Formlabs Fuse 1+ 30W vs. HP Jet Fusion 3D Series

Looking for a versatile, professional 3D printer for producing strong, long-lasting parts? See why the Formlabs Fuse 1+ 30W is the leading industrial-grade SLS 3D printing platform, chosen by more than half the SLS users in the world.

Compare the Formlabs Fuse 1+ 30W vs. HP Jet Fusion 3D Series

Formlabs Fuse 1+ 30W

Costs

$29,499-$57,442

The Fuse 1+ 30W starts at $29,499 for the starter package that including manual post-processing tools and a service plan, while the complete setup that includes automated depowdering and media blasting solutions costs $57,442. Build your quote in our online store and buy directly from Formlabs via sales or locally from a worldwide partner network.

MATERIAL COSTS

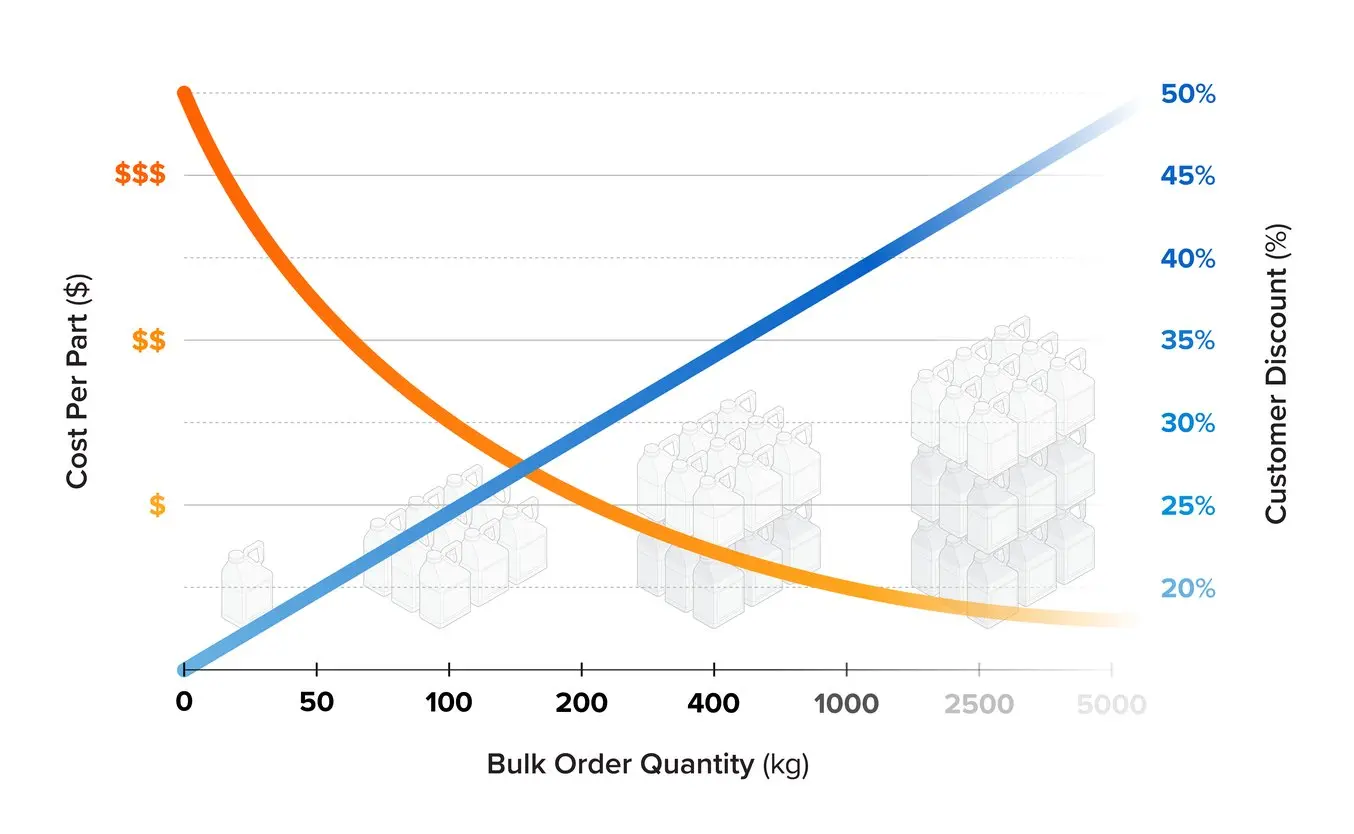

$99/kg, discounts for bulk orders

The most common general purpose Nylon 12 Powder costs $99/kg, while other high-performance or more niche materials are offered at only a slight premium. Significant discounts are available for high-volume orders, starting at 20% for customers purchasing 50 kg of powder in bulk and prices can reach as low as $45 per kilogram.

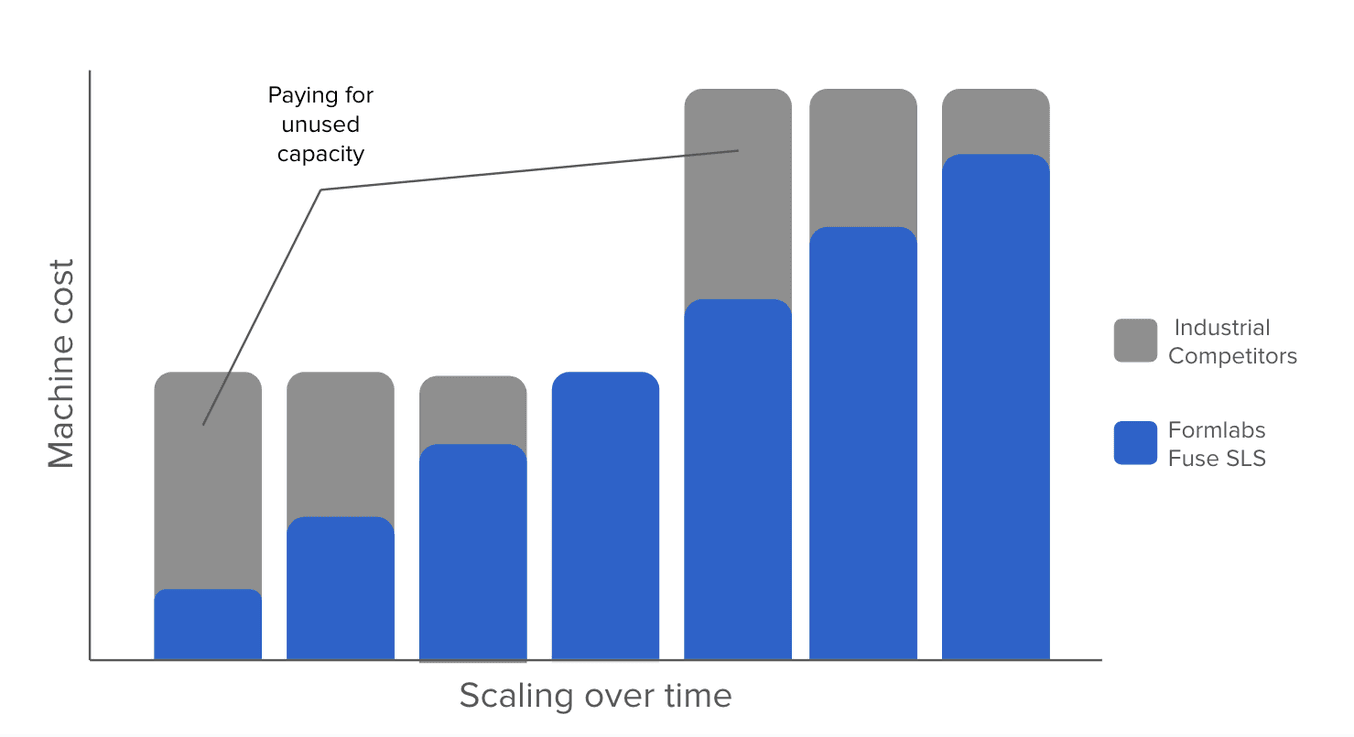

SCALE, REDUNDANCY, AND VERSATILITY

Scale as you grow

The Fuse Series enables incremental scaling so your costs always reflect your need at the time — there’s no wasted capacity or uncertainty while you’re planning for future demand.

A fleet of Fuse Series SLS 3D printers also makes it possible to allocate production volume to different materials and provides the redundancy that protects your business. Shift capacity between your fleet to maintain uptime, even during printer maintenance periods.

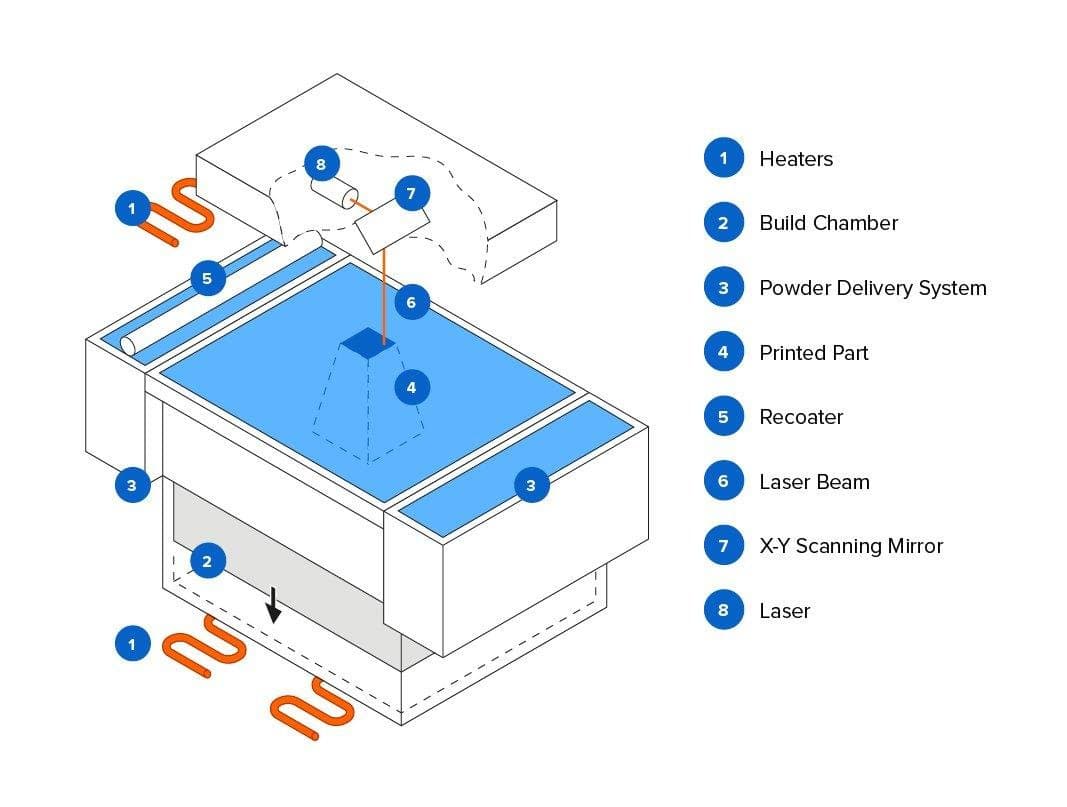

Print Technology

Selective Laser Sintering (SLS)

The Fuse 1+ 30W is the first benchtop industrial SLS 3D printer that offers high quality, compact footprint, and a complete, simplified workflow at a fraction of the cost of traditional industrial SLS systems.

PRINT SPEED AND THROUGHPUT

Same-day parts

The Fuse 1+ 30W is designed for nonstop throughput. It comes with a high-power laser, a removable build chamber, and industry-leading cooldown times. Most builds finish within 7 hours and 95% of tightly packed builds within 14 hours, with cooldown time equal to the print time until post-processing. The removable build chamber, allows you to start new prints within 1-2 hours after the previous print has finished to minimize downtime. Enable same-day delivery for small prints or deliver a full build within 24 hours.

You can match the productivity of one HP MJF printer with a three-unit Fuse 1+ 30W fleet for 1/5 of the price if you produce 1 ton/year and the Fuse Series offers a lower total cost of ownership for up to 5 tons/year. Contact our team for a detailed analysis based on your own volume and applications.

EFFICIENCY

Minimal waste

Parts in the Fuse 1+ 30W’s build chamber can be packed tightly together to maximize density. Thanks to the 30% powder refresh rate for all materials, you can print with up to 70% recycled powder for unlimited cycles. This means that you can print with minimal waste for tightly packed production builds.

Build Volume

16.5 x 16.5 x 30 cm

6.5 x 6.5 x 11.8 in

Materials

Seven validated materials

The Fuse 1+ 30W currently enables seven high-performance materials with fine-tuned settings that are undergoing constant testing and improvement through software updates to ensure peak performance. Formlabs not only meticulously tunes settings, but also updates the printing process to enable new materials.

Available now: nylon 12 (standard, tough, glass-filled, white), nylon 11 (standard, carbon fiber-filled), and TPU. More materials are in development. It's also possible to print with any 1064 nm powder with Open Material Mode.

MATERIAL CHANGEOVER

Multi-material capable

Switching materials is possible within a few hours. Due to the lower hardware costs, it's also substantially cheaper to build out a multi-material fleet.

Workflow and Requirements

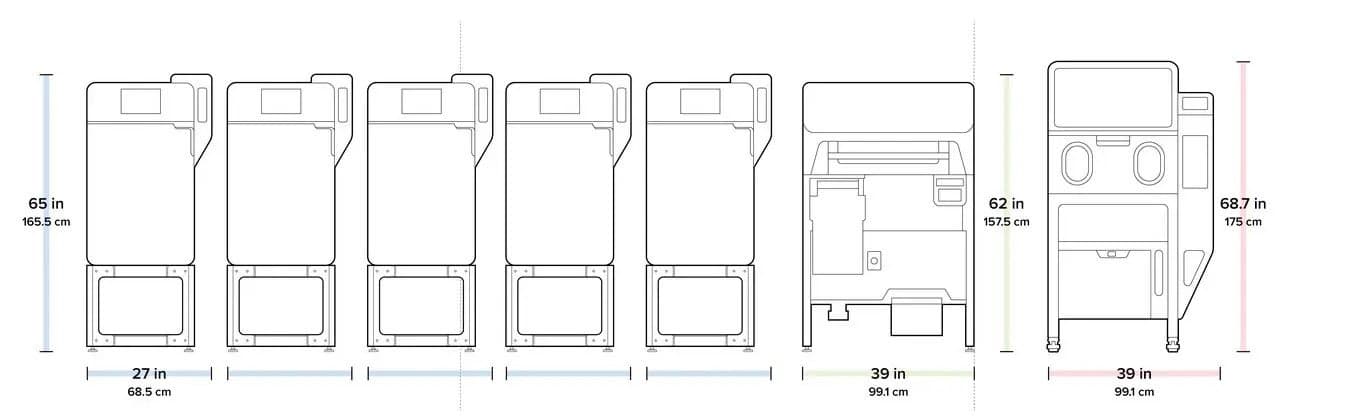

Compact format and no special requirements

The Fuse 1+ 30W has a compact form and a low footprint. Inert gas environment is optional. The lower energy consumption means that it can run on standard AC power without requiring specialized infrastructure.

EASE OF USE

Plug and print

From print setup to powder recovery, our easy-to-use hardware and software are designed to maximize your efficiency at every step of the process. Easy workflow empowers anyone at your company to use the system independently after a quick online or in-person training.

POST-PROCESSING

Fast and automated

Go from printed to finished parts in as little as 15 minutes with the streamlined Fuse Series post-processing ecosystem. Fuse Sift is an all-in-one, safe, efficient powder recovery system that filters, measures, mixes, and stores powder, while Fuse Blast is an easy-to-use, fully automated cleaning and polishing solution (media blaster) to deliver consistent, professional-grade parts with minimal manual labor.

MAINTENANCE

Efficient

The Fuse 1+ 30W is designed for minimal upkeep. The system offers proactive maintenance alerts and a full-color touchscreen interface guides you through every step of printing and maintenance. The hopper-based powder delivery system enables completely contained powder loading. The self-regulating dosing system paired with adaptive dosing algorithms minimizes wasted powder in the print process.

Software

Powerful, easy to use, free

Formlabs' free print preparation software, PreForm®, makes it easy to set up a print in minutes and offers the industry-leading packing algorithm to maximize efficiency. PreForm is available for both Windows and Mac. You can also use the online Dashboard to manage a fleet of printers, monitor prints, track materials and consumables, and work with your team.

Service

Premium service

Up to five years of premier support service with direct phone and email support, customized remote training, on-site visits and repairs from local certified SLS experts, annual preventative checkups, and worry-free warranty — worldwide.

HP Jet Fusion 3D Series

Cost

$350,000-$600,000+

Prices for HP MJF 3D printers start around $350,000 for the 5000 Series and reach $600,000+ for the 5200/5400/5600 Series. Only the compulsory service plan costs $40,000+ a year, enough to buy a Fuse Series printer. Pricing is complicated and opaque, requiring multiple quote requests and negotiation.

MATERIAL COSTS

N/A

Material pricing for MJF is more complex and opaque. While per kilogram prices might start lower than for SLS, there are additional costs for the detailing agent and the MJF printing process generates substantially more waste than SLS due to the lower maximum packing densities, which increases materials costs.

SCALE, REDUNDANCY, AND VERSATILITY

Pay for unused capacity

MJF systems limit your ability to match your production to customer demand, so you're quite likely to end up paying for unused capacity. The higher hardware costs also make it cost-prohibitive to try out or run more niche materials given the lower demand and higher barrier to entry.

For any production scenario requiring under five tons of powder each year, the Fuse Series is more effective, affordable, reliable, and versatile than the HP MJF Fusion Series.

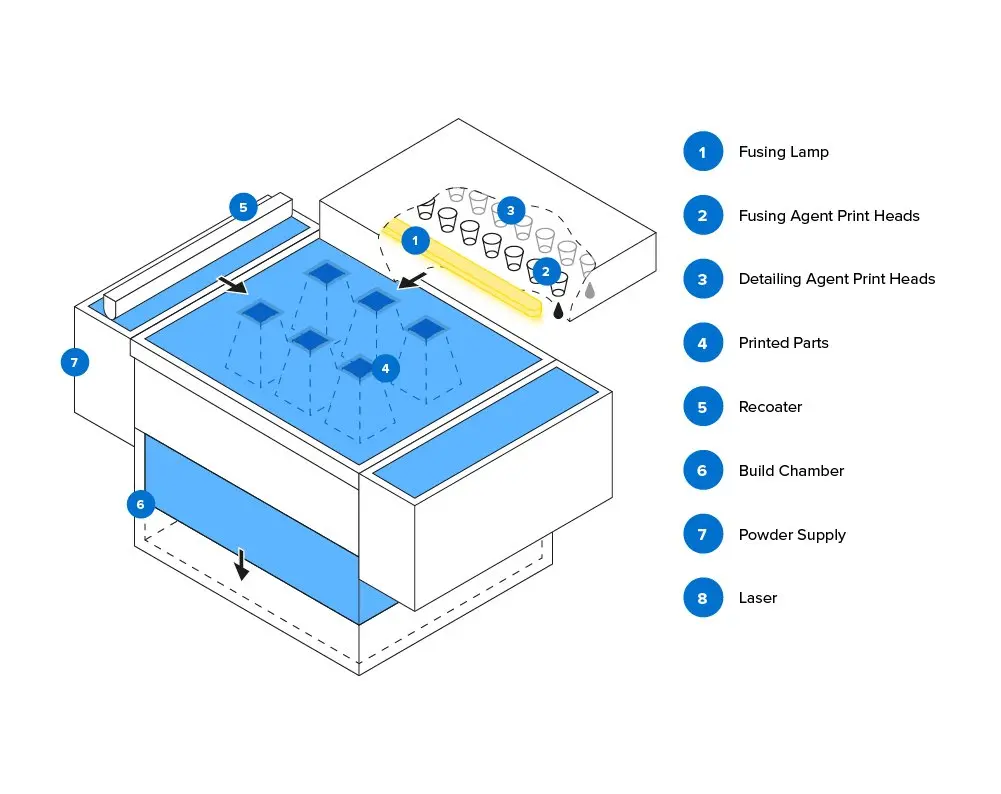

Print Technology

Multi Jet Fusion (MJF)

HP MJF 3D printers use an inkjet array that first deposits fusing, detailing, and coloring agents, and during another pass, exposes the powder bed to infrared energy which fuses the part’s layers together. While the process is different, the end result is similar to SLS.

PRINT SPEED AND THROUGHPUT

Optimized for large builds

HP's MJF 5000, 5200, 5400, and 5600 models offer high throughput thanks to the fast print speed and removable build chambers, but have longer cooldown times. A full build chamber consistently prints within 12 hours, but cooldown time can take up to 2x the print time, which means that the total time until parts are ready for post-processing is often substantially longer than with the Fuse 1+ 30W. Lightly packed builds take as much time as full ones.

EFFICIENCY

Wasteful

The MJF process requires you to space parts widely apart to reduce the potential for thermal buildup. Recommended pack density is limited to roughly 8-10%, which means that you’ll need to throw away as much material as the amount that goes into the printed parts.

Build Volume

38 x 28.4 x 25 cm

15 x 11.2 x 9.9 in

38 x 28.4 x 38 cm

15 x 11.2 x 15 in

Materials

One-seven materials, depending on the printer

HP's MJF 5000 and 5200 printers can print with nylon 12, nylon 11, glass-filled nylon 12, PP, and TPU. The 5400 series is limited to nylon 12. The 5600 series can print with nylon 12, flame-retardant nylon 12, and TPU.

MATERIAL CHANGEOVER

Single-material operation

Switching materials is extremely complex, time-consuming (½ to 1 full day of cleaning), and is generally not advised.

Features and Ease of Use

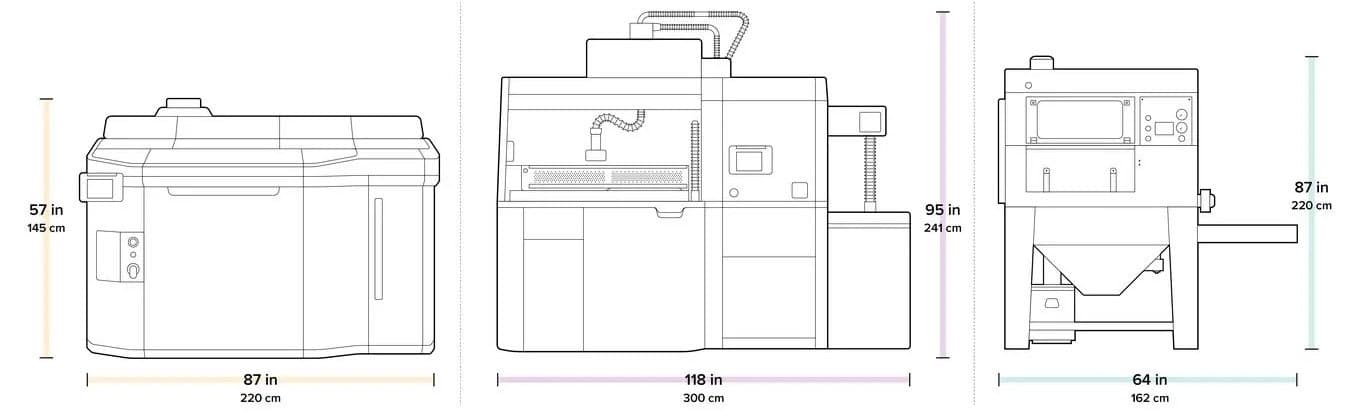

Large space and specialized infrastructure

HP MJF 3D printers are substantially larger and their ecosystem comes with a larger operating footprint. They require specialized power infrastructure and a dedicated technician to operate and maintain. These represent additional costs and time to the customer that are not captured in the quote.

EASE OF USE

Highly complex

Multi-day setup and training with on-site installation required. The complex workflow and the steep learning curve mean that the system requires a skilled technician in-house to operate and maintain.

POST-PROCESSING

Expensive

HP’s post-processing station offers similar functionality, but at an 8x higher price. HP doesn't offer its own media blasting solution, but MJF users can purchase third-party tools, such as Fuse Blast to streamline their post-processing workflow.

MAINTENANCE

Labor-intensive

A less user-friendly workflow means that the operator has to carry out a long list of manual maintenance steps between each print.

Software

Paid and complicated

HP software solutions offer similar features, but using 3rd party software is also recommended, for an additional $12,000. Print setup requires intensive fine-tuning, which results in a steep learning curve and the need for a skilled operator to prepare prints.

Support

Expensive

HP offers multiple service tiers that offer similar benefits, but cost $40,000+ annually — enough to buy a complete Fuse Series setup each year.

Do you have more questions about the differences between these solutions? Download our white paper that compares traditional Formlabs Fuse Series and traditional large footprint powder bed fusion systems or talk to our experts directly.

Request a Free Sample 3D Print

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Build an Entire Factory for the Price of a Single HP 3D Printer

Build a factory with 10+ Fuse 1+ 30W printers for the price of a single HP 5210/5200/4200 system to scale your throughput, be able to print different materials simultaneously, and have peace of mind to avoid downtime.

Meet the Fuse 1+ 30W SLS Printer

FROM DESIGN TO FINISHED PART

An Innovative Workflow, Intuitive From Start To Finish

PreForm

Efficient Print Packing for Optimal Part Density

Use our free print preparation software, PreForm, to import STL, OBJ, or 3MF files, orient models, estimate print times, and pack parts for optimized density, reducing print time and limiting waste.

Fast, Simple

Optimize Prints in One Click

Use our free print preparation software, PreForm, to import 3MF, STL, or OBJ files, orient models, estimate print times and material usage, and monitor prints.

PreForm’s powerful 3D packing algorithm automatically arranges models to increase throughput and reduce material waste by optimizing the packing density.

Manageable

Monitor and Manage Your Printer From Anywhere

Take control of your production across multiple locations and machines. Monitor the live video feed from the comfort of your desk and track print jobs and material flow with our cloud-based tools to ensure minimum downtime and maximum output.

Powder Recovery

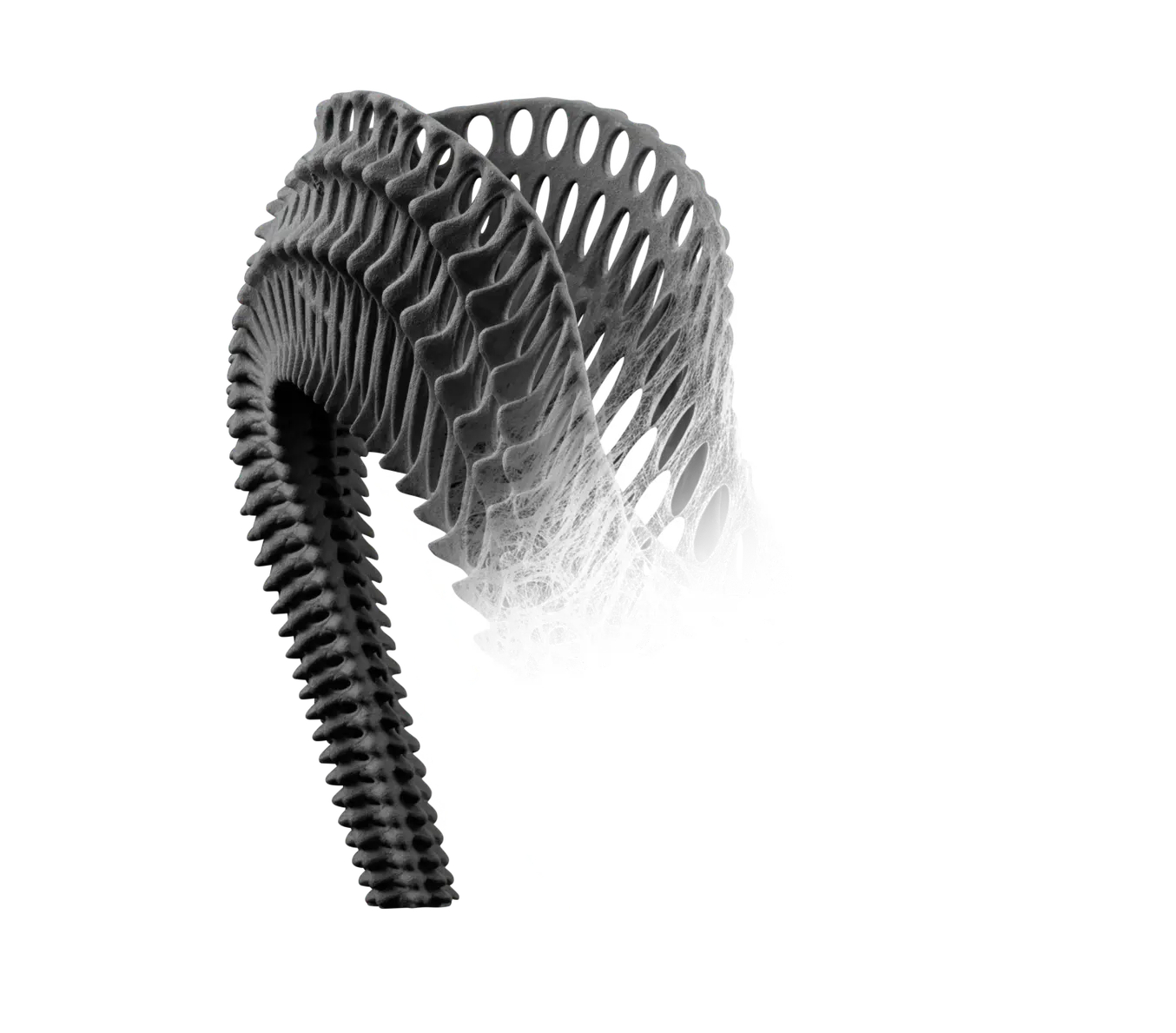

Consistent Results and Complete Design Freedom

Unsintered powder supports your parts during printing so you can create complex, interconnecting designs with no need for support structures.

Fine-tuned settings and Formlabs’ patent-pending Surface Armor technology enable mechanical properties and surface quality and ensure professional, consistent results every time.

Consistent

Ready-to-Use Parts in 15 Minutes

Go from printed to professionally finished parts in as little as 15 minutes with a fully automated workflow.

Extract your parts from the unsintered powder in only 5 minutes with Fuse Sift, our all-in-one SLS powder management station, and reuse up to 80% used powder in your next print to minimize cost and eliminate waste.

Fuse Blast, our fully automated cleaning and polishing solution, delivers consumer-grade parts in as little as 10 minutes thanks to the pre-programmed routines.

Nonstop Throughput

Designed for 24/7 Uptime

Achieve faster-than-ever printing speeds to deliver prototypes and small series of end-use parts in under 24 hours.

Industry-leading rapid cooldown times allow you to start a new print within 75 minutes of your previous print job.

Enable continuous throughput by adding a second, removable build chamber and relying on the streamlined, automated post-processing workflow.

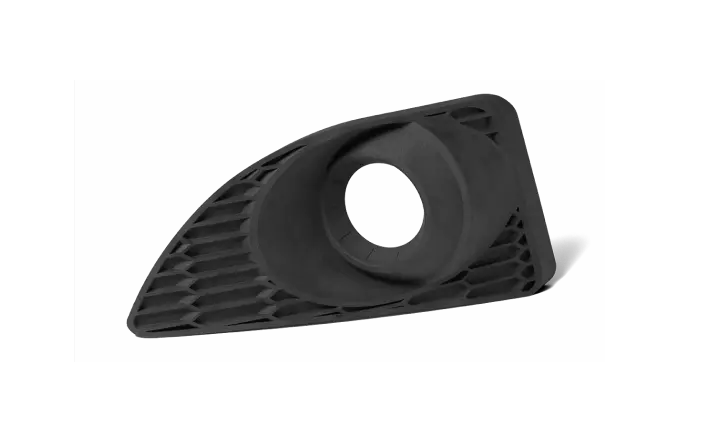

A Material That Does It All

Balancing strength and detail, Nylon 12 Powder is a highly capable material for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability.

Ductile, Dimensionally Accurate, and Accessible Parts

Best-in-class refresh rate among Nylon powders, high ductility, and great dimensional accuracy across the build chamber. Choose Nylon 12 Tough Powder to print more durable parts for prototyping and small batch production that have reduced warpage without sacrificing strength.

Versatile, Customizable, Customer-Facing Parts

All of the great qualities of Nylon 12 Powder with the customizability of white parts. Choose Nylon 12 White Powder to create functional prototypes and end-use customer-facing parts that can be easily dyed to match brand aesthetics as well as medical devices and models with high contrast and detail.

Highly Ductile, Impact-Resistant Parts

For highly ductile, robust parts, Nylon 11 Powder is our higher-performance nylon material for functional prototyping and small batch production. Compared to Nylon 12 Powder, our Nylon 11 Powder is more flexible, less brittle, and better at printing thin walls.

Tough Elastomer for Resilient, Skin-Safe Products

Balancing high elongation at break and superior tear strength, TPU 90A Powder enables you to 3D print flexible, skin-safe prototypes and end-use parts that withstand the demands of everyday use – all at a low cost per part thanks to a 20% refresh rate.

Stiff, Stable, Functional Parts

A glass-filled material with enhanced stiffness and thermal stability for demanding industrial environments. Choose Nylon 12 GF Powder to produce stiff functional prototypes or end-use parts for applications where structural rigidity and thermal stability are critical.

Carbon Fiber SLS, for Strong and Lightweight Parts

Get the best of nylon and carbon fiber with this highly stable, high-performance material, perfect for end-use applications that require both high stiffness and superior strength. Choose Nylon 11 CF Powder to produce lightweight rigid parts that can withstand repeated impact and remain stable over time, even at high temperatures.

Print With Any 1064 nm Powder

Unlock the possibility to print with any 1064 nm powder on Fuse Series SLS 3D printers, empowering researchers and expert users to experiment with an advanced printing tool. Optional purchase, one-time lifetime license fee per printer.

Bulk Powder Pricing for Your Lowest Cost Per Part

3D printing is now cost-effective even at higher volumes thanks to substantial volume discounts for our SLS Powders. Discounts start at 20% for customers purchasing 50 kg of powder in bulk and prices can reach as low as $45 per kilogram.

Explore Material Properties

Make Anything With Fuse Series SLS 3D Printers

Bring production in-house and reduce cost per part with a proven, scalable, and accessible SLS ecosystem.

Bring production in-house and reduce cost per part with a proven, scalable, and accessible SLS ecosystem.

High Quality Parts, Quickly and Affordably

Reduce costs, iterate faster, and bring better experiences to market with our advanced 3D printing materials designed to deliver beautiful final parts for a wide range of applications.

$16

5 hours

3 bindings

30 bindings

300,000,000 Parts Printed With Formlabs Technology

Explore SLS Webinars: User Stories, Tutorials, and More

A New Wave of Independent Manufacturing Starts Now

Rethink product development and take control of your own manufacturing. Configure your Fuse Series setup today.