3D Printing for Engineers & Product Designers

Concept Exploration

Elevate initial ideas with low-risk concept models, proof-of-concept (POC) prototypes, and looks-like prototypes. 3D printing empowers you to go from CAD to physical object in no time, and rapidly develop, evaluate, and iterate a range of designs in-house.

Watch the video: How Ford Developed the New Explorer Using Formlabs SLA and SLS 3D Printers

See Also

How Black Diamond Reduced Costs by 84% With Rapid Prototyping on the Form 3L

How Ford Developed the New Explorer Using Formlabs SLA and SLS 3D Printers

Producing High-Precision Prototypes for Mechanical Watches Using 3D Printing

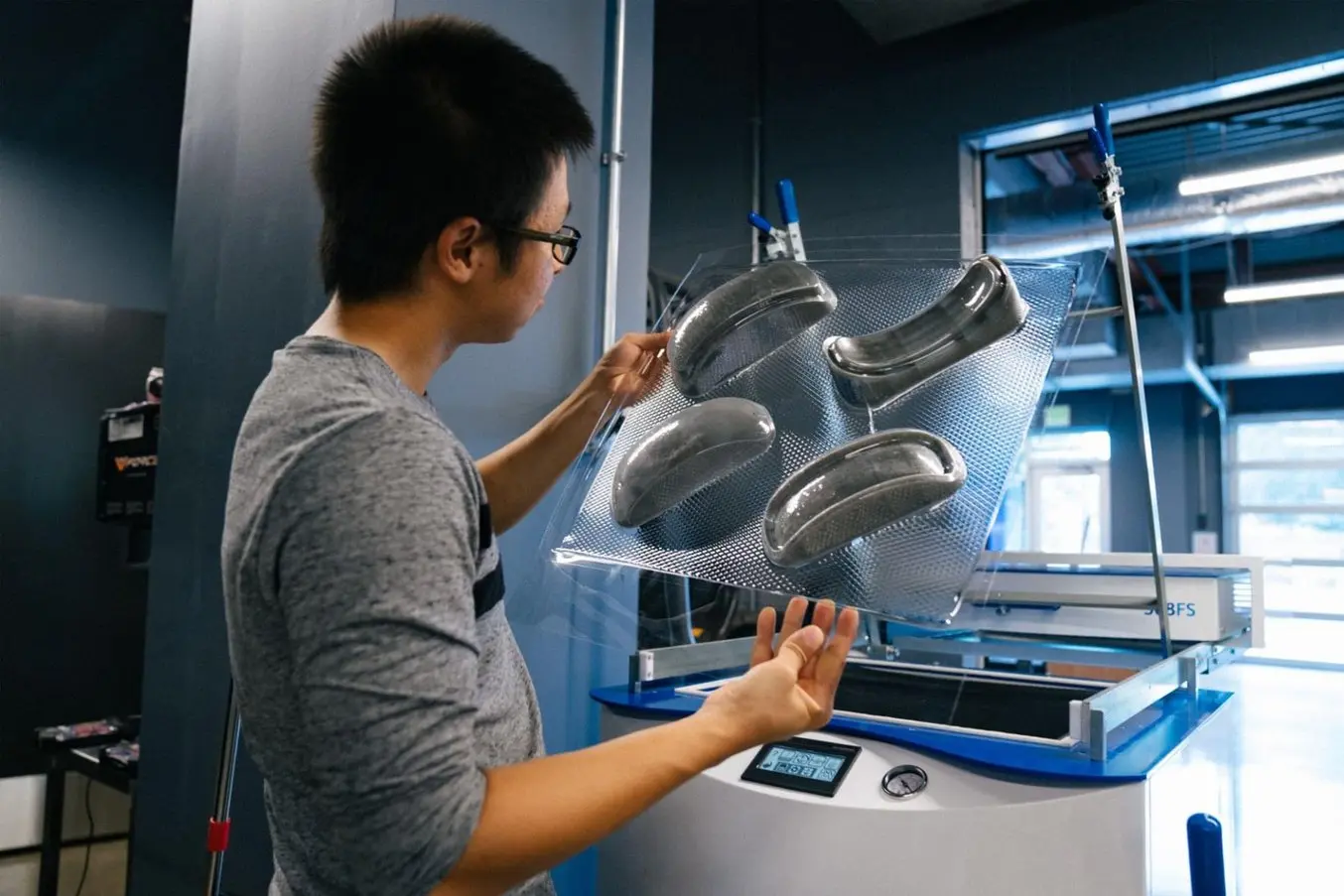

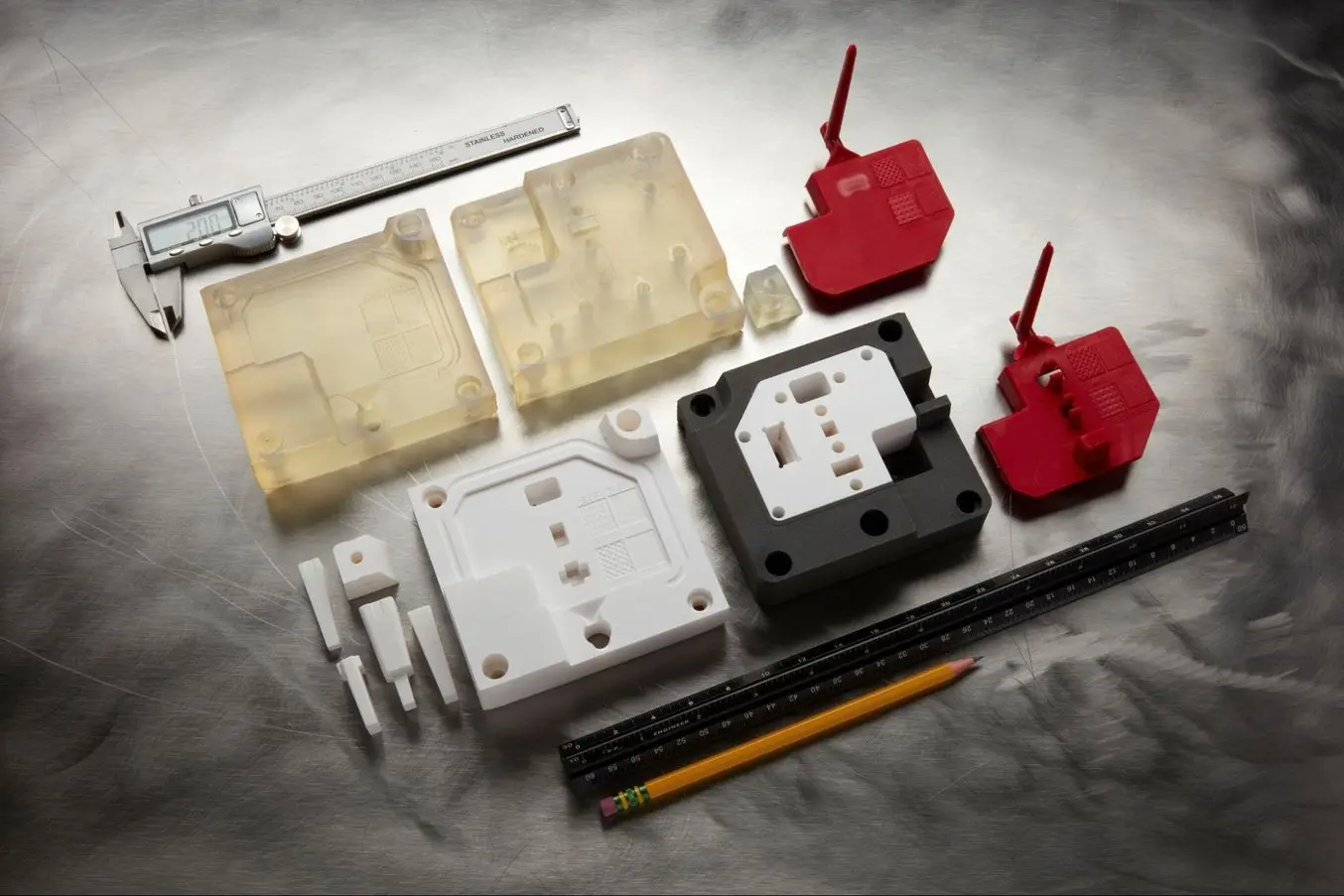

Rapid Prototyping

Looks-Like: Test design iterations and communicate ideas to stakeholders affordably and quickly.

Works-Like: Reliably develop proofs of concept and test functional prototypes with materials closely matching common injection-molded plastics.

Feels-Like: Simulate a range of materials from rubber to rigid, and create prototypes with the smooth finish and feel of end products.

Watch the video: How a 3D Printing Station Supports Hundreds of Engineers at the AMRC

See Also

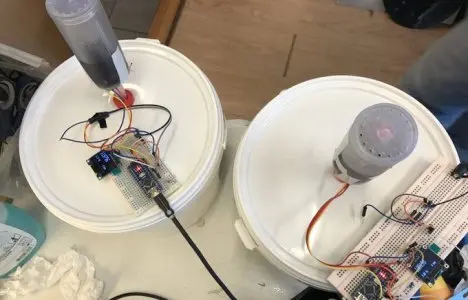

Prototyping an Optically Clear Airlock for Homebrewing With 3D Printing

How Lush Cosmetics Take Ideas From Concept to Reality in Under 24 Hours with 3D Printing

A Product Development Company Using 3D Printing To Do It All

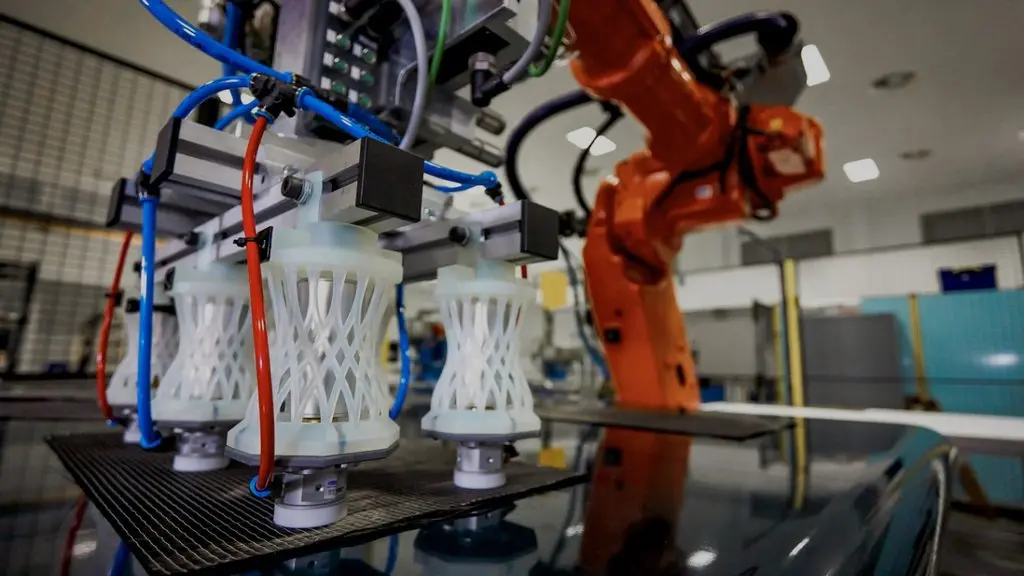

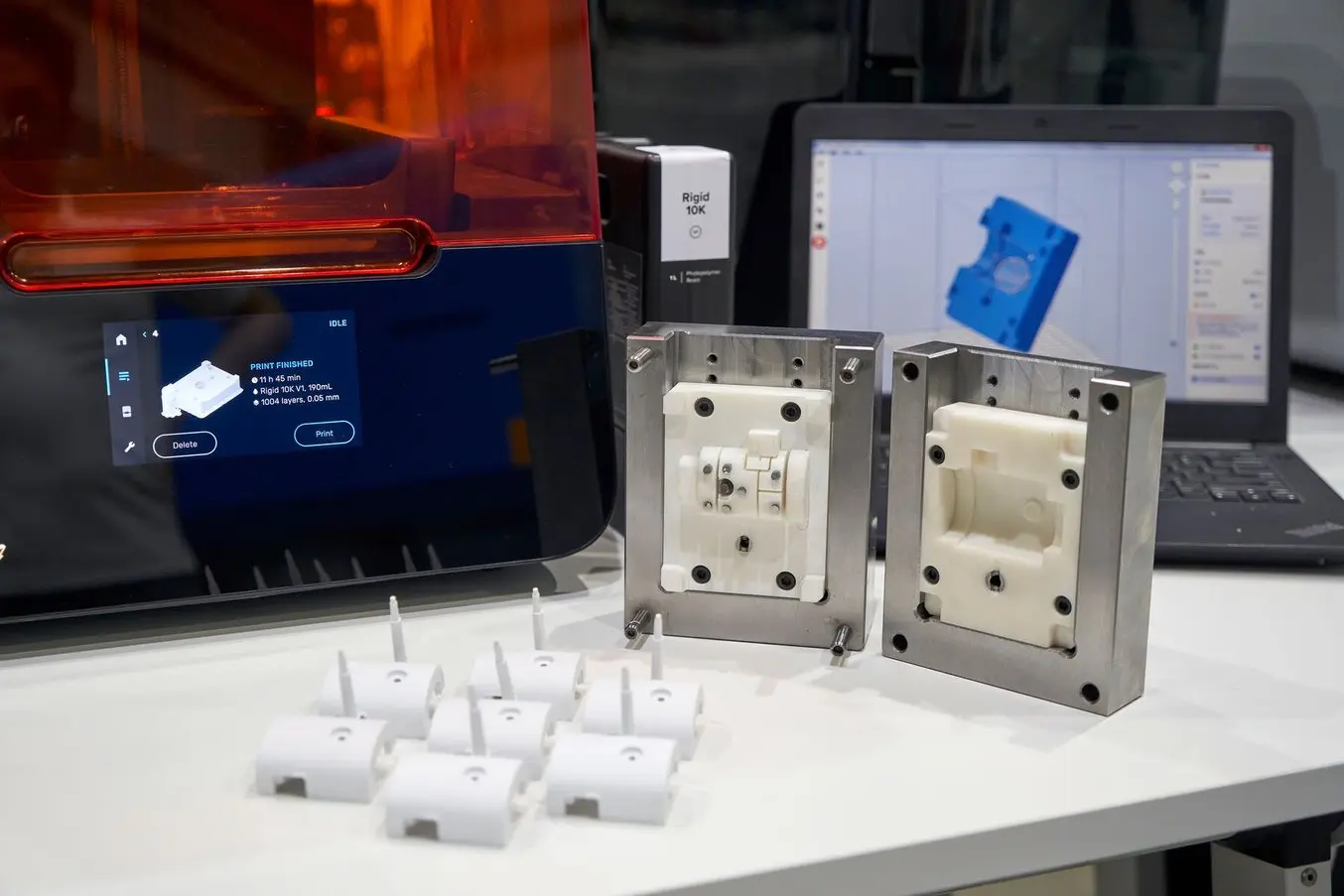

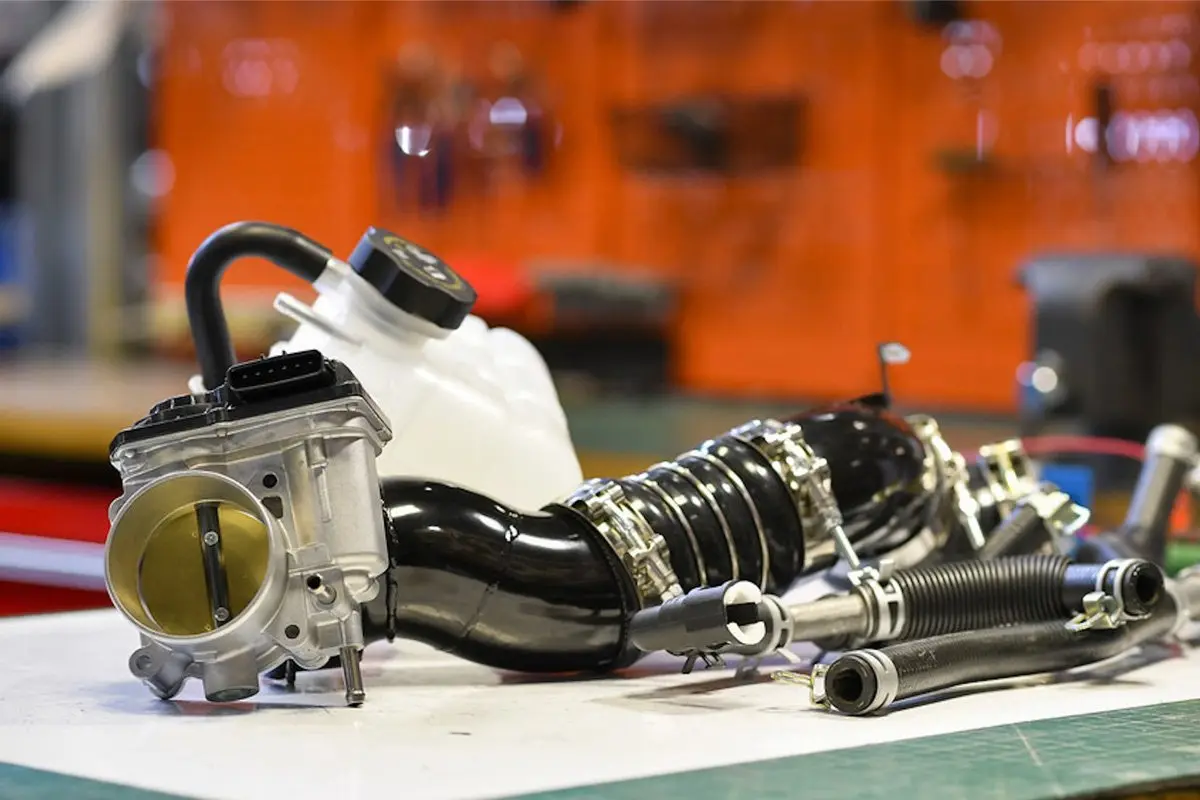

Pre-Production

Use advanced materials to design for manufacturability. Create small-batch runs or one-off custom solutions for comprehensive field and in-house testing before investing in expensive tooling for production.

Watch the video: Inside Google ATAP: Bridging Pre-Production Challenges With 3D Printing

See Also

How a Contract Manufacturer Uses 3D Printed Molds for Low-Volume Production

How IGESTEK Develops Composite Parts With 3D Printing and Rapid Tooling

Moving towards production? Learn how 3D printing can be used in manufacturing.

Cut Your Prototyping Cycle to 24 hours

Never again wait weeks for prototypes to arrive from a service provider. With in-house 3D printing, you can create rapid prototypes within a day, run tests, tweak your design, and print again.

Design

Design your object in CAD during work hours.

3D Print

3D print the prototype parts overnight.

Test

Clean, measure, test, create assemblies, and collect feedback on your design in the morning.

Iterate

Tweak your design and repeat the process.

Save Money and Time

A 3D printer setup can pay for itself in just a couple of weeks or months when you compare it with how much you’d spend on outsourcing or an alternative production method.

9 hours

$80

7 days

$450

Curious to see how much you can save? Try our interactive ROI tool to calculate cost per part and lead time when 3D printing on Formlabs 3D printers.

16.5 x 13.5 x 13.5 cm

6.5 x 5.3 x 5.3 in

A Full Suite of 3D Printing Solutions

Form 4

Form 4L

Fuse 1+ 30W

High-Performance Engineering Materials

Simulate a range of common injection-molded plastics with materials designed for the most demanding applications and produce durable end-use parts and complex assemblies with high environmental stability.

Draft Resin

Tough 1500 Resin

Nylon 12 Powder

Rigid 10K Resin

Formlabs is Open

Maximize your 3D printer’s potential with Formlabs Developer Platform. Unlock the possibility of printing with any 405 nm photopolymer resin or 1064 nm powder on Formlabs 3D printers, customize your print settings, or build software integrations.

Start Scaling Your Prototyping and Production Today

Explore our 3D printers to find the right solution for your business or contact a Formlabs Solution Specialist for a 1-1 consultation.