A SpaceX Dragon Capsule. Photo courtesy of NASA’s Goddard Space Flight Center.

Formlabs To Be Included In ISS Resupply Mission

Later this summer, SpaceX will launch its 25th commercial resupply services (CRS-25) mission to the International Space Station (ISS). On board the cargo capsule will be 4,500 pounds of food and equipment for the crew members on board the ISS. This mission is part of the ongoing cargo contract between SpaceX and NASA, and involves collaboration and partnership between the two entities.

Among the pieces of equipment on the CRS-25 flight will be electroplated samples printed on a Form 3 stereolithography (SLA) 3D printer. Using Alpha Space’s International Space Station test platform Materials International Space Station Experiment (MISSE-16) the samples will be exposed to the external environment of the space station and will later be returned to earth for further testing. In a recent publication, NASA speaks about the objectives of a different experiment as well as how 3D printing can influence the efficacy of the project.

The 3D printed and plated parts will be exposed to the harsh environment of space and the results could inform how NASA and possibly other aerospace manufacturers may incorporate additive manufacturing into potential future product plans.

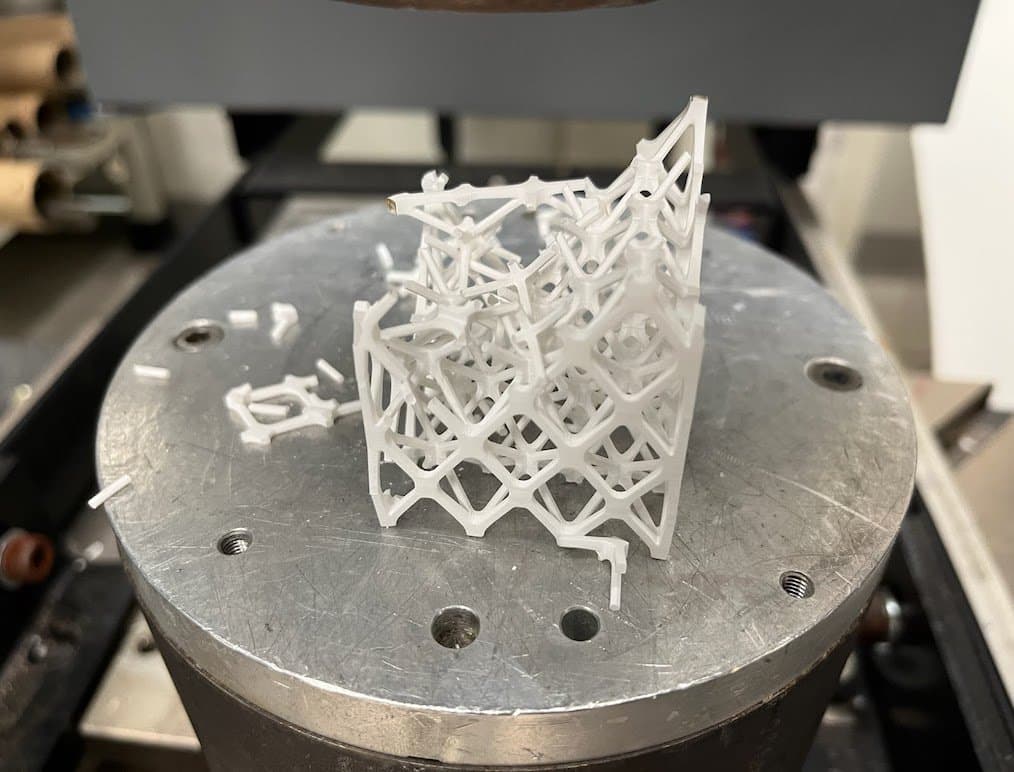

NASA engineers at the agency’s Goddard Space Flight Center have been working with the Formlabs printed parts to optimize the design of these brackets for maximum strength. The parts were printed in Rigid 10K Resin, a glass-filled material ideal for stiff, thermally and chemically resistant parts.

Pre-test Rigid 10K lattice compression sample (left) and post-test samples (right) that were loaded from the top.

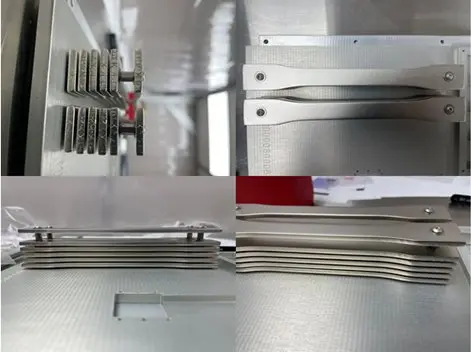

Plating Parts For Lightweight Strength and Reduced Off-Gassing

Electroplating the Rigid 10K Resin printed part increases its strength, as well as mitigates the amount of off-gassing the part emits. The plating process, done by plating specialist company RePliForm, created parts that were much lighter than traditionally machined components for the same application, and the Goddard team was able to design, print, iterate, and redesign in a much shorter time frame than with typical machining processes. Every component and process has to be priced out, but by reducing labor time, eliminating machining costs, and iterating in-house, the team was able to reduce their overall impact on that budget.

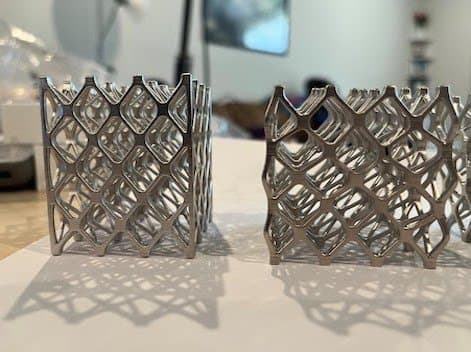

Pre-test electroplated Rigid 10K lattice compression sample (left) and post-test samples (right) that were loaded from the top

Electroplated Rigid 10K 3D printed parts being sent to the ISS.

Strength from Metal: Strategies and Use Cases for Electroplating SLA Parts

Read on to learn how engineers are adding metal to resin 3D prints, and why hybrid metal parts can open doors to a surprising range of applications, including (but not limited to) end-use strength and durability.