“In the marine industry, many yacht components are unique to a model or even a single build. We might make a part a hundred times, or only once — exactly the kind of high-mix, low-volume demand where 3D printing excels.”

Winston Zeberlein, Advanced Manufacturing Engineer, Viking Yachts

Six years ago, Winston Zeberlein joined Viking Yachts to bring 3D printing into the design and engineering departments. While traditional fabrication methods remain essential, highly custom yacht parts could take a week or more and hundreds of hours of skilled labor. Today, with the speed, finish, and material performance of the Form 4L, many of those parts — especially small fiberglass molds and tooling — can be produced in a single day with a fraction of the labor.

Building yachts presents two key challenges: lots of one-off customizations, and a final product that must withstand harsh marine conditions including exposure to UV, water, salt, and heat. With Form 4L, Zeberlein has found time and material savings by printing the following:

-

Prototypes, including for stainless steel investment casting.

-

Fiberglass molds and tooling, such as resin-printed inserts used to form small features in composite parts.

-

End-use parts in Tough 1500 Resin including custom brackets, mounts, and hardware that integrate seamlessly with client-specified features like sound systems, navigation equipment, and fishing accessories.

Viking Yachts is known for its high level of customization — no two boats are the same. Tough 1500 Resin makes it easy to integrate one-off hardware or equipment selections with minimal post-processing, while delivering a finish that looks and feels like an injection-molded part.

Talk to Our Sales Team

Whether you need to prototype at speed, or are producing end-use parts, we’re here to help. The Formlabs Sales team is composed of dedicated specialists who know exactly how to support you and your company's needs.

Form 4L: No Tinkering Required

Zeberlein got his first 3D printer in 2013 and has been involved in additive manufacturing ever since. A self-described tinkerer, he started by tweaking settings and repairing machines.

“The more involved I get in my role at Viking, the less time I have to tinker and fix printers. That’s why I appreciate Formlabs printers — right out of the box, they just work. I’ve never had a failed print or any issues. I click print and know I’ll get a quality part.”

Winston Zeberlein, Advanced Manufacturing Engineer, Viking Yachts

Reliability, speed, size, resolution, and material performance were all important factors for selecting a printer that would streamline processes at Viking Yachts. Additionally, Zeberlein says that printers larger than Form 4L jump up drastically in price, and often use laser-based stereolithography, which can take many more hours to print. Form 4L was a Goldilocks of speed, build volume, and cost.

Dams and Knockouts for Fiberglass Molds

“The Form 4L benefits boat manufacturers of every size — from custom builders making one or two boats a year to large yards producing hundreds a month. With its low barrier to entry, it’s accessible to any builder, and every builder needs fiberglass dams for their molds. 3D printing has game-changing potential for the industry.”

Winston Zeberlein, Advanced Manufacturing Engineer, Viking Yachts

Dams, also called knockouts, form specific features in a fiberglass mold, creating space for elements like windows, underwater lights, and more. Traditionally, they are made from foam or HDPE, either shaped by hand or cut on a CNC. Foam parts require fairing with high-build primer, followed by sanding and polishing, a process that can take two to four days depending on complexity. With Form 4L, “a part can take four to eight hours to print and 30-45 minutes of polishing. In one workday, we can have a finished part ready for use,” says Zeberlein.

Dams printed with Black Resin V5 are highly polished prior to use.

A polished dam (left) compared to an unpolished dam (right) both printed with Black Resin V5.

Once dams are polished, they’re added to the fiberglass mold.

Dams are printed in either Black Resin or Tough 1500 Resin depending on how many times the part will be used. “The Black Resin polishes a little bit easier because it's slightly harder. So, for one-off parts, the polishing goes quicker, but it is more brittle. For a part that lives in a production environment where it might be hammered out or dropped, Tough 1500 Resin holds up really well.”

Robust End-Use Parts With Tough 1500 Resin

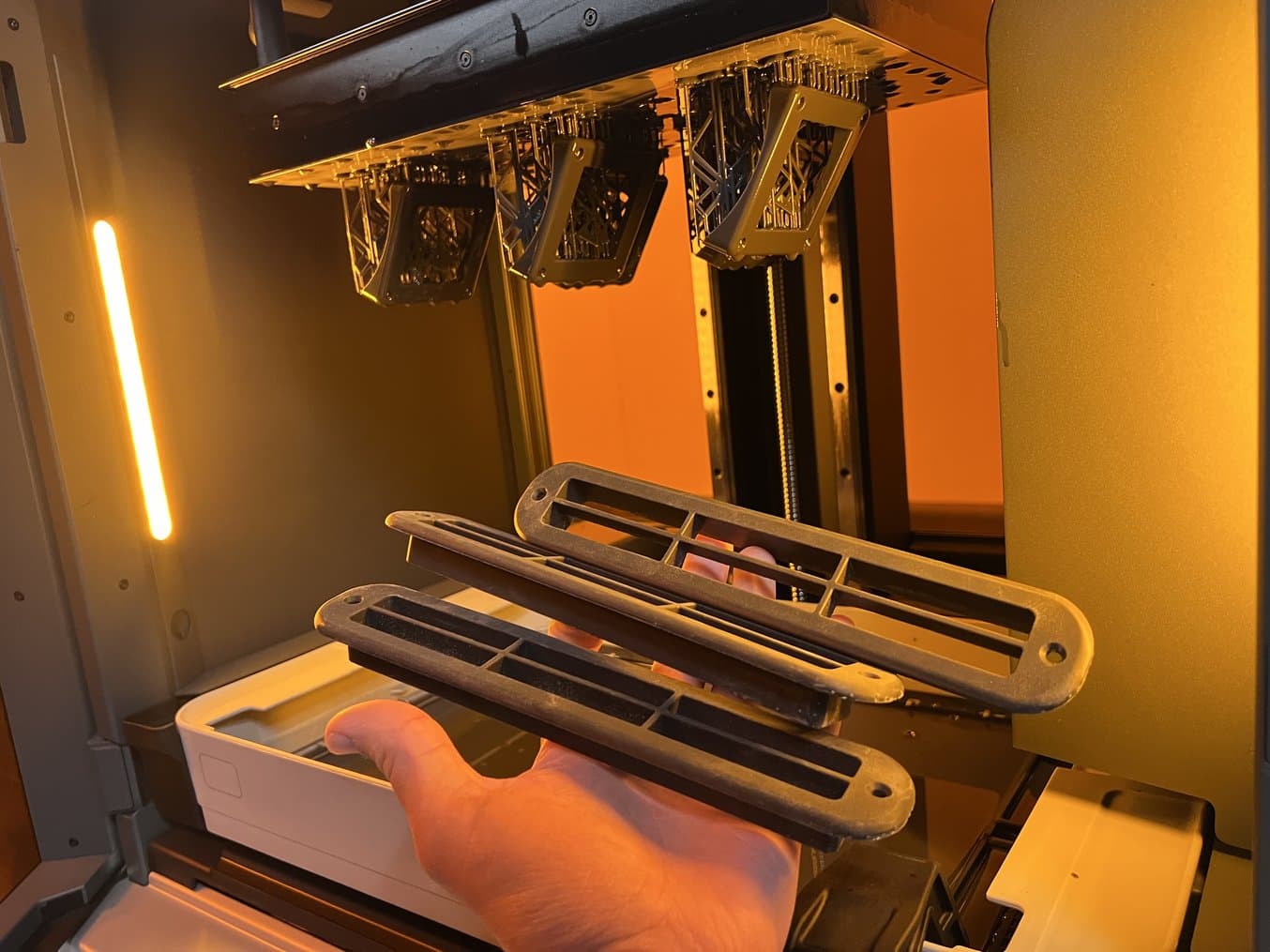

End-use parts printed in Tough 1500 Resin on Form 4L, including electrical switch bezels (on build platform) and AC vents.

“Before Tough 1500 Resin, I really was careful about doing an end-use resin part. Tough 1500 Resin really helped me replace the filament printers because ASA is UV resistant. I was using those filament parts that we'd have to put a lot more sanding work into and then paint. Tough 1500 Resin gave me the confidence to start putting out some of those parts.”

Winston Zeberlein, Advanced Manufacturing Engineer, Viking Yachts

Zeberlein started 3D printing at Viking Yachts with a filament 3D printer. While the ASA material held up to UV exposure, it required a lot of labor to sand each part before painting to match surrounding the boat parts.

The fine surface quality of parts printed with masked stereolithography (MSLA) on the Form 4L requires minimal sanding and polishing, making it easier to achieve an injection-molded appearance. With the release of Tough 1500 Resin, Zeberlein could access a resilient material with strength, stiffness, and toughness comparable to polypropylene (PP), offering exceptional resistance to fractures, impacts, and shattering. In his experience, parts printed with Tough 1500 Resin withstand both drops and repeated tapping without damage.

“I’m making one-off custom parts that look like they were injection molded — that’s the extra Viking touch, something you can take pride in.”

Winston Zeberlein, Advanced Manufacturing Engineer, Viking Yachts

End-use parts printed with Tough 1500 Resin are painted to color-match the yacht, with the paint also acting as UV protection. Since the release of the resin, Zeberlein has also been doing some UV exposure testing with uncoated, unpainted parts, to see how Tough 1500 Resin holds up to the elements. At the time of writing, Zeberlein’s parts have been in the sun for over four months with no signs of UV damage.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.

Industry Impact

“You not only have to have someone that's very talented and knows how to use equipment and tools, you also have to have someone that cares and takes pride in the work. It’s not just skilled labor, you need passionate skilled labor to make these parts.”

Winston Zeberlein, Advanced Manufacturing Engineer, Viking Yachts

Fabricating custom boat parts using traditional methods requires skilled labor and long timelines. Like other industries, the adoption of 3D printing has made it easier and faster to prototype these parts. But when it comes to end-use production, while 3D printing is easier, marine applications require materials that can withstand not just impact and use, but also exposure to the elements.

Tough 1500 Resin is one of these materials. For Zeberlein, the mechanical properties have empowered the direct 3D printing of end-use parts for custom yachts, all in a fraction of the time of traditional methods of production.

3D printed molds can shorten timelines, save on material waste, and optimize how skilled labor is allocated.

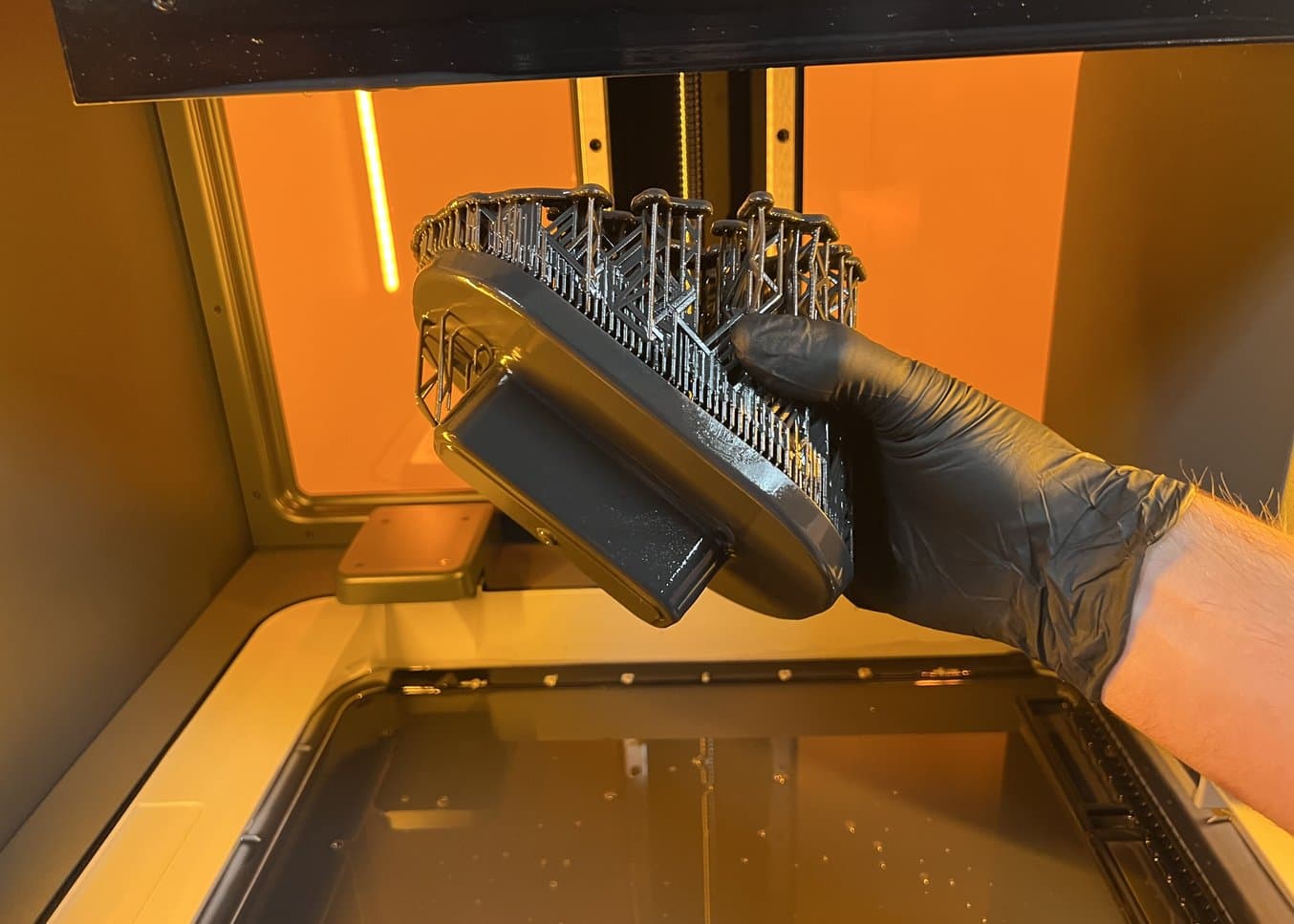

This fiberglass mold is printed in Tough 1500 Resin.

Zeberlein sees the printing of end-use parts and dams for molds as having huge implications for the marine industry: shortening timelines, saving on material waste, and helping those who are skilled and passionate about their work optimize their time and labor.

Request a free sample part to evaluate Formlabs materials for yourself. To start printing, explore Form 4L or contact sales.