Industrial Vacuum 230V

VC-FS-230V-01

Estimated delivery: Feb 25 - Mar 2The Fuse Sift powder recovery station for Fuse Series SLS 3D printers incorporates an external vacuum, sold separately, to help you efficiently and safely maintain a clean workspace. The integrated hose and controls allow you to easily tidy up your workspace, clean off a build chamber, or remove debris from the sifter mesh.

Due to potential hazards associated with powders, a static dissipative vacuum that is NFPA 652 compliant is required. This Class II Division 2 vacuum fulfills all safety requirements for the Fuse Sift

- Industrial Vacuum 230V

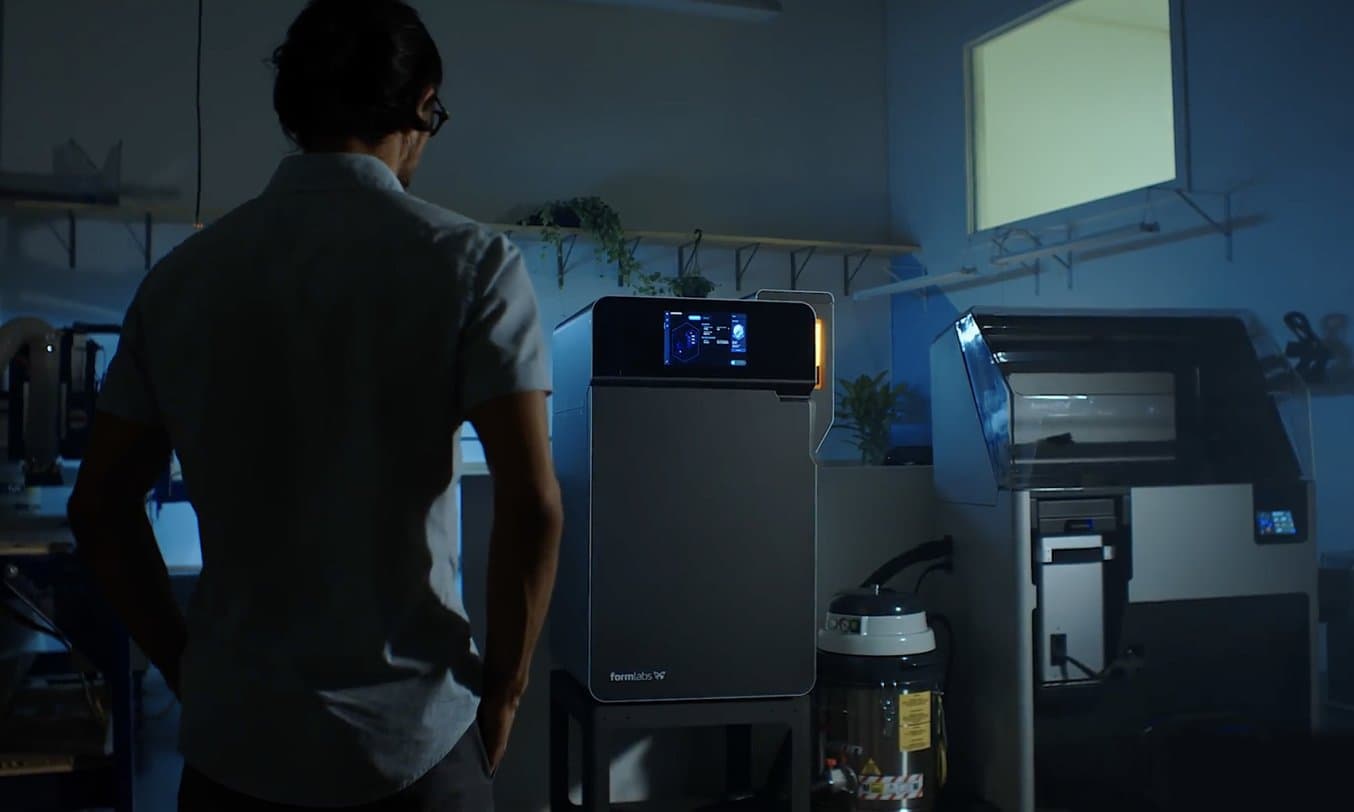

The Fuse Series ecosystem allows for a cyclical workflow that optimizes SLS 3D printing production at low waste and with minimum printer interaction.

Features

The industrial vacuum for the Fuse Series SLS 3D printing ecosystem helps ensure a safe, powder-free and efficient work environment.

Safety First

This NFPA 652 compliant vacuum is certified for operation in Class II Division 2 environments and is recommended for use with the Fuse Series ecosystem.

Mess-Free Environment

Plug the vacuum into Fuse Sift to post-process your parts in a controlled environment and keep your workspace powder-free.

Optimized Part Cleaning

See the vacuum tool in Fuse Sift to assist in removing powder from your printed parts while collecting used powder for your next print jobs.

Minimum Waste, Maximum ROI

Achieve low to zero-waste printing by recovering and re-using your unsintered powder easily and maximize your ROI.