The Form 4 Ecosystem

Complete Your 3D Printing Experience

Discover how upgrading from Form 2 to Form 4 gives you major gains in speed, throughput, cost efficiency, reliability, and material flexibility.

Improvement

form 4 vs. form 3

Form 4’s Low Force Display™ print engine delivers most prints in under 2 hours, compared to 12–18 hours on Form 2. Print more parts in a day, respond faster to design changes, and boost throughput without adding machines.

“The dramatic increase in print speed for Form 4 has significantly accelerated our fabrication cycle.”

NASA Goddard Space Flight Center, Matt Mullin, Laser Engineer, Laser and Electro-Optics Branch

Increase productivity by printing more parts in a single build or optimizing orientation for faster print speed.

The new Resin Tank for Form 4 lasts over 75,000 layers, minimizing downtime and waste while improving consistency.

Form 4 uses next-generation resins priced from $79/L, versus $159/L on Form 2. Combined with 5× longer tank life, users cut material costs per part by more than half.

Form 4’s 50 μm XY resolution and advanced pixel smoothing deliver injection-molded surface quality with crisp, accurate details. Compared to Form 2’s 140 μm laser spot, parts are cleaner and more precise.

Remote monitoring, faster calibration, and built-in diagnostics make Form 4 smarter and easier to maintain.

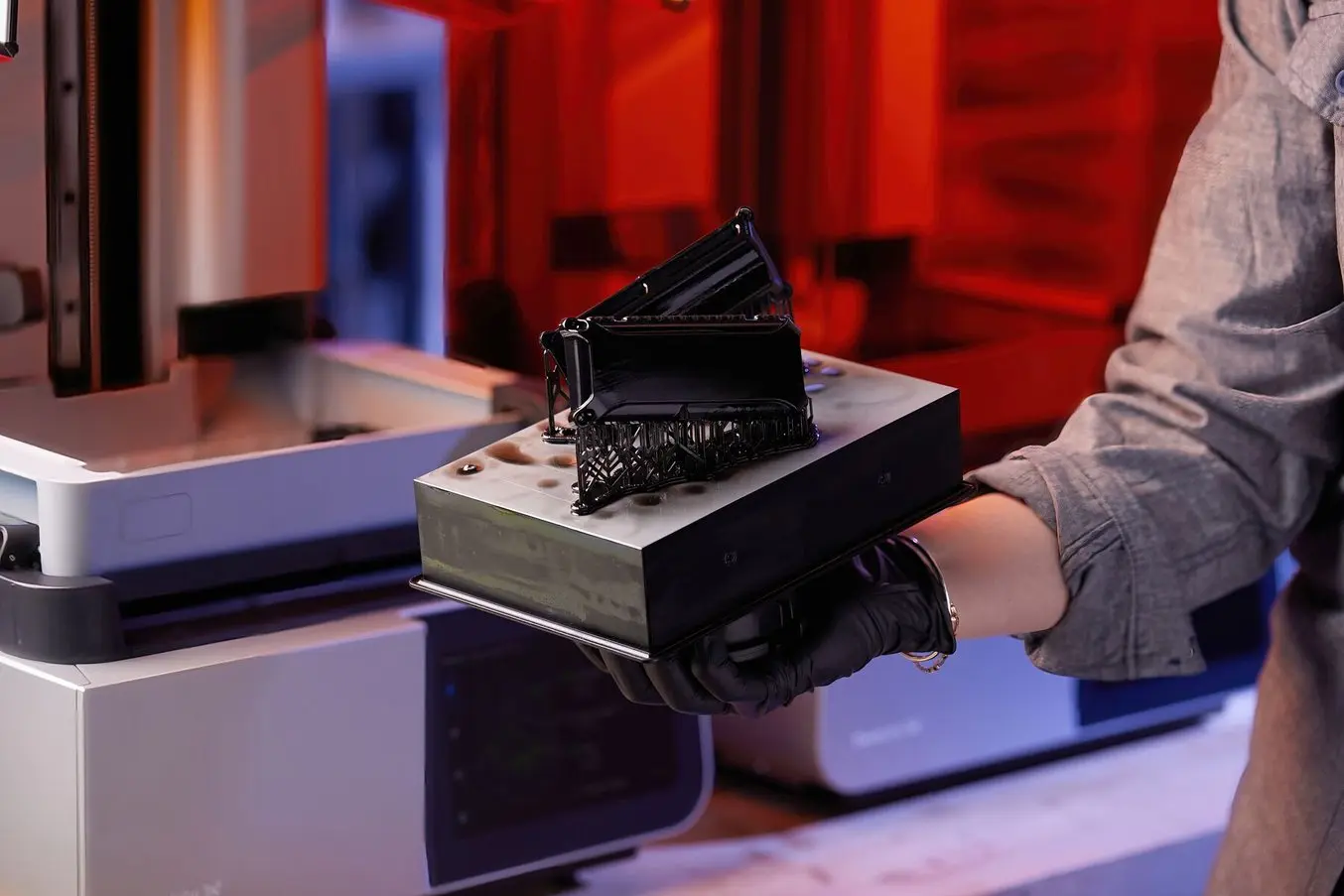

Compatible with Form Wash and Form Cure, plus a quick-release Flex Build Platform for faster post-processing and light-touch supports that tear away cleanly.

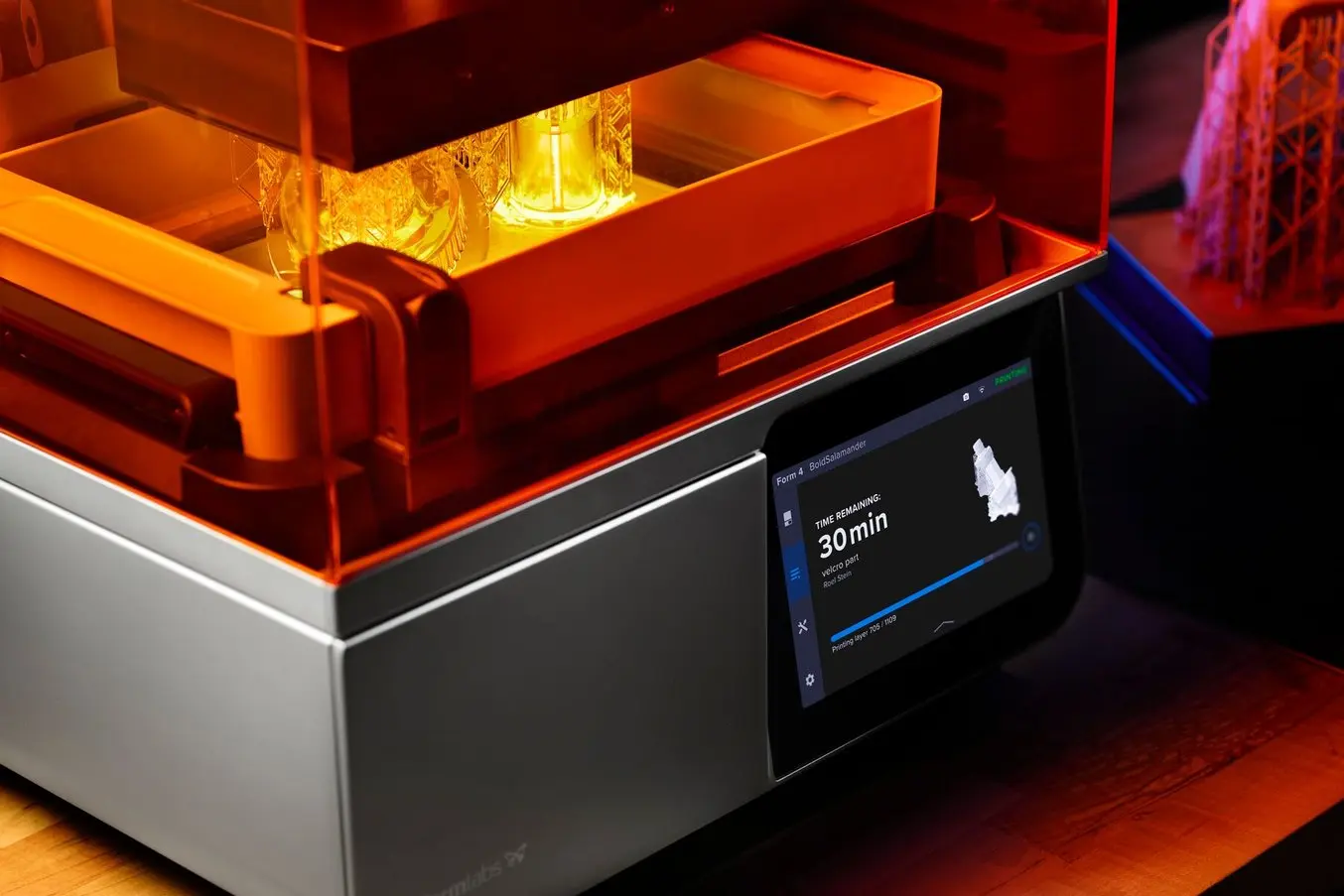

Access images and timelapses online to remotely monitor your prints.

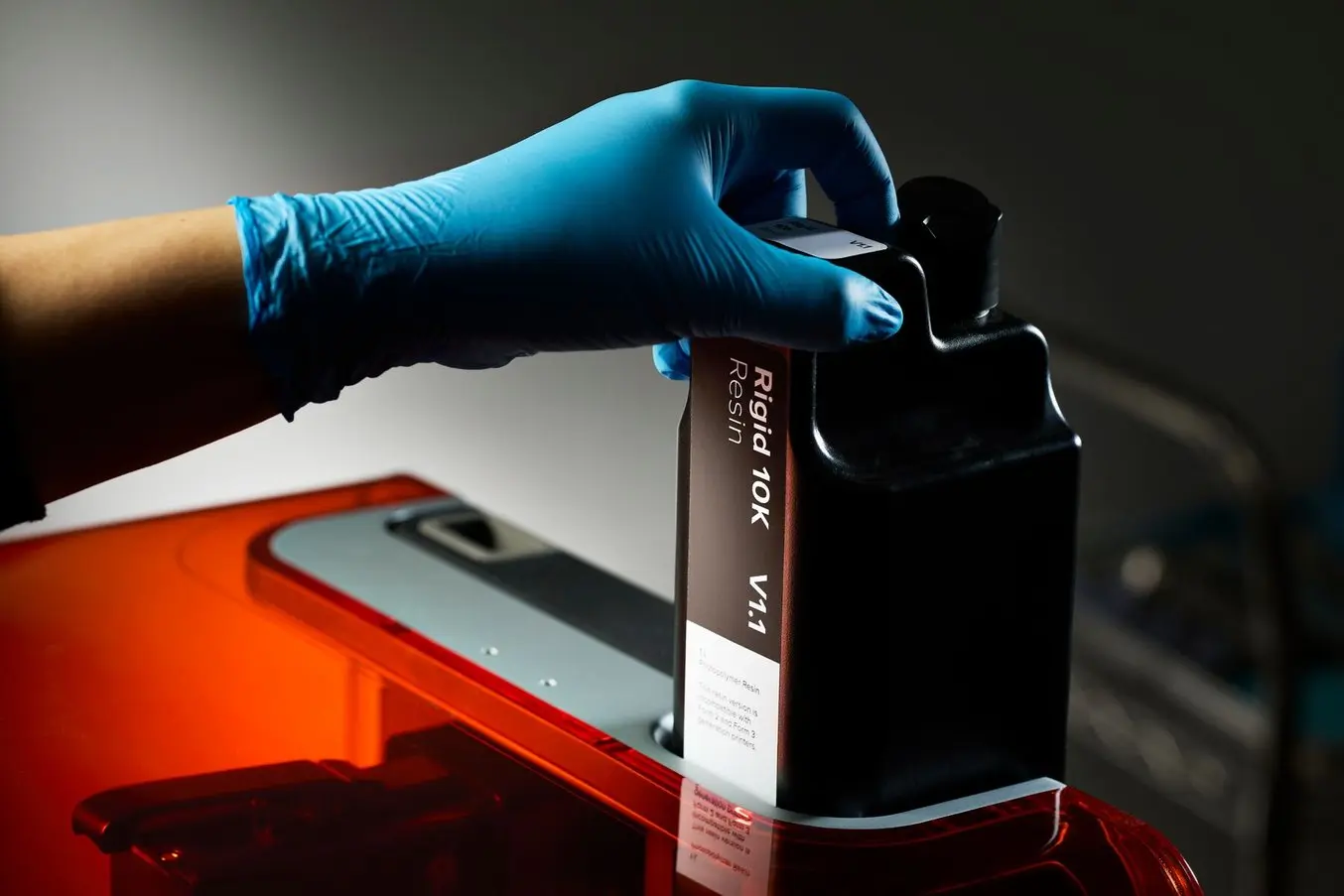

Our next-generation resin cartridge enables hassle-free, efficient, and fast automatic resin dispensing.

Form 4 has a backlight Unit with 60 uniform-wavelength LEDs for faster, even layer exposure. While Form 2 has a Laser and galvanometer system (405 nm beam).

Ecosystem

Additional Tech Specs

Key Components of the Print Engine

Form 4

Technology

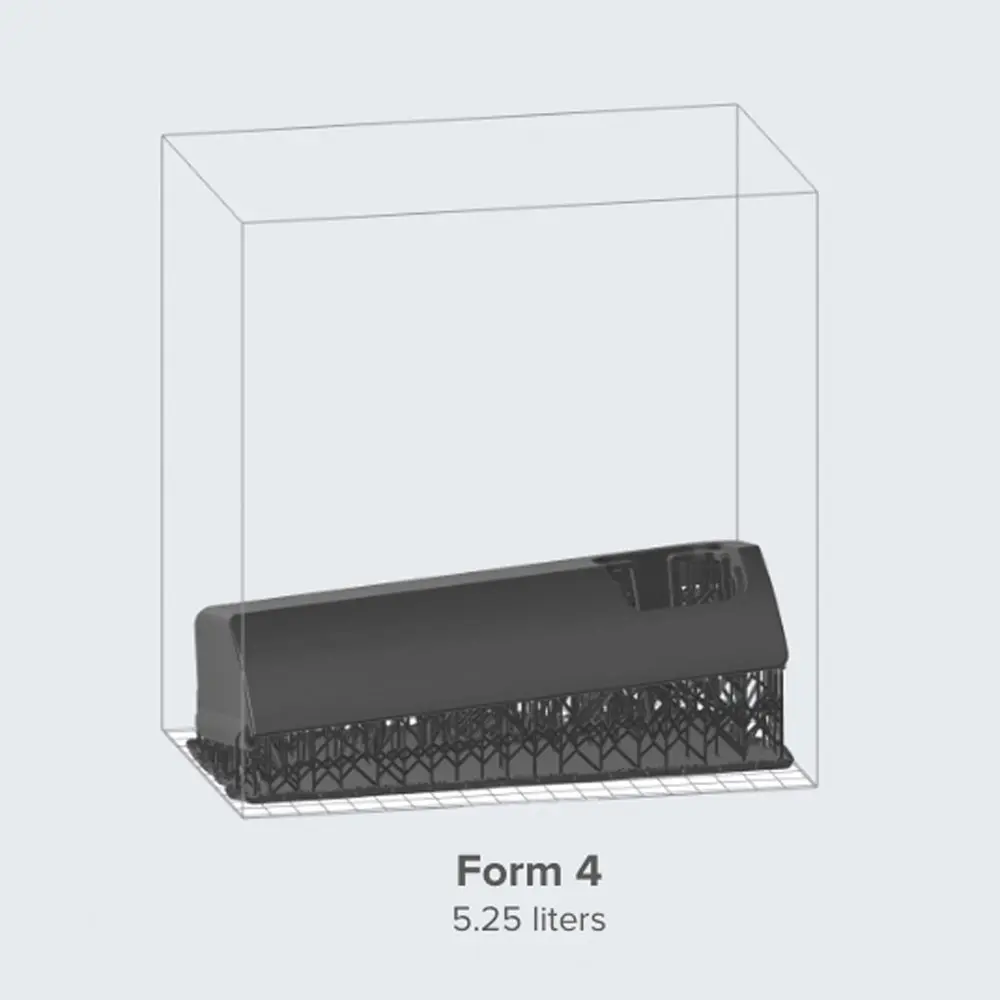

20.0 × 12.5 × 21.0 cm

7.9 × 4.9 × 8.3 in

5.25 liters

75,000+ layers with any Formlabs material.

Approximately 190 prints using average height model (39 mm tall), any resin, and 100µm layer height.

Form 4 unlocks our library of next-gen materials

Our new General Purpose Resins provide higher performance, richer color, and crisper features

Clear Resin V5

Prints 3x faster

Tougher — 2x elongation at break and 25% higher impact strength

Improved in clarity and color

2592 x 1944 resolution (5MP)

Remote monitoring, print history, and print timelapses

Can be easily disabled, covered, or removed

5-10x faster tank filling

63% less waste

30% less shelf space

Test

form 4 vs. form 3

27.3 cm

10.7 in

1-30 mm features: ±0.15% (lower limit: ±0.02 mm)

31-80 mm features: ±0.2% (lower limit: ±0.06 mm)

81-150 mm features: ±0.3% (lower limit: ±0.15 mm)

Average: 40 mm/hour across all materials

Range: 15-100 mm/hour depending on the material

100 mm/hour

3.9 in/hour

18.3 kg

40.4 lb

40.7 × 47.8 × 84.4 cm

16.0 × 18.8 × 33.2 in

Backlight Unit with 60 uniform-wavelength LEDs for faster, even layer exposure

Form 2

Technology

14.5 × 14.5 × 17.5 cm

5.7 × 5.7 × 6.9 in

3.5 liters

Form 2 resins sunset in 2026.

Form 2 supports legacy resins only.

Uses a different tank and SLA process that introduced strong peel forces, requiring sturdier supports and longer cleanup times.

No camera

Original resin cartridge

Test

form 4 vs. form 3

17.5 cm

6.9 in

±0.2 mm per 100 mm of part length

Average: 7 mm/h across materials.

Range: 3–15 mm/h, depending on material

15 mm/h

0.6 in/h

13 kg

28.5 lb

35 × 33 × 52 cm

13.8 × 13 × 20.5 in

Laser and galvanometer system (405 nm beam).

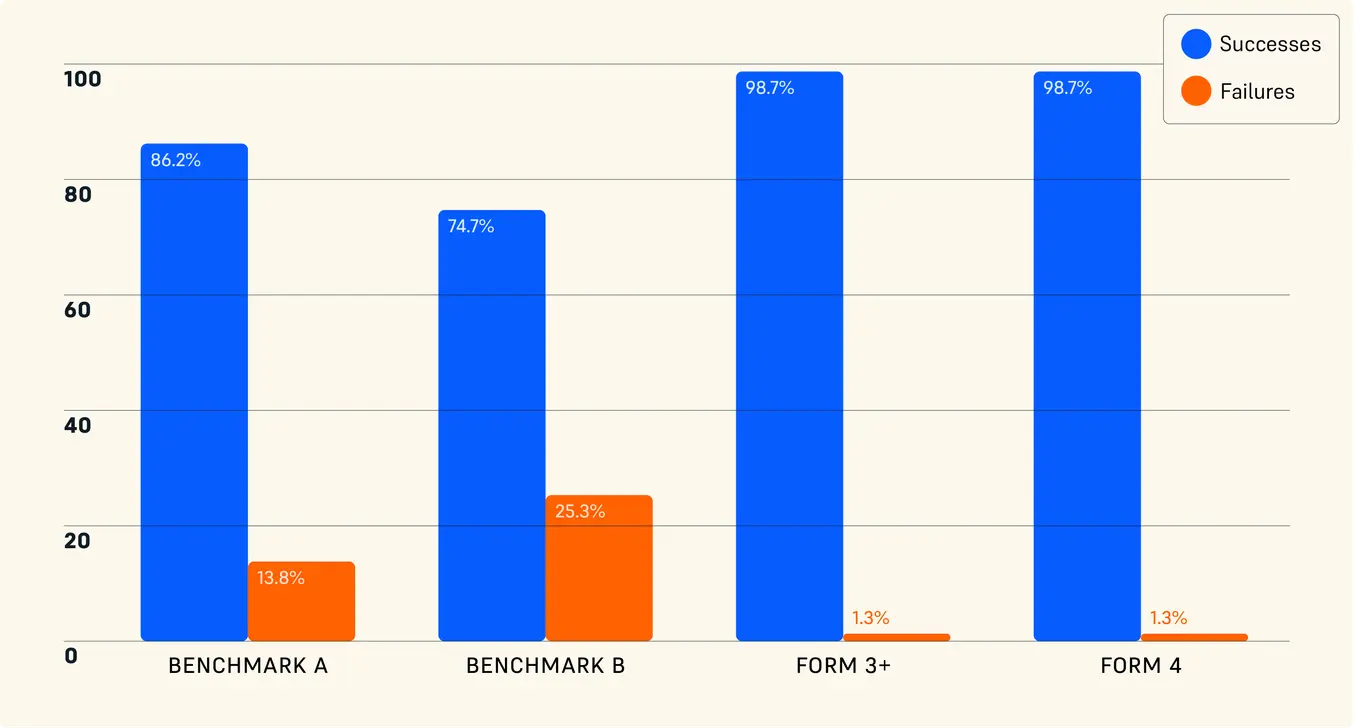

Form 4 achieved stellar results in a series of comprehensive performance tests conducted by an independent third-party lab to evaluate the success rate and repeatability of parts produced on different SLA 3D printers.

The Form 4 Ecosystem

Complete Your 3D Printing Experience