We recently launched the latest addition to our family of Tough and Durable Resins, Tough 1500 Resin. Kathy Bui, a materials product manager at Formlabs, hosted a webinar to explain the differences between the materials in this resin family and give a deep dive into Tough 1500 Resin. The webinar was highly attended, and we received almost 100 questions from attendees.

Our company mission is simple: Expand access to digital fabrication, so anyone can make anything. In order to achieve this mission, Formlabs continues to aggressively expand our resin library. As the library grows, users naturally have questions around use cases and best practices.

Introducing Tough 1500

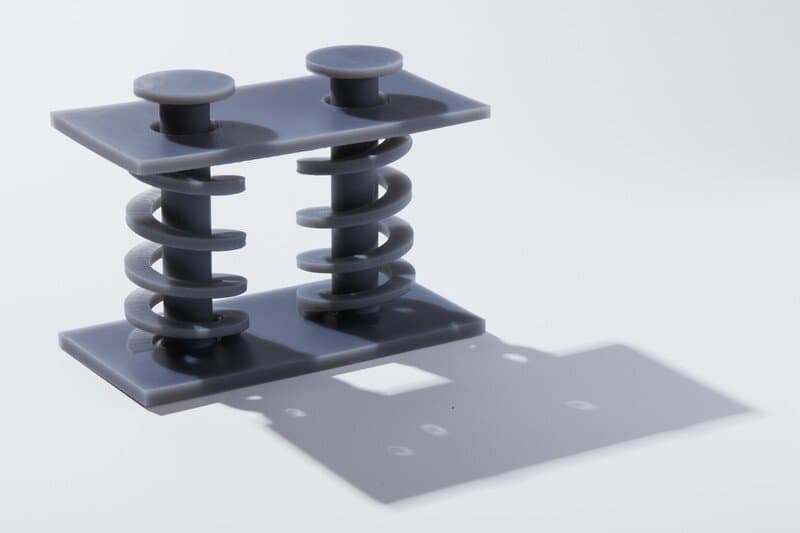

Tough 1500 Resin produces stiff and pliable parts that bend and spring back quickly under cyclic loading. This material is ideal for functional prototypes, connectors, as well as jigs and fixtures undergoing temporary deflection. It also simulates polypropylene parts in terms of stiffness and strength.

Here are the most popular questions about Tough 1500:

Q: What do I need to start printing with Tough 1500?

Tough 1500 is compatible with the Form2, Form 3, and Form 3B. An LT Tank is needed when printing on the Form 2, where as either Tank V1 or Tank V2 will work on the Form 3.

When using the Form Wash and Form Cure, we recommend washing for two periods of 10 minutes each and curing at 70 °C for 60 minutes.

Q: How does a Tough and Durable material like Tough 1500 compare to other engineering resins?

When picking a material, it is important to think about the required properties of your final print. Choose Tough and Durable Resins for dynamic applications where bending at lower stress levels is preferred to sudden brittle failure at higher stress levels, which may occur in stiffer engineering resins like Rigid or Grey Pro.

In general, parts made from Tough and Durable Resins offer a better balance of stress and strain and can withstand stronger impacts compared to Rigid Resin or Grey Pro Resin. Parts made from Rigid Resin or Grey Pro Resin are typically able to withstand higher stress levels before deforming, but when they do strain significantly, they experience a sudden brittle failure.

Tough and Durable Resins are ideal for:

- Housings and enclosures, such as electrical housings, bottles, and packaging

- Jigs and fixtures, such as non-marring grips, drill guides, and locators

- Connectors, such as snap fits, press fits, hinges, threads, and joints

- Prototypes undergoing wear and tear, such as consumer goods, tools, and assemblies

Our family of Tough and Durable Resins

Q: What thermoplastics do the materials in our family of Tough and Durable Resins most closely represent?

Polypropylene is a common thermoplastic used in numerous consumer packaged goods products. Tough 1500 Resin can be used to simulate the strength and stiffness of products that will be manufactured out of polypropylene.

See more of the technical data behind Tough 1500 in our introductory blog post.

Tough Resin and Durable Resin simulate ABS and polyethylene respectively, similarly in terms of strength and stiffness.

Q: How does Tough 1500 react under stress?

Due to its balance of elongation and modulus, Tough 1500 Resin is ideal for parts that bend, but require high memory retention. When pushed to normal stress limits, parts made from Tough 1500 will strain and spring back to its original shape when that stress is relieved. When pushed to its stress limit, parts made from Tough 1500 will strain significantly before permanently deforming and ultimately breaking.

Bending Tough 1500 under stress

Request a Sample Part

Tough 1500 Resin is just the first of many resins added to the Form 3 ecosystem. If you still have questions about using Tough 1500 Resin for your project, order a free sample part below or watch our webinar filled with specs, applications, and case studies.