L'utilizzo di parti stampate in 3D tramite sinterizzazione laser selettiva (SLS) si sta diffondendo nei settori più diversi: da quello aerospaziale fino alla progettazione di occhiali, questa tecnica viene scelta perché offre ottime proprietà meccaniche e metodi di produzione convenienti. Per migliorare ulteriormente le proprietà meccaniche ed estetiche, chi si affida alla stampa 3D SLS spesso implementa anche tecniche di post-elaborazione, come la tintura, il rivestimento, la placcatura o la verniciatura.

La tintura delle parti stampate in 3D in Nylon 12 White Powder sulle stampanti 3D SLS della serie Fuse permette di realizzare prototipi convincenti e parti pronte per la produzione in un'ampia gamma di colori.

Questa guida illustra il processo di tintura delle parti stampate in 3D tramite sinterizzazione laser selettiva e i numerosi vantaggi di questa tecnica. Per scoprire il workflow completo per la tintura, scarica il nostro whitepaper.

Perché tingere le parti 3D SLS

L'utilizzo di parti stampate in 3D tramite sinterizzazione laser selettiva è sempre più diffuso in tutte le fasi dei processi, dalla progettazione alla fabbricazione. A causa della superficie leggermente granulosa delle parti 3D SLS, è in incremento anche l'adozione di soluzioni di post-elaborazione, tra cui levigazione, rivestimento e tintura.

La tintura è un metodo conveniente che consente di colorare parti SLS e migliorarne l'aspetto estetico senza alterare le proprietà meccaniche. Esistono metodi di tintura per qualsiasi workflow: dalla colorazione di piccoli lotti fino alla produzione in grandi quantità di parti con precise tonalità Pantone.

Il nostro team ha testato quattro metodi di tintura comuni e ha raccolto i risultati in un rapporto. Questa guida fornisce una panoramica sull'argomento. Per vedere i risultati completi, scarica il nostro whitepaper.

La tintura è ideale sia per la prototipazione funzionale che per la produzione di parti per utilizzo finale con colori personalizzati che rispecchiano il branding aziendale.

Richiedi un campione SLS gratuito

Guarda e tocca con mano la qualità di Formlabs. Saremo lieti di inviare presso la tua azienda una parte stampata in Nylon 12 White Powder con la Fuse 1+ 30W come campione gratuito.

Dyeing Equipment

We tested dyeing equipment to assemble the optimal setup for dyeing Nylon 12 White Powder. Below, we outline the hardware, dye mixture, and dye bath parameters that achieved the best results in our testing.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

| Metodo | Dimensioni | Quantità | Colore | Resistenza ai raggi UV | Costo |

|---|---|---|---|---|---|

| Tintura in pentola | ★★ | ★★ | ★★ | No | Sotto i 50 € |

| Tintura a ultrasuoni | ★★★ | ★★★ | ★★★ | No | 100 € - 1000 € |

| Tintura a pressione | ★★ | ★★ | ★★★★ | No | 100 € - 500 € |

| DM60 di DyeMansion | ★★★★★ | ★★★★★ | ★★★★★ | Sì | Oltre 50 000 € |

The hardware that we recommend for dyeing is the ESVC-28 - Spectrum Thermal Circulator from Winco. This machine is affordable, available from multiple sources, and is easy to set up and use.

US Source: $699.99

EMEA Source: €659.99

APAC Source: $299

The Winco ESVC-28 Spectrum Thermal Circulator is an ideal solution for ultrasonic dyeing.

Any system that is able to reach the necessary temperatures of 80 °C to 90 °C as well as circulate the solution should be adequate for dyeing. We also recommend having stainless steel tongs nearby to assist in removing parts from the dye bath.

There are also industrial solutions available on the market for dyeing SLS parts, like the Dyemansion DM60, that are cost-effective for high volumes of parts and when extremely consistent results are necessary. This product is capable of holding up to 60 L of components per dyeing batch and will automatically inject the dye as well as rinse the parts post-dye.

The DM60 confers a much higher degree of consistency when compared to pot dyeing as well as improved UV stability of the dyes. An additional service offered by Dyemansion is tailored color development. For users with a strict color requirement or who are looking to dye a very high volume of parts (end-use parts, production runs of 1000+ units), using an industrial machine such as the DM60 may be a good choice.

These larger format solutions take much of the manual labor out of the dyeing process and include programmed settings for different types of parts and colors. However, higher upfront costs mean the return on investment will be faster for those printing very high volumes of parts.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

Dyeing Station

When choosing a dyeing system, one should consider the part size, quantities, price, and levels of color consistency required. Dyeing systems range from a few hundred dollars to tens of thousands of dollars, and the price is often commensurate with the level of quality and consistency achievable. The four most common methods for dyeing 3D printed parts each have distinct advantages, and it’s important to set expectations regarding color quality and budget before choosing a method.

Come tingere parti 3D SLS

Formlabs has conducted extensive testing to determine what colors can be achieved with SLS printed parts using accessible, low-cost dyeing techniques. The dye used was RIT ProLine dye, a low-cost, easily accessible powder that contains a mixture of direct, acid, and disperse dyes, and is effective on nylon fibers. Further variables tested include temperature, acidity, saturation of dye, duration of dye time, and detergent additive in the dye solution. Both Nylon 12 Powder and Nylon 12 White Powder parts were tested and the effect of each variable is covered below.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

Temperature and time have a huge impact on the final part color. Based on our tests, higher temperatures lead to a more saturated color in a shorter amount of time.

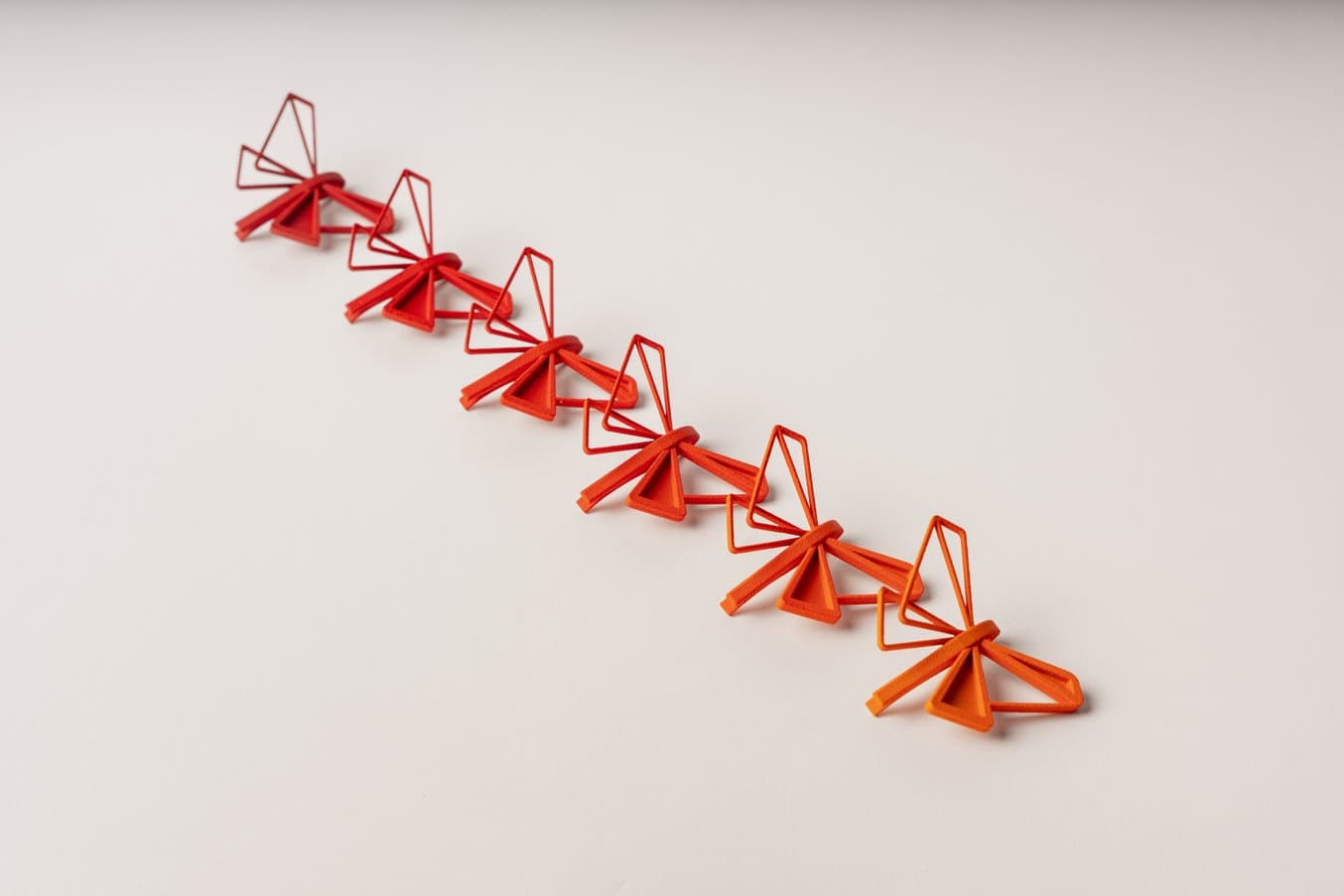

The parts in this image were dyed in the same dye bath, at 90 °C, with parts removed at 3-minute intervals from right to left.

If a lighter shade is desired, consider reducing the dye solution temperature to 70 °C or lower. At higher temperatures, saturation can occur extremely quickly, leaving very little margin for deviation and potentially resulting in variance of finished parts. There is an increase in part uptake of dye over time but this trend plateaus at 20-25 minutes as the part reaches a saturation point where no more dye can penetrate the surface.

Changing Dye Bath Colors

When changing the colors of a dye bath, first drain the entirety of the current solution and dispose of it according to local regulations and the dye’s safety data sheet (SDS). Alternatively, the dye bath can also be stored in liquid form to be used at a later date, according to local safety regulations.

As a dye solution is heated and cycled, some settling can occur. Due to this, the walls and base of the tank should be wiped down after draining to ensure no cross-contamination of colors occurs. Once these two steps are completed, a rinse with clean water is recommended to make sure any remaining dye in the circulation system is removed.

Only after the machine is cleaned should a new dye solution be prepared. If multiple colors are going to be used frequently, getting multiple circulators to prevent frequent swapping is an option.

Ken Pillonel designed an easy workaround for this step, using large flasks filled with dye solution within the tank, and a rotating magnet on the bottom of them to agitate the liquid. This way, he can use different flasks for each dye color, without waiting for cooling and cleaning. To learn more about his method and this workaround, watch his video, shared at the end of the article.

1. Part Preparation

It is essential to ensure that parts are properly cleaned prior to dyeing. Loose powder remaining on the surface of the part may absorb dye differently from sintered powder, leading to a less controlled, nonuniform dye finish, and making the part less wash-safe. We recommend cleaning parts with the Fuse Blast automated cleaning and polishing solution. This will ensure that all loose powder is removed from the part without adding additional labor time to the workflow. Alternatively, a manual media blaster can be used to ensure the parts are clean.

When cleaning parts printed with Nylon 12 White Powder, a blasting cabinet that was previously used for gray powders is not recommended as the residual powder can give the white parts a grey sheen.

Combinazioni di colori e materiali

Tintura di parti bianche

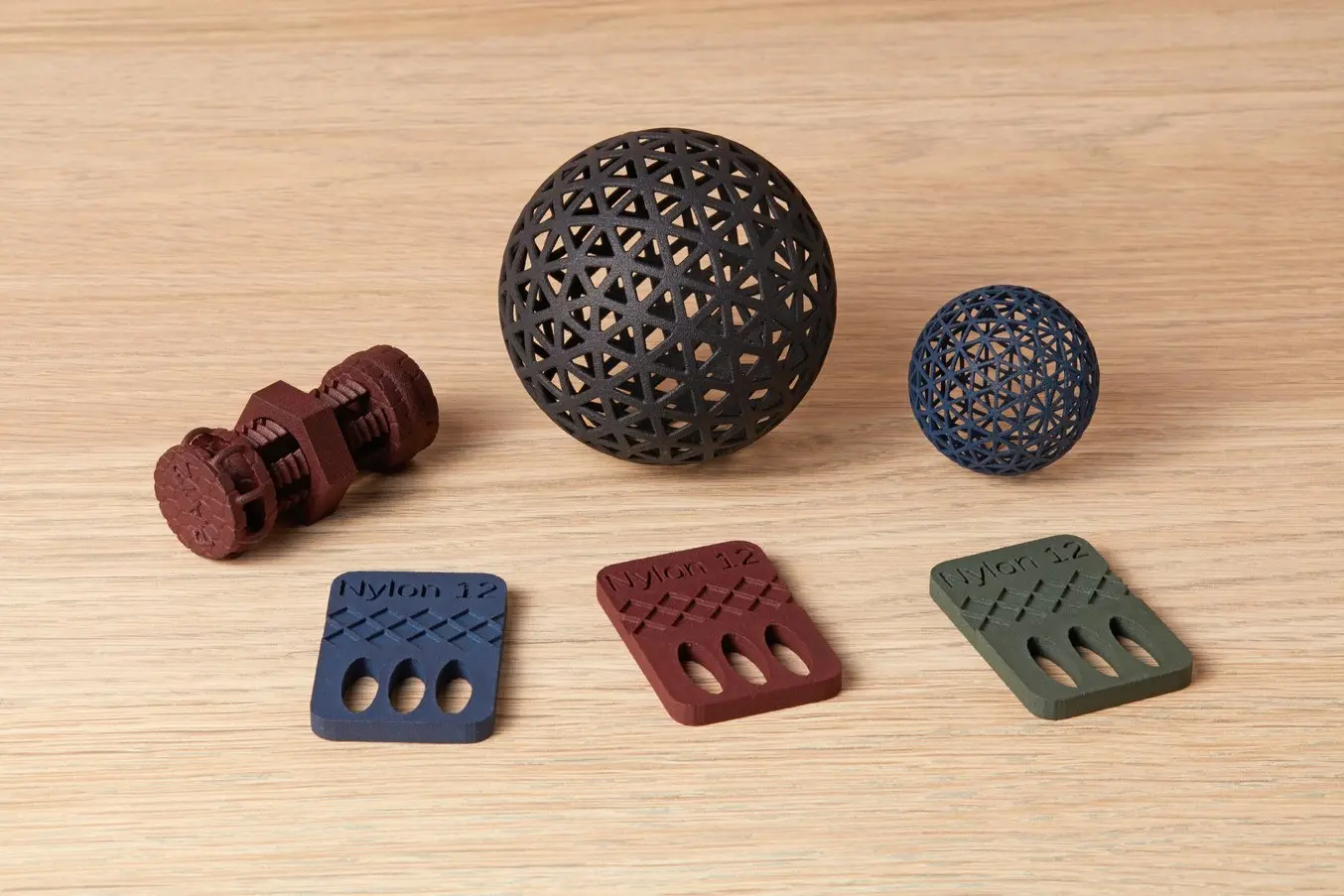

La tintura della Nylon 12 White Powder è l'opzione migliore per ottenere la gamma di colori più ampia. Questa resina si presta alla tintura in tutti i colori chiari, compresi quelli pastello, ma anche in colori vivaci.

Parti stampate in 3D in Nylon 12 White Powder sottoposte a tintura in una postazione a ultrasuoni.

Tintura di parti grigie

Il processo descritto nel nostro whitepaper è stato utilizzato per tingere parti in Nylon 12 Powder. Tuttavia, poiché le parti stampate con la Nylon 12 Powder sono di colore grigio scuro, è possibile ottenere solo tonalità più scure, che spesso risultano meno vivaci.

Parti in Nylon 12 Powder di colore grigio scuro tinte in tonalità più scure.

Tintura delle parti di nero

Se il colore finale desiderato è il nero, consigliamo di utilizzare la Nylon 12 Powder standard di Formlabs con il colorante Rit ProLine Black. Questo materiale ha un substrato più scuro che rende più uniforme il passaggio al nero.

Tingere di nero parti realizzate con la Nylon 12 White Powder, pur essendo fattibile, non è consigliato. Il substrato più chiaro di questa resina rende più difficile ottenere colori scuri rispetto alla Nylon 12 Powder, che invece parte da un substrato scuro.

Advantages of Dyeing

Dyeing is typically implemented as an alternative to coatings. The advantages of dyeing over conventional paints and coatings are lower cost and labor needs, and the possibility to color complex geometries.

Costo

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Manodopera

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Geometria delle parti

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Advantages of Dyeing

Dyeing is typically implemented as an alternative to coatings. The advantages of dyeing over conventional paints and coatings are lower cost and labor needs, and the possibility to color complex geometries.

Costo

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Manodopera

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Geometria delle parti

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Geometria delle parti

The equipment required to bring dyeing in-house is highly accessible. Once the equipment has been sourced, the cost of running dye trials is incredibly low. Due to this, dyeing is more cost-effective than paints and coatings in the majority of situations.

Dyeing is ideal for both functional prototyping and end-use production of parts with custom colors to match brand aesthetics.

Tintura di parti SLS in nylon: l'esperimento di Ken Pillonel

Ken Pillonel, ingegnere e fondatore del popolare canale YouTube Exploring the Simulation, ha creato un'azienda individuale di produzione in materie plastiche basata sull'ecosistema SLS della serie Fuse. Dopo aver ampliato le sue capacità e aver aggiunto una seconda stampante Fuse 1+ 30W, una Fuse Sift e una Fuse Blast, è stato in grado di produrre e tingere le sue custodie di ricarica per AirPods per utilizzo finale in Nylon 12 White Powder. Per una discussione approfondita sulla stampa 3D SLS di parti per utilizzo finale, sull'impostazione di un processo in atmosfera di azoto e su come ottenere risultati di tintura precisi, ripetibili e di alta qualità, guarda il video di Pillonel qui sotto.

Inizia a tingere le parti 3D SLS

L'esistenza di workflow convenienti come quello a ultrasuoni rende la tintura di parti realizzate tramite sinterizzazione laser selettiva un modo facile e accessibile per migliorare l'aspetto estetico delle parti.

La tintura di parti in Nylon 12 White Powder e Nylon 12 Powder utilizzando hardware e coloranti facilmente reperibili è un metodo conveniente ed efficiente per colorare parti finite indipendentemente dalla tonalità desiderata. Questo processo offre una valida alternativa alle soluzioni di rivestimento tradizionali, in quanto richiede manodopera minima e consente di colorare in modo efficace anche le geometrie complesse.

Se stai valutando un'applicazione che richiede parti realizzate tramite stampa 3D SLS colorate, contatta i nostri rappresentanti per scoprire di più sull'ecosistema Fuse e sulla tintura delle parti in nylon.

Per scoprire di più sulla stampa 3D SLS o sulla tintura di parti 3D SLS, contatta il nostro team. Per vedere i risultati completi dei test condotti e il workflow dettagliato, scarica il whitepaper.