Sinterex has been at the forefront of medical 3D printing in Dubai since 2017. Today, they are a team of 16 doctors and engineers using six Formlabs 3D printers, working with the Dubai Health Authority (DHA), the leading public health care entity in the United Arab Emirates (UAE). Additionally, they are part of the Dubai 3D Printing Strategic Alliance, which promotes 3D printing within the UAE.

According to the FREOPP World Index of Healthcare Innovation, the UAE health system has “excellent” fiscal sustainability and public health care spending but is “poor” in terms of medical advances, health digitization, and access to new therapies. Sinterex’s mission is to change this status quo, working with the most innovative, forward-looking, and creative clinicians, and often with the most complex cases in the greater Gulf Region.

The majority of its experience to date has been on anatomical models for surgical planning. The team is taking the patient's CT or MRI data using segmentation software to isolate the specific anatomical features of interest. They are using 3D printing to produce either a model, a surgical guide, or patient-specific implants. Among all benefits, models were particularly important to patient comprehension and communication. Additionally, having a model to devise a surgical plan had a really big impact on surgical success.

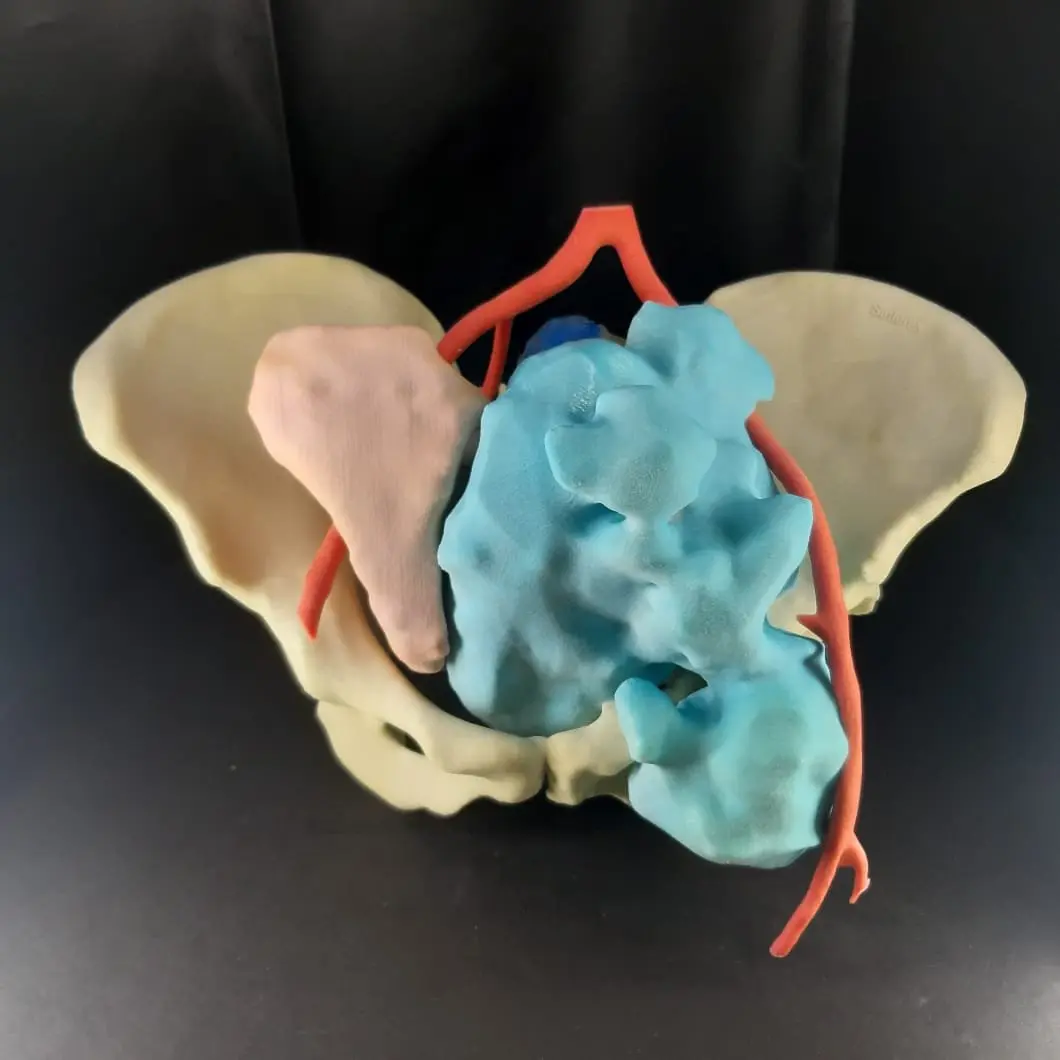

Case Study: Using 3D Printing to Create a 3D Model of a Malignant Chondrosarcoma

A chondrosarcoma is a type of bone cancer that forms in bone cartilage. It usually starts in the pelvis (between the hip bones), the shoulder, the ribs, or at the ends of the long bones of the arms and legs. Chondrosarcomas are the third most common primary malignancy of bone after myeloma and osteosarcoma and account for 20 to 27 percent of primary malignant osseous neoplasms.

After a young Filipino lady failed to conceive after four years of marriage, she decided to see a gynecologist, who after an initial investigation, discovered a pelvic mass. This is when the patient was introduced to Dr. Mohamed Ahmed Mashhour, a Consultant Orthopedic Surgeon specializing in orthopedic oncology for musculoskeletal bone and soft tissue tumors with 26 years of experience.

A full investigation proceeded with MRI with contrast, and the team discovered a huge pelvic mass coming from the ischiopubic ramus and invading internally inside the pelvic cavity, and part of it outside the pelvic cavity.

MRI with the 3D virtual model and large pelvic mass in red.

“It was deep-seated in the pelvis. It could be palpated from the abdomen. It was raising, crossing almost the umbilicus.” said Dr. Mashhour. A multidisciplinary team, including a vascular surgeon, an obs and gyne consultant, medical oncologists, and radiation oncologists, discussed the case extensively in NDT. There was a lot of debate about whether to proceed with surgery or not because of the extent of the tumor.

“As a tumor surgeon, we really study the images and take a lot of preparation. It’s why I need each and every tool to make, modify or assist a decision. At the end of the day, I value anything that will get to the most precise surgical plan possible, avoiding complications, malalignment, and other issues for my patients”, said Dr. Mashhour.

CT with a 3D virtual model and the tumor highlighted in blue.

The tumor occupied more than 80% of the pelvis and and went outside the pelvic region. Critical vessels were entangled within the tumor mass. If resected, they could have retracted in the pelvic cavity and caused deadly bleeding.

This is when the 3D model came in. The results showed that the tumor was nonresectable at that time. Dr. Mashoour’s team, unfortunately, learned that they were not able to conduct the surgery. However, they were glad that 3D printing helped them reach a scientific decision. In fact, for this particular case, avoiding surgery was the right thing to do.

Dr. Mashhour believes that the concept of 3D modeling in the field of orthopedic oncology is really a brilliant idea and says that this is an innovative technology.

“In the older days, we used to have what we call custom-made prostheses for patients with tumors. You see the patient, you do the MRIs, you take the measurement, and you send those to the manufacturer to create a customized templated model of the same size for that patient. It usually took about a month and a half or two months. During that time, the tumor progresses and the dimensions change. But thanks to 3D printing, nowadays we quickly produce models to see tumors in their real size, something that unfortunately two-dimensional images cannot help with.”

- Dr. Mashhour

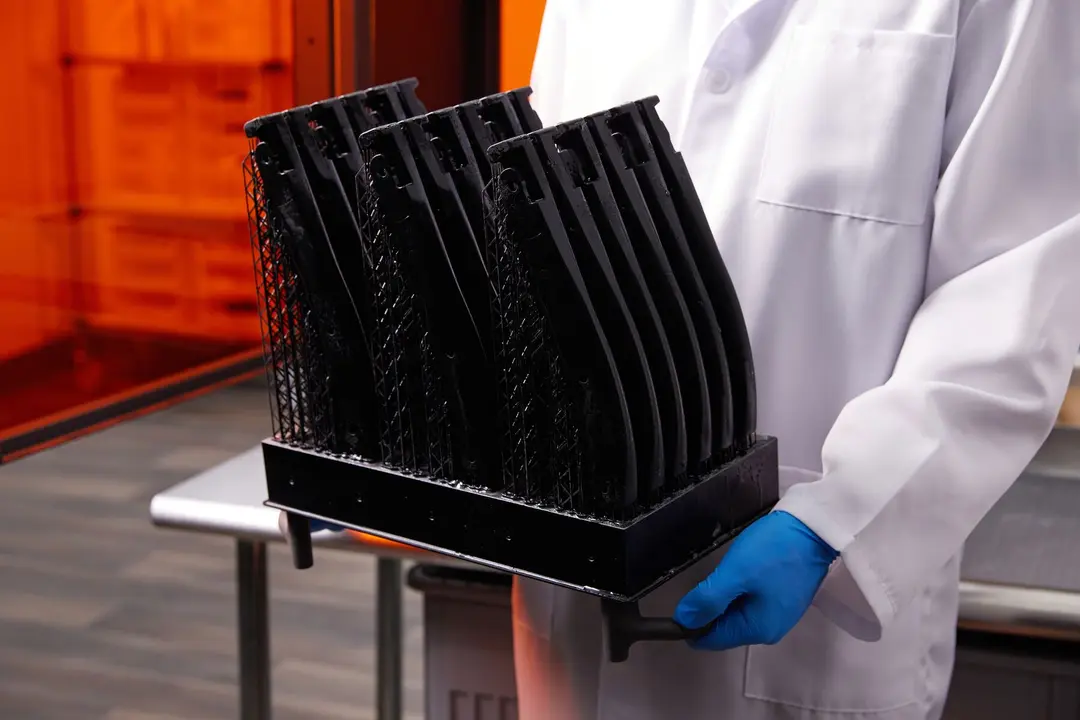

How the 3D Tumor Model Was Fabricated

Sinterex combined the MRI and the CT together to get a really clear understanding of what was happening. The model consists of five or six different parts printed using a combination of different resins. White Resin is used to replicate a white bone. Elastic 50A Resin is used for organs. Finally, part of the model was painted using acrylic paint as a base cover and finally sprayed with a gloss to get that nice shiny finish.

When Sinterex Managing Director Julian Callanan presents a model ahead of kidney surgery, for example, he knew that other surgeons are particularly interested in vascular structures, which is why the painting process is extremely helpful. It helps them understand what they are seeing.

“One of the things that I find most powerful is seeing the CT or MRI format and then seeing that contrasted with the 3D model. Medical professionals spend a lot of time training and being experts at reading CT or MRI data. However, the human brain is used to three dimensions. It lives in a three-dimensional world. To construct 2D images presented on three separate planes into an accurate 3D image in your head, I think is almost impossible. That's really the incredible thing that 3D printing does.”

- Julian Callanan, Managing Director at Sinterex

The assembly was quite intricate. In fact, Sinterex’s team had to make small studs to be able to connect different parts together and to have the right spatial relationship between them.

Additionally, getting the medical imaging right was probably the most challenging part of the process. “Two people were working on it for three days. You can imagine all that time, all that knowledge, all that expertise gets baked into the cost. Now with AI, there are some amazing companies out there that are automating the process. The segmentation, which may need a manual check, is just one click away. Printing and production are also getting faster and faster with time”, said Callanan.

Future Outlook of Precision Surgery in UAE

The use of 3D modeling can be very useful in complex revision cases, for example, surgeries for hip arthroplasty, or knee arthroplasty, where doctors are facing a real-time challenge.

“Complex cases, complex deformities, mismanaged cases, these are the cases where 3DP stands out. While the technology is still cutting edge in this region, it reminds me exactly of the early days of navigation systems when surgeons who adopted the tool were sometimes 2-3 times faster than those who did not. It is out of the discussion that this is the future and now is the time to get on pace.”

“It was incredibly powerful for us to see the impact on Dr. Mashhour and his reaction. I think, having gone through this process and understanding the limitations that sometimes surgeons work with and the challenges that they face, it's really amazing. Formlabs technology is excellent in a number of different ways. The equipment is affordable, the printers deliver very good quality parts, and are very easy to use. We use 3D printing both on the medical side and in the dental space.”

- Julian Callanan, Managing Director at Sinterex

Dr. Mohamed Mashhour concludes by saying, “I am so enthusiastic about this technology, we need to enforce its presence and existence because it's definitely useful. We need to start by making the providers accept it, and the hospitals take it into consideration.”

Special thanks to Raidy Printing Group, our official reseller in UAE, for working with Dr. Mashhour on this project.