After just one year with the Formlabs Fuse Series, Eaton’s manufacturing plant in Olean, NY, has reduced operating costs significantly, replacing 90% of their previously machined Delrin fixtures, and improving their responsiveness and efficiency on the factory floor.

“We anticipated about a nine-month ROI on the Fuse system. And we ended up getting that in about six.”

TJ Zurell, Senior Manufacturing Engineer, Eaton at Olean

In manufacturing terms, a ‘single-piece flow’ requires many, many moving parts. At Olean, 15,000 metal oxide varistors (MOVs) move through their single-piece flow every day, ushered along by a complex fleet of machines as raw material is compressed, painted, ground to parallel, welded, tested, and assembled into the final product: surge arrestors for utility poles and stations.

With so many machines, robots, and moving parts, the team at Olean requires a constant supply of new production consumables and manufacturing aids that range from jigs, fixtures, and end-of-arm tooling (EOAT) to automation aids, replacement parts, and more. These parts are essential but traditionally have long lead times, are excessively costly to machine, or are simply clunky and hard to use.

We spoke with Olean’s Senior Manufacturing Engineer, TJ Zurell, and Eaton’s Additive Manufacturing Center of Excellence (AMCoE), to learn how manufacturers can reduce costs, improve efficiency, encourage creative thinking and buy-in, and insulate their supply chain with SLS 3D printing.

A Hub and Spoke Approach to Industry 4.0

With over 209 manufacturing locations across 35 different countries and nearly 93,000 employees, new methods, processes, and products are developed all the time. Eaton’s strategy for implementing Industry 4.0 — the ongoing digitization of manufacturing and other industries — includes using 3D printing to solve everyday problems on the assembly line, improve worker safety, increase productivity, reduce costs, and more.

The AMCoE was founded in 2016 as a specialized 3D printing research project for the aerospace division of Eaton. It has become a 3D printing knowledge hub and a 3D printing resource for Eaton’s 209 distributed manufacturing sites. “Our Additive Manufacturing Center of Excellence is one piece where we’re here to help support some of the issues that come up within our manufacturing plants,” says Kathleen Chou, AMCoE Additive Manufacturing Applications Manager.

The AMCoE faces a complex challenge — supporting the 209 different manufacturing locations with vastly different product catalogs. A plant like Eaton Olean, producing these surge arrestors, has a completely different workflow than an aerospace plant.

The AMCoE has to understand what each plant does in order to recommend the right additive tools for the job. It’s a two-way street, and oftentimes a 3D printing solution will come up from a plant that the AMCoE can then share with other plants that have similar workflows or equipment.

Cameron Peahl, Eaton’s Global Additive Manufacturing Strategy Manager for Industry 4.0, leads a global oversight committee comprised of leaders from across the company to ensure every Eaton location has access to the best technology and most up-to-date knowledge possible. “Eaton is a really exciting place for additive because we have such a diverse manufacturing footprint and such a diverse product portfolio… So that leaves us with a lot of opportunities, but it also means that there's a lot for us to go after, and it requires a lot of focus,” says Peahl.

These metal oxide varistors (MOVs) are manufactured by just three plants in the United States, including Eaton Olean. Olean produces 15,000 of them every day, and manufacturing efficiency, productivity, and throughput are of the highest importance.

After they’re pressed, painted, ground, tested, and finished, the MOVs will be assembled into these surge arrestors for use in protecting utility lines everywhere, from the telephone pole outside your house to the airports managing global traffic.

The 3D printing industry moves fast — new materials, new printers, and new applications come out seemingly every day. Eaton’s global council was formed to narrow the field and do some of the heavy lifting of evaluation and integration for the plants, so they can focus on their own unique workflows. “We've come up with a portfolio of standards across all the different modalities that our sites can adopt and choose to invest and grow with,” says Peahl.

To adhere to the standards set by the global council, the AMCoE conducts a rigorous evaluation of new technologies to determine their suitability for different Eaton sites. “It usually takes six to nine months to do a proper vetting of a system. And what we're really looking for there is ease of use, reliability, and repeatability,” says Peahl.

Easy to Integrate: Formlabs at the AMCoE

The Fuse 1+ 30W and Fuse Sift at the AMCoE — the system’s accessibility and small footprint have made it easy to integrate into an already packed workroom, and easy to learn for all the technicians.

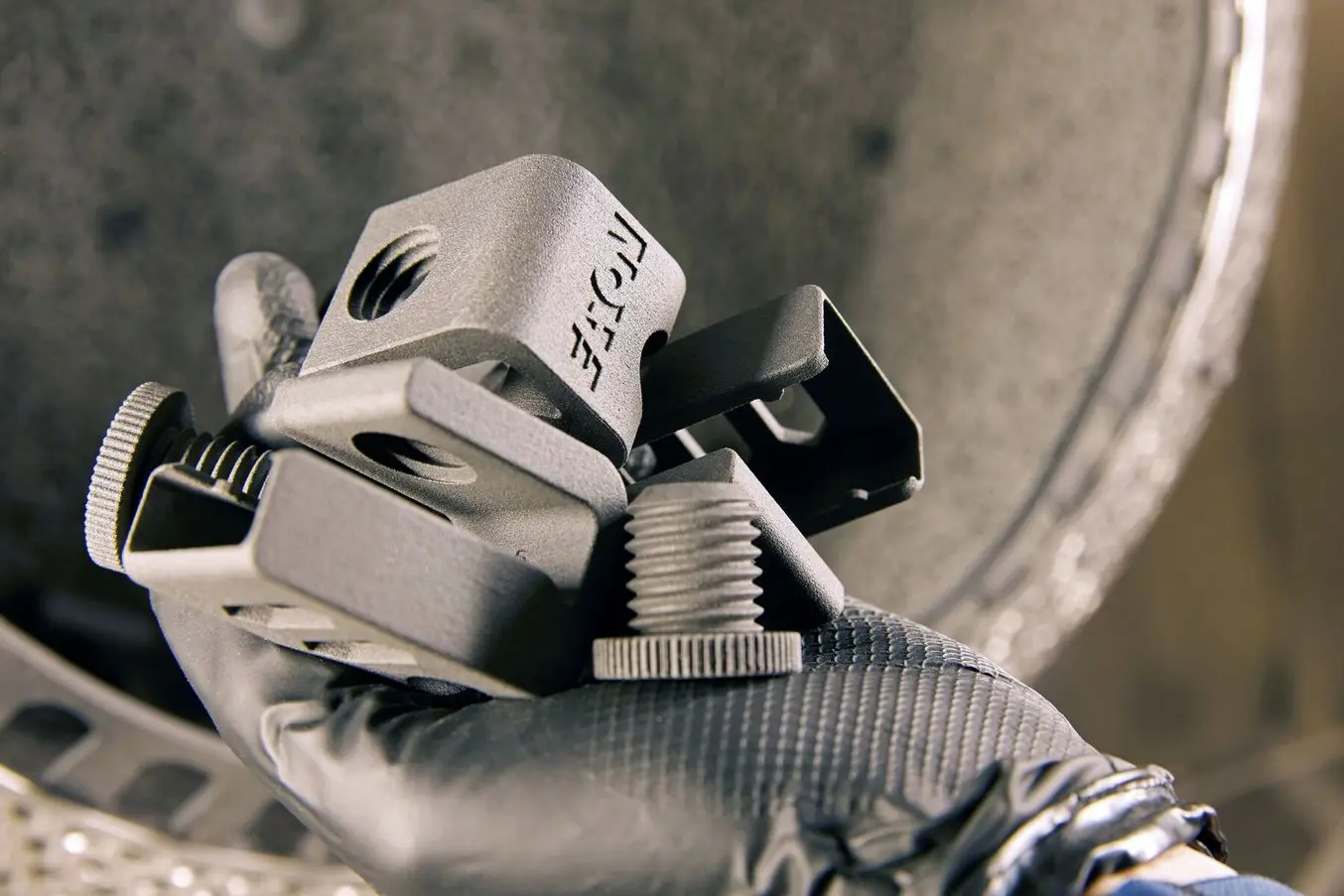

These helmet clip parts were requested by a plant employee who had to wear voltage warning monitors, but was frustrated with the wearables available. The solution was a custom-designed SLS 3D printed hard hat clip. The new clips keep the monitors out of everyone’s way while still doing the job of ensuring safety.

For manufacturing sites, any time spent tinkering with machines is production time wasted, and with increased pressure on productivity for all domestic manufacturers, 3D printers have to be incredibly reliable and straightforward. “We want industrial machines that we can rely on and leverage… we don’t have time to wait on service calls, we don’t have time to tinker with settings. It needs to print what we want to print when we want to print it… Every day that machine sits on the floor and it’s not plugged in, it’s not running, is money and opportunity lost for us,” says Peahl.

SLA and a Step-Change With Form 4

In 2021, the AMCoE team had evaluated several stereolithography (SLA) machines, but hadn’t settled on a single manufacturer that provided the three main tenets of their search: ease of use, reliability, and repeatability.

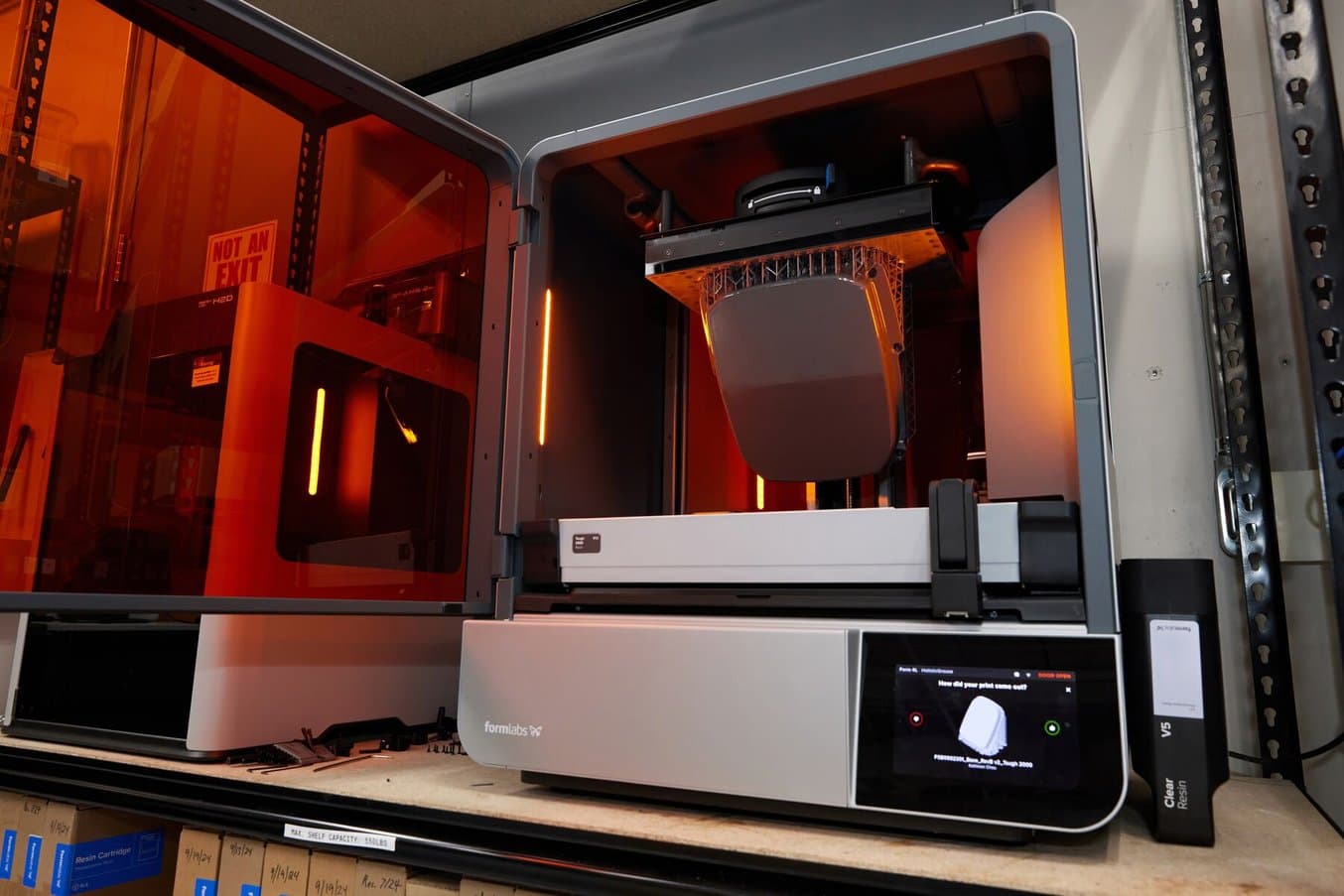

“We brought Formlabs in around that time and immediately found a difference in terms of ease of use,” says Peahl. After standardizing the workflow for Formlabs SLA with the Form 3 generation, in 2024, the Eaton team upgraded to Form 4 and Form 4L.

“When we upgraded to Form 4, it truly was like a step change in the technology. All of a sudden, this process that was really intriguing from a quality standpoint and a dimensional accuracy standpoint is now lightning fast. So now we’re combining ease of use with efficiency and accuracy and reliability.”

Cameron Peahl, Global Industry 4.0 Additive Manufacturing Strategy Manager

The reliability and size of Formlabs Form 4L have made it indispensable for the AMCoE’s operations. “The ability to actually print something big can be really important for us, and the other way that we use it is having a smaller number of parts…. We can process those and move through those much more quickly with the speed and size of the Form 4L,” says Chou.

The Eaton Additive Manufacturing Center of Excellence (AMCoE) acts as a knowledge hub and resource center for Eaton’s many manufacturing plants, providing test parts, machine evaluations, and integration plans for new technologies.

Years after first vetting Formlabs SLA printers, the Form 4 and Form 4L are the printers Eaton will recommend to manufacturing plants that are looking for highly accurate parts for use on their production and assembly lines. Or, if a site needs a specific replacement part for an injection molded plastic component, the AMCoE can print and ship it to them for just a few dollars and in less than a week. For replacement components on huge manufacturing equipment systems, there often isn’t any solution other than to wait for months for a unique injection molded component from the OEM. 3D printing offers a fast, inexpensive alternative for these one-off cases.

“If I'm engaging with a factory that says, we need sub-micron level accuracy, really good surface finish, high repeatability on fixtures or tools, that immediately often triggers a ‘hmm, I think we might be talking about SLA here,’” says Peahl.

Material variability also plays a role in the AMCoE recommending Formlabs SLA printers — plants are often dealing with chemicals like coolants, insulators, coating solutions, and more, at a range of temperatures and in different environments. Being able to access a range of materials within one system can prove invaluable when a site has something new pop up every day.

“SLA can provide unique material properties in terms of hardness, strength, rigidity, and temperature resistance… and the other one we liked is Formlabs Color Resin. When we need custom coloring or very specific colors, it allows us to prototype in a real color that we can’t do in some of the other systems,” says Peahl

Case Study: SLA Cover Part

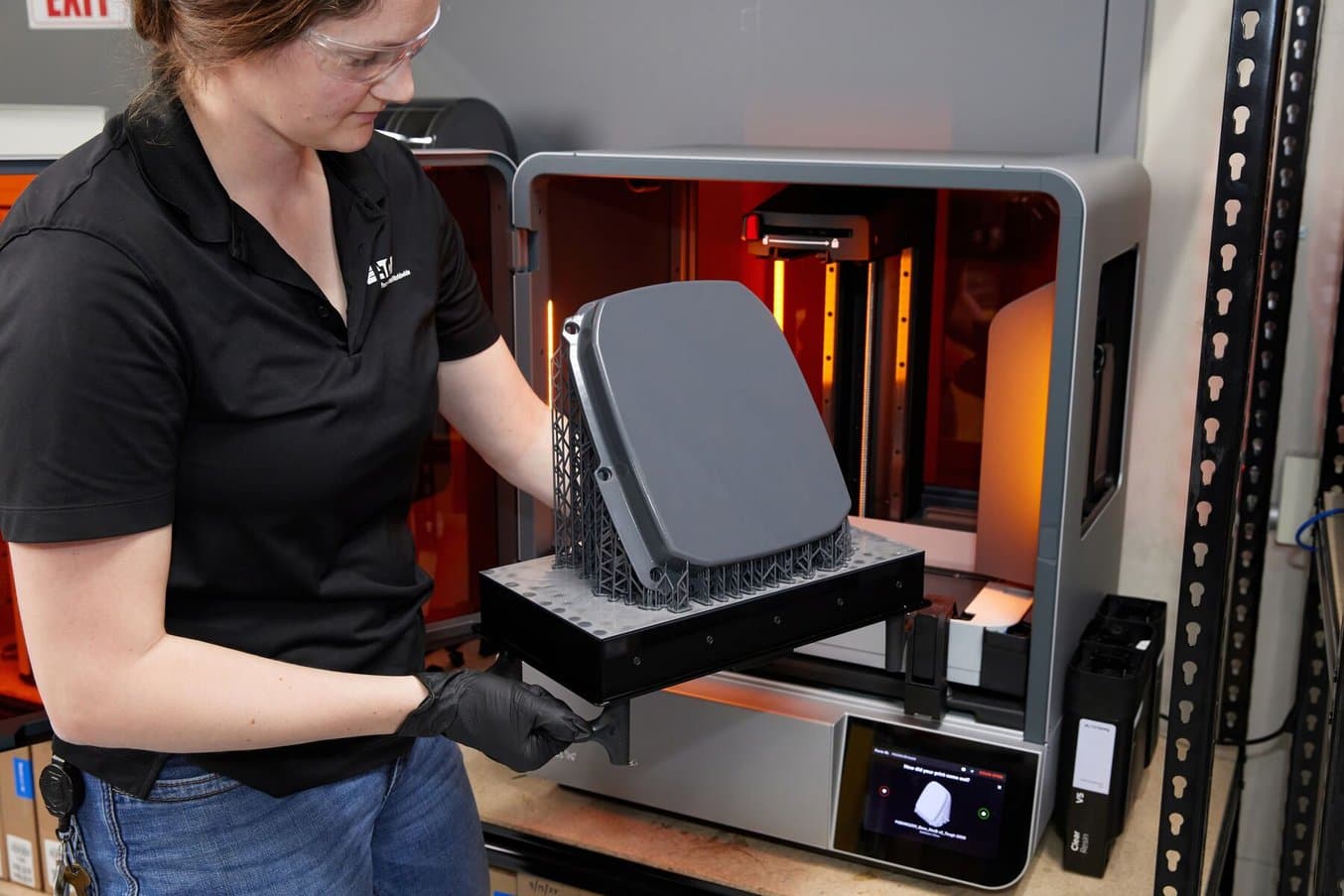

This cover part was printed on Form 4L at the AMCoE in Tough 2000 Resin for a plant developing a covered assembly exposed to moisture and heat.

One of Eaton’s product design teams recently reached out to Chou at the AMCoE with a request for an assembly cover component that would be used in functional testing. To source the part from another supplier could take weeks, if not months; it required high moisture resistance, dimensional accuracy, and durability, and was too large for the FDM printers. Chou was able to finalize the design and print it on Form 4L in Tough 2000 Resin, creating a rugged, waterproof part with a quick turnaround time. “We wanted something that would hold up being exposed to water and could be a robust system for covering the rest of the assembly. This cover part is a really great example of being able to leverage the actual size of Form 4L as well as some of the materials,” says Chou.

Fuse for the Factory Floor at Eaton

The Fuse Blast has made on-demand manufacturing aids even easier — with 80% less time spent in the sifting stage, Zurell and the other engineers can spend more time evaluating processes and seeing where a 3D printed part could improve the workflow.

This tester cup includes delicate engraving that indicates the MOV size and the model part number. Fuse Blast can completely clear it out, hands-free.

Eaton’s AMCOE had selective laser sintering (SLS) technology for years before they vetted the Formlabs Fuse system. “SLS has a lot of advantages — you can have supportless printing, making it efficient to clean out parts, you have good geometric tolerance, and you have engineering-grade materials such as nylons. That’s a huge advantage for when we’re trying to do prototyping work as well as the tooling where we need extra stiffness,” says Chou.

The previous SLS printers at the AMCoE were large, industrial powder bed fusion machines, with price tags close to half a million dollars and complicated workflows that required dedicated operators and lots of technical support. These machines were used for requests completed by the trained staff at the AMCoE, but weren’t the type of ‘no tinkering’ machines that they would typically recommend to manufacturing sites as reliable, easy-to-use options. “The problem with those machines has been that they’re messy, they’re big, they’re cumbersome and prohibitively expensive,” says Peahl.

The AMCoE needed a printer that could deliver the engineering-grade materials and supportless printing of SLS, but with the ease of use and reliability necessary to make a printer work on-site in different manufacturing environments. In 2022, they brought the Fuse printer in to put it through its paces.

“The Fuse is attractive because it's a price point that is easily adoptable. The build volume is right for what a factory generally needs, and so when you match the footprint size plus the cost, it makes it attainable to a lot of our factories. Then the ecosystem around it and the usability was a step change in the SLS category.”

Cameron Peahl, Global Industry 4.0 Additive Manufacturing Strategy Manager

The SLS Advantage in Manufacturing: Factory Resiliency

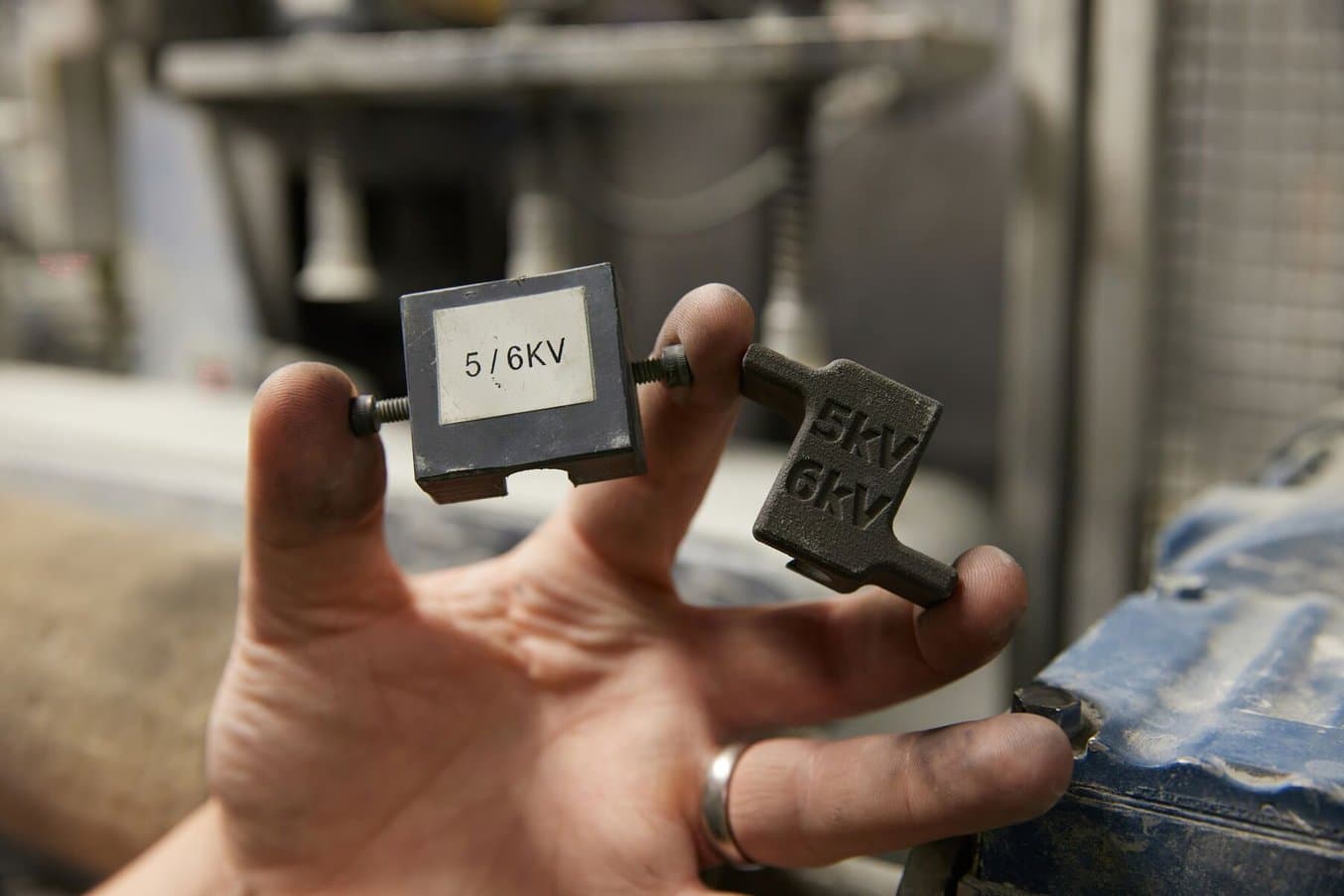

These spindle rings go around the end-of-arm tooling that holds MOVs during a painting process. They need to be available in multiple sizes for the different-sized MOVs, and be easy to change out.

Previously machined from Delrin (white parts, left), they are now printed in Nylon 12 Powder (grey, right) faster, less expensively, and with additional features like part numbers and identification markings.

After evaluating the Fuse Series ecosystem — the Fuse 1+ 30W, the Fuse Sift, and the Fuse Blast — the AMCoE started to recommend it as a solution for fast, inexpensive, complex manufacturing aids on the factory floor. “I think the real advantage to additive in factories, in an industrial environment, is speed. Speed, resiliency, and creativity,” says Peahl.

For industrial manufacturers, downtime is the enemy. The complex choreography of 50 different pieces of heavy machinery, all working inside a single-piece flow, means that any hiccup, broken piece, or slight delay could have big, downstream effects on throughput. “If something goes down on a shop floor, you’re waiting for an integrator to show up on site to help you replace those parts… or you’re sending out parts to a machine shop. And that might be eight to 12 weeks of downtime for parts to come back. That is nearly crippling for a factory,” says Peahl.

Finding new, efficient ways to reduce that downtime is the responsibility of those on the factory floor. Understanding on-demand fabrication with SLS 3D printing has encouraged them to try new things, suggest workarounds, and point out inefficiencies in their day-to-day. Having the Fuse Series accessible to everyone at Olean has led to new ideas and more efficient processes actually getting implemented.

“It allows our engineers to be more creative. In a matter of hours, they can test new fixtures, aids, and grippers. Our engineers can really step outside their comfort zones and keep innovating, helping our factories to keep doing better.”

Cameron Peahl, Global Industry 4.0 Additive Manufacturing Strategy Manager

Case Study: SLS Production Consumables at Olean

Olean now prints thousands of parts on their Fuse Series printers, but the engineering team’s exposure to 3D printing started early with desktop FDM printers at home. “We are all hobbyists at home; we’ve all had small printers. We still definitely like FDM to do an initial prototype, but we’re always thinking about how many of these we are going to make, or how frequently we are going to need this. And if it’s something more than once a year, we’re going to be putting it in SLS,” says Zurell.

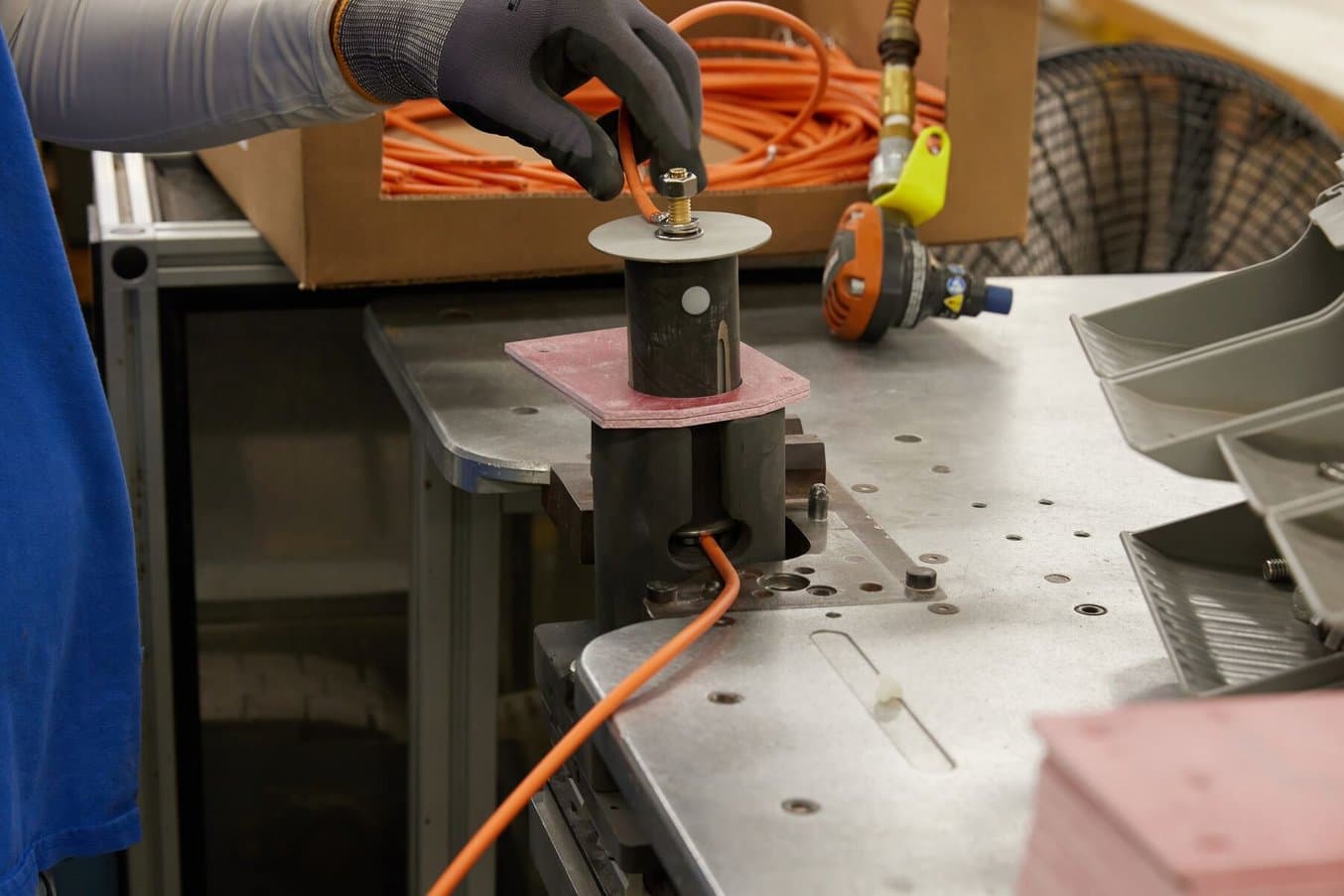

Step 1: Spring Plungers During Press Extrication

During the pressing stage, where large compression machines turn raw powder into a cylindrical MOV, an extricator goes in, grabs the part, and pulls it back to a conveyor belt. The spring plunger presets the height of the extricator for different-sized MOVs.

Previously machined nylon (left) in a multi-part assembly with screws; they’re now SLS 3D printed in one piece, with their identifying symbols engraved into the file. The new parts make it easier and faster for operators to change programs.

The first step in the manufacturing flow for MOVs is for raw powder to be pressed into a cylindrical shape. After the powder is pressed, an extricator arm reaches in and grabs the part, bringing it back out to enter the rest of the single-piece flow. The spring plungers preset the height at which the extricator arm operates. Previously, these parts were machined nylon with a printed and taped-on label identifying which preset was programmed. Now, they’re designed for an easy snap-fit application, with engraving showing the preset, no tape required. “These generally get lost; they wear out. It’s much quicker to replace them with 3D printing, we can get them overnight rather than a week. The old machined one, you had to adjust this hardware, it was kind of messy. With this, you slip it over the shaft and turn it in place,” says Zurell.

Step 2: Glass Collaring Ring Scraper

During glass collaring, paint builds up on this metal ring (mask) and needs to be cleaned so it doesn’t deposit paint onto the parts. A ring scraper keeps paint from building up.

Previously machined nylon (left) in a multi-part assembly with screws; they’re now SLS 3D printed in one piece, with their identifying symbols engraved into the file. The new parts make it easier and faster for operators to change programs.

For production consumables that wear out fast, batch printing on the Fuse Series means the team always has spares on hand. They can add these scraper parts to a nearly full SLS build whenever they run low on stock, rather than send a new request to the machinist and wait for a replacement. “Because we have so much product going through, they tend to wear out. That’s where production consumables become a factor,” says Zurell.

Step 3: (Distribution Class) Grinding V-Block Holders

These V-Blocks hold the MOVs as they go through a grinding process to parallelize their two flat surfaces. The main body of the part is machined bronze alloy, but it needs interchangeable pads for different-sized MOVs with softer gripping pads on top.

Previously, a cast urethane part with a steel insert was difficult to obtain on short notice if one was lost or damaged. The pads are now printed in bulk on the Fuse Series and designed with TPU covers (yellow) for easy changeover and part size identification.

During the grinding step, precision is everything. The surface holding the part needs to remain square as it brings the MOV through the grinder. If it’s out of square, they’ll have a tolerance issue later on, affecting the performance of the final arrestor. “We ensure that we keep a tolerance of less than 0.08 millimeters of parallelism on these sides. The SLS part does a very nice job at ensuring that squareness and parallelism are achieved,” says Zurell.

Prior to using SLS, the team was utilizing a combination of machined and overmolded urethane parts. Together, an individual urethane molded pad costs $45. Printed on the Fuse Series, these assemblies cost just $4.

“We don’t go through a lot of them, but it is about a $6,000 cost savings each year for us.”

TJ Zurell, Senior Manufacturing Engineer, Eaton at Olean

Step 3 (Station Class): Grinding With SLS Flipper Arms

The flipper arm picks up the larger, station-class MOVs and moves them through the grinding process, exposed to coolant chemicals the whole time. To increase grippiness, the SLS parts have an inset of FDM 3D printed TPU (neon yellow) on them, which is printed in long strips and cut down to size.

The flipper arm part holders are an improvement from the previous machined Delrin, around which the team just wrapped a rubber band for extra grip on the MOV parts. SLS printed Nylon 12 Powder combines the strength and chemical coolant resistance necessary for this application.

For larger MOVs, those used in station class arrestors that you can see on power stations or outside airports, there is a separate grinding machine and process. Instead of the V-blocks with SLS inserts and TPU pads, the part movers here are flipper arms made from SLS with an insert of TPU for grippiness. Previously, the parts were machined Delrin with a rubber band wrapped around for grippiness.

Step 4: (Distribution Class) Transfer Station

The new Centering Device is made up of a main base that stays the same, with interchangeable top parts that have been redesigned and optimized for material usage, strength, and printing efficiency.

The previously machined Delrin centering blocks (white Delrin affixed on top of a solid aluminum base, left) were heavy, clunky, and inefficient, not to mention expensive and difficult to get machined on short notice.

Different stages in the single-piece flow require MOVs to move through them at different speeds and with different spacing. To facilitate the transfer from one operation to the next, a transfer station has to rearrange the spacing of each MOV on the conveyor belt. A robotic elevator-like device picks up each MOV and moves it to the next conveyor belt, placing it down at its new spacing interval.

Historically, these recentering devices were bulky, heavy for the robotic operation, and made from clunky, machined Delrin. Though at first the team 3D printed a 1:1 replacement, the geometric possibilities with SLS 3D printing have allowed them to go one step beyond, creating a lightweight, easy-change device that saves on material and simplifies operations.

“When we first started incorporating 3D printing, we did direct replacements of machine nylon components. Now, we've kind of taken that a step further: how can we improve those original designs where we aren't confined by ease of machinability or ease of adoption. So it's been able to open up a lot of doors, a lot of new, more elegant designs."

TJ Zurell, Senior Manufacturing Engineer, Eaton at Olean

Step 4: (Station Class) Transfer Station

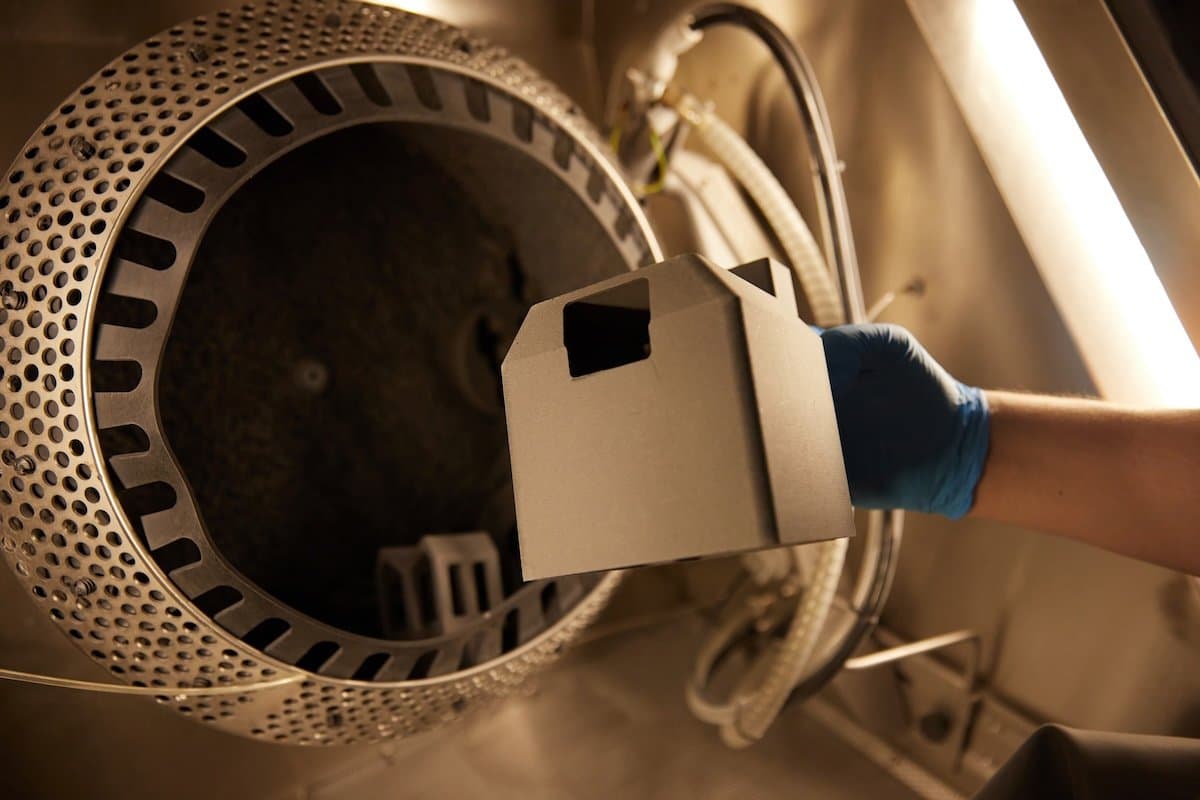

These part covers hold the MOVs as they’re moved into the metallizer by robot arms, protecting the metal conveyor belt from scratching or depositing metal on the surface of the MOVs.

This robotic end-of-arm-tooling (EOAT) picks up the MOVs from one conveyor belt and moves them to another as they enter the metallizing station. The EOAT can wear out, and reprinting in bulk on the Fuse Series is the easiest and least expensive replacement method.

SLS parts excel in preventing wear and tear on end-use products or machinery, or replacing components when they wear down past the point of utility. During this transfer stage, where the MOVs move from an ultrasonic wash after grinding to the metallizer, robot arms lift the parts from a conveyor belt and place them on another conveyor as they enter the metallizer. The part covers keep the metal conveyor from scratching or depositing metal on the surface of the MOVs, while the robotic ‘finger’ type EOAT parts have been designed to fit a range of MOV sizes and replace easily when worn down.

“Robots tend to be pretty generalized. They become more personalized when they reach your product, and additive manufacturing has helped us bridge that connection with our product to the robots.”

TJ Zurell, Senior Manufacturing Engineer, Eaton at Olean

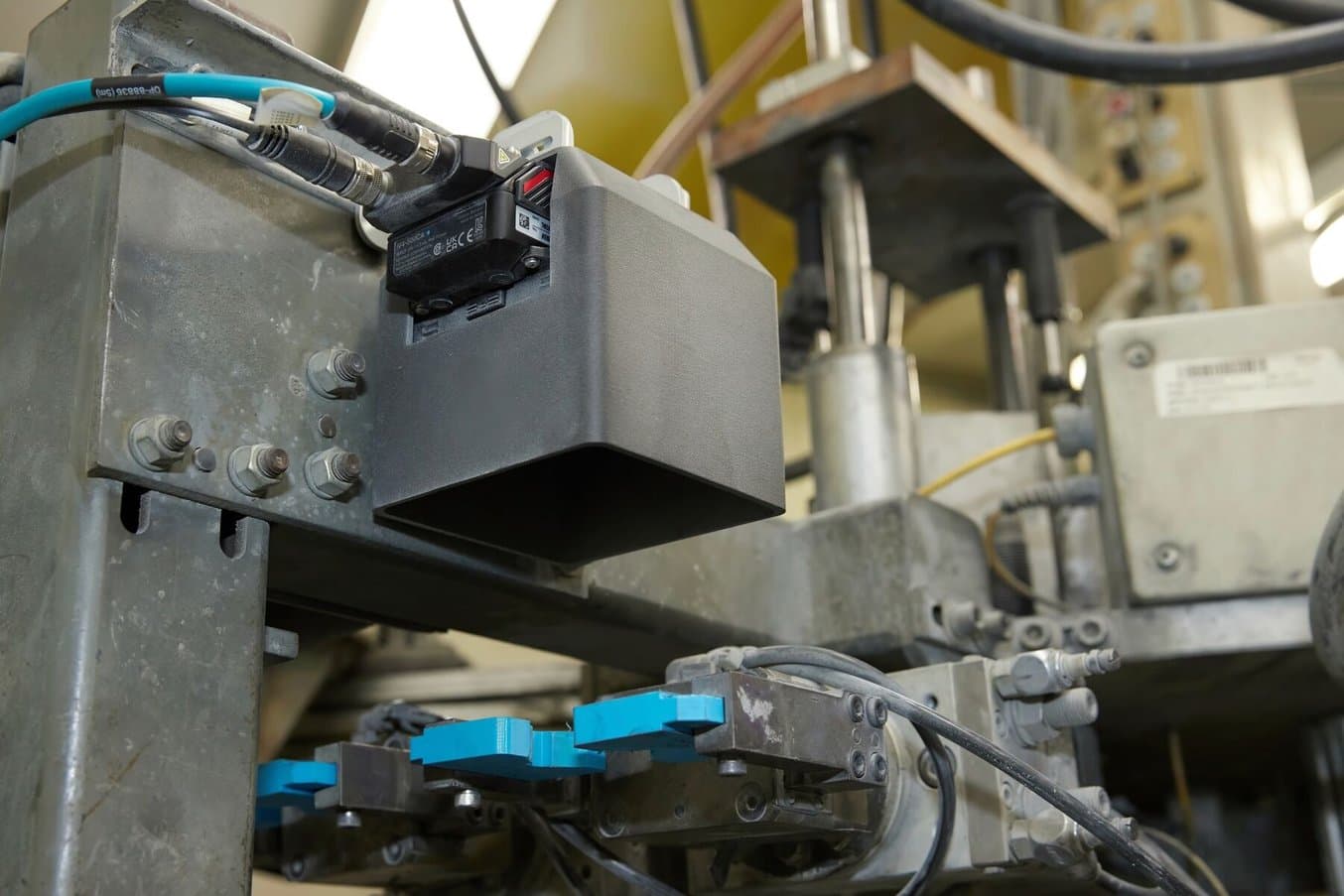

Step 5: Metallizer Station With AI Camera Overviews

This camera cover was developed by Eaton Olean specifically to protect the expensive and delicate AI cameras from too much environmental light, so they can focus more easily on the MOVs in front of them as they’re being checked for quality.

Access to an on-demand SLS solution at Olean made it easy to craft a solution, check the fit, and install it the next day. The hollow camera cover even allows for other small parts to nest inside it in the Fuse Build Chamber, making each print more efficient.

The MOVs move from grinding into welding, where their ends are tinned by adding an aluminum arc spray across each flat side. Inside the robotic welding room, each part is checked by AI cameras to ensure there are no irregularities. The team was aware that stray or inconsistent light from the welding process could affect the cameras’ image quality, so they created a custom-built housing that would both physically protect the camera and maintain consistency in image quality.

“Previously, there was no inspection, so we would accumulate about 70 scrap parts until we saw the issue. Now, with the camera system, we've been able to limit that to five, and it'll stop the line automatically so that we don't create a lot of scrap. SLS has helped us along the way to quickly implement this product solution,” says Zurell.

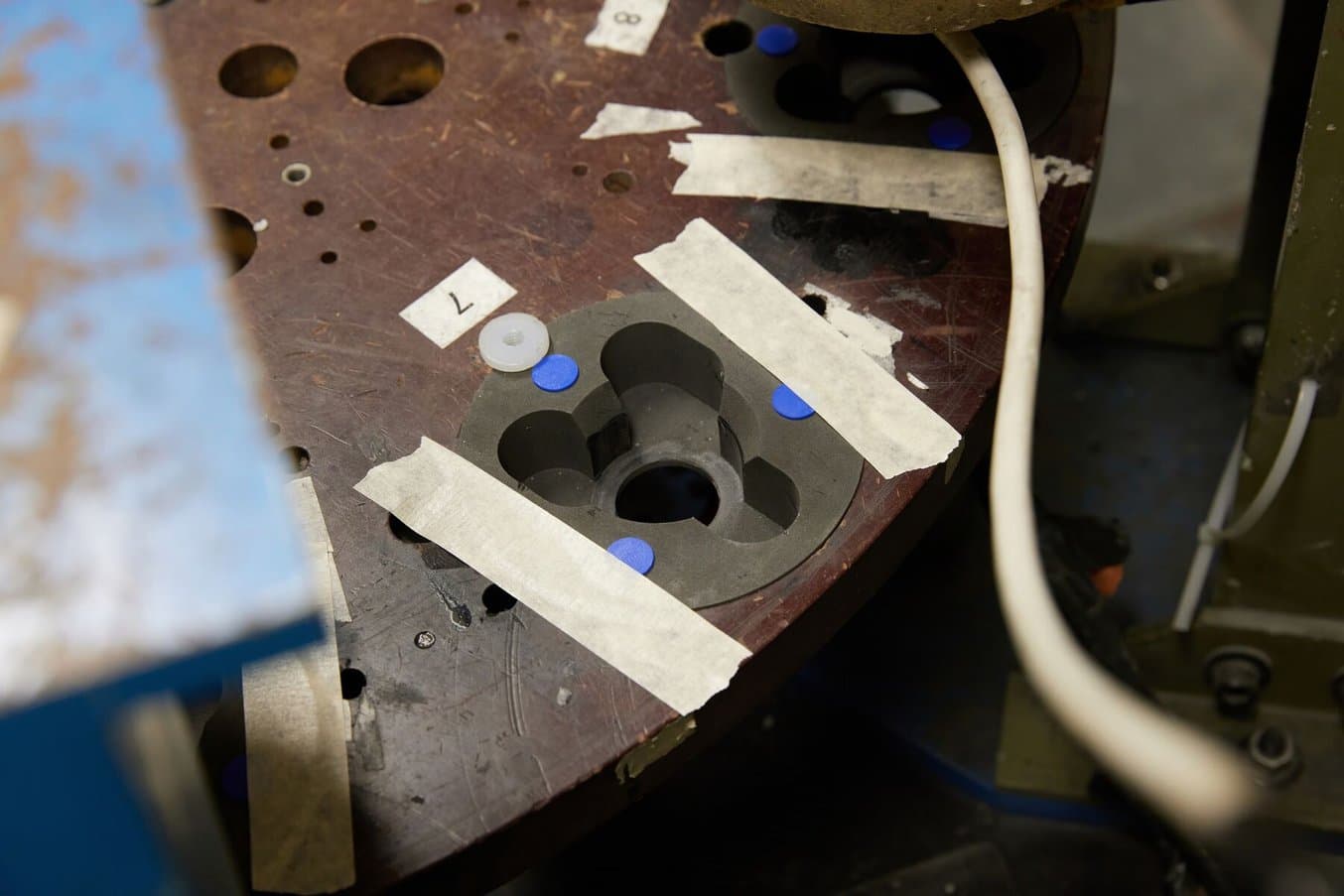

Step 6: Electrical Testing in Color-Coded Tester Cups

These tester cups hold the MOVs during the electrical testing phase, where voltage is shot through the parts to ensure performance when they’re assembled into full surge arrestors.

Previously machined from Delrin, the tester cups are needed in high volumes and for different-sized MOVs, which are identified by small colored FDM TPU inserts in the tester cups.

Ease of operation is a big driver of innovation at Olean. Previous versions of these tester cups were machined from Delrin and required masking tape or printed labels to identify which size of MOV was being tested. During line changeovers, these colored inserts make quality assurance easy — it’s immediately identifiable which part is being tested or needs to be changed. “We came up with a color coding system, a chart that will help operators quickly change over. So you'll see we have green, blue, and orange, and those all signify a certain size disc,” says Zurell.

The tester cups are a great example of utilizing both SLS and FDM 3D printing for their respective strengths. The cups themselves need to be highly accurate, strong, and impact-resistant, while the FDM colored dots are fast, easy to print, and require no special mechanical properties. “These were originally done in machined nylon. I think the cost out was about $17,400 for a full suite of parts that was needed. So this was huge,” says Zurell.

Step 7: Assembly

During assembly, this jig holds an underoil lighting arrestor in place to be placed into stacks that will eventually become the surge arrestors.

Previously, the jig was a multi-piece assembly machined Delrin and aluminum, expensive and difficult to get quickly if it wore out. Now, operators can request a replacement printed on the Fuse Series and have it the next day.

This assembly fixture was one of the workflow improvements proposed by the operators themselves. The previous machined Delrin fixtures were large, clunky, and had to be assembled onto an aluminum base, making them hard to use. When they wore out, new fixtures could take weeks to arrive from the machinist and cost many times more than the improved, SLS 3D printed versions.

Getting to Truly Advanced Manufacturing

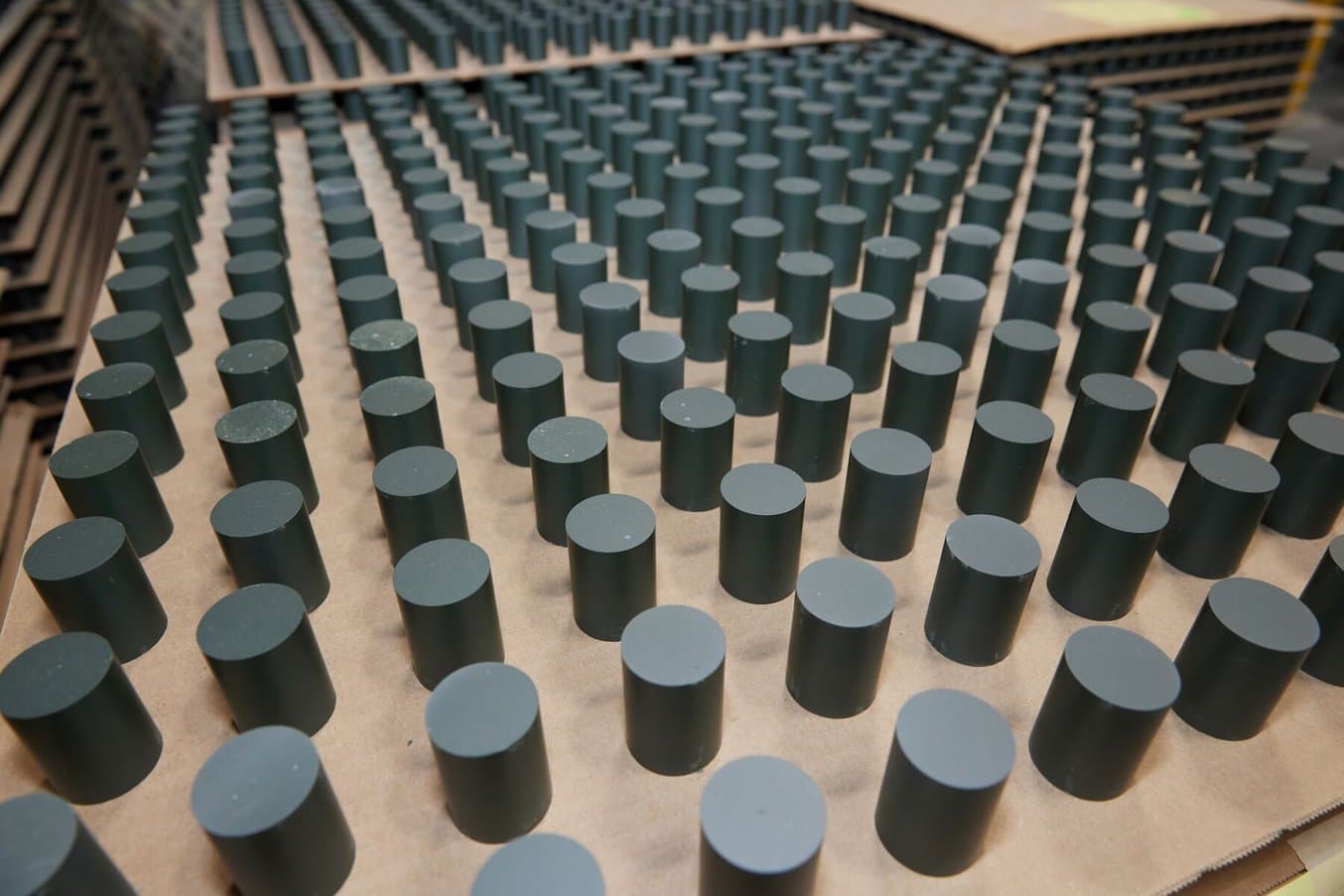

Eaton Olean’s many SLS 3D printed manufacturing aids, from robot EOAT to grippers, part movers, holders, and more.

SLS 3D printing isn’t a magical fix for everything that can go wrong at a factory like Olean. But an in-house Fuse Series SLS ecosystem has given Zurell and the team at Olean a way to make small changes that can add up to big savings in time and money.

“Cost savings is always a benefit… we're able to replace a lot of things that we would traditionally machine at high cost with low-cost additive. But I think the value is even higher by making our factories more self-sustaining, more resilient. And it allows our engineers to be more creative.”

Cameron Peahl, Global Industry 4.0 Additive Manufacturing Strategy Manager

With such a wide range of products, locations, languages, and workflows, there isn’t a one-size fits all approach to 3D printing, but the AMCoE has been able to narrow the field for factories like Olean, and deliver advice and solutions that can be tailored from the very general to the very specific, just like the robots on the floor at Olean.

Extras are everywhere — and easily replicated for whatever needs come up on the factory floor.

“Additive gives our engineers the ability to iterate quickly, to get immediate feedback, learn fast, and fail fast. And it just makes us move from manufacturing, stepping into true, advanced manufacturing,” says Peahl. When Olean brought in the Fuse, they predicted a nine-month ROI. But once they started printing, new ideas were continually put forward by those on the floor who pointed out everyday difficulties in their workflows.

“The adoption of 3D printing here has kind of taken off by storm down to the operator level. They’ve seen the improvements we’ve made just on the machined nylon components and come up to us all the time saying, ‘hey, can you make this?’ I’ve definitely changed my mindset as to how I design a product or tool, with 3D printing in mind.”

TJ Zurell, Senior Manufacturing Engineer, Eaton at Olean

Learn more about the Fuse Series or request a free sample part to test our nylon and TPU powders for yourself.