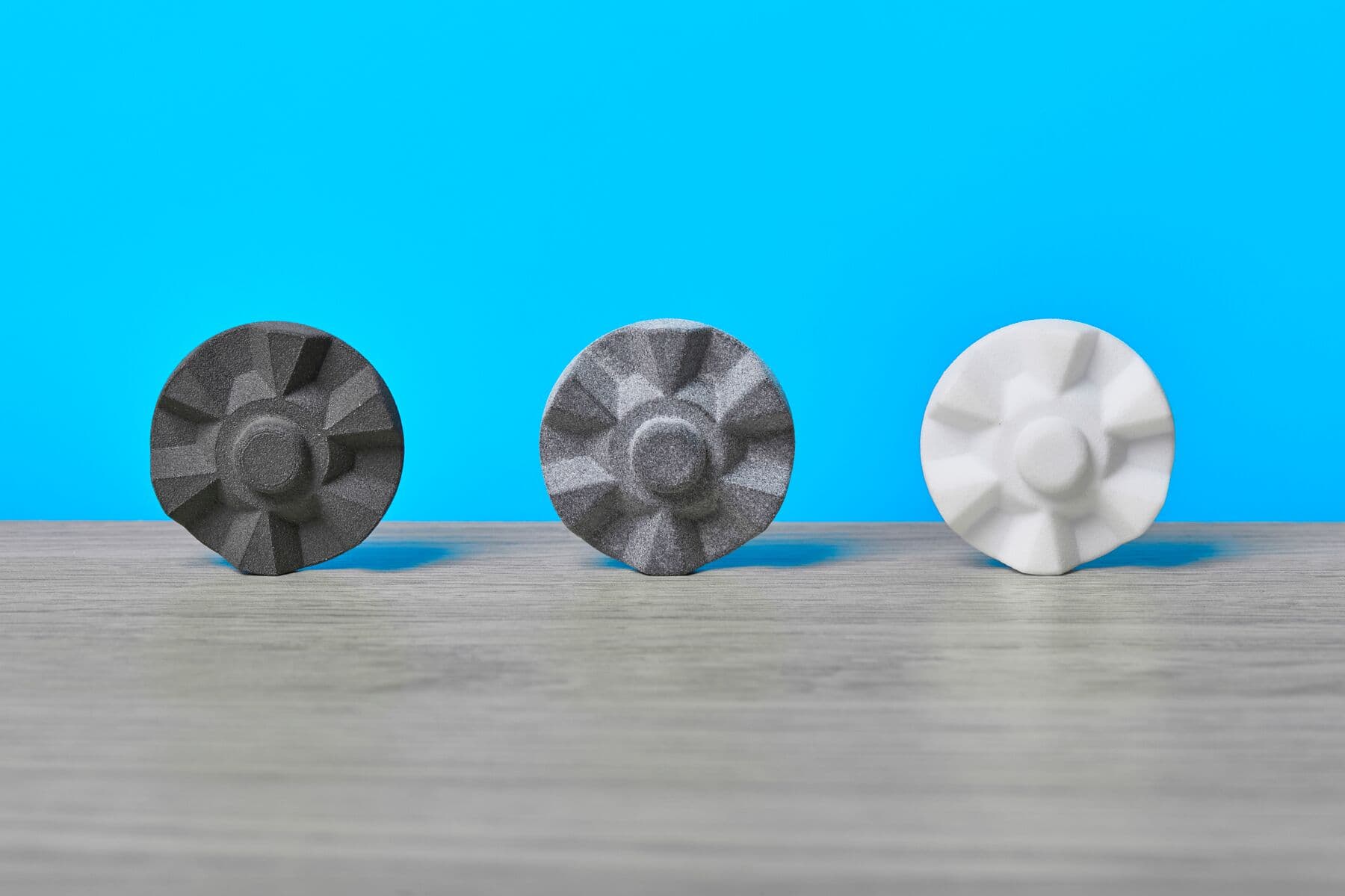

The in-house SLS 3D printed turntable gear (left) was printed for only $0.33 each, while an outsourced gear (HP MJF, center or EOS, right) costs $1.09

For small parts that need to be produced rapidly, SLS 3D printing presents an efficient and cost-conscious option. In this one build chamber, you can stack 374 gears, with a turnaround time of one day.

| Fuse 1+ 30W In-House | Service Bureau SLS | |

| Print Time | 18 h 53 m | |

| Additional Cooling (in Fuse Sift) | 13 h 50 m | |

| Sift/Part Extraction (hands-on) | 15 m | |

| Blast Time (automated) | 15 m | |

| Total Time to Part | 33 h 13 m | 7 business days |

| Materials Cost* | $111.14 | |

| Labor Time (hands-on) | 43 m* | |

| Labor Cost | $12.18 | |

| Total Cost: | $123.32 | $407.66 |

| Cost Per Part | $0.33 | $1.09 |

** Material cost for in-house 3D printing has been calculated using bulk powder discounting tiers, with the smallest possible discount, 20% off when purchasing 50 kg of powder at a time.

*Labor time is taking into account only five minutes for print preparation (because production builds are often pre-determined/repeated from previous days), but more time for part extraction in the Fuse Sift because there are so many small parts.

As shown in our white paper, the breakeven point for injection molding this turntable gear was at quantities close to 8,000 units when compared to SLS 3D printing on the Fuse 1. In a single build on the Fuse 1+ 30W, 320 parts can be printed for about $206. Utilizing multiple build chambers, a technician can start a print each day of the week and post-process builds the next day after the cooling period.

With this workflow, four full production builds can be completed each week for a total of 1,870 parts produced weekly. An in-house Fuse 1+ 30W could produce more than 8,000 parts each month, creating a reasonable alternative for production, when it often takes that time to create a new injection mold for traditional manufacturing. Due to the higher per part costs, outsourcing offers substantially worse economics.

Application 3: Manufacturing Aids, Rapid Tooling, Replacement Parts

Manufacturing aids and tooling can take a variety of forms — customized grippers that help automated machines pick and place products more efficiently, tooling that helps shape a final product into the proper geometry, or jigs and fixtures that support assembly or quality assurance process (QA). Any production run requires a range of these tools and can often benefit from the strength and durability that SLS 3D printed parts offer.

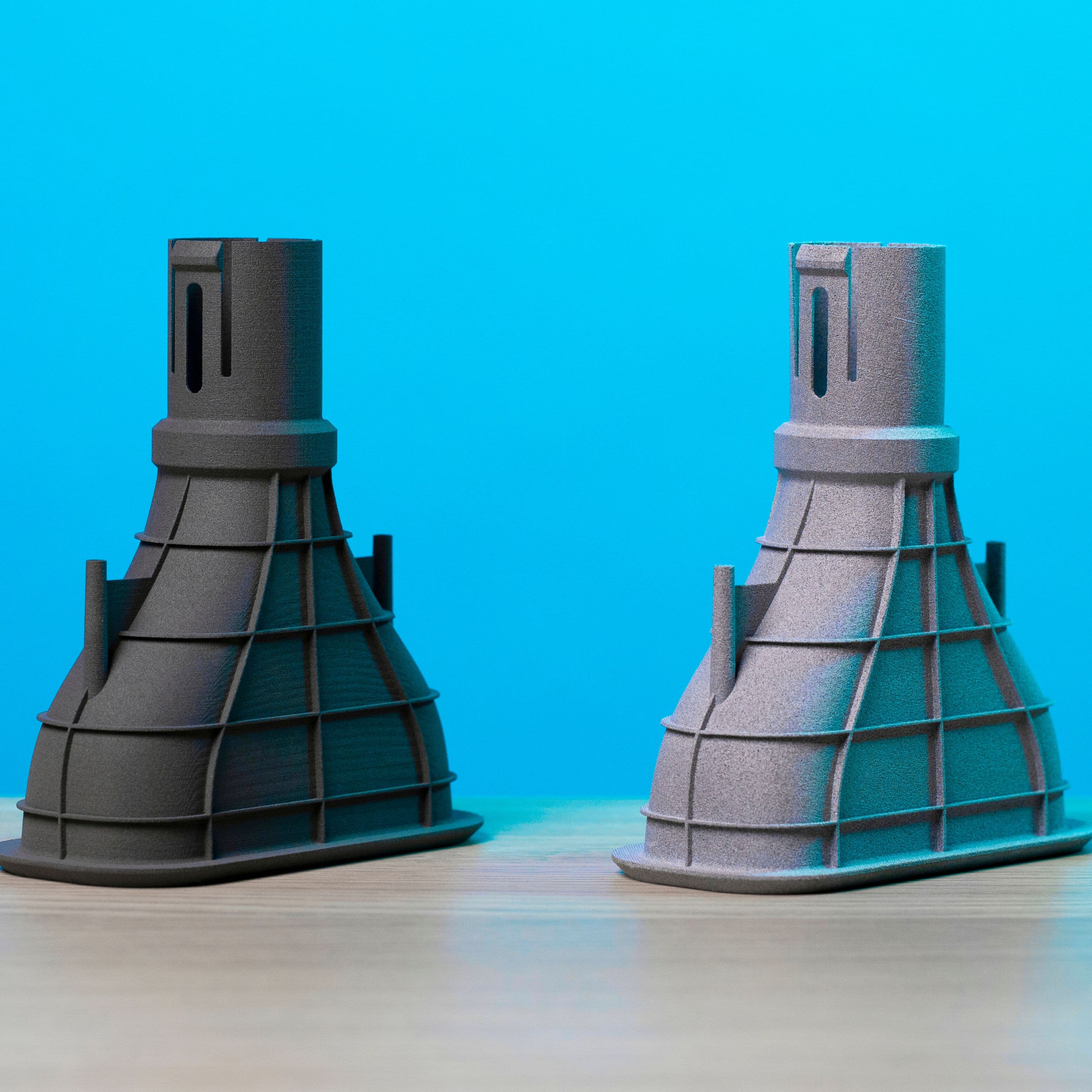

Replacement parts have a similar demand pattern — they aren’t needed in large quantities, but when a part breaks and the assembly line remains stalled, speed and accuracy are of the utmost importance. For these applications, in-house SLS can be a faster and more cost-effective alternative to machined aluminum parts..

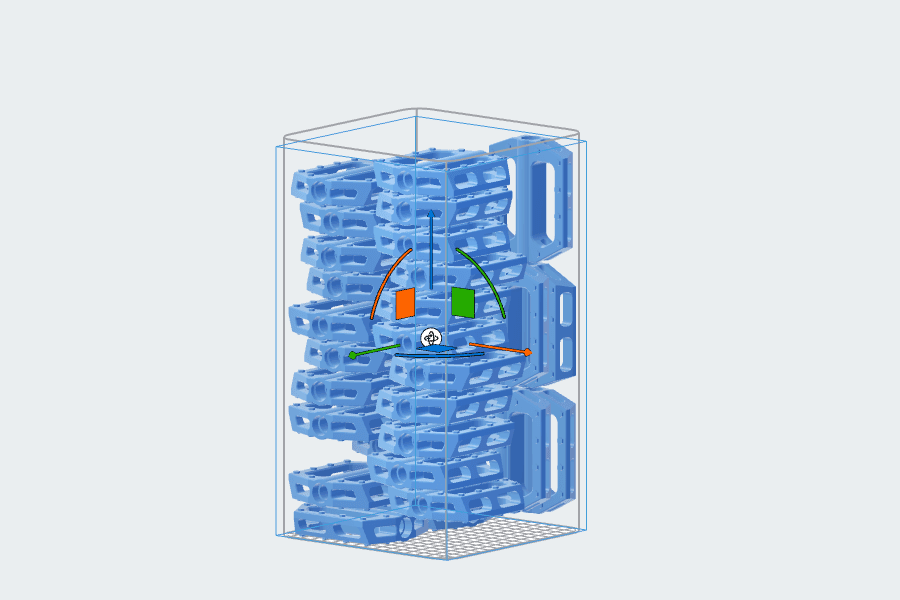

Our first example is an SLS printed tool used by Marcus Marienfeld for shaping titanium eyewear frames. The geometry is customized, and the manufacturer creates these based on different customer facial geometries. A collection of frames might cover multiple geometries, and custom tooling is necessary for each one. This type of customization in tooling would be impossible with expensive, traditional tooling creation, but with SLS 3D printing, it’s much more feasible. This case study prints 19 different tooling shapes in one SLS build chamber, optimizing powder packing density and refresh rate.

The second example is a crank handle replacement part — a sort of part that might break off during a manufacturing process and needs to be replaced in a rigid, strong material. Because these parts would only be printed on demand, the quantity is only one — despite printing small quantities being less optimal for powder packing and refresh rate utility.

Rapid Tooling: Titanium Eyewear Frame Forming Tooling

Marcus Marienfeld, a Swiss eyewear designer, uses his Fuse Series SLS 3D printer to create these customized tooling pieces that press metal eyewear frames into shape.

Customization in tooling is only possible with 3D printed tooling. These 21 tooling presses represent small changes in the eventual eyewear frame and would be cost-prohibitive to make through traditional means.

| Fuse 1+ 30W In-House | Service Bureau SLS | |

| Print Time | 16 h 52 m | |

| Additional Cooling (in Fuse Sift) | 13 h 45 m | |

| Sift/Part Extraction (hands-on) | 10 m | |

| Blast Time (automated) | 15 m | |

| Total Time to Part | 30 h 37 m | 9 business days |

| Materials Cost* | $196.81 | |

| Labor Time (hands-on) | 53 m** | |

| Labor Cost | $15.02 | |

| Total Cost: | $211.82 | $540.17 |

| Cost Per Part | $11.15 | $28.43 |

* The material cost is set at $99/kg, without any discount, as manufacturing aids like tooling aren’t typically required in the higher volumes that would prompt a bulk powder purchase.

** The labor time takes into account a longer print preparation time, 20 minutes here, to account for the arrangement, labeling, and orienting of these very slightly different tooling presses.

Tooling for consumer products like eyewear is typically made once and then re-used for high volumes of the exact same product. However, in Marcus Marienfeld’s case, he offers multiple styles of eyewear frames, which all require custom tooling. For low volume customization options, SLS 3D printing in-house delivers high quality parts fast, so that the real work of pressing the titanium frames can happen as soon as possible. Though the prices for outsourcing aren’t that much more expensive, the nine business days of lead time is the real disadvantage that outsourcing poses here.

Replacement Part: Crank Handle

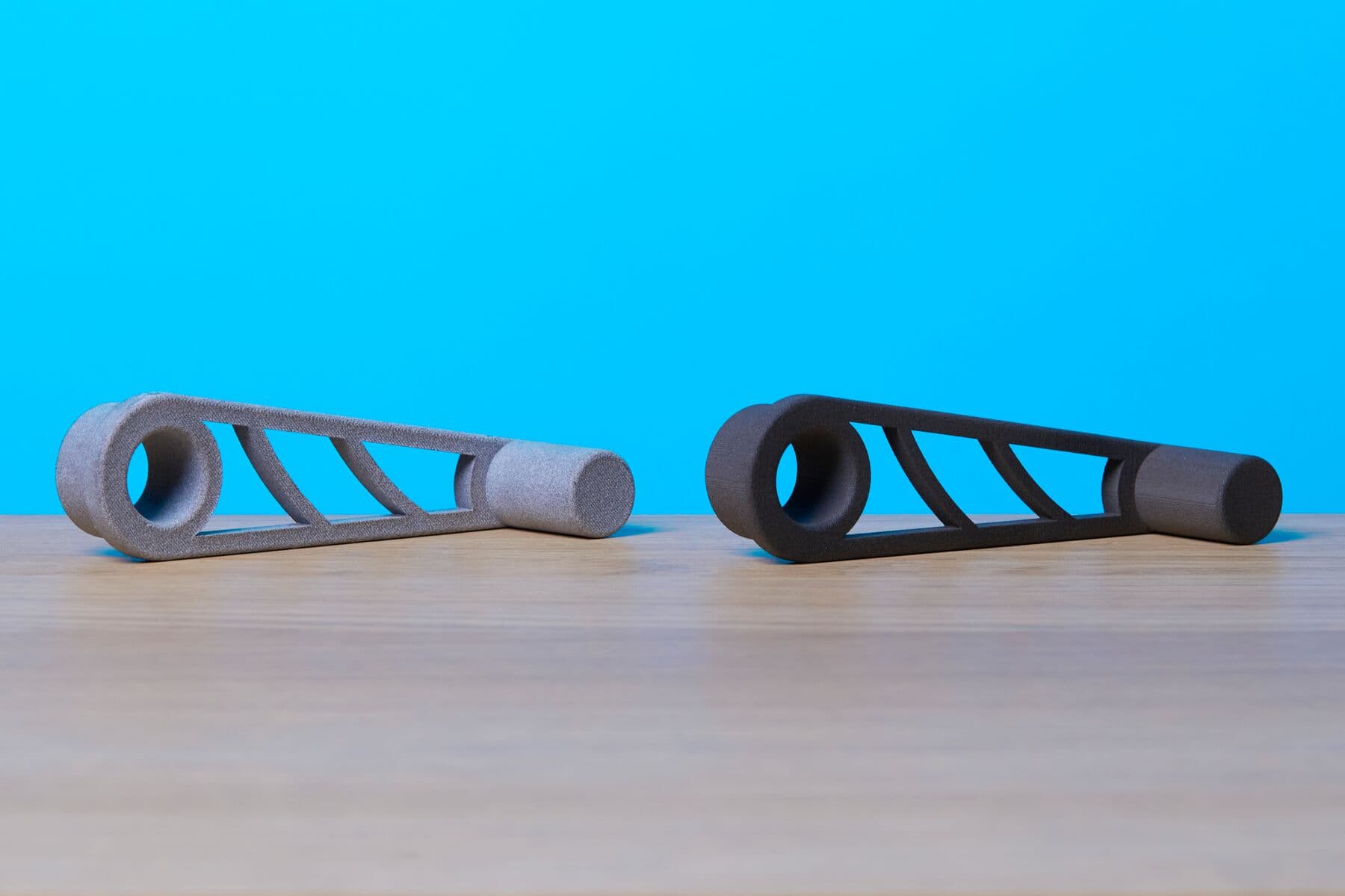

These replacement parts are not often needed on-demand in large quantities, but when they're needed, it's always time-sensitive on the factory floor. On-demand SLS 3D printing makes it possible to get a replacement part in less than a day.

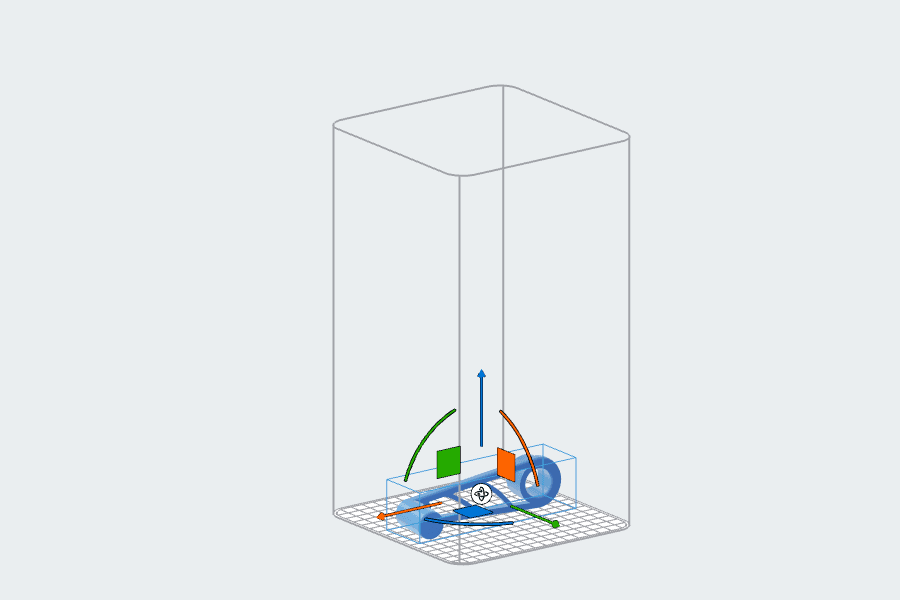

Though this build chamber looks inefficient, the Fuse Series printers only print build the powder bed to the height necessary for the build, so there isn't actually much powder wasted here. Another way of making single replacement parts efficient would be to include this crank handle in a build full of other parts that had already been scheduled.

| Fuse 1+ 30W In-House | Service Bureau SLS | |

| Print Time | 3 h 3 m | |

| Additional Cooling (in Fuse Sift) | 1 h 45 m | |

| Sift/Part Extraction (hands-on) | 5 m | |

| Blast Time (automated) | 15 m | |

| Total Time to Part | 4 h 48 m | 6 business days |

| Materials Cost* | $17.33 | |

| Labor Time (hands-on) | 33 m* | |

| Labor Cost | $9.35 | |

| Total Cost: | $26.68 | $18.93 |

| Cost Per Part | $26.68 | $18.93 |

*The labor cost here represents a significant portion of the total cost, and is only divided by one part. However, in a real life scenario, this would be mitigated by the other parts in the build chamber, to which a user added an on-demand replacement part that came up over the course of a day.

The ROI of an in-house SLS machine printing single replacement units is not easily shown by looking solely at the per part cost. Though about more expensive than outsourcing to a service bureau, it would still take hundreds of these single parts, if not thousands, to pay back the cost of the printer.

However, how much is it worth to your company to have a production line down for a day, versus up to two weeks? Obviously the answer differs case by case, but this shows how the efficacy of having an in-house SLS printer for replacement parts should instead be measured by how quickly replacement parts can get a machine back up and running. For every hour a machine is waiting for a repair part, the entire company is losing money. With an in-house machine, you can have a part by the next day and get the entire manufacturing process back up and running within 24 hours, which might be enough to pay for the price of the printer if it happens only once.

ROI With the Fuse 1+ 30W: Months, Not Years

Joshua Drigg's business, ZapWizard, relies completely on the Fuse 1+ 30W for production of his end-use Leatherman holster products. It was so much more efficient to print in-house rather than outsource to Shapeways that Driggs paid off his investment (of $135,000 for a full facility build-out) in just seven months.

In each prototyping, production run, and manufacturing aid case study, except for the final, crank handle case, the cost of printing in-house when compared to outsourcing to a service bureau was significantly lower. This cost comparison assumes that the in-house SLS printer has already been purchased, and the cost of a printer is not being amortized into the cost of production.

ROI reports from customers show that most companies that have a single application and enough demand for SLS printing to use a Fuse 1+ 30W to just 10% of its capacity would benefit from adding an SLS 3D printer in-house rather than outsourcing. And once a business has an SLS printer in house, expanding to new applications comes with a lower barrier to entry than with outsourcing, encouraging innovation.

For most businesses that need to produce new products, a prototyping sprint can be accelerated by several months, and these results prove that having an SLS printer in-house can create a return on investment within just one product’s prototyping process. Both the automotive manifold and the power drill use cases show that prototyping in-house is often 10X faster and cheaper than outsourcing. Printing 60-80 different builds will accomplish a positive return on investment, which, for a company that develops products continuously, could happen in less than three-four months.

For the production runs, both the turntable gear and bike pedal show that cost per part is substantially lower when printing parts in-house. This is influenced by the small part size and the efficiency of packing the parts into the chamber. Production use cases of small parts make it very easy to accomplish optimal packing density. This leads to a zero-waste printing process, where every bit of unsintered material can be used in the next printing cycle, while still staying within the optimal ratio of recycled to fresh powder. For situations where hundreds, or even thousands, of end-use parts are needed quickly (such as low volume production, supply chain disruption, or an impending deadline), using a Fuse 1+ 30W can provide a more cost-efficient in-house solution or an alternative if outsourcing or traditional methods will take too long.

For the first manufacturing aid application, a tool for forming eyewear frames into a particular shape, the return on investment is more in line with the prototyping and production use cases — if there’s enough demand for printing, the machine will be paid off in just a few months. Creating tooling like this is an easy, inexpensive way to increase access to customization. In this scenario, the user can print 19 different iterations of the tooling press, for 19 different face-shapes. The eyewear manufacturer can then offer eyewear frames for different frame shapes as well as different face shapes.

The notable exception to the quick ROI of prototyping and production runs is the replacement part use case. As only one part is required, the cost savings are not significant. However, it’s important to think about this particular scenario — a piece of equipment has broken and needs an immediate replacement. The broken component is actively halting production, which can have an impact on the bottom line for each minute it’s non-functional. The options for finding replacement parts are:

- Order from the machine manufacturer

- Create tooling and mold/cast/machine another one

- Order a 3D printed part from a service bureau

- 3D print the part in-house

When time is of the essence, the option that gets a replacement part installed the fastest, and production running again, is 3D printing that part in-house.

Conclusion

SLS is an ideal way to prototype functional, strong, and industrial-quality parts quickly and inexpensively, and a viable solution for cost-effectively producing low- to medium-volume end-use parts.

For these scenarios, when SLS has already been ordained as the best method, the decision between outsourcing these parts or printing them in-house is clear — printing SLS parts in-house is faster and less expensive.

Traditional, non-3D printing alternatives still make sense for production with large enough volumes and stable, predictable demand. In-house SLS is a viable alternative for any production with low or unpredictable volumes, whether that’s aftermarket, stop-gap, new product, or replacement part manufacturing.

The Fuse Series ecosystem has made in-house SLS 3D printing accessible for the first time, enabling hundreds of manufacturers to create parts in only a few days, with the entire workflow under their control. The communication process between departments, from requestor to design, engineering, technician, testing, and customer-facing teams, can happen within a week.

Relying on an in-house SLS 3D printer puts control back into the hands of the manufacturer. The Fuse Series’ accessible price point, intuitive workflow, and variety of industrial-quality materials make it the ideal choice for those looking to reduce their reliance on third parties.

Determining the exact timeline for ROI can be complicated, taking into account various applications, materials, and production schedules. After working with hundreds of Fuse Series customers, our SLS expert team can help you plan a schedule for your specific parts and determine how fast you can achieve an ROI on bringing SLS in-house.