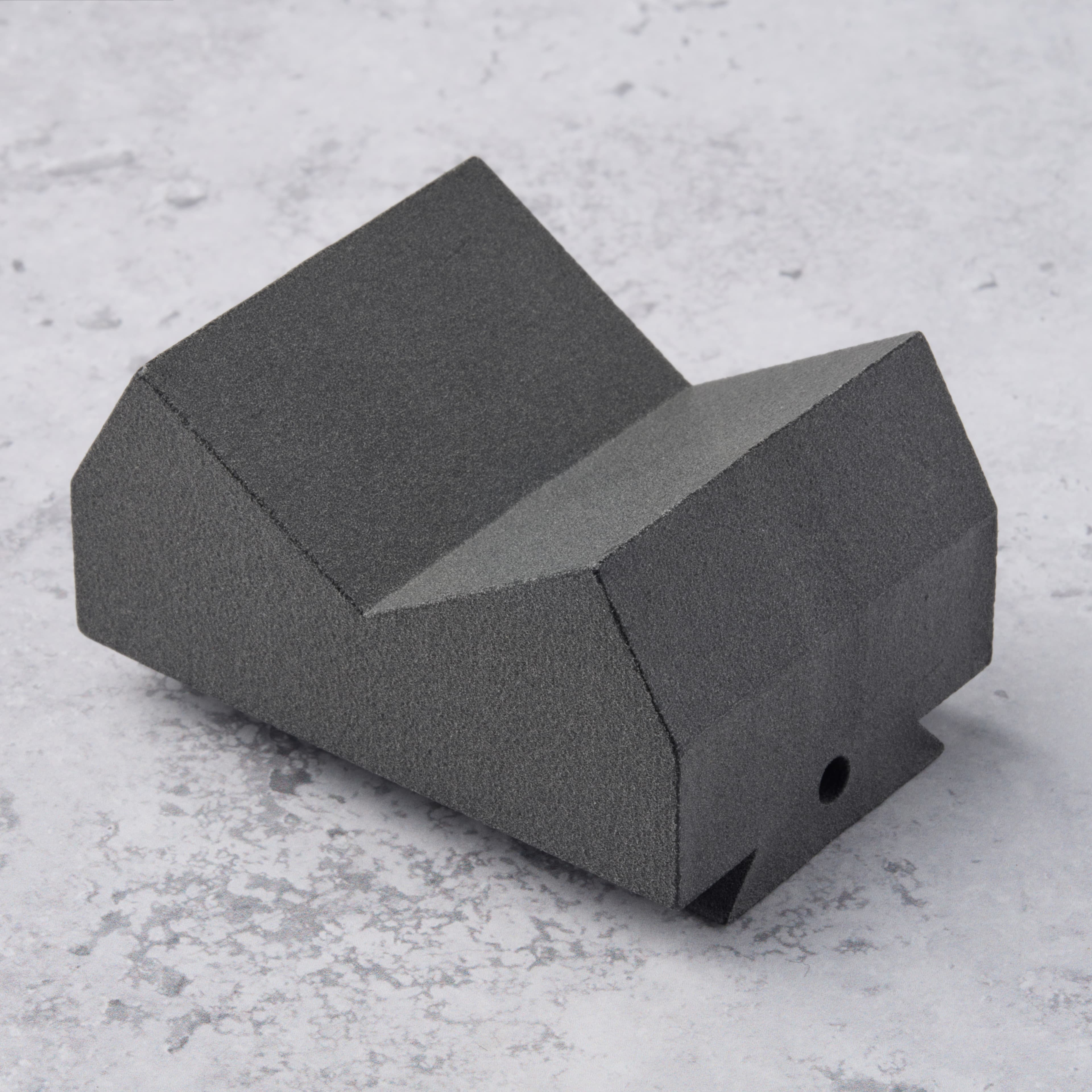

Familiar, industry-standard materials now possible on-demand, with an agile workflow that eliminates reliance on external machinists or tooling.

FuseSeries

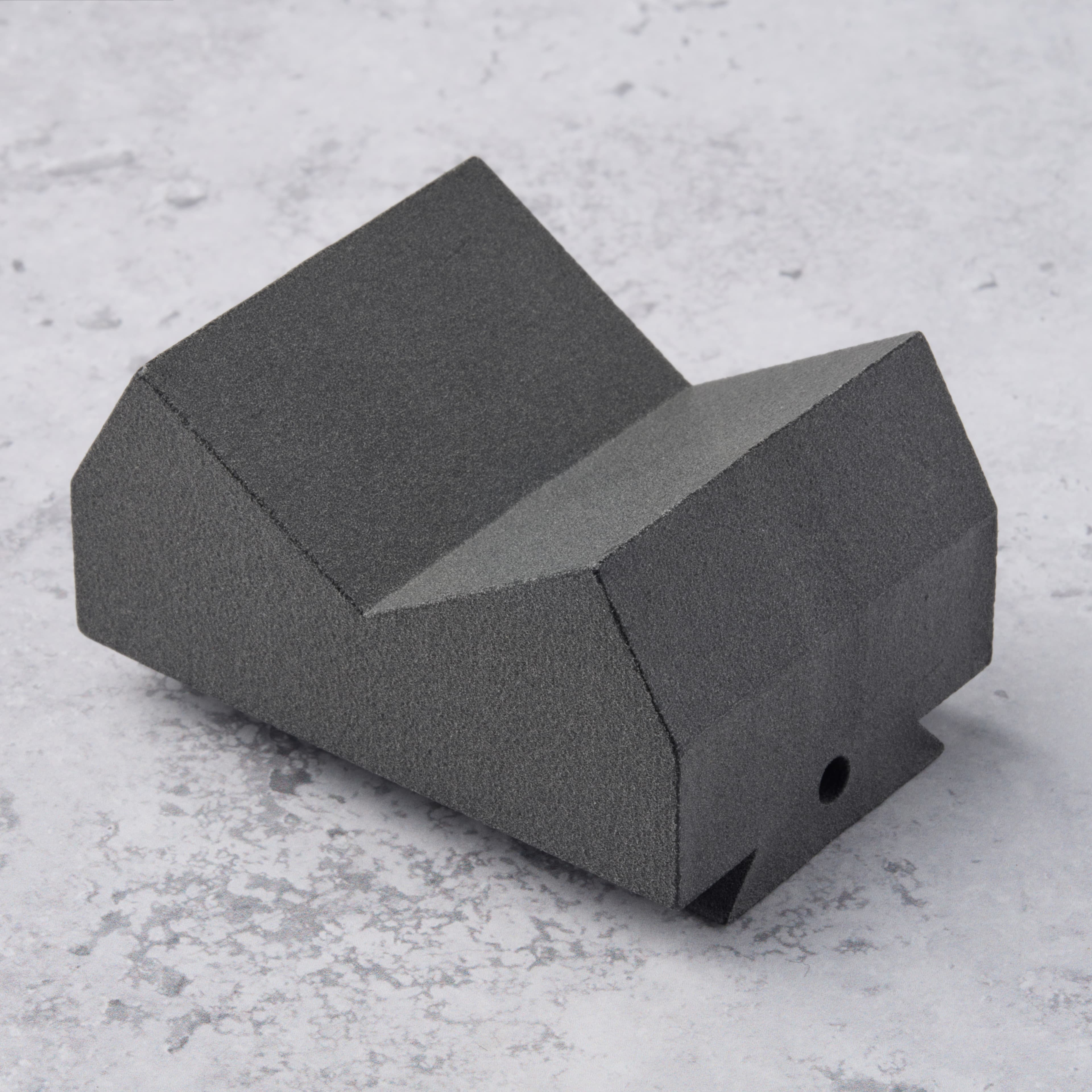

Replace and improve molded or machined plastics

Avoid costly tooling and shorten lead times

An easy and intuitive workflow from start to finish

Solve problems in your office and on the factory floor

Expand as the demand grows with agile manufacturing

FuseSeries

Explore Material Properties

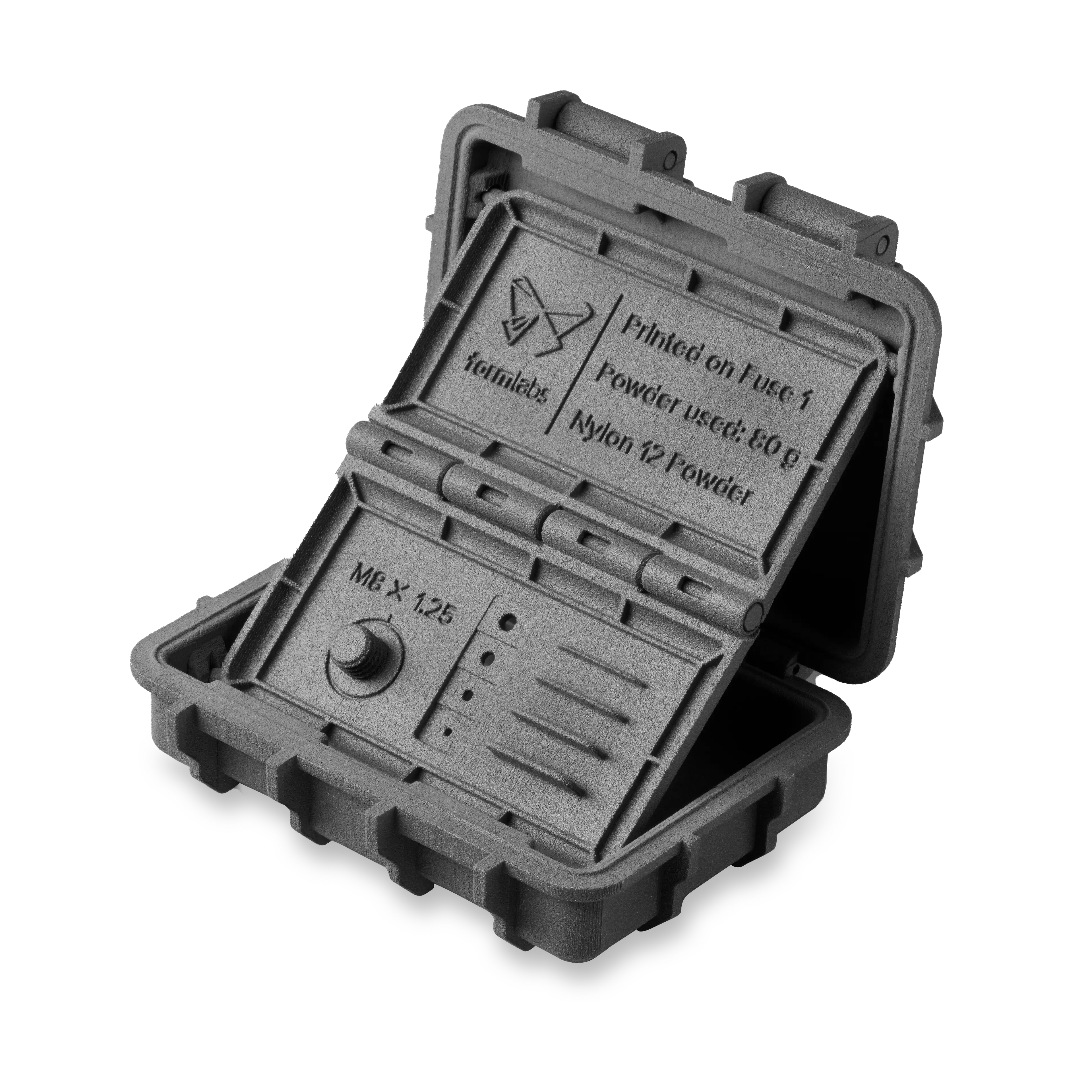

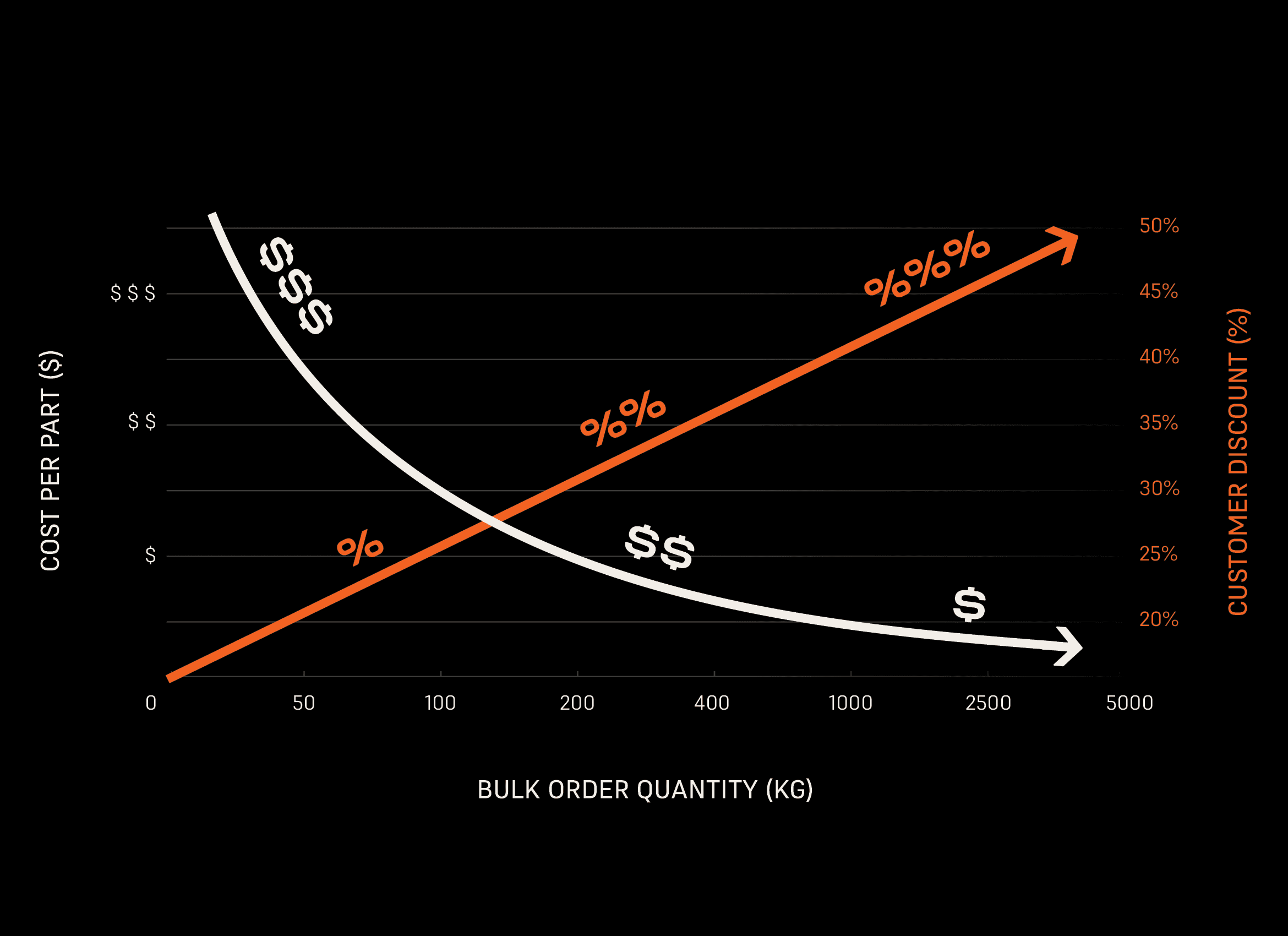

Bulk Powder Pricing for Your Lowest Cost Per Part

3D printing is now cost-effective even at higher volumes thanks to substantial volume discounts for our SLS Powders. Discounts start at 20% for customers purchasing 50 kg of powder in bulk and prices can reach as low as $45 per kilogram.

Lowest cost per part for up to tens of thousands of parts, faster than with any traditional manufacturing method.

- €10.7Fuse 1+ 30W*Nylon 11 PowderLead time: 2 day

€37.2Industrial SLS (Outsourced)Lead time: 10 day€228.74Machining Cost (Outsourced)Lead time: 13 day€9.39Injection Molding (Outsourced)Lead time: 5 weeks

€37.2Industrial SLS (Outsourced)Lead time: 10 day€228.74Machining Cost (Outsourced)Lead time: 13 day€9.39Injection Molding (Outsourced)Lead time: 5 weeks

- €9.03Fuse 1+ 30W*Nylon 12 PowderLead time: 2 day

€29.91Industrial SLS (Outsourced)Lead time: 6 day€102.05Machining Cost (Outsourced)Lead time: 20 day€9.35Injection Molding (Outsourced)Lead time: 6 weeks

€29.91Industrial SLS (Outsourced)Lead time: 6 day€102.05Machining Cost (Outsourced)Lead time: 20 day€9.35Injection Molding (Outsourced)Lead time: 6 weeks

- €0.87Fuse 1+ 30W*Nylon 12 PowderLead time: 2 day

€4.22Industrial SLS (Outsourced)Lead time: 6 day€496.08Machining Cost (Outsourced)Lead time: 10 day€9.09Injection Molding (Outsourced)Lead time: 5 weeks

€4.22Industrial SLS (Outsourced)Lead time: 6 day€496.08Machining Cost (Outsourced)Lead time: 10 day€9.09Injection Molding (Outsourced)Lead time: 5 weeks

- €6.93Fuse 1+ 30W*Nylon 12 PowderLead time: 2 day

€39.53Industrial SLS (Outsourced)Lead time: 9 day€881.46Machining Cost (Outsourced)Lead time: 20 day€9.29Injection Molding (Outsourced)Lead time: 6 weeks

€39.53Industrial SLS (Outsourced)Lead time: 9 day€881.46Machining Cost (Outsourced)Lead time: 20 day€9.29Injection Molding (Outsourced)Lead time: 6 weeks

*Powder discount 10%

Scalable and Affordable: Expand Your Fleet As Necessary, On-Demand

Affordability & Ease of Use: Get Started

Industrial power, without the industrial infrastructure — add the Fuse Series into any office or workshop environment, without breaking the bank.

Add Redundancy For Low-Risk Manufacturing

Improve and adapt with agile SLS. Respond to requests faster and easier with a flexible fabrication solution. Create single prototypes or replacements on-demand, or free up your machine shop by 3D printing thousands of parts a week.

Scale With Your Demand

Scale incrementally and grow your fleet as demand increases. Offer versatile materials or increase throughput by scaling a reliable production workflow.

INDUSTRIAL POWER, WITHOUT THE INDUSTRIAL INFRASTRUCTURE

INDUSTRIAL POWER, WITHOUT THE INDUSTRIAL INFRASTRUCTUREAffordability & Ease of Use: Get Started

Industrial power, without the industrial infrastructure — add the Fuse Series into any office or workshop environment, without breaking the bank.

Add Redundancy For Low-Risk Manufacturing

Improve and adapt with agile SLS. Respond to requests faster and easier with a flexible fabrication solution. Create single prototypes or replacements on-demand, or free up your machine shop by 3D printing thousands of parts a week.

Scale With Your Demand

Scale incrementally and grow your fleet as demand increases. Offer versatile materials or increase throughput by scaling a reliable production workflow.

1 Printer:Getting Started IMPROVE AND ADAPT WITH AGILE SLS

IMPROVE AND ADAPT WITH AGILE SLSAffordability & Ease of Use: Get Started

Industrial power, without the industrial infrastructure — add the Fuse Series into any office or workshop environment, without breaking the bank.

Add Redundancy For Low-Risk Manufacturing

Improve and adapt with agile SLS. Respond to requests faster and easier with a flexible fabrication solution. Create single prototypes or replacements on-demand, or free up your machine shop by 3D printing thousands of parts a week.

Scale With Your Demand

Scale incrementally and grow your fleet as demand increases. Offer versatile materials or increase throughput by scaling a reliable production workflow.

2 Printers:Add Redundancy SCALE INCREMENTALLY AND GROW YOUR FLEET

SCALE INCREMENTALLY AND GROW YOUR FLEETAffordability & Ease of Use: Get Started

Industrial power, without the industrial infrastructure — add the Fuse Series into any office or workshop environment, without breaking the bank.

Add Redundancy For Low-Risk Manufacturing

Improve and adapt with agile SLS. Respond to requests faster and easier with a flexible fabrication solution. Create single prototypes or replacements on-demand, or free up your machine shop by 3D printing thousands of parts a week.

Scale With Your Demand

Scale incrementally and grow your fleet as demand increases. Offer versatile materials or increase throughput by scaling a reliable production workflow.

3+ Printers:Fleet Production

Simplified Workflow

- 1

Auto-Pack, Optimize, and Organize in PreForm

With automated packing, hollowing, orienting, labeling, and more, PreForm optimizes your parts and your workflow from the first step.

- 2

Print Quickly and Reliably on the Fuse Series

Set it and forget it. Print overnight and have multiple iterations or batch production parts ready in the morning.

- 3

Unpack and Recycle Your Powder in the Fuse Sift

Depowder parts in just 10 minutes with Fuse Sift to reclaim unused powder.

- 4

Clean and Polish Your Parts With Optional Automated Media Blasting

Leverage automation with Fuse Blast and Polishing System to achieve smooth, end-use quality parts, without added labor.

- 5

Add Color, Coating, and Sophisticated Surfaces With Advanced Post-Processing Techniques

Create high-performance, end-use parts with smooth surface finishes or vibrant colors through coating, dyeing, painting, smoothing, and more.

- 6

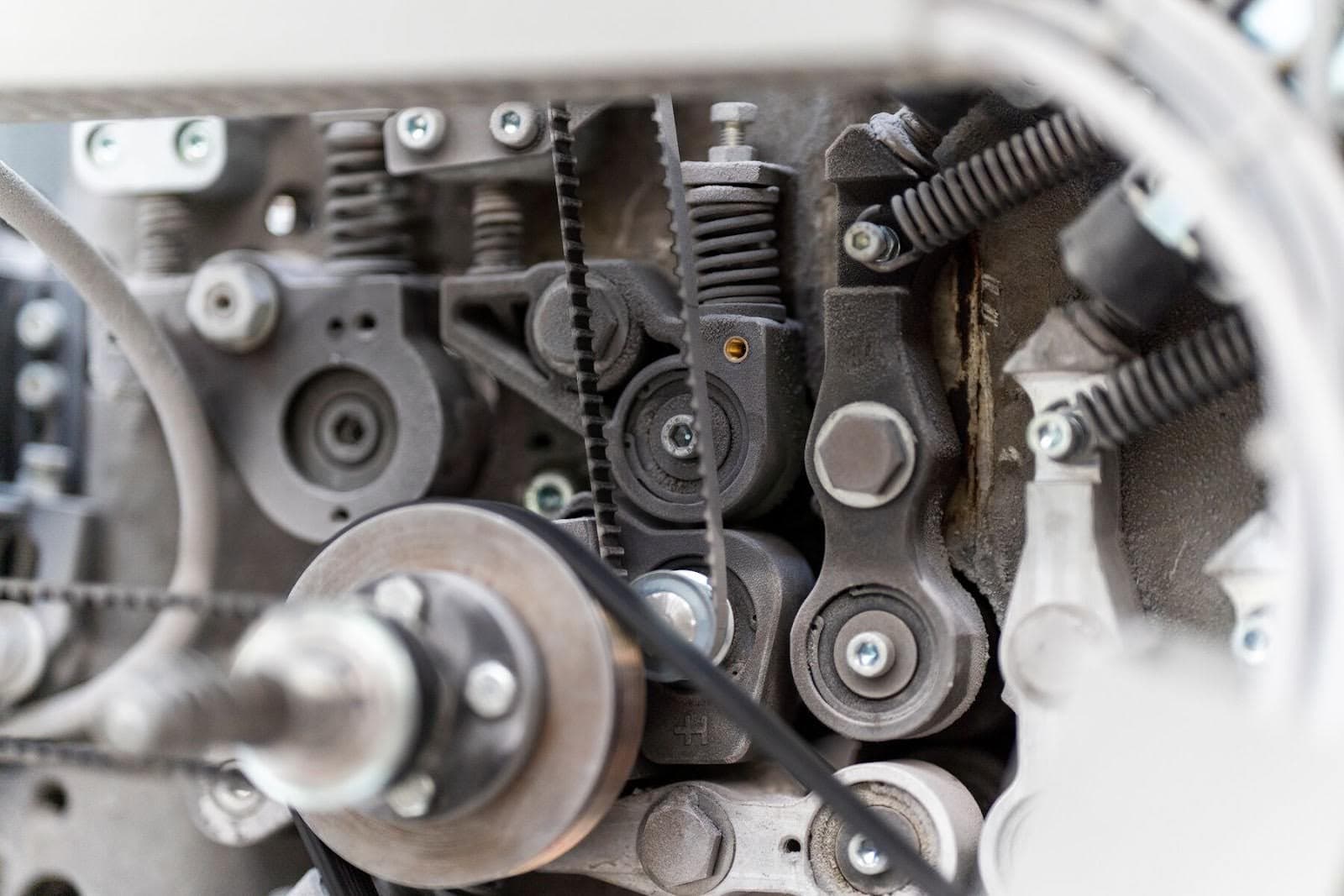

Easy, Quick Maintenance Keeps Your Focus on the Parts, Not the Printers

Maintain near-constant uptime with an on-screen checklist for your 10 minutes of between-print maintenance and cleaning.

Solve problems, fast. Move quickly through iterative changes and eliminate production bottlenecks with strong, functional parts.

The proliferation of drone manufacturers and their success in gaining a foothold in a competitive field can be partly attributed to the accessibility and power of modern manufacturing methods, namely 3D printing.

The proliferation of drone manufacturers and their success in gaining a foothold in a competitive field can be partly attributed to the accessibility and power of modern manufacturing methods, namely 3D printing.

Brose prints hundreds of thousands of end-use car parts for brands like BMW, Volvo, and Volkswagen on their three Fuse Series printers using Nylon 12 GF Powder.

Your 3D printers should be as agile, accurate, and scalable as the drones you manufacture. Companies like Boresight, Nextech, Skydio, Heliguy, and more, use Fuse Series printers to get their models in the air ahead of a competitive field.

Factories that rely on heavy machinery can’t afford to wait on replacement parts — every minute of downtime can mean thousands of dollars lost. Heidelberg eliminates downtime by printing on-demand replacement components on their Fuse Series printer in TPU 90A Powder.

Watch the Video

See More Manufacturing and Industrial Applications

Radio Flyer relies on their Fuse Series printers for functional products that go home with families for consumer testing. With aesthetics that match injection molding and the same material properties as the final parts, the Fuse helps consumer products reach market faster.

Learn More

See More Consumer Product Applications

NOAA uses SLS 3D printed parts to customize their coral study tanks. Printing parts in-house is faster and more affordable than ordering components off the shelf — so NOAA can scale their research significantly while staying within their budget.

Kriwat uses their fleet of Fuse Series printers to make thousands of customized insoles for their patients. 3D printing has helped them move from a messy, time-consuming manual workflow and enabled them to offer faster, more affordable case to their patients.

Explore SLS Webinars: User Stories, Tutorials, and More

Selective Laser Sintering

The Power Behind Fuse 1Selective Laser Sintering

The Power Behind Fuse 1The FUSe 1+ 30W Ecosystem

Complete Your 3D Printing Experience

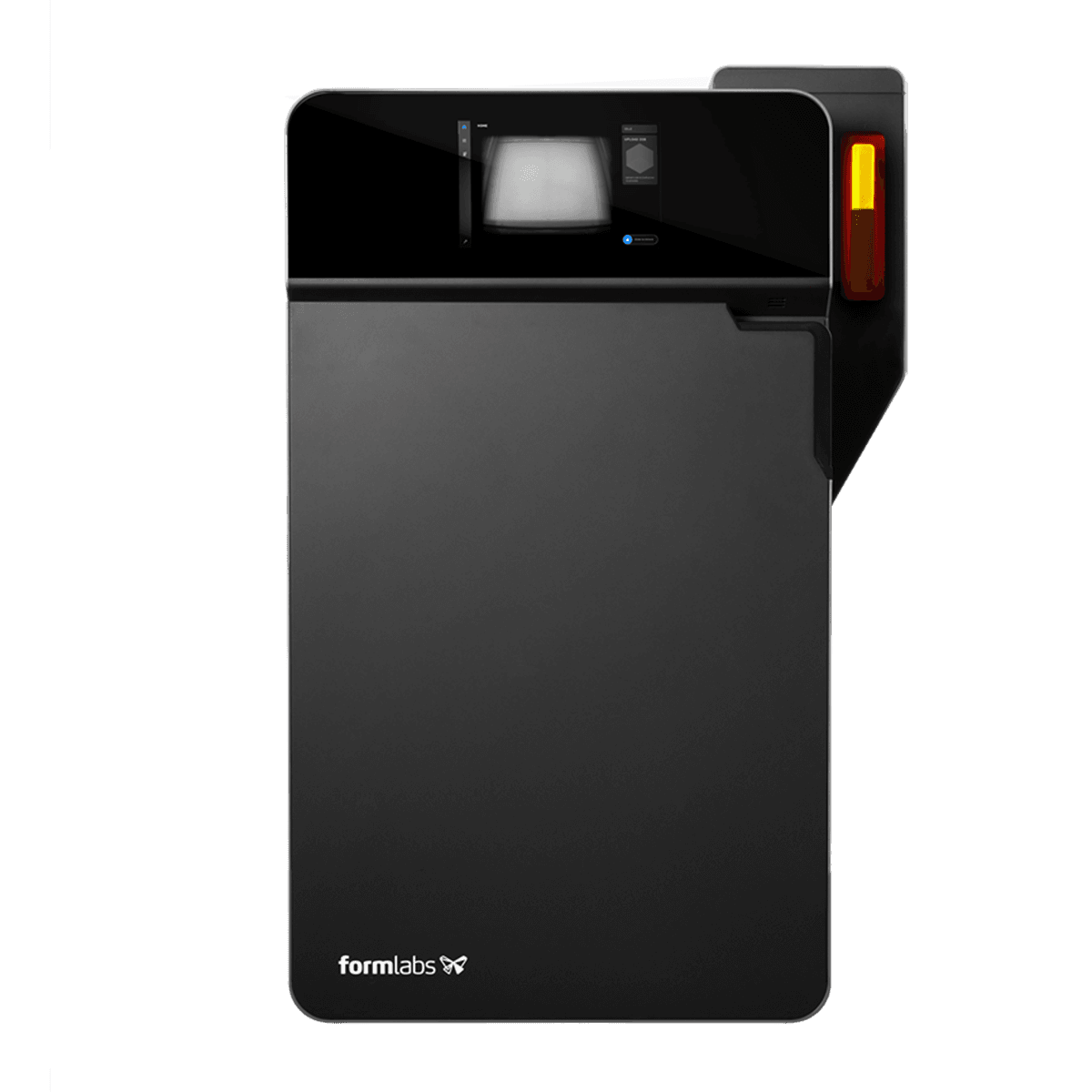

Fuse 1+ 30W

Fuse Blast

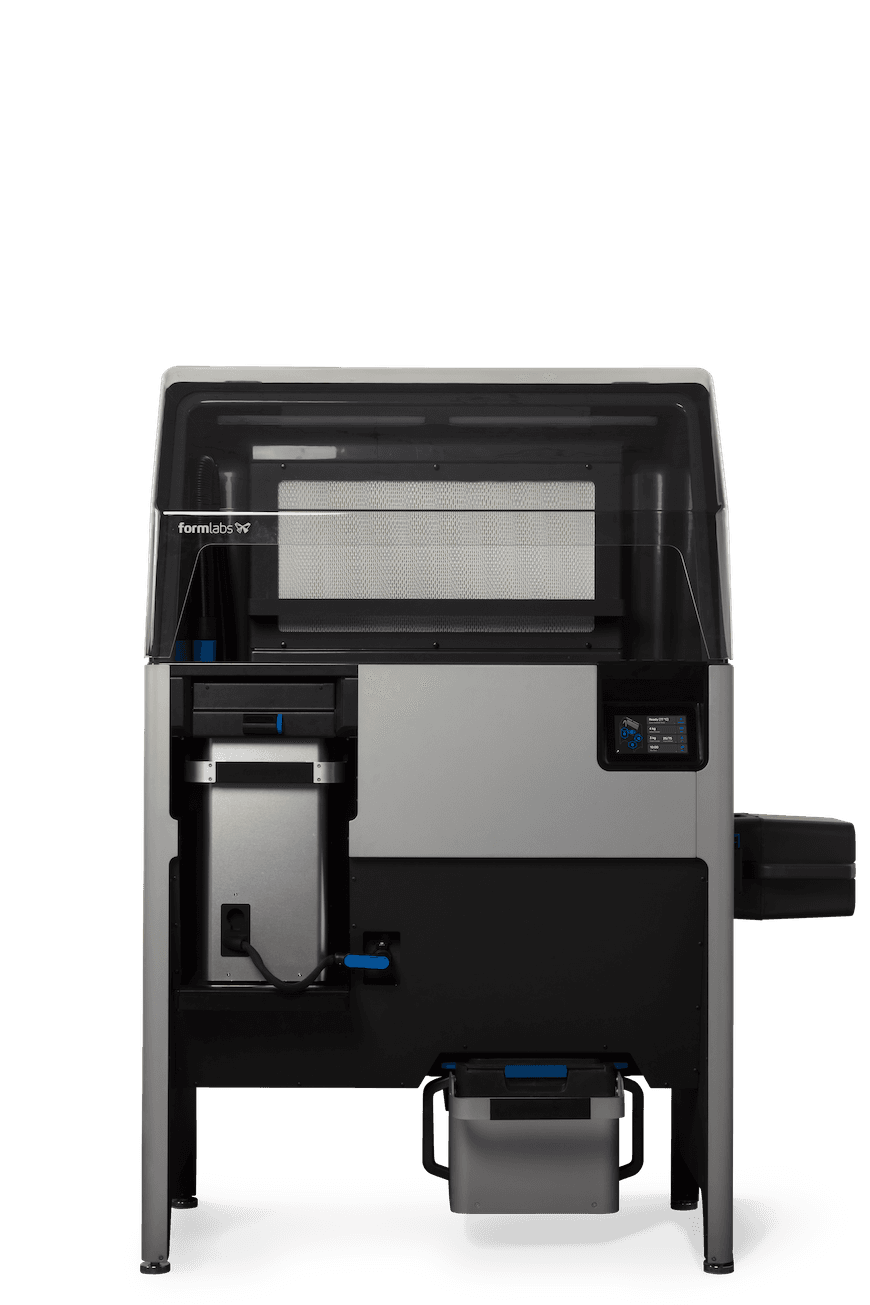

Fuse Sift