3D Print Accurate, Low Ash Patterns for Investment Castings Directly in House

Formlabs stereolithography (SLA) 3D printers and Clear Cast Resin enable direct production of industrial investment casting patterns in-house. This workflow reduces costs, decreases turnaround times, and improves flexibility for prototyping as well as the production of small to medium batches and complex geometries.

Why Go Digital?

Lower Costs

Faster Turnaround Time

Design Freedom

Clear Cast Resin: Accurate and Reliable Casting Material

See Also

Precision and Cost-Efficiency in Casting: Leveraging 3D Printing for Metal Parts

Industrial Investment Casting With 3D Printed Patterns Using Formlabs Clear Cast Resin

Built from Experience and Validated by the Casting Industry

Formlabs has produced industry-leading investment casting resins for large, third-party SLA printers at its state-of-the-art manufacturing facility in Ohio, and leveraged this experience in developing Clear Cast Resin for its own SLA printers.

To validate Clear Cast Resin, Formlabs worked with the Foundry 4.0 Center of the University of Northern Iowa, as well as several industrial foundries, service bureaus, and art foundries.

Mechanical and Burnout Properties

| Ultimate Tensile Strength | 65 MPa |

|---|---|

| Tensile Modulus | 2.8 GPa |

| Flexural Modulus | 2.2 GPa |

| Thermal Expansion, -30-140°C | 94.8 μm/m/°C |

| Ash Content | <0.20% |

| Antimony | <10 ppm |

| Detected Transition Metals (>10 ppm) | Al, Cu |

| High Concentration Transition Metals (>50 ppm) | None |

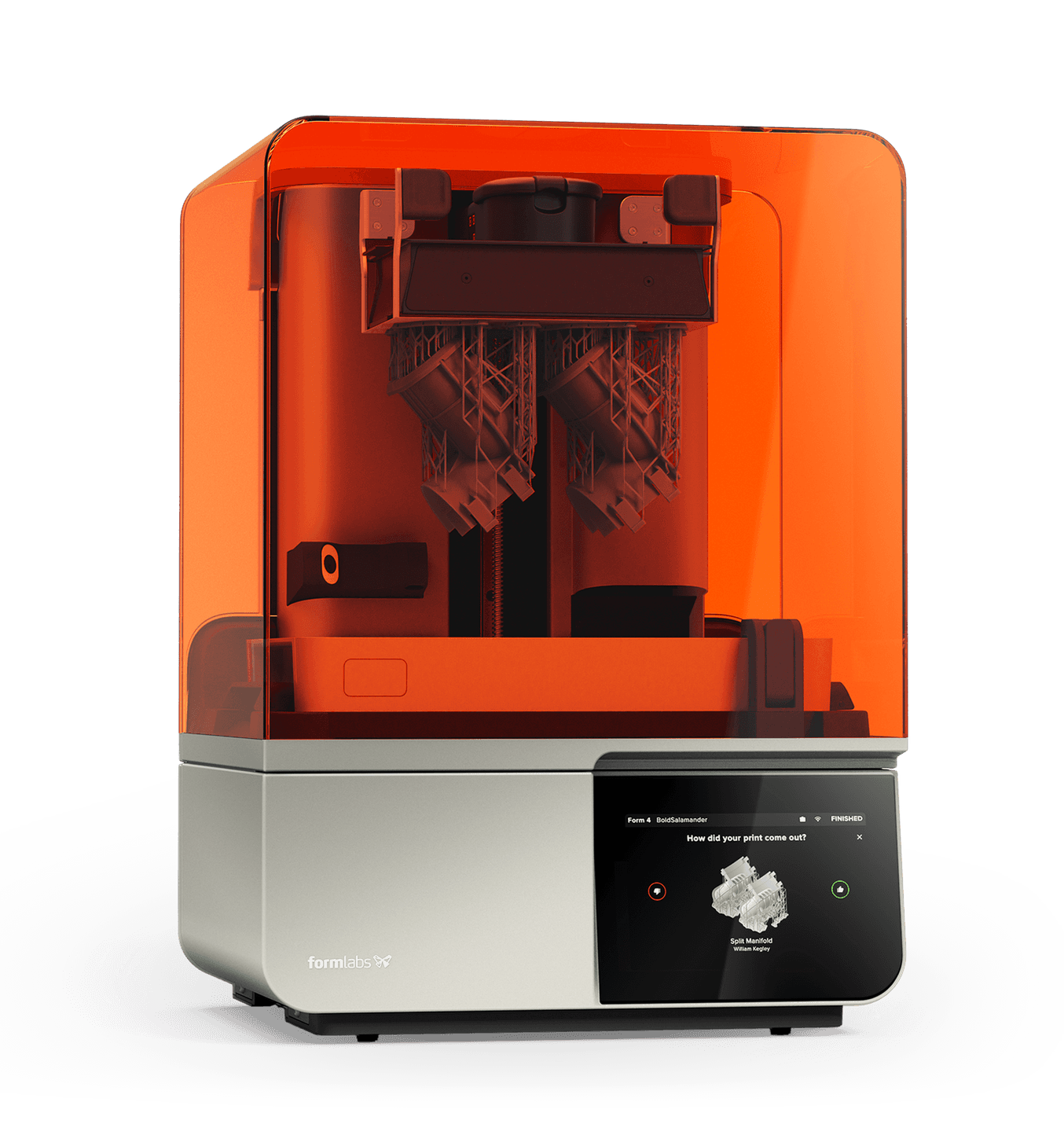

Form 4: Blazing Fast Desktop SLA 3D Printer

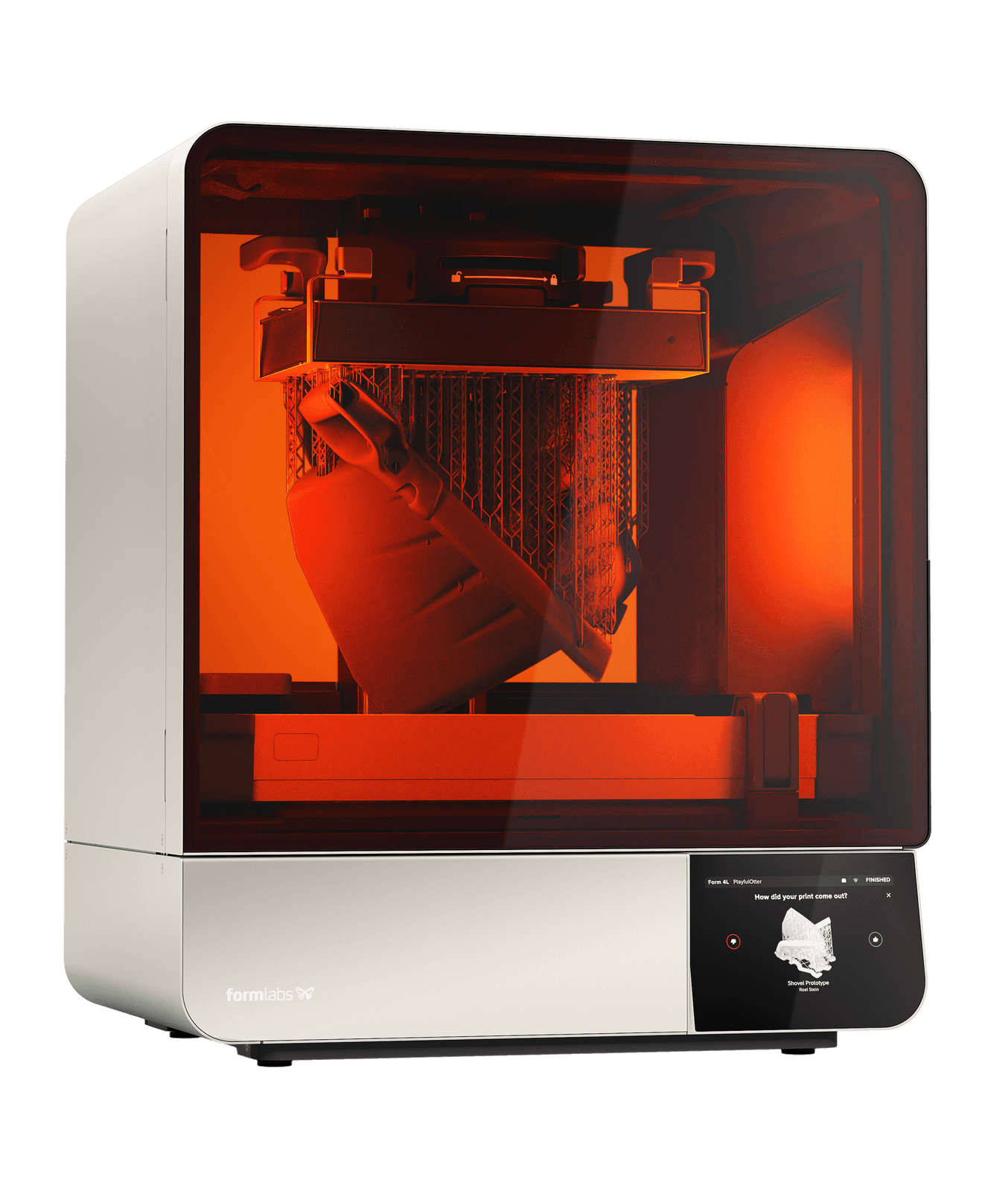

Form 4L: Blazing Fast Large-Format SLA 3D Printer

Eliminate Tooling

Directly 3D printing patterns eliminates the wax molding step, and enables a faster workflow, so that you can have a pattern in hand within 24 hours. Free up CNC capacity and skilled operators’ time by 3D printing investment casting patterns directly.

Curious to see how much you can save? Contact our team to run the numbers specifically for your parts and unique workflow.

| Part | Complex Impeller Part | Simple Pump Impeller - 12” |

|---|---|---|

| Volume of Production | 50 parts | 50 parts |

| Alternative Tooling Method | Wax injection with metal tooling, soluble wax cores, and wax chills | Wax injection with metal tooling |

| Alternative Tooling Cost | $60,000 | $11,000 |

| Cost 3D Printed | $78/part | $30/part |

| Lead Time Savings | 14 weeks | 8 weeks |

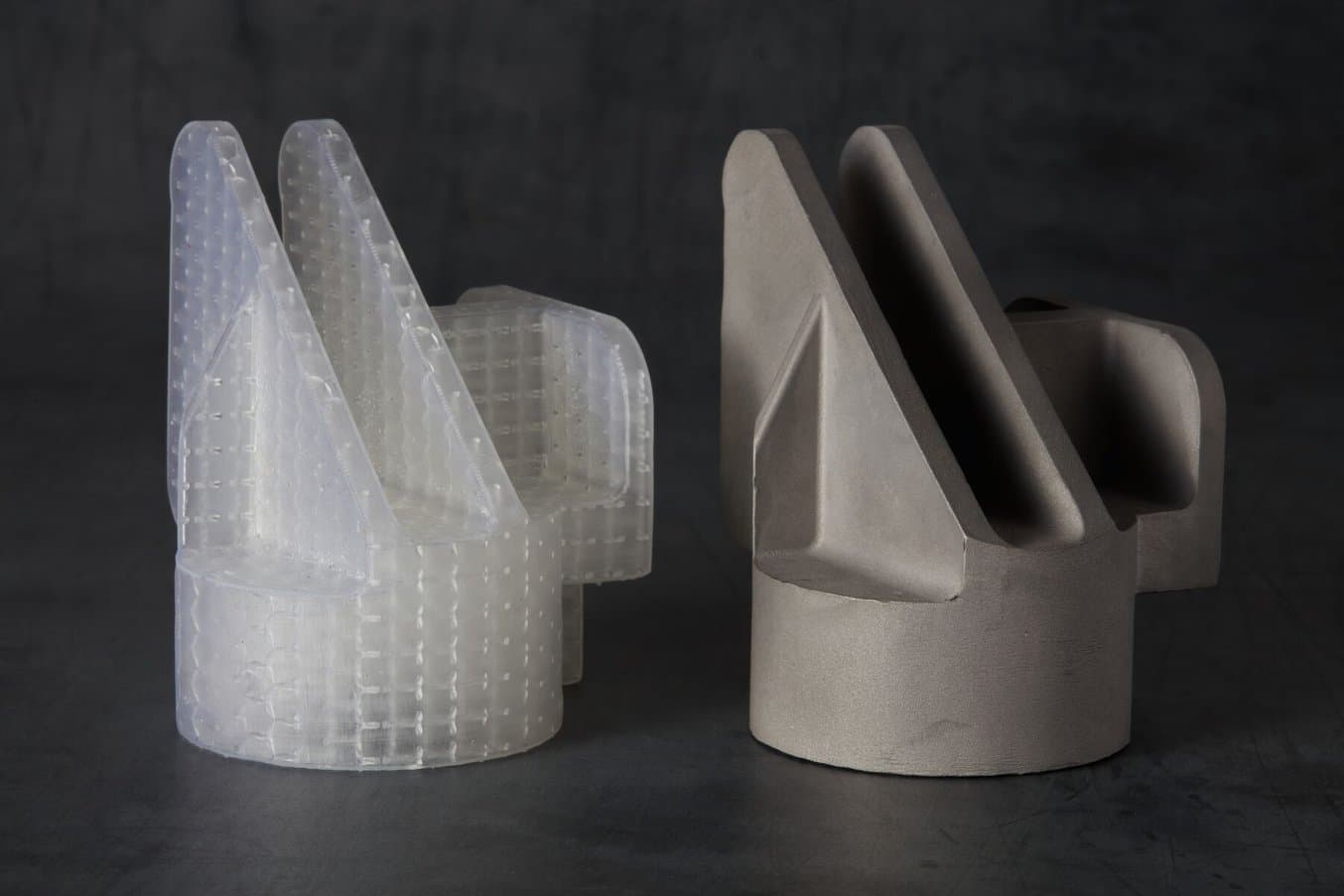

Investment Casting With 3D Patterns: Process Overview

1. Pattern Design

Design the part in CAD software. Hollow your part and build an internal lattice structure. Find recommended steps and settings in our white paper.

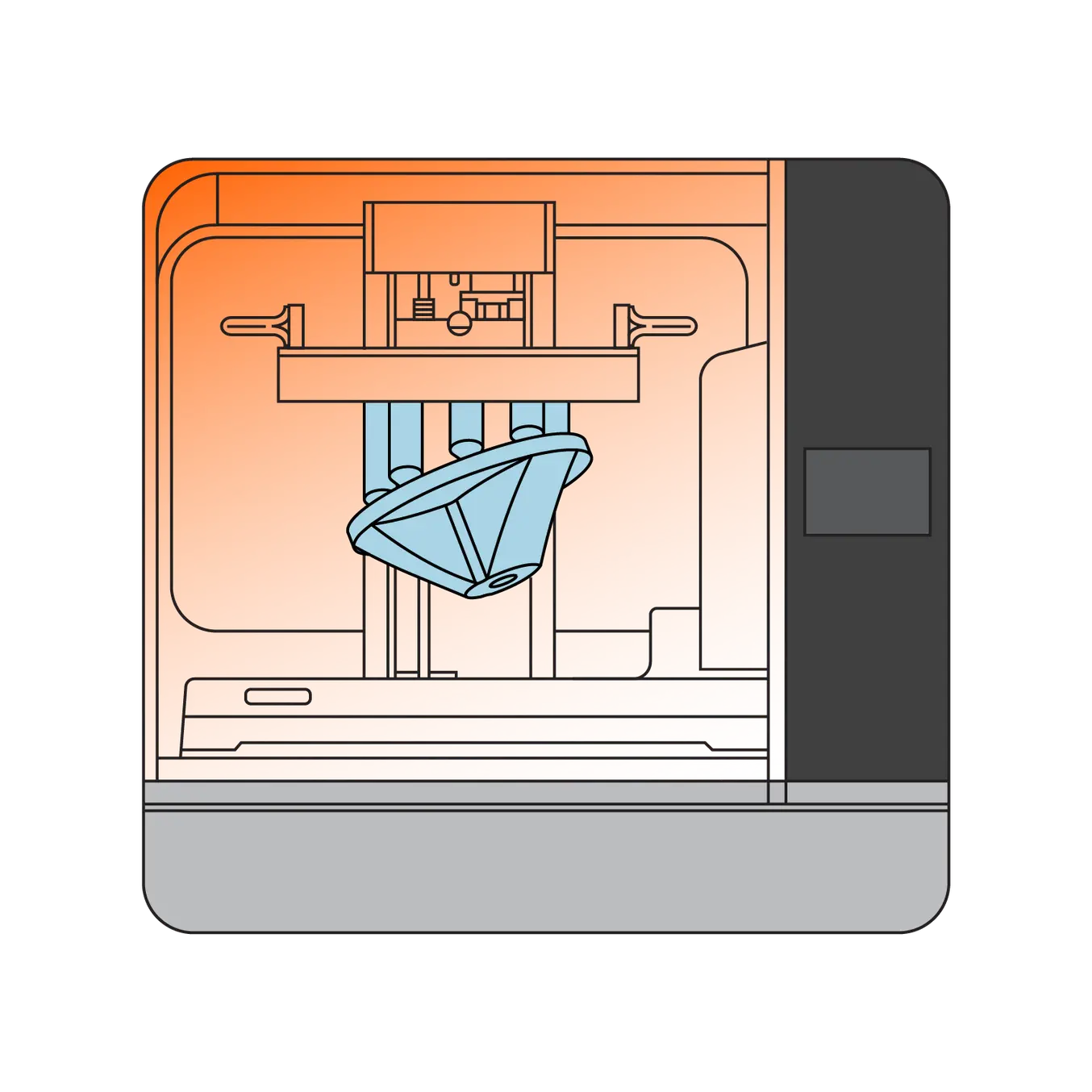

2. Pattern 3D Printing

3D print on Form 3L or Form 4 with Clear Cast Resin following Formlabs’ instructions.

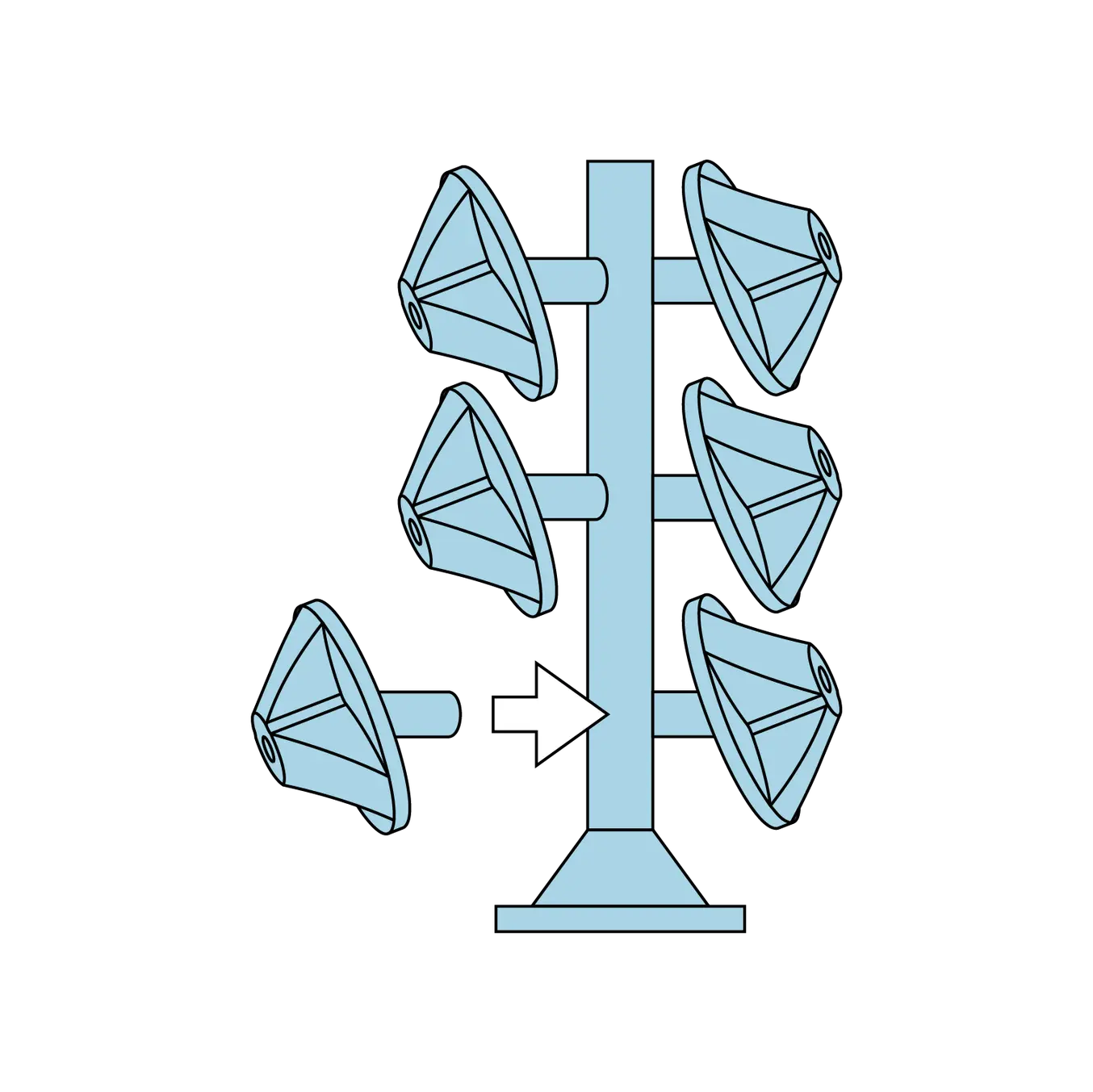

3. Pattern Preparation

Fill the vents and drain holes using standard foundry wax then follow your usual process for pattern assembly.

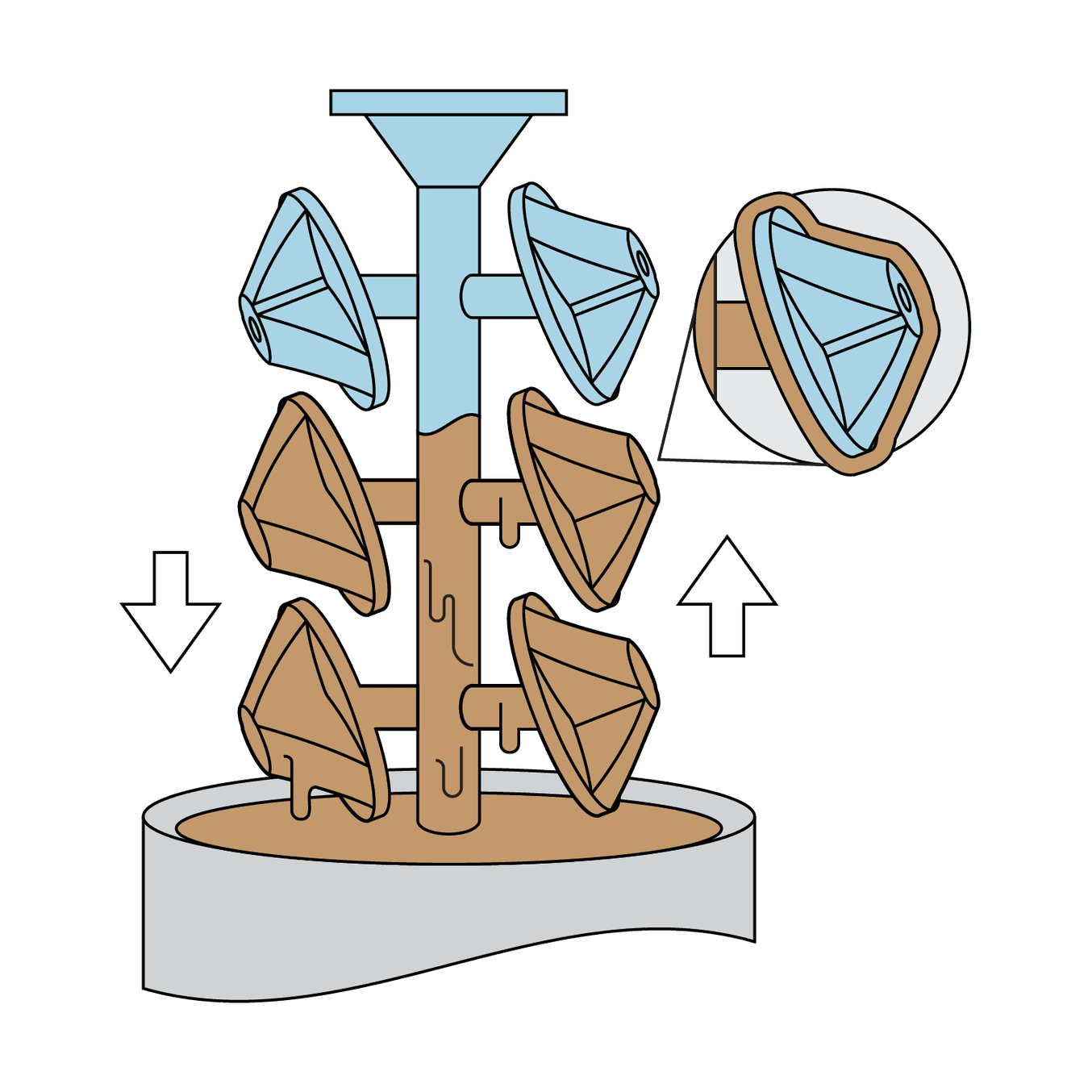

4. Shell Making

Follow your usual recipe and process to dip the tree in the slurry. Some foundries alter their slurry or add dips to reduce cracking.

5. Pattern Burnout

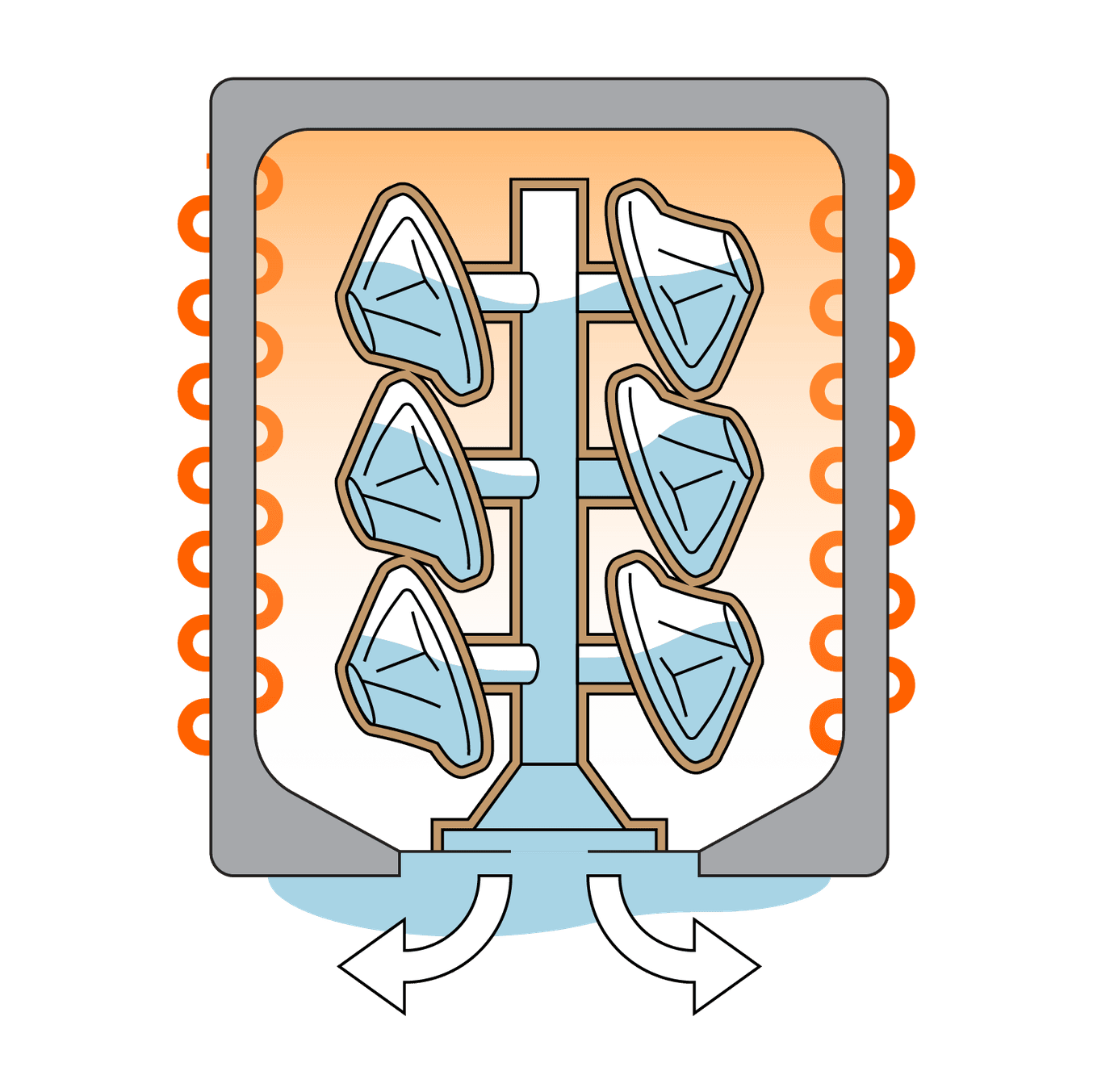

Follow your usual process. Flash fire is a standard method that can be employed. It heats the parts in a furnace between 700 °C and 900 °C (1,300 °F and 1,650 °F) for 2 hours.

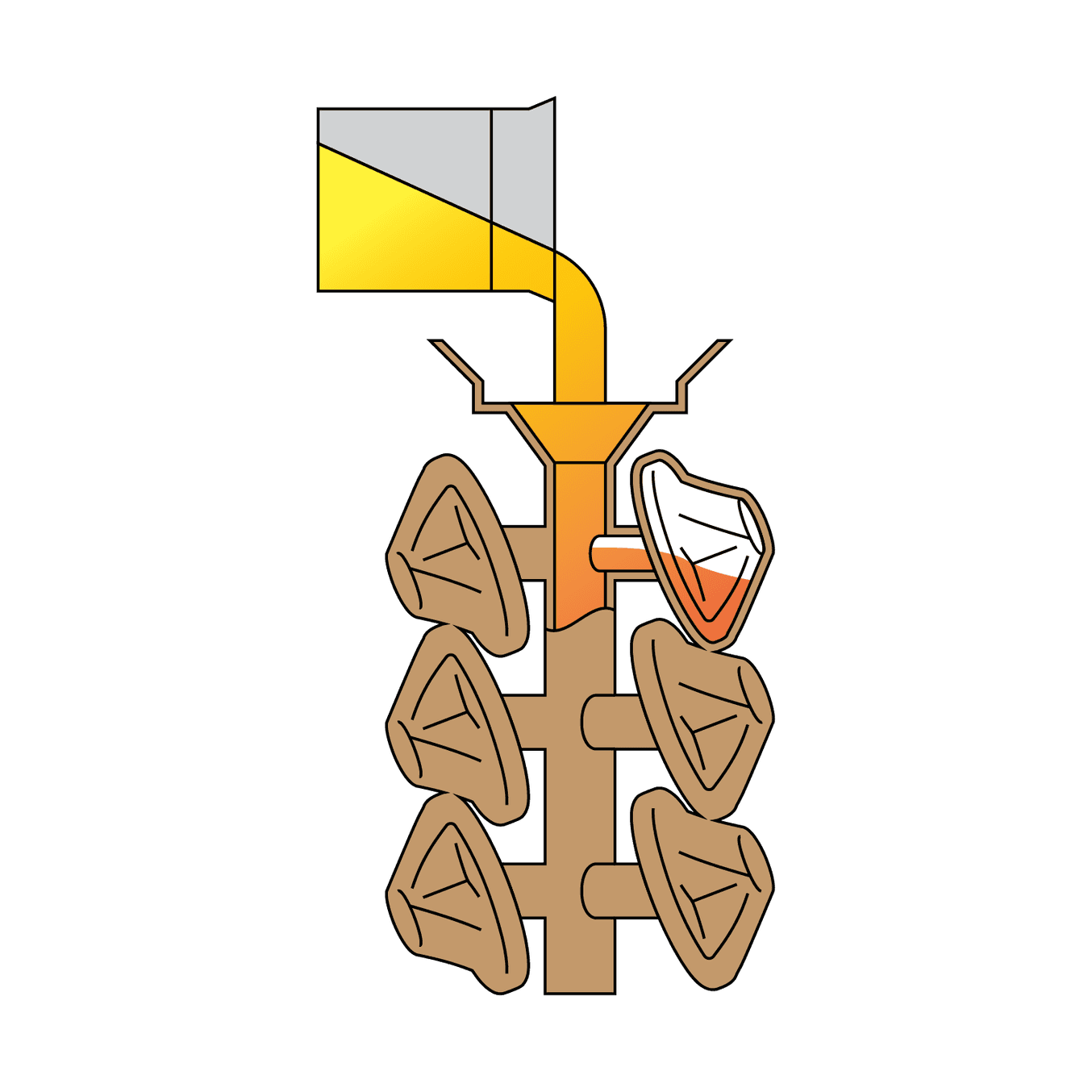

6. Casting

Follow your usual process. Partner foundries cast with success bronze, brass, aluminum (A356), 6-4 titanium, 4140 and 8620 steels, and 17-4 and 316 stainless steels.

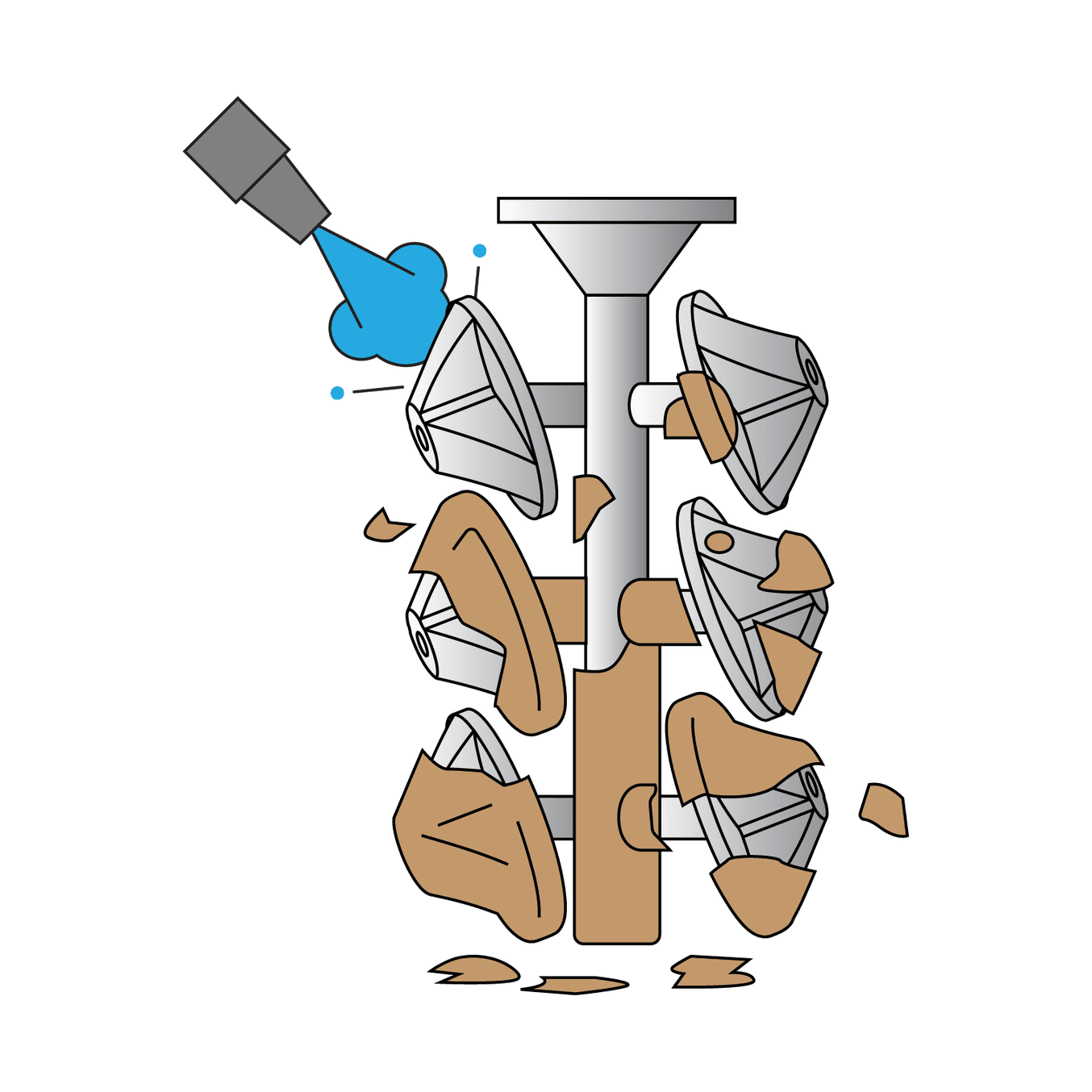

7. Shell Removal

Let the metal cool then remove the ceramic shell using a water or sandblaster.

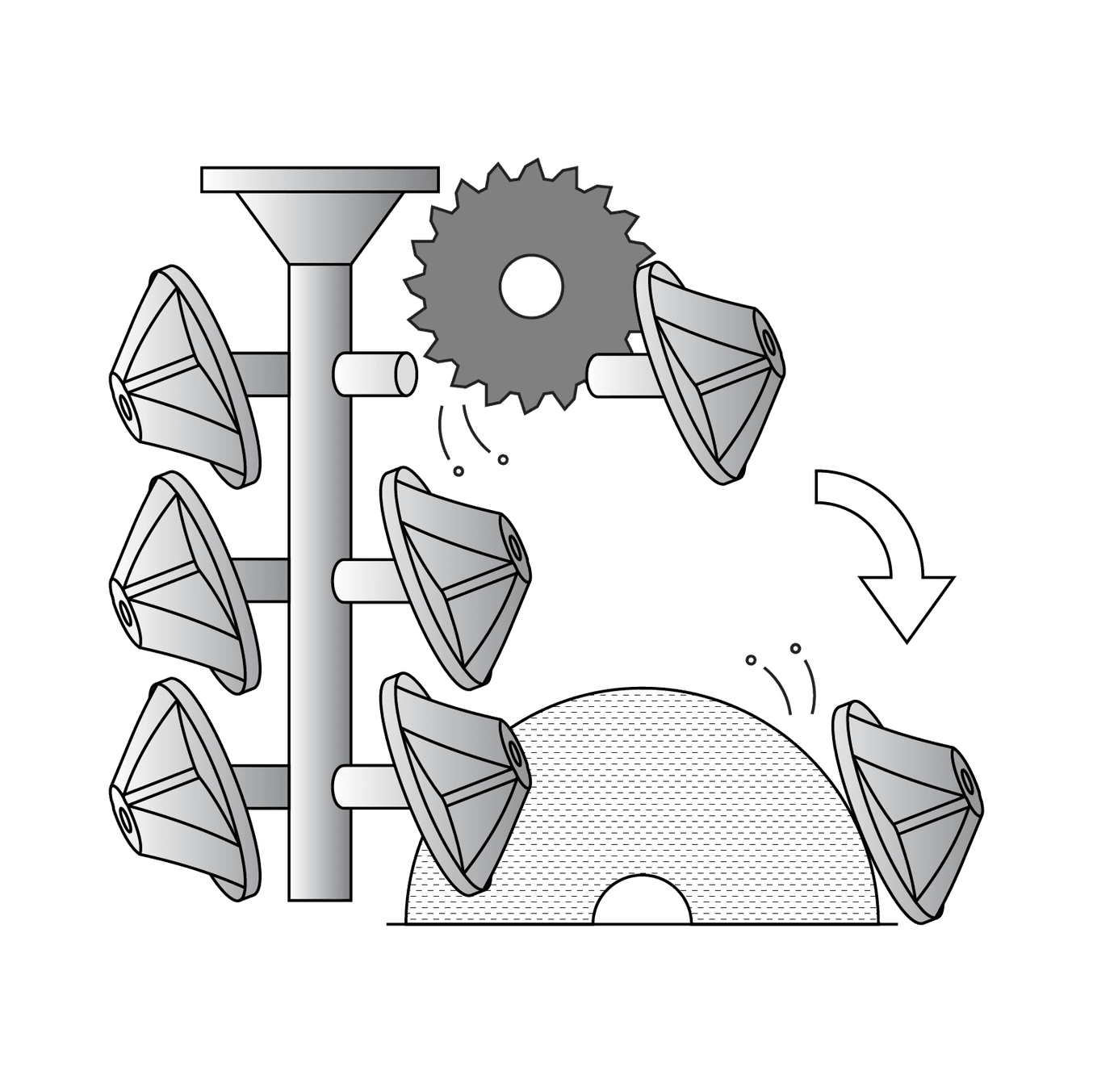

8. Cutting Off

Separate the parts from the tree using a bandsaw or other tools.

Get Started With 3D Printing Investment Casting Patterns

Get in touch with our 3D printing experts for a 1:1 consultation to find the right solution for your business, receive ROI analyses, test prints, and more.