Improving Cost-Savings and Communication for Mercedes-Benz Trucks With 3D Printing

Developing and shooting advertisements for the automotive industry presents numerous challenges: vehicles are not yet available in their final version, are only allowed to leave the factory disguised as prototypes, or are difficult to fit into the film studio due to their size.

Mercedes-Benz Trucks’ eActros 600 is no exception. But instead of relying exclusively on CGI, director Felix Aaron of Studio 11:40 and CGI producer Chris Stingel from TomSporer also used 3D printing to bring the abstract world of CGI directly onto the film set.

This innovative combination improved communication between stakeholders, reduced production costs, and shortened timelines — all with the help of a large-format Form Series 3D printer.

The Challenge of Automotive Advertising and the Costs of CGI

Producing commercials for the automotive industry includes a number of typical problems: visual ideals failing due to physical laws, adverse weather and lighting conditions, and retroactive design adjustments. All can be solved by CGI so that customers "don't have to shoot the entire commercial again and pay a lot of money for it," says Stingel.

If products are not yet available or are to be kept secret, the footage is filmed with placeholder products that CGI producers like Stingel then replace digitally. This was the case for the Mercedes-Benz Trucks’ eActros 600 — it was not yet available to shoot, so Aaron had to resort to CGI.

“In post-production, it's not like on set, where I can see, evaluate, and film everything immediately. First of all, I have to set up everything digitally in the CGI and then it has to be rendered. It can take hours or days to achieve the first result.”

Chris Stingel, CGI Producer

CGI takes time, and, therefore, costs. Stingel says, "Many customers think that you can do everything in CGI, which is theoretically true, but involves a great deal of time and, as a result, costs. Clients often can't imagine what it will look like in CGI in the end. We struggle with this time and time again. The problem with digital work is that you don't collaborate in the moment and agree on a solution, because a client isn't going to sit in an online conference for eight hours and watch a digital artist move cameras from A to B. This makes everything more complicated and time-consuming," says Stingel.

Few film studios have enough space for large vehicles like the eActros 600, so filmmakers often have to resort to CGI (source: Mercedes Benz Trucks).

Webinar On-Demand: SLS at Brose for End-Use Automotive Production

In this on-demand webinar, Matthias Schulz, Manager of Seat Prototyping at Brose North America, demonstrates how Brose uses SLA and SLS technology for everything from quick welding jigs to production runs of 250,000 end-use parts.

Accelerating CGI Production With 3D Printing as a Tool for Visualization

As the eActros 600 was not yet available for the commercial shoot, Aaron knew the costs and time frame associated with the shoot would already be substantial. To prevent going over budget, he looked for a way to better communicate with production stakeholders — enter 3D printing.

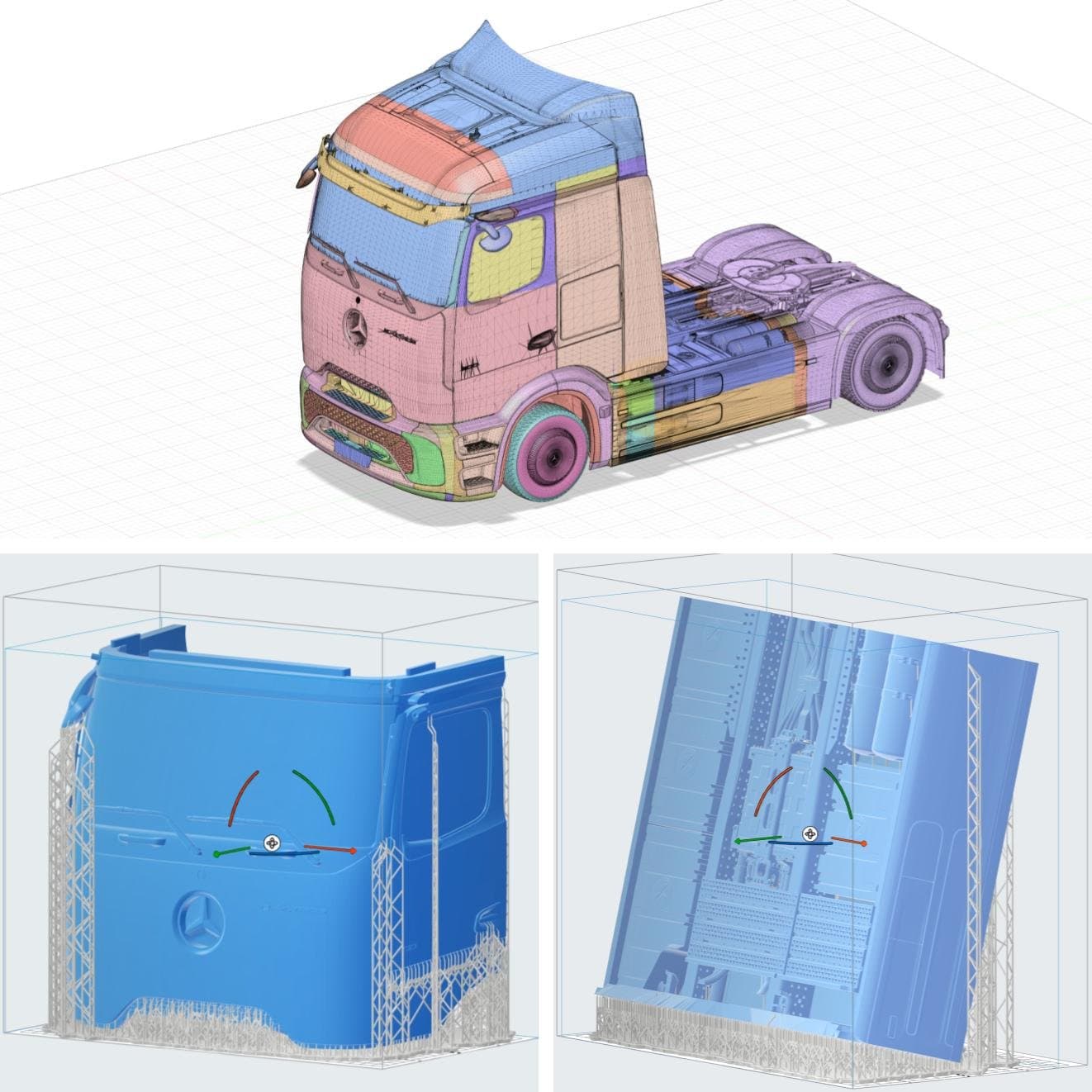

Using a 3D printed prop, Aaron filmed the printed truck with a macro lens in various tracking shots, which he programmed into the motion control system. After agreeing on camera movements with the client, he filmed the same route again without the 3D printed model.

The motion control system stores all the metadata of the camera movements that are necessary for so-called match moving, making it possible to insert the digital model of the eActros 600 into the moving image that was filmed "empty."

"The live image of the illuminated 3D print was shown to the customer, who gave me feedback on site,” says Aaron. “Later in the film, we see the CGI model in a comparable position. This way, the client gets an idea about what the final shot will look like right on set, so we can decide together there and then which variants will be implemented in post-production."

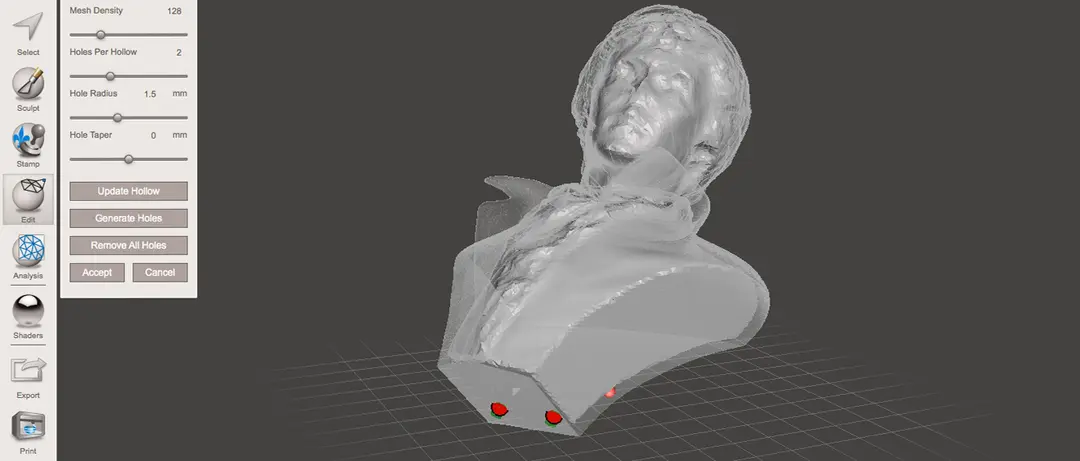

The detailed model of the eActros 600 printed in Rigid 4000 Resin enables the visualization of CGI work on the film set.

“In this specific project, we primarily saved time and stress, which enabled us to avoid potentially unwanted costs for the customer.”

Felix Aaron, Director

The visualization allowed Aaron and Mercedes-Benz Trucks to decide on specific camera movements directly on set, mitigating the potential costs of post-production. The time involved in post-production was reduced, as only one pre-coordinated version was produced for each scene. "We were able to respond to customer feedback on site, make adjustments, and fine-tune shots that we would then reproduce in CG," explains Aaron.

After just three hours, the shots were not only agreed upon but also fully filmed, compared to a few days.

Aaron was able to speed up the project as he had footage available immediately, presenting the finished rough cut to Mercedes-Benz Trucks just two weeks after filming. "We could start editing straight after shooting, which was important because the timing was very tight. Thanks to the visualization through the 3D model, we were able to define a cut without having to wait for the final CGI work," explains Aaron.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.

Large-Format Resin 3D Printing

"In order to make decisions on set and get an idea of what the shot would look like, we needed a fairly lifelike model," says Aaron. Fine details, including brand logos, and a smooth surface finish were vital, and the model had to withstand repeated handling.

Rigid 4000 Resin, a durable, glass-filled material with high thermal resistance, was used to print the model, allowing it to withstand the spotlights on set or at trade fairs.

The high accuracy of SLA 3D printing means especially large models can be printed and assembled.

To create the model, 14 parts were printed in Form 3L and then assembled with epoxy, enabling the creation of a model even larger than the 21.4 L build volume. Learn more about printing larger than your printer’s build volume here.

Product Demo: Form 4L

See how Form 4L, our next-generation large-format resin 3D printer, takes the speed, accuracy, and reliability of Form 4 to a completely new scale.

3D Printing: Improved Communication, New Parts, & More

Aaron had considered using 3D printing as CGI visualization on set for some time and was delighted that Mercedes-Benz Trucks was as enthusiastic about the approach as he was. The 3D printed model made collaboration between all stakeholders more efficient, reduced project costs, and ensured that the commercial was completed on time despite a tight deadline.

"With 3D printing, we have found a way to combine the advantages of classic advertising production with new possibilities. We can discuss everything on set and have the technical freedom of CGI. This can be a sensible alternative, especially in the automotive sector."

Felix Aaron, Director

Mercedes-Benz Trucks also used the 3D printed model of its new eActros 600 as a visual asset at the launch event.

For Aaron, 3D printing brings the design freedom of CGI from the digital realm into the real world, opening up numerous applications for filmmakers for future projects, such as the preparation of camera lenses. "So far, we have used 3D printing to prepare our camera, for example. We printed the matching shell for lenses that we bought," says Aaron.

"There are no limits to either CGI or 3D printing. If you imagine something, then you can make it."

Felix Aaron, Director

Explore Form 4L to see how you can 3D print most large parts in under six hours, or contact a 3D printing expert to learn more.