Need for Speed: Rome Snowboards Accelerates Product Development With SLS 3D Printing

Justin Frappier, product designer at Rome Snowboards, is able to design, prototype, and iterate every day by bringing SLS 3D printing in-house.

We’re always trying to do something that hasn’t been done before… We’re already seeing ROI, saw it in the first five months through just speeding up the prototyping.

Justin Frappier, Product Designer at Rome Snowboards

Since its invention in the 1960s, the sport of snowboarding has been associated with rebellion; its youthful, brash stars, baggy apparel, and flashy terrain park flips make it the punk younger brother of the posh winter sports world, while the style similarities to surfing and skateboarding help draw the same crowds and strengthen its counterculture image.

Snowboarding was born out of a desire to do things differently, and the requisite equipment is a highly technical reflection of that spirit. Snowboard equipment companies are constantly finding new ways to keep riders on the mountain longer with reliable, rugged, comfortable gear that can handle a full season on the slopes. To speed up their iterative process and maintain a steady stream of innovative new designs, manufacturers are turning to in-house 3D printing.

Rome Snowboards, a small, ten person company in Waterbury, Vermont, has a motto: All Ways Down. That applies to their ethos on the mountain and to their development process—product designer Justin Frappier is always looking for new processes and methods of creating bindings and boots. Rome’s overarching goal is to create equipment for longer, more comfortable rides that can withstand the torque and impact generated during flips, spins, and slides. With the addition of an in-house Fuse 1 selective laser sintering (SLS) 3D printer, Rome has been able to innovate faster and test their prototypes on the mountain, enabling a more rigorous iterative process. “We’re always trying to do something that hasn’t been done before… We’re already seeing ROI, saw it in the first five months through just speeding up the prototyping,” says Frappier.

Rome already creates some of the most well-respected products in the industry, earning reviews from outlets like White Lines, who chose Rome’s Vice bindings for their 2021-2022 100 Best Snowboarding Products list, saying “They’re a supremely versatile binding that blend tried and trusted tech with some premium features… Rome have hit the bullseye with the latest version of their best-selling Vice.”

Introduction to Selective Laser Sintering (SLS) 3D Printing

Looking for a 3D printer to create strong, functional parts? Download our white paper to learn how SLS printing works and why it's a popular 3D printing process for functional prototyping and end-use production.

Taking the Plunge With SLS

Before the Fuse 1, Frappier and his colleague on the design team at Rome had been doing the majority of design work by hand—working with materials like clay, bondo adhesive, and outsourced parts that all needed to be assembled and post-processed for a final looks-like prototype. 3D printing was on his radar, but it wasn’t until the Fuse 1 teaser put the spotlight on a 3D printed snowboard binding that Frappier started the research process. “It’s been something that I’ve wanted to get into the office for probably eight years….We weighed the pros and cons of different printers, different prices, and the Fuse 1 seemed a really good fit because it had the Fuse Sift and the printer—everything seemed well thought out,” says Frappier.

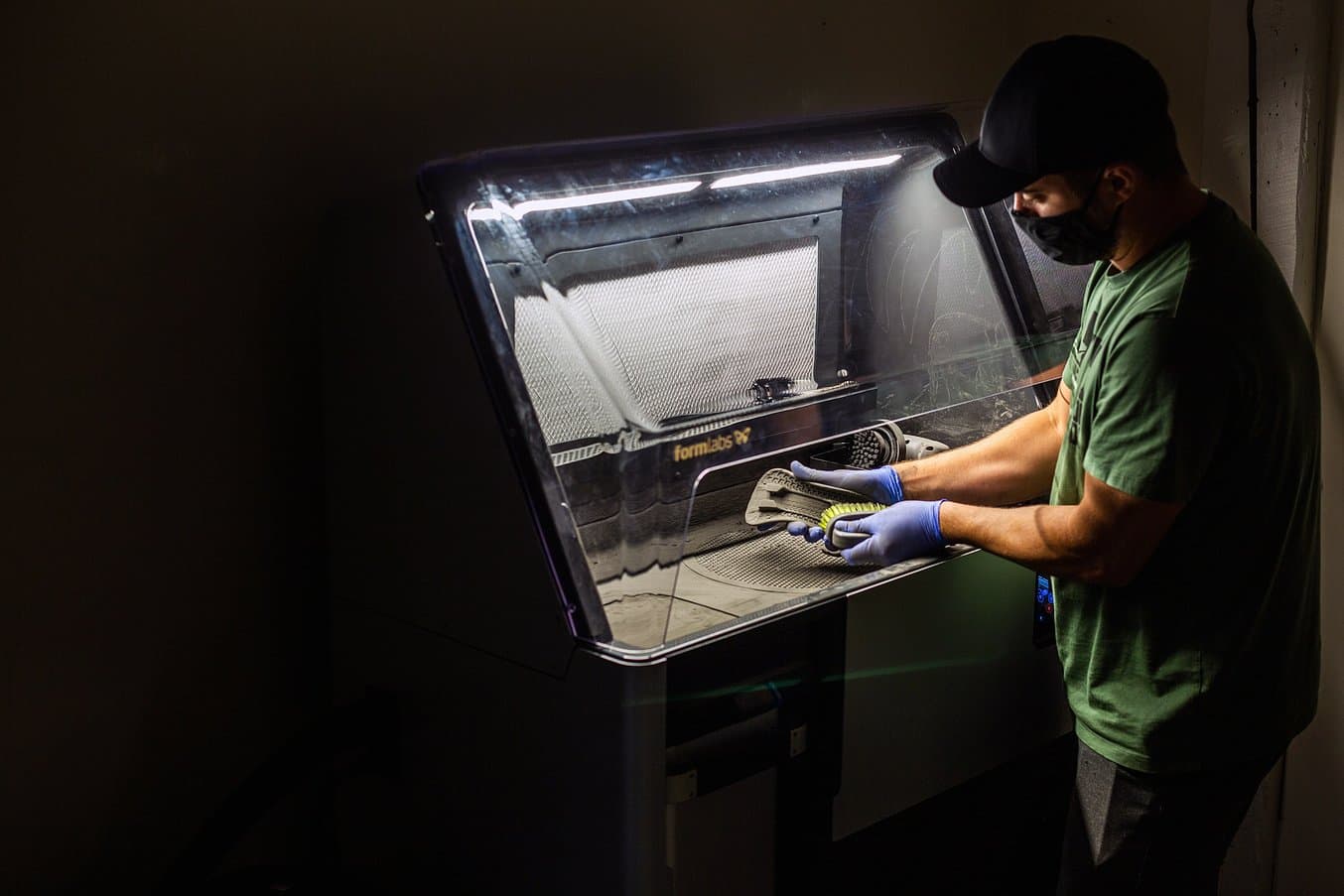

The Fuse Sift streamlines the post-processing and powder recyling process, freeing up Frappier's time for more design-intensive tasks.

Along with clay carving, the team had been ordering some 3D printed parts from just over the border in Montreal. Though it wasn’t exorbitantly expensive, the lead time did impact their ability to design at the speed they were used to. “We were in a waiting line with other companies, so the speed at which we were developing was dependent on getting the parts back,” says Frappier.

For a small company like Rome, known for having highly customizable binding components, delays in development put them at a disadvantage to larger manufacturers. Their strength lies in their ability to iterate, to get internal approvals quickly, and create unique, ‘industry-first’ products like their patented AuxTech, PivotMount, and AsymWrap technologies.

“We’ve only had the Fuse 1 for about six months, but we pretty much right away saw the benefit of having it in-house. We were working on buckles for six months or so. Printing a buckle, assembling it, seeing how it ratchets, the issues and interferences. It was super helpful to be able to use the printer, print a part, then the next morning check it, assemble, make revisions, and make it again the next day,” says Frappier.

The award-winning Vice binding, pictured here in the White Lines review. Photo courtesy of White Lines.

Outsourcing vs. In-House: When Does it Make Sense to Bring SLS 3D Printing In-House?

In this white paper, we evaluate the value proposition of bringing SLS 3D printers in-house, in comparison with outsourcing SLS parts from a service bureau.

Different Strokes for Different Folks

With Rome’s products, snowboarders can create a customized fit by adjusting several components, allowing them to account for different weight and size, riding style, or conditions. Having that many components however, necessitates a more complicated design, and requires that tolerances are exact, so that the assembly is seamless. The review from White Lines said “the highback, constructed from 100% nylon for a flex level that’s mercifully not bone-jarringly stiff. Essentially any rider will be able to jump aboard the Vice and feel instantly comfortable.”

That ease of use is all thanks to the care and time that the Rome team puts into each step. Frappier says, “We’re constantly trying to make sure our parts are perfect and reliable. Even if we have more parts and it’s a perfect assembly, the customer has a great experience because the binding is designed meticulously. 3D printing is great because we can fine tune every part, and make sure that every part works great as an assembly.”

Small Footprint, Big Output

Many companies reach that same level of design detail by relying on huge teams full of designers that can build off each other. Rome has only two designers, which allows them to move with agility, but can make the work environment non-stop. The Fuse 1 works alongside them, delivering continuous all-day printing when the team needs it, and has been a selling point when courting potential sponsorship-level athletes. Its accessible size and price make it an easy solution to integrate, even for companies that don’t operate with a ton of square footage or a big staff.

We’re such a small company compared to other binding manufacturers. We’re only eight to ten people in the Waterbury office and the fact that we have a full 3D printing set-up is pretty awesome. A lot of people think that we’re a bigger company. That’s the really nice thing about the Fuse 1, it’s attainable for a lot of small companies to have it.

Justin Frappier, Product Designer at Rome Snowboards

When athletes and equipment distributors come visit the Waterbury office, Frappier said the response to the Fuse 1 has been overwhelmingly positive. “When people see the printer they’re blown away. We’re able to take designs and show them a part right then, for both athletes and equipment distributor sales reps. Then we’re able to get their feedback on a part before we send it to tooling,” says Frappier.

Faster And Faster On Functional Prototypes

The 2022 product line from Rome won’t be mass-produced through 3D printing, but that hasn’t stopped the team from running some very realistic final validation tests. In the first winter season after getting the printer, the design team decided to do some very functional testing. They wanted to push the prototypes to their limit, to ensure that each buckle and each assembly would hold up to the conditions, and that they weren’t sending a part to a manufacturer without really making sure it was perfect.

“We don’t want to be wasting time, and we’re not wasting tooling because we’re messing up by going to the tool too early, so it’s making us more efficient,” he says.

Frappier and his colleagues took entirely printed bindings (except for a few metal hardware screws) out on the mountain in Vermont, increasing their speed with each run. Testing the flexion, strength, and durability of the bindings while on the mountain allows Frappier to cut weeks off their typical development timeline. Their success as a brand depends on that innovative spirit, and the surest way to kill creativity is for creative teams to be waiting for weeks on end for parts from outside vendors.

The main selling point was that we could ride the printed parts. We’ve never been able to do that with other parts. The first time for us we were on the base plate and the chassis components. Every run we’d go faster and faster, and they held up great, felt great. Now we can print, ride, and reprint the next day.

Justin Frappier, Product Designer at Rome Snowboards

Giving the design team complete control over the entire creative, testing, and iterative process has allowed Rome Snowboards to continue pushing the boundary of what’s possible with snowboarding equipment.

“We’re doing industry first things in every category. We’re always trying to do something that hasn’t been done before, and we’re only going to get better and better. We’re already seeing ROI, saw it in the first five months through just speeding up the prototyping,” says Frappier.

Removing and recycling unsintered powder is easy in the self-contained and streamlined Fuse Sift workflow.

Fuse Series printers enable designers to functionally test their products and iterate their products with no down-time waiting for parts from providers. For Rome Snowboards, the Fuse 1 has sped up the development process by an order of magnitude, allowing Frappier to take ‘All Ways Down’ while riding on 3D printed bindings. To see if the Fuse 1 can do the same for your products, order a sample or read our whitepaper case study comparing in-house SLS to service bureau printed parts.