Large-format 3D printers are one of the fastest-growing sectors of the 3D printing market. While some might think large-format 3D printers are inaccessible — only a few years ago, prices would start around $100,000 — the truth is that today’s large-format 3D printing options are finally within reach for more and more businesses.

Large-format 3D printers are available across the entire spectrum of cost and complexity. Traditional, industrial large 3D printers can cost over $500,000, but more accessible systems are now available for between $3,000 and $30,000 for all three of the most popular plastic 3D printing processes on the market today. Given the high cost of outsourcing large parts and prototypes, this means that investing in a large 3D printer can have a positive return on investment in months.

These accessible options are the focus of this article, where we’ll compare their advantages and disadvantages, and share a framework for how to evaluate which large-format 3D printer you should purchase.

Book a Free Consultation

Get in touch with our 3D printing experts for a 1:1 consultation to find the right solution for your business, receive ROI analyses, test prints, and more.

What is a Large-Format 3D Printer?

In essence, large-format 3D printing today means that the printer has a build volume beyond the 15-20 cm (5.9-7.9 in) cubic dimensions common in desktop 3D printers.

The sweet spot for most large 3D printers today is around 30 cm (11.8 in) in one of the dimensions and around 15-30 cm (5.9-11.8 in) in the remaining two. This build volume enables human-scale design and engineering, as well as the production of many smaller parts at once.

There are also 3D printers on the market that go well beyond this size and can print 50-100 cm (19.5-39 in) parts, but this often means that options are limited to industrial 3D printers, where prices skyrocket, complexity increases, and facility requirements become stringent.

Types of Large-Format 3D Printers

The three large-format 3D printing technologies available at accessible prices are the following: fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). Let’s take a closer look at each technology.

Fused Deposition Modeling (FDM)

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), builds parts by melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the build area. FDM is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers.

Mid-range large-format FDM printers are available from $3,000 and can typically print objects up to about 30 x 25 x 30 cm in size, while larger systems that can create up to 60 cm tall parts start around $6,000.

FDM Benefits

FDM works with a range of standard thermoplastics, such as ABS, PLA, and their various blends. The technique is well suited for basic proof-of-concept models, as well as low-cost prototyping of simple parts, such as parts that might typically be machined.

Disadvantages of FDM

FDM has the lowest resolution and accuracy when compared to SLA or SLS and is not the best option for printing complex designs or parts with intricate features. Higher-quality finishes require labor-intensive and lengthy chemical and mechanical polishing processes. Some large-format FDM 3D printers use soluble supports to mitigate some of these issues and offer a wider range of engineering thermoplastics, but they also come at a steep price. With large parts, FDM printing also tends to be slower than SLA or SLS.

Stereolithography (SLA)

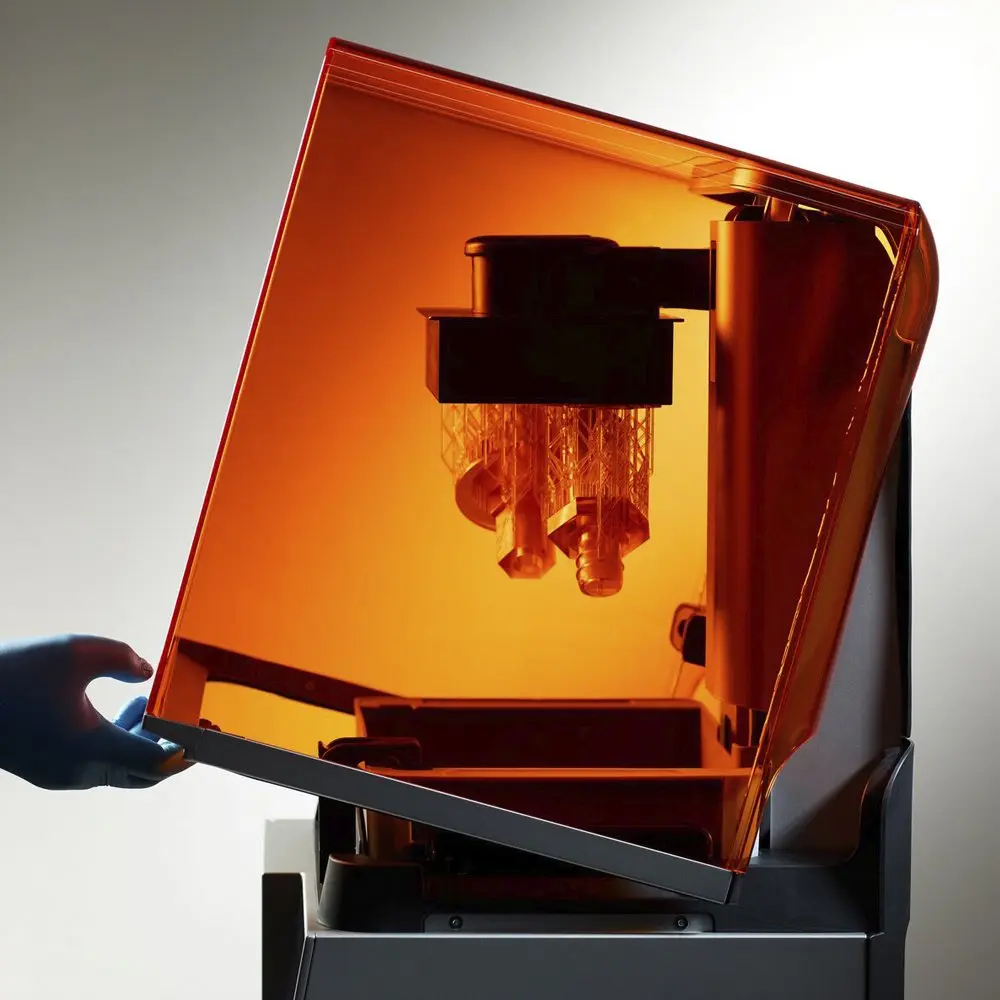

Stereolithography (SLA) printers use a light source to cure liquid resin into hardened plastic in a process called photopolymerization. SLA is one of the most popular processes among professionals due to its high resolution, precision, and material versatility.

While SLA used to be available only in smaller desktop printers or large industrial 3D printers that cost more than $200,000, with Formlabs’ Form 4L large-format resin 3D printer, businesses now have access to industrial-quality SLA for just $9,999. Form 4L has a build volume of 35.3 × 19.6 × 35.0 cm, making it ideal for rapid prototyping large parts for consumer products, human-scale medical models and devices, or producing multiple parts in one job for manufacturing applications.

Radio Flyer, the maker of the iconic Original Little Red Wagon®, uses Form 4L to prototype large components for final design reviews, like this scooter cover part printed on Form 4L in Grey Resin.

Introduction to 3D Printing With Desktop Stereolithography (SLA)

Looking for a 3D printer to produce high resolution models fast? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating parts with incredible detail, high dimensional accuracy, and superior surface finish.

SLA Benefits

SLA parts have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies, but the main benefit of SLA lies in its versatility. SLA resin formulations offer a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

SLA is a great option for large, highly detailed prototypes requiring tight tolerances and smooth surfaces, as well as molds, tooling, patterns, medical models, and functional parts. It also offers the material with the highest heat deflection temperature of 238 °C — which makes it an ideal choice for certain engineering and manufacturing applications — as well as the widest selection of biocompatible materials for dental and medical applications. SLA is also the fastest option for 3D printing large parts, up to 10-20x faster than FDM 3D printing with materials like Fast Model Resin on Form 4L.

Print Speed Comparison: Radio Flyer Seat Prototype

| FDM 3D Printing | SLA 3D Printing | |

|---|---|---|

| 1 prototype | 42 hr 3 min | 2 hr 37 min |

Compared printers and printing parameters:

- FDM 3D printer: Ultimaker S7, PLA, 100 microns layer height, 20% infill density

- SLA 3D printer: Form 4, Fast Model Resin, 200 microns layer height

Disadvantages of SLA

SLA’s versatility comes with a slightly higher price tag than many large-format FDM options. Resin parts also require post-processing after printing, which includes washing the parts and post-curing.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free SLA sample part to your office.

Product Demo: Form 4L

See how Form 4L, our next-generation large-format resin 3D printer, takes the speed, accuracy, and reliability of Form 4 to a completely new scale.

Selective Laser Sintering (SLS)

Selective laser sintering (SLS) 3D printers use a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for dedicated support structures, which makes SLS an especially effective choice for complex mechanical parts.

Because of its ability to produce parts with excellent mechanical capabilities, SLS is the most common additive manufacturing technology for industrial applications.

Just like SLA, SLS used to be only available in industrial machines starting at about $200,000. With Formlabs Fuse 1+ 30W SLS 3D printer, businesses can now access industrial SLS starting from just below $30,000 with a 30 x 16.5 x 16.5 cm build volume.

Parts printed on a Fuse Series SLS 3D printer.

Introduction to Selective Laser Sintering (SLS) 3D Printing

Looking for a 3D printer to create strong, functional parts? Download our white paper to learn how SLS printing works and why it's a popular 3D printing process for functional prototyping and end-use production.

SLS Benefits

Since SLS printing doesn’t require dedicated support structures, it’s ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-molded parts.

The most common SLS material is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon 3D printing creates parts that are lightweight, strong, and flexible, as well as stable against impact, chemicals, heat, UV light, water, and dirt. Other popular SLS 3D printing materials include nylon composites, polypropylene (PP), and flexible TPU.

The combination of low cost per part, high productivity, and established materials make SLS a popular choice among engineers for functional prototyping, and a cost-effective alternative to injection molding for limited-run or bridge manufacturing.

Disadvantages of SLS

SLS has the highest entry price of the three technologies. While nylon, polypropylene, and TPU are great all-rounder materials, material selection for SLS is more limited than for FDM and SLA. Parts come out of the printer with a slightly rough surface finish and require media blasting for a smooth finish.

Request a Free Sample Part

See and feel Formlabs SLS quality firsthand. We’ll ship a free sample part to your office.

Rapid SLS Production of High Performance Parts with the New Fuse 1+ 30W

Watch our product demo for a walkthrough of the Fuse 1+ 30W and SLS 3D printing with Formlabs experts.

Compare Large-Format FDM, SLA, and SLS Printing

Large-format 3D printing technologies aren’t interchangeable — the technologies all have distinct advantages and disadvantages that make them suitable for different applications.

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | |

|---|---|---|---|

| Resolution | ★★☆☆☆ | ★★★★★ | ★★★★☆ |

| Accuracy | ★★★★☆ | ★★★★★ | ★★★★★ |

| Surface Finish | ★★☆☆☆ | ★★★★★ | ★★★★☆ |

| Throughput | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| Complex Designs | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| Ease of Use | ★★★★★ | ★★★★★ | ★★★★☆ |

| Pros | Low-cost consumer machines and materials Fast and easy for simple, small parts | Great value High accuracy Smooth surface finish Fast printing speeds Range of functional applications | Strong functional parts Design freedom No need for support structures |

| Cons | Low accuracy Low details Limited design freedom | Some materials are sensitive to long exposure to UV light | Slightly rough surface finish Limited material options |

| Applications | Concept modeling Rapid prototyping Functional prototyping Manufacturing aids | Concept modeling Rapid prototyping Functional prototyping Rapid tooling Manufacturing aids Low volume, bridge, or custom manufacturing Dental models and appliances Medical models and medical devices Jewelry prototyping and casting Models and props | Rapid prototyping Functional prototyping Low volume, bridge, or custom manufacturing Long-lasting, durable manufacturing aids Medical devices, prosthetics, and orthotics |

| Print Volume | Up to 300 x 300 x 600 mm (desktop and benchtop 3D printers) | Up to 353 x 196 x 350 mm (desktop and benchtop 3D printers) | Up to 165 x 165 x 300 mm (benchtop industrial 3D printers) |

| Materials | Standard thermoplastics, such as ABS, PLA, and their various blends. | Varieties of resin (thermosetting plastics). Standard, engineering (ABS-like, PP-like, flexible, heat-resistant, rigid glass-filled), castable, and dental and medical (biocompatible). Pure silicone and ceramic. | Engineering thermoplastics. Nylon 12, nylon 11, glass or carbon-filled nylon composites, polypropylene, TPU (elastomer). |

| Training | Minor training on build setup, machine operation, and finishing; moderate training on maintenance. | Plug and play. Minor training on build setup, maintenance, machine operation, and finishing. | Moderate training on build setup, maintenance, machine operation, and finishing. |

| Facility Requirements | Air-conditioned environment or preferably custom ventilation for desktop machines. | Desktop and benchtop machines are suitable for an office environment. | Workshop environment with moderate space requirements for benchtop systems. |

| Ancillary Equipment | Support removal system for machines with soluble supports (optionally automated), finishing tools. | Washing station and post-curing station (both can be automated), finishing tools. | Post-processing stations for powder management and part cleaning. |

| Equipment Costs | Budget FDM printers and 3D printer kits start at around $200. Professional desktop FDM printers range from $2,000 to $8,000, and industrial systems are available from $15,000. | Low-cost resin 3D printers are available for $200 to $1000, professional SLA 3D printers are in the $2,500 to $10,000 range, and large-format resin 3D printers are in the $5,000 to $25,000 range. | Benchtop industrial SLS 3D printers start just under $30,000 for the printer and $60,000 for the entire ecosystem, including powder management and cleaning stations. Traditional industrial SLS printers start at around $200,000. |

| Material Costs | $50-$150/kg for most standard filaments, and $100-$200/kg for support materials or engineering filaments. | $100-$200/L for most standard and engineering resins, $200-$500/L for biocompatible materials. | $100/kg for nylon. SLS requires no support structures, and unfused powder can be reused, which lowers material costs. |

| Labor Needs | Manual support removal (can be mostly automated for industrial systems with soluble supports). Lengthy post-processing is required for a high-quality finish. | Washing and post-curing (both can be mostly automated). Simple post-processing to remove support marks. | Simple and semi-automated workflow for cleaning parts and recovering powder. |

How to Choose a 3D Printing Technology

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Large-Format 3D Printing: Outsourcing vs. In-House Production

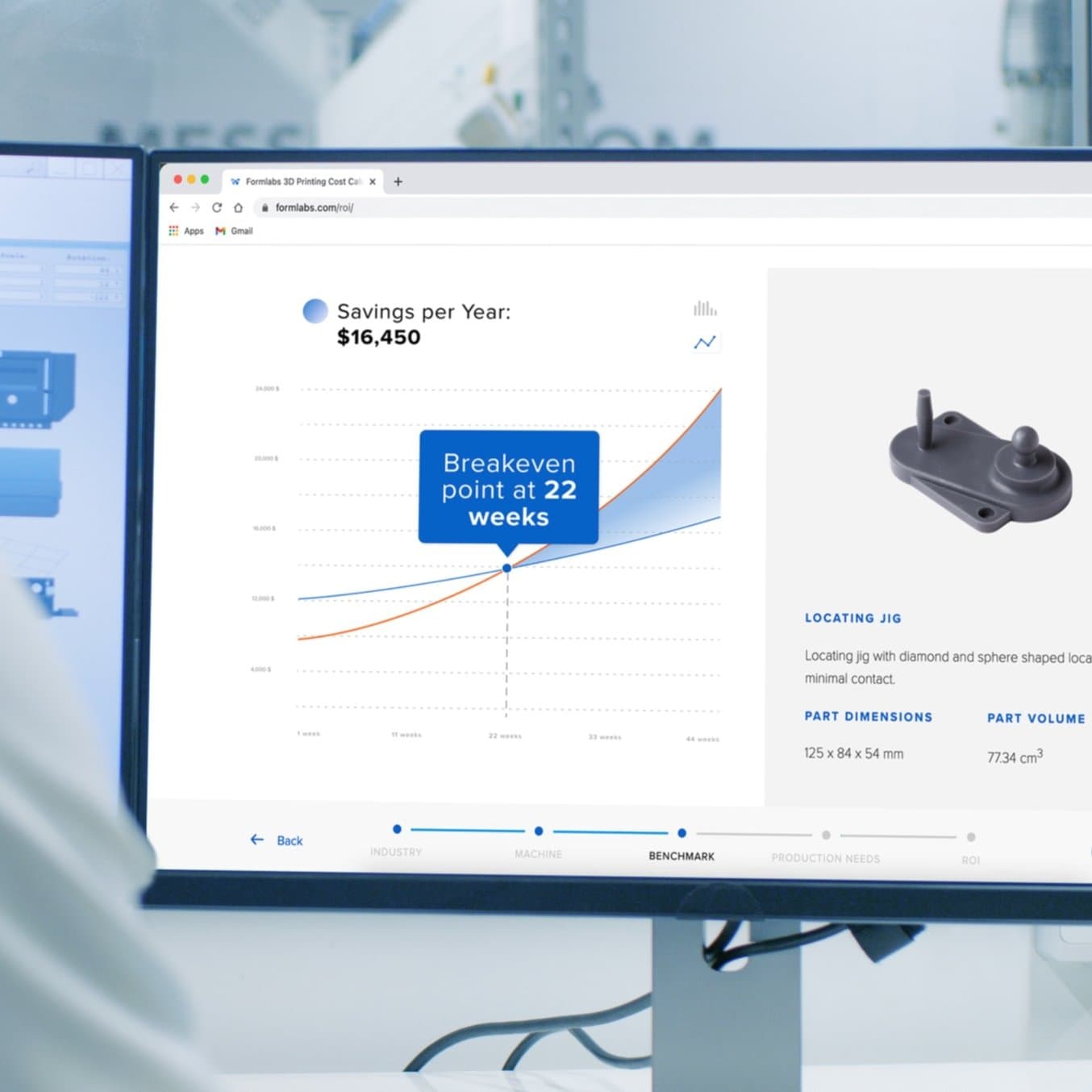

A large-format 3D printer represents a significant initial investment, but it can often recoup the initial investment even faster than smaller machines.

Outsourcing production to service bureaus is recommended when your business requires 3D printing only occasionally. Bureaus generally have several 3D printing processes in-house such as SLA, SLS, FDM, and metal 3D printers. They can also provide advice on various materials and offer value-added services such as design or advanced finishing.

The main downsides of outsourcing are cost and lead time. One of the greatest benefits of 3D printing is its speed compared to traditional manufacturing methods, which quickly diminishes when an outsourced part takes a week or even multiple weeks to arrive.

Outsourcing large 3D printed parts is also often very expensive. Depending on the number of parts and printing volume, investing in a large-format 3D printer can break even within merely a few months.

For example, climbing and skiing gear manufacturer Black Diamond added a large-format SLA printer to their fleet to create full-scale prototypes in-house.

“We have reduced our costs on full-size prototypes from $425 a print to $70 a print. With that savings, Form 3L would pay for itself in only three months, said R&D technician Matt Tetzl.

| Outsourcing | In-House | |

|---|---|---|

| Time | 7 Days | 3 Days |

| Cost | ~$425 | ~$70 |

By 3D printing full-scale prototypes in house on a Form 3L, Black Diamond reduced their prototyping costs by 80-90%.

Calculate Your Time and Cost Savings

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Microsoft’s Advanced Prototyping Center (APC), has used Form 4L to complete orders for 50 proof of concept (POC) builds of one of their most popular product lines. With Form 4L’s blazing fast speeds, the APC completed the order faster than they expected, with minimal post-processing.

“We were able to do three full builds in three days instead of a week and a half. So Form 4L already paid for itself in that build alone.”

Mark Honschke, Additive Prototyping Lead at Microsoft’s Advanced Prototyping Center

Inside Microsoft’s Advanced Prototyping Center: Where Prototypes Are Printed in 3D

In this discussion and Q+A, you'll get an exclusive look at the APC’s service bureau model — a centralized hub that functions as an internal production service for Microsoft’s hardware teams.

Harnessing the Power of Large-Format 3D Printing

The latest generation of large-format 3D printers has made manufacturing large prototypes and parts faster and much more affordable, opening the doors for almost any company to use 3D printing to improve product development and production.

With Form 4L and the Fuse Series, the first accessible large-format SLA and SLS 3D printers, Formlabs strives to revolutionize professional 3D printing. If you’re ready to leverage 3D printing in your business, find the right Formlabs 3D printer for your needs today.

Not sure which 3D printing solution fits your business best? Book a 1:1 consultation to compare options, evaluate ROI, try out test prints, and more.