For Meticuly, a medical device manufacturer from Thailand, patient outcomes and safety depend on accuracy and precision at every stage in their advanced 3D design and production process. Meticuly specializes in providing end-to-end solutions, including 3D segmentation, implant design, and personalized implant manufacturing for a wide range of surgeries that utilize 3D printed implants.

To expand accessibility and speed of care, Meticuly’s subsidiary, OSS3O, delivers integrated 3D printing systems for hospitals, called their “factory-in-a-box” solution, enabling the production of patient-specific implants and surgical guides directly at the point of care. OSS3O combines modular hardware, cleanroom-ready environments, and smart manufacturing software to bring high-quality, on-demand medical device production closer to the patient.

Meticuly’s network of doctors and hospitals routinely presents complex cases that require extreme levels of accuracy and resolution for their 3D printed titanium implants. To maintain this precision throughout the treatment process, Meticuly utilizes planning models printed on the Fuse 1+ 30W printer using Nylon 12 White Powder. These models are used directly in the operating theater to assist surgeons during procedures.

OSS3O takes 3D printing a step further, bringing custom-developed point-of-care manufacturing systems to hospitals and training them on developing their own in-house solutions.

“Without these preoperative planning models and surgical guides, doctors are more likely to make inaccurate judgements and affect the quality of the patient’s outcome and recovery. We recommend the Fuse Series for accurate models with good surface finish and speed.”

Thanachai Boonchuduang, Senior Process Engineer, Meticuly

Creating Bone Simulation Models for Cutting and Drilling

This application guide walks through the bone-simulation material options for stereolithography (SLA) 3D printing and the entire in-house manufacturing process for bone- like anatomical models intended for cutting and drilling.

The Roadmap for Medical Innovation

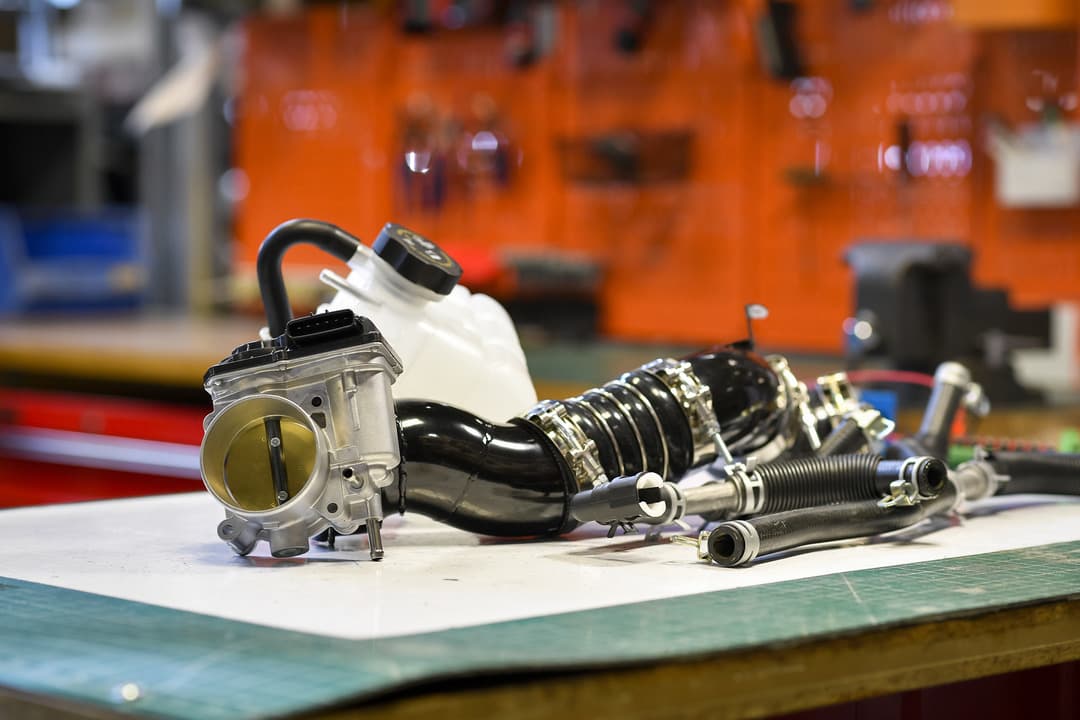

Meticuly’s solutions help surgeons prepare and execute complex, highly technical operations. Their planning models, seen here in Nylon 12 White Powder with integrated titanium implants, are essential to surgical success.

In 2015, Meticuly’s founders developed the world’s first metacarpal prosthesis. During their work on the device, they recognized a critical need among surgeons for better accuracy, consistency, and efficiency in the pre-surgical planning process. Two years later, Meticuly was formed and received Thai FDA approval for patient-specific implant production.

Since 2017, Meticuly has accrued more approvals and clearances for a range of procedures and devices, further cementing their place as providers of cutting-edge solutions for cranio-maxillofacial surgeries. In the United States, their cranio-maxillofacial mesh products received FDA 510(k) clearance, a significant milestone made possible by their meticulous digital design and extensive validation processes.

To extend this innovation closer to the point of care, OSS3O was established to equip a leading hospital in Thailand with an on-site 3D printing system (factory-in-a-box) for producing surgical models, guides, and implants. This implementation has accelerated treatment timelines, enhanced surgical precision, and empowered the medical team to deliver truly personalized healthcare at the point of care."

“The Fuse Series is perfectly suited for point-of-care use — compact, reliable, and easy to operate. It enables hospitals to deliver faster, more precise, and personalized care right where it’s needed most.”

Kanin Sirichatchai, Executive Vice President, OSS3O

3D Printed Medical Devices for Precision Surgery: Clinical, Commercial, and Regulatory Perspectives

Watch this on-demand panel, moderated by Formlabs, to hear perspectives from a health system, two commercial medical device firms, and the FDA on the current state of 3D printing in the medical industry.

Integrating SLS at the Point of Care

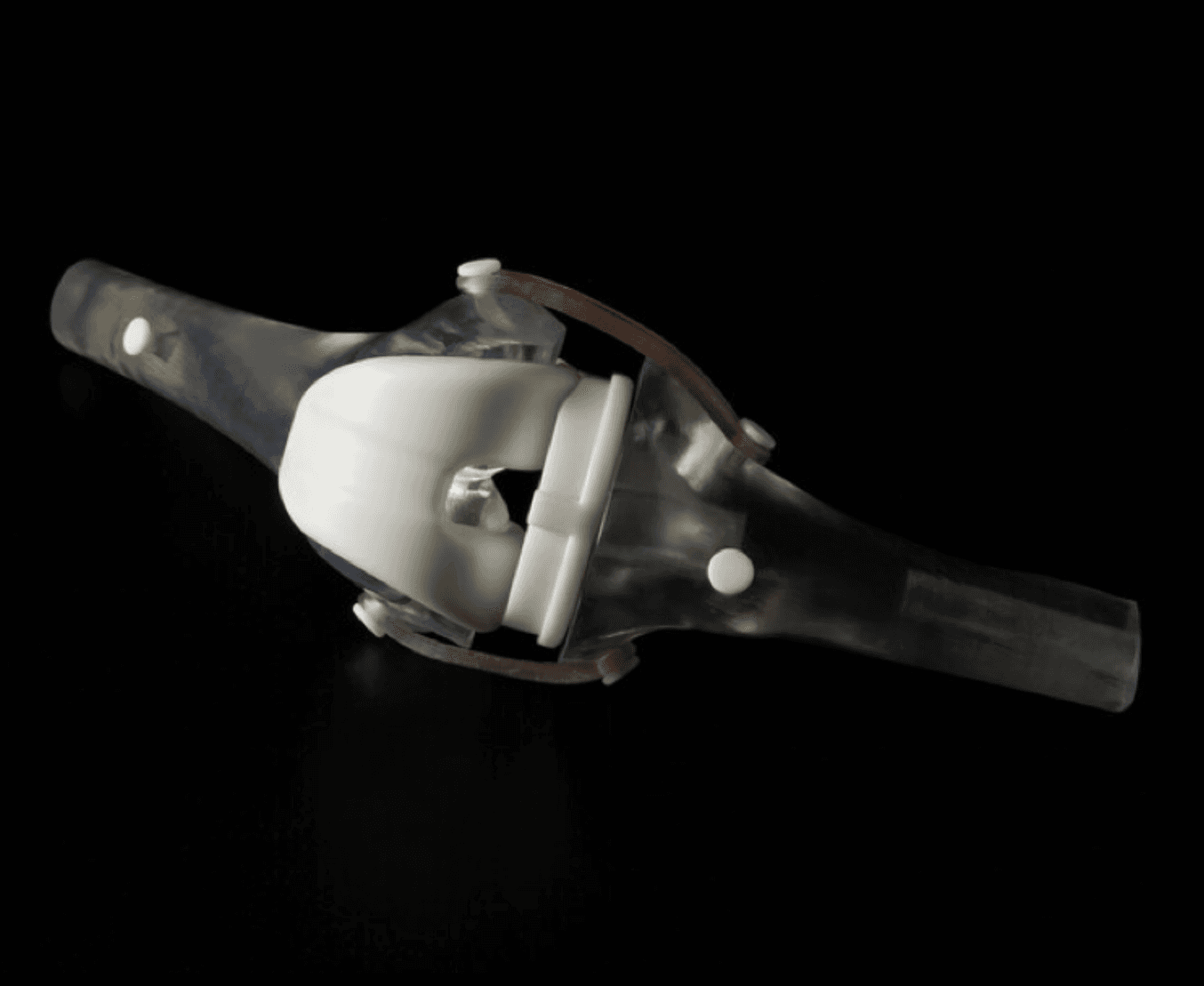

The high dimensional accuracy of parts printed on the Fuse 1+ 30W makes precise integration of implants on the preoperative planning model possible. White nylon material closely mimics the mechanical and visual properties of bone, preparing surgeons for their operation as much as possible.

Though accuracy and consistency are top of mind for surgical preparation, planning, and practice, when it comes to helping hospitals bring this technology in-house, there are additional concerns.

Despite the growth of biomedical engineering and educational programs for 3D design skills, the vast majority of physicians, healthcare professionals, and hospital technicians are not familiar or comfortable with digital design or fabrication technology. OSS3O works hard to address a complex, multilayered problem. Though 3D printing models would help improve patient results and drive OR costs down, the initial start-up fee can discourage hospitals from investing in new technologies. The lack of familiarity poses a challenge for 3D printing operations and design. “Hospitals need easy-to-use and integrated solutions,” says Boonchuduang.

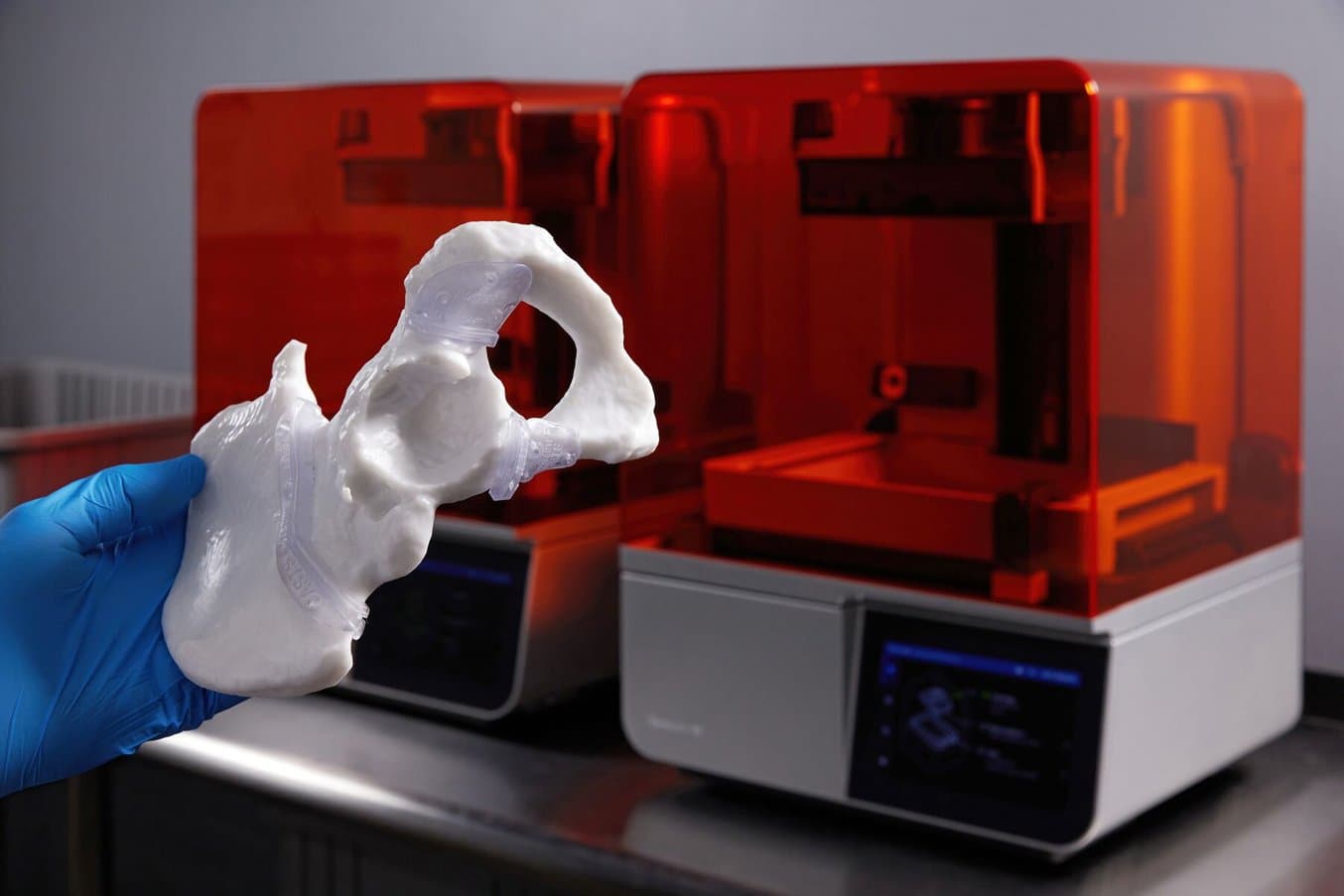

When OSS3O was evaluating different SLS 3D printing options to put forward and recommend to their partner hospitals, they evaluated the traditional powder bed fusion options available and found them too large and complicated to install. “Many SLS printers are too big to be installed in a hospital setting. These facilities don’t have large rooms with lots of extra power sources for a massive machine,” adds Boonchuduang. The answer for OSS3O’s hospital clients is compact — yet still powerful — SLS. “The Fuse 1+ 30W printer is easy to integrate because it’s so much more compact than other SLS machines. It’s the hardware that makes our point-of-care model feasible,” says Boonchuduang.

How to 3D Print Anatomical Models for Preoperative Planning and Enhanced Patient Consent

This white paper offers a practical walkthrough for physicians and technologists to get started creating 3D printed anatomicals models from patient scans, reviewing best practices for setting up a CT/MRI scan, segmenting datasets, and converting files to a 3D-printable format.

Powder Makes It Possible: Nylon 12 White

There are high standards for accuracy, size, surface finish, color, and machinability for orthopedic surgery models, but with white nylon material on the Fuse 1+ 30W printers, surgeons can now practice their operation on a lifelike model.

Meticuly and OSS3O need solutions that can act as swiss army knives for hospitals — creating surgical cutting guides and implant fit models reliably and on a consistent production schedule. All of these parts, pre-operative study models, sizing models for the 3D printed titanium implants, and surgical cutting guides, need to be hyper-accurate to ensure the surgery and implant succeed.

Once they determined that the Fuse Series could address the accuracy and functionality challenges, there was one problem left. They needed a powder that mimicked bone and could help surgeons and patients visualize how the titanium implant would act in-use, in other words, a white material.

Large, industrial systems offered white powders, but the cost of bringing those solutions in-house outweighed the benefit. Boonchuduang’s team couldn’t find a solution that fit all their criteria, until he heard that there would be a white powder available on the compact, affordable Fuse Series.

“We had known about the Fuse Series and liked its accuracy and consistency, but we needed a white material. When we heard Formlabs was developing a white SLS powder, we contacted our Formlabs Thai representative right away,” says Boonchuduang.

Since getting started with Nylon 12 White Powder, OSS3O has brought in new clients and printed consistently on their Fuse 1+ 30W printer with the white material. They can also batch together multiple parts in the self-supporting SLS build chamber, so they’re more efficient and productive every day.

“We really like using Nylon 12 white models for preplanning in the operating theater, and we can get these parts the same day. Before, we would be waiting multiple days for a large FDM part to finish.”

Thanachai Boonchuduang, Senior Process Engineer, Meticuly

White SLS Material for Pre-Operative Planning

Meticuly can SLS 3D print multiple models in a day, reducing the lead time for surgeons to access these planning tools and enhancing the patient’s experience.

The movement to bring advanced technologies like 3D printing and 3D design into hospitals is gaining traction every day. As businesses like Meticuly help make adoption easier, 3D printing is making good on its enormous potential for positive impact on patients’ lives and the practice of healthcare.

Meticuly’s success with the Fuse Series shows accessible, easy-to-use technology can make an immediate difference for hospitals and patients. By pioneering a ‘factory-in-a-box’ approach for implants and deploying a powerful, compact solution through OSS3O, Meticuly is not just a user of technology — they are a key architect of the future of medicine in the region.

The combination of Fuse 1+30W and Nylon 12 White Powder makes it possible for surgeons and medical care providers to improve their patients’ outcomes and create a more productive, efficient workflow at the point of care.

To learn more about the Fuse Series, visit our website. To speak to a medical 3D printing expert, contact our team.