Formlabs Showcases New Large-Format 3D Printer and Materials at Virtual Engineering Week

Virtual Engineering Week (VEW) unites the global design, engineering, and manufacturing communities with keynotes, panel discussions, live Q&As, and virtual exhibitor booths. The digital event recently ended.

Formlabs was pleased to present two sessions at VEW. First, Form 3L Product Manager Kyle McNulty led a session on the Form 3L, our new large-format low-force stereolithography (LFS) 3D printer, covering the following topics:

- Giving an overview of stereolithography (SLA) technology.

- Diving into the LFS workflow.

- Giving an overview of the Form 3L and going through our materials library.

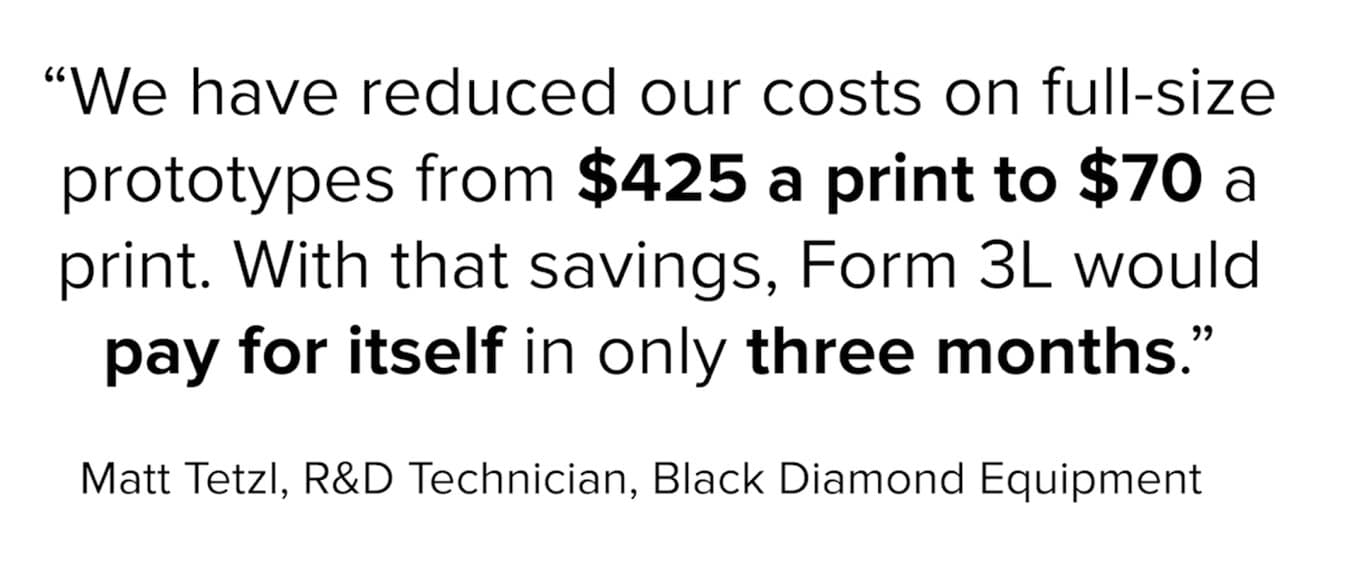

- Highlighting a case study with our customer, Black Diamond.

Our second session covers your questions about how to optimize materials when 3D printing, and was led by Formlabs Product Marketing Manager Matt Lewis.

It can be challenging to identify the best material for a specific use case, especially with photopolymers like SLA 3D printing resins. This session will help you understand how to select a 3D printing material using a unique framework which groups resins into functional material families. Material families group resins that behave relatively similarly under certain conditions, enabling them to be viewed on a spectrum differentiated by only a few key properties. Additionally, this session will cover how to select a material under normal operating conditions, and what to consider when pushing materials to their limits. Lewis included the following topics:

- Benefits of viewing SLA resins in functional groups when selecting a material.

- Mechanical properties to consider when selecting an SLA material.

- Comparisons of SLA materials to common thermoplastics.