Any 3D printer is only as powerful as the parts it can produce. New materials open up new workflows and new ways that additive manufacturing can supplement and transform your business. As we expand our library of Engineering Resins for our stereolithography 3D printers (the Form 3 and Form 2 for the desktop, and the large format Form 3L), we want to make sure it’s as easy as possible for you to identify which material is the best fit for your project.

Based on browsing data from our website and your direct feedback, we’re introducing a new level of categorization to our resin library: material families. Within each family, resins share an overarching material characteristic, such as toughness, rigidity, or softness.

We hope this switch will make it easier to browse our materials library, choose the material family that is best suited for your job, and ultimately identify the resin within that family that best meets your design requirements based on its unique properties.

Our First Resin Family: Tough and Durable Resins

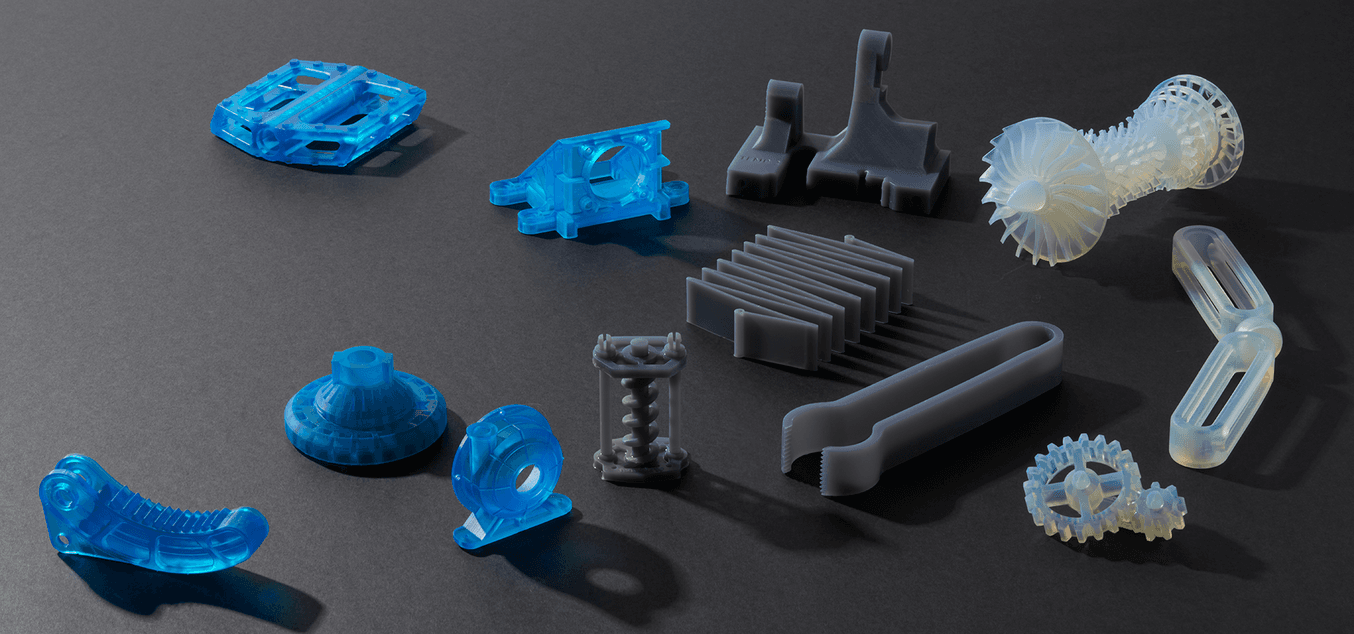

With the launch of Tough 1500 Resin, we’re also introducing our first resin family: the Tough and Durable Resins. Our most robust, functional, and dynamic materials, these resins can handle repeated compression, stretching, flexing, and impact and will strain slightly without breaking.

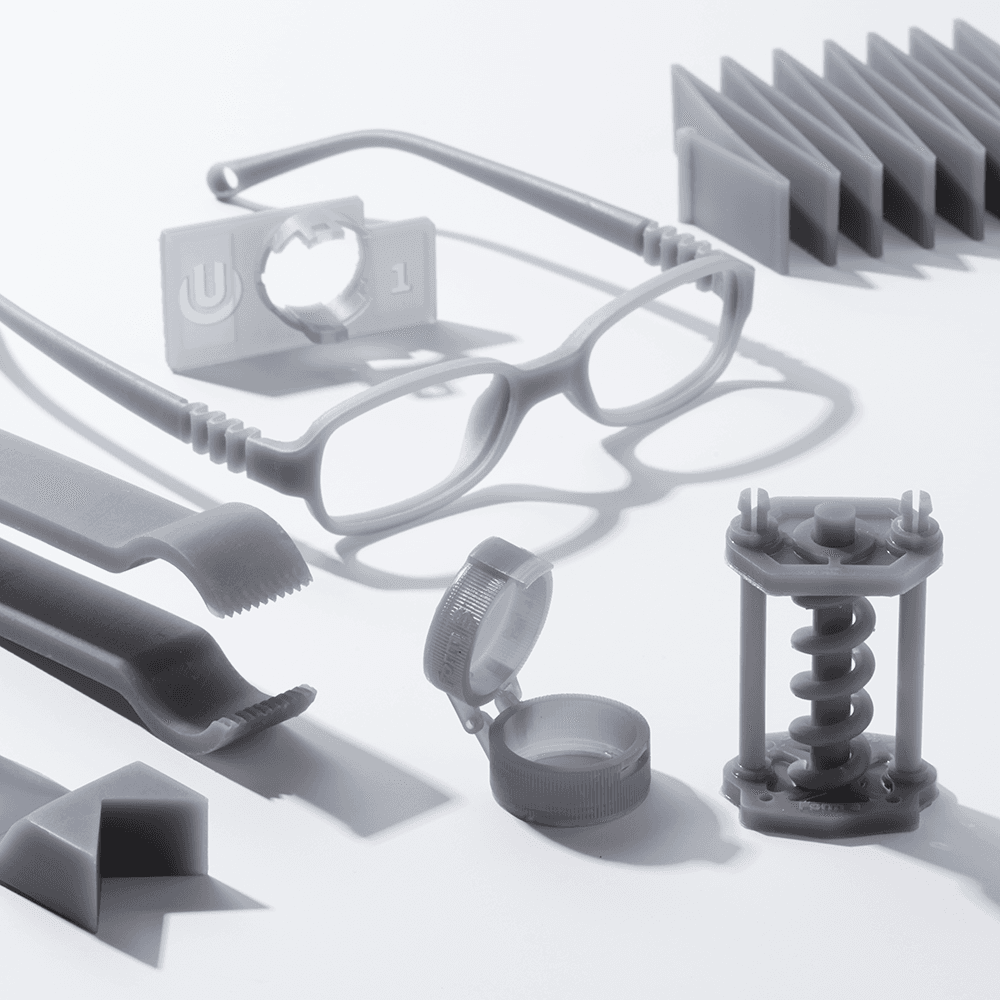

Use the family of Tough and Durable Resins to print parts that need to handle repeated compression, stretching, flexing, and impact.

Explore Tough and Durable Resins Read More About New Tough 1500 Resin

Ideal uses for this family of materials include:

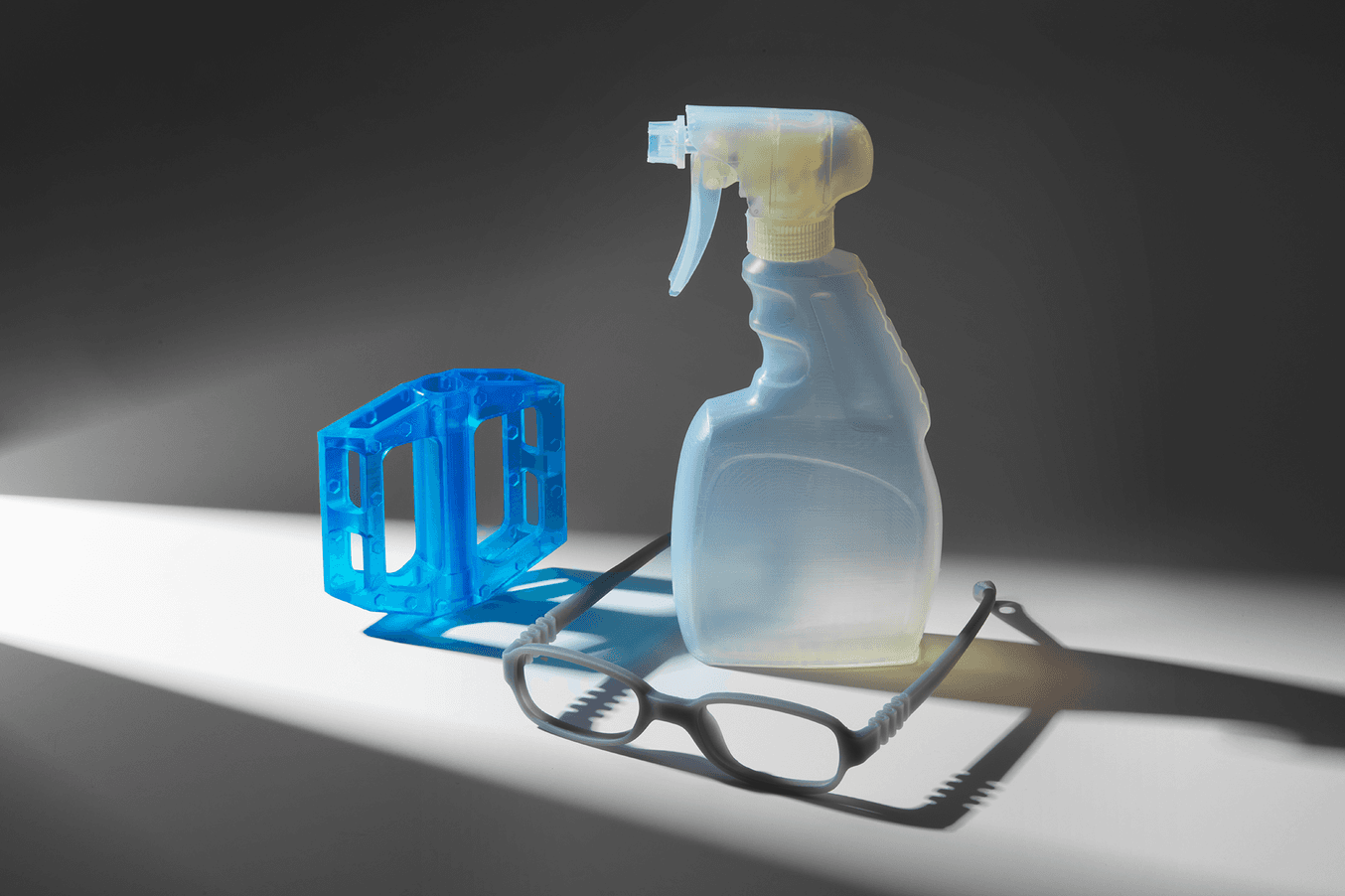

- Housings and enclosures, such as electrical housings, bottles, and packaging

- Jigs and fixtures, such as non-marring grips, drill guides, and locators

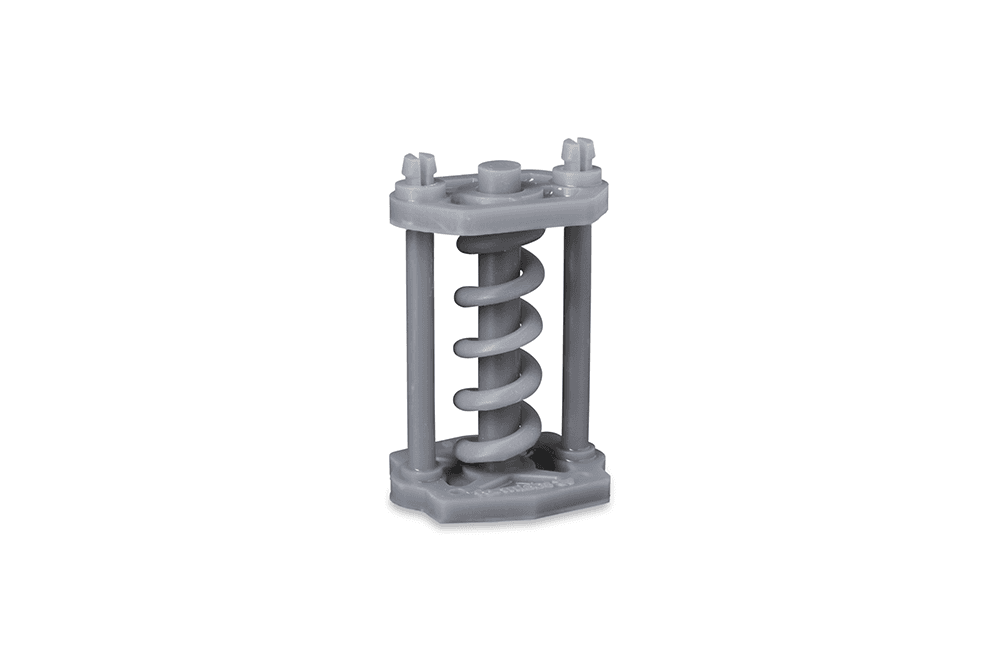

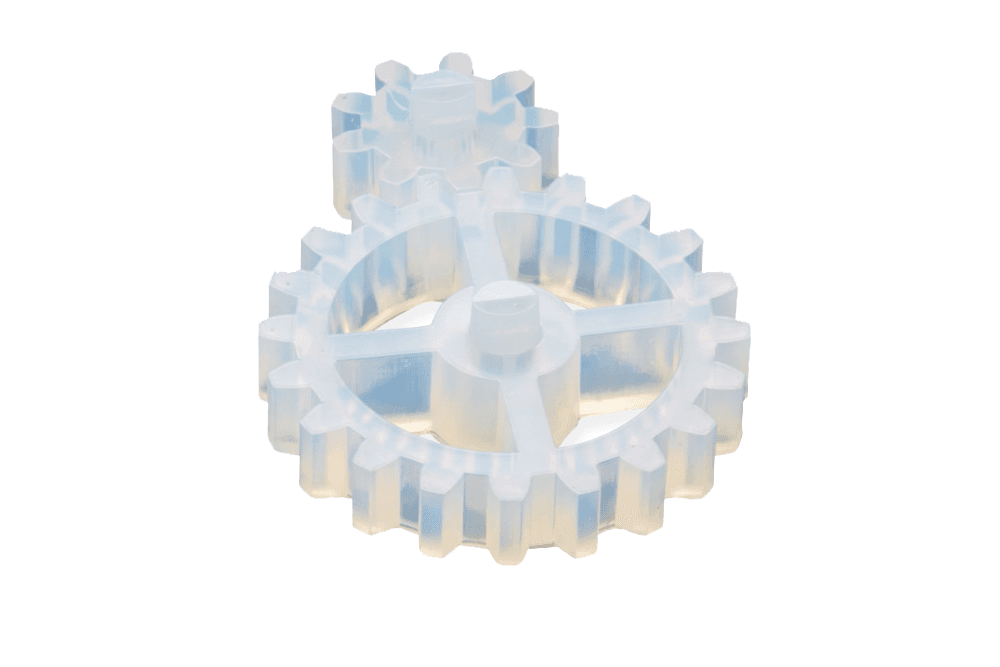

- Connectors, such as snap fits, press fits, hinges, threads, and joints

- Prototypes undergoing wear and tear, such as consumer goods, tools, and assemblies

As of today, the family of Tough and Durable Resins includes the following materials:

Tough Resin, for stiff and sturdy parts that are difficult to bend. Simulates the strength and stiffness of ABS plastic.

Request a Sample Part

Tough 1500 Resin, for stiff and pliable parts that bend and spring back quickly. Simulates the strength and stiffness of polypropylene (PP).

Request a Sample Part

Durable Resin, for soft and pliable parts that bend easily and spring back slowly. Simulates the strength and stiffness of HD/LD polyethylene (PE).

Request a Sample PartChoosing the Right Material: Key Properties

Plastics are complex materials, and finding the right one for your specific project requires balancing a variety of attributes. Within this particular materials family, modulus, elongation, and springback indicate best how a part will behave while in use.

Modulus: How easily does it bend?

Elastic modulus is a material’s resistance to elastic deformation under stress. There are two types of modulus: flexural modulus and tensile modulus (also known as Young’s modulus), which are closely related and don’t vary largely.

The “1500” in Tough 1500 Resin represents its tensile modulus (in MPa). As we expand this family of materials, we’ll continue using tensile modulus as the key distinguishing property, allowing you to identify where each material falls on a spectrum of stiffness. Other materials in this family may be renamed over time for consistency with this naming convention.

Elongation: How Far Will It Bend?

Elongation is a measure of how far a material can strain without breaking.

Springback: Does It Return to Shape Quickly?

A material with high springback balances high elongation and modulus and can bend and return to shape quickly.

Pushing Materials To Their Limit

For many prototyping use cases, you may not be pushing these materials to their breaking point. For situations that do push the material to failure, such as high stress or repeated impact, you might also consider properties like tensile strength and impact strength.

Mechanical Properties: Summary

Tough Resin

Tough 1500 Resin

Durable Resin

Overall, choose our Tough and Durable Resins for dynamic applications where bending at lower stress levels is preferred to sudden brittle failure at higher stress levels.

Further reading: Six key mechanical properties to consider when choosing a 3D printing material.

Visit Our New Tough and Durable Resins Page

To learn more about our family of Tough and Durable Resins and compare these materials side by side, visit our new resin family page to examine technical data, see galleries of parts printed in each material, and more. We’ll be releasing new family pages for other material families over the coming months to make exploring our entire resin library even easier.

Meet Tough 1500 Resin

Tough 1500 Resin is the most resilient material in our newly segmented family of Tough and Durable Resins. This material is ideal for functional prototypes, jigs and fixtures, and connectors undergoing temporary deflection.