PreForm 3.45 Includes Improved Large-Format SLA Packing Algorithm, Form 4 Rapid Print Time Estimations, and More

The latest update to PreForm Print Preparation Software, version 3.45.0, is here to enhance your pre-print experience, optimize your workflow, and save you time and material. New updates for stereolithography (SLA) and selective laser sintering (SLS) include:

- Smarter auto-layout for SLA 3D printers

- Real-time print estimation for Form 4 Series 3D printers

- Precise auto-packing for SLS

- Printer aliases

- Improved statistics and reporting

Updates to PreForm make it easier than ever to go from design to 3D printed part, with powerful tools at your fingertips.

Talk to Our Sales Team

Whether you need to prototype at speed, or are producing end-use parts, we’re here to help. The Formlabs Sales team is composed of dedicated specialists who know exactly how to support you and your company's needs.

Saving Time and Optimizing Space on SLA 3D Printers

Smarter Auto-Layout for SLA Printers

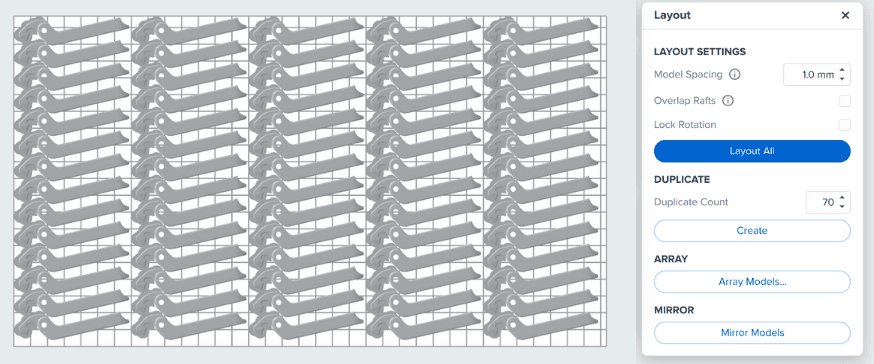

Automatically arranging multiple models on a build platform is now easier, for improved pack density on all SLA 3D printers. The auto-layout tool now increases the one-click capacity of the packing algorithm, so more parts can be printed in a single build.

Autopacking makes it easy to layout 70 Form 4 mixer latches with one click, versus 60.

Rapid Print Time Estimator for Form 4 Series 3D Printers

Real-time print time estimates are now available for all Form 3 and Form 4 Series 3D printers. As builds are prepared, an instant estimate of how long the print will take will automatically update, responding to changes in print settings like print orientation, material, support density, etc. This dynamic estimation empowers users to make informed decisions about build setup and timing. This tool is unique to PreForm — no other software on the market offers dynamic print time estimates.

Optimize Print Set-Up and Workflows for SLS 3D Printers

Print Voting for SLS

Print Voting for SLS is now available for Fuse 1+ 30W and Fuse 1 prints directly in PreForm, enabling users to indicate with one click how a print turned out. This feature helps users to easily track materials and settings that yield the best results. Formlabs also uses this data to improve our print settings, optimize workflows, and develop new features.

Precise Auto-Packing for SLS

PreForm’s auto-packing feature has been updated for SLS, allowing the configuration of a Distance to Wall. This makes it easier to move parts to the center of the build, which is recommended for best results.

When a Distance to Wall value is set (we recommend ≥10 mm), the algorithm will ensure an offset of that distance from the build chamber walls.

User Experience Enhancements

Better Statistics and Reporting

Part cages for SLS parts are no longer counted as models in print statistics, leading to more accurate tracking of material usage and print efficiency.

Updated System Requirements

As part of ongoing performance optimizations, PreForm 3.45.0 no longer supports Windows 7 and 8. The minimum system requirement is now Windows 10 October 2018 Update (version 1809) or later.

Start Using the Newest PreForm Features

PreForm software updates level up your pre-print experience, making it faster and easier to get from design to 3D printed part. New features allow you to do more right in PreForm, and give you the metrics you need to track material usage and print time for improved print efficiency.

To start using new features, existing PreForm users can navigate to the Help menu and click Check for Updates. For new users, download our free PreForm software.