3D printing, along with AI and VR technologies, is transforming surgery. By incorporating 3D printed models into preoperative planning processes, surgeons have been able to improve results while dramatically reducing operation time, cost, and risk.

Trauma patients and others who must undergo emergency surgery, however, have largely been excluded from the benefits of advanced technology in surgical planning. Most surgical planning workflows that leverage 3D printing take seven to 10 days to deliver, far too long for trauma patients, who often go into surgery mere hours or days after an accident occurs.

ImmersiveTouch, a Chicago-based medical software company, is on a mission to change the way emergency surgery is conducted. Their preoperative planning workflow will equip doctors to utilize AI and Spatial Computing to produce a 3D printed patient model in a matter of hours at the point of care. Jay Banerjee, CEO and co-founder of ImmersiveTouch, believes this capability can revolutionize how surgical teams approach trauma — and the success of the surgeries they perform.

“Our surgeons believe over 50 percent of trauma patients can benefit from this,” says Banerjee. “That’s over two million patients.”

ImmersiveTouch’s sophisticated ecosystem uses patented technology to help patients during medical emergencies. In order to be put into practice, ImmersiveTouch needed to secure FDA clearance for each element of its workflow, an expensive and lengthy process that required medical, legal, and technological expertise. To help secure FDA clearance, ImmersiveTouch partnered with the Formlabs Regulatory Affairs and Quality Assurance (RAQA) team.

“In the medical industry, large companies often maintain entire divisions dedicated to regulatory compliance. Startups can find themselves at a disadvantage,” says John Anderson, Healthcare Marketing Manager at Formlabs. “But companies like ImmersiveTouch produce ideas that can change the practice of medicine for the better. At Formlabs, we built the RAQA team to help those ideas get to market.”

The Ultimate Guide to Quality Assurance and Regulatory Affairs in Medical 3D Printing

This document aims to guide users in the medical device industry through every stage of the product development process.

3D Printing’s Vital Role in the ImmersiveTouch Workflow

Though ImmersiveTouch’s platform can support preoperative planning for many different surgery types, the benefits of using AI, mixed reality, and 3D printing are especially apparent when considering trauma cases. Trauma surgery needs to be performed quickly in order to minimize damage and give the patient their best chance at recovery.

“The digital revolution in surgery has made a significant impact in elective cases, where there is time to adequately plan and rehearse the surgery,” says Dr. Pravin K. Patel, Chief of Cranio-Maxillofacial Surgery at the University of Illinois at Chicago and Professor of Surgery.

Trauma surgery, however, has not experienced the same level of improvement. In order to work with maximum speed, emergency surgeons often have to forgo steps that would improve the results of the surgery and reduce the chance that revision will be required, such as pre-bending the metal plates to custom-fit the patient’s cranial structure. Dr. Patel sees an immense opportunity for platforms like ImmersiveTouch to make a significant impact on the field of trauma surgery.

“Up until now, training residents how to be good reconstructive trauma surgeons was theoretical, learned in textbooks. There was no rehearsal or high fidelity simulation for operative planning for trauma cases,” says Dr. Patel. “Rehearsing the operative procedure before the incision is made can decrease the operative time: optimizing the operative sequence, knowing the points where challenges may occur, and having picked the specifics of the skeletal fixation hardware through virtual trial. For the first time, the surgeon and the residents in training can manipulate the complex anatomy of the fractures seen in CT scans within minutes of the CT scan. Moreover, the virtual rehearsal can be 3D printed and the solid model used in the operating theater, an invaluable roadmap for the surgeon and the resident in training.”

"Research indicates that virtual surgical planning for trauma can be time-consuming. However, we've addressed this challenge with rapid virtual surgical planning coupled with on-site 3D printing," says Banerjee.

Dr. Amar Pravin Shah, Chairman of Radiology at Sinai Chicago, which is a Level 1 Trauma Center, says, “Every day I interpret a fracture of the face, spine, and/or other bones. Many of these fractures are complex and would undoubtedly benefit from ImmersiveTouch.”

Pre-adapted plates have been shown to reduce surgical time, improve the adaptation of surgical plates, decrease plate fatigue, and decrease scar formation, among a number of other benefits. One of the best methods for pre-bending plates involves the use of a 3D printed model of the patient’s anatomy. Unfortunately for trauma patients, current workflows for pre-bending plates typically take too long to be incorporated into emergency surgery.

According to Banerjee, reducing current surgical planning time from approximately 10 days to a matter of minutes will greatly increase the frequency with which surgeons implement preoperative planning methodologies, and therefore increase patient access to superior care. ImmersiveTouch is already being used widely, and the company has positioned itself for further expansion.

“Our mission is to provide optimal outcomes for people who suffer traumatic accidents.”

Jay Banerjee, CEO and Co-Founder, ImmersiveTouch

Talk to Our Medical Sales Team

Whether you need to make patient-matched surgical tools or are prototyping for a cardiac medical device, we’re here to help. Formlabs Medical team are dedicated specialists who know exactly how to support you and your company's needs.

Beyond pre-bent plates, the incorporation of 3D printing into preoperative planning can significantly improve surgeons’ ability to perform. 3D printed models have been shown to reduce operating time by nearly 20 percent, intraoperative blood loss by over 25 percent, and fluoroscopy use by over 23 percent for some surgeries.

Today, many patients miss out on those benefits. Over three million people suffer accidental injuries each year in the U.S. alone, and trauma is the leading cause of death for individuals under the age of 45. The surgeons who aim to mitigate damage and save lives cannot sacrifice time, but that means making compromises elsewhere. ImmersiveTouch aims to change that. With an AI-enhanced workflow, surgeons can go from CT scan to 3D printed model in just a few hours.

“The only platform that can give surgeons the ability to manipulate complex fracture components to reconstruct the anatomy is ImmersiveTouch,” says Dr. Patel. “The ability to export that reconstruction and rapidly produce a 3D-printed model makes the ImmersiveTouch workflow a game-changer for trauma surgery, not only for urban civilian trauma but opens up the opportunity for high volume military trauma.”

“With ImmersiveTouch, I am excited to be at the forefront of radiology, which allows my field to not only interpret cases, but to also be the guardian of this amazing technology so that all our surgeons have equal access and awareness of this powerful suite of tools.”

Dr. Amar Pravin Shah, Chairman of Radiology, Sinai Chicago

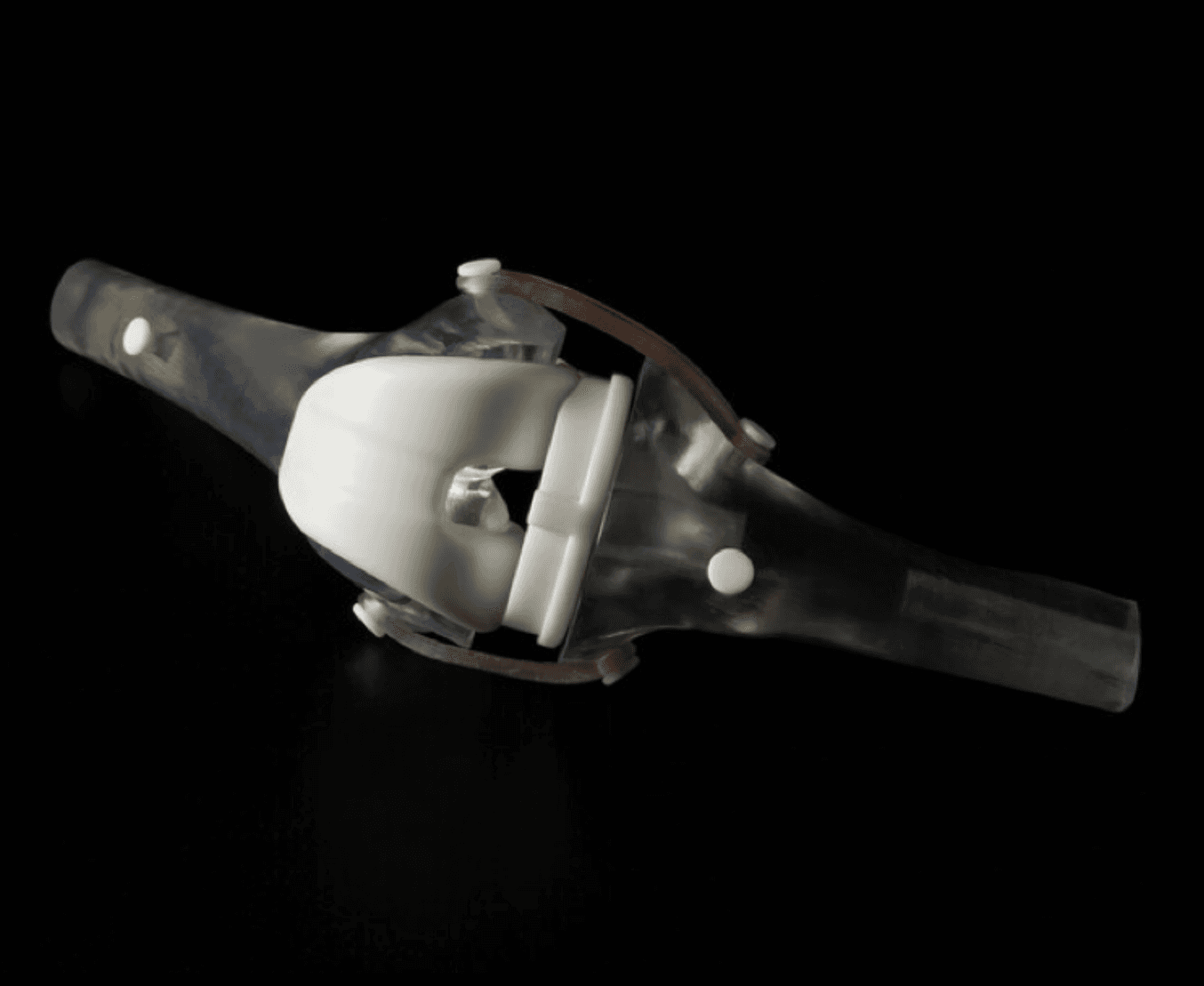

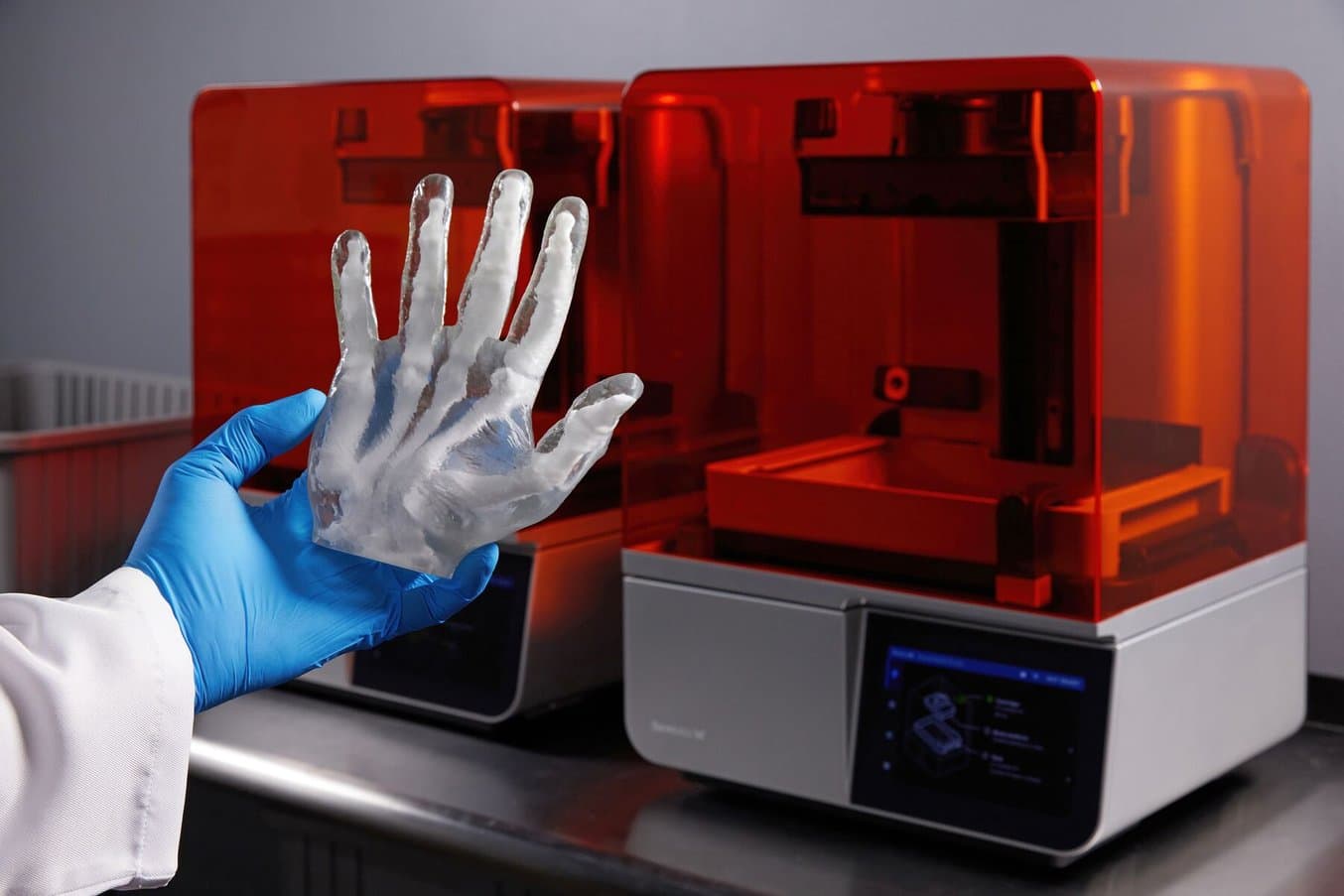

For instance, a patient who suffers multiple skull fractures in a car accident needs to be operated upon as soon after they arrive in the hospital as possible. Using ImmersiveTouch, surgical teams can examine their CT scan in a virtual 3D environment in minutes, segmenting their individual fractures. Next, they can optimally reconstruct their bones in the same 3D environment using ImmersiveTouch’s patented VR and AR technologies. Once they’re satisfied with their reconstruction, they can export the file to PreForm, Formlabs’ print preparation software, and print on a Form 3B+ desktop stereolithography (SLA) 3D printer for healthcare.

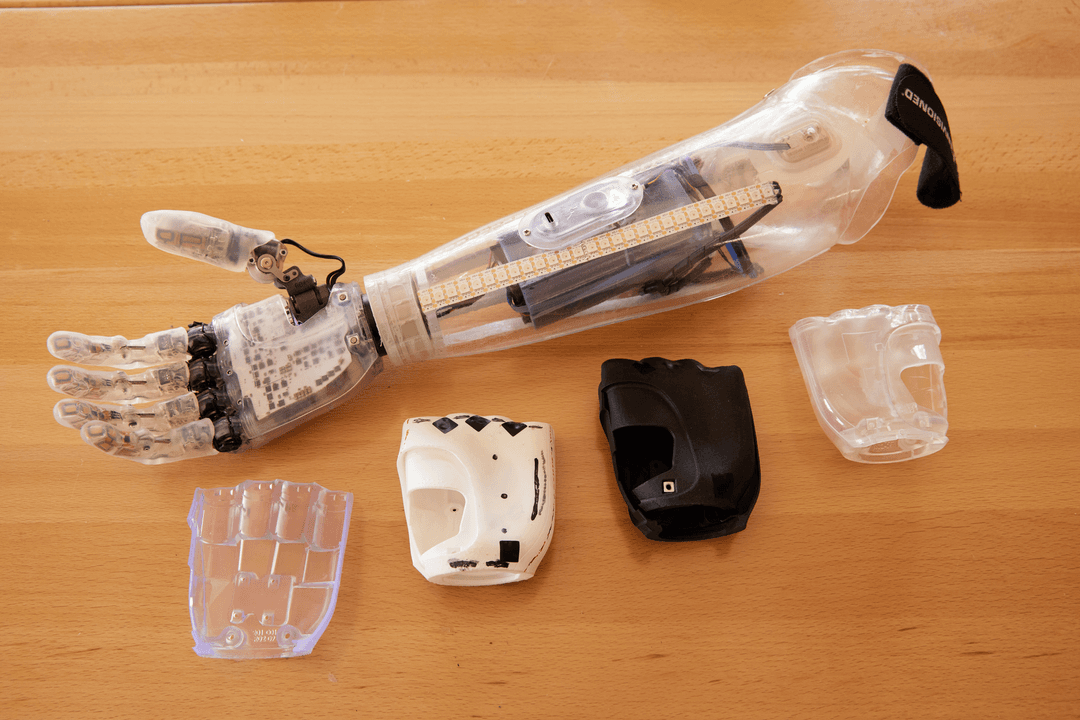

Anatomical models printed in BioMed White Resin and BioMed Durable Resin by ImmersiveTouch.

“Using that model, surgeons can pre-bend their plates according to their contours,” says Banerjee. “This is important because the surgeons can now simply place the plates on those fractures to fixate them and operate in record time — finishing on average about two hours ahead of time.”

“It is well known that surgical time is a critical variable that affects total blood loss and increased risk of infection. ImmersiveTouch’s VR and 3D printing workflow can decrease that time. Ultimately the patient benefits.”

Dr. Pravin K. Patel, Professor of Surgery and Chief of Cranio-Maxillofacial Surgery, University of Illinois at Chicago

“I see this technology as a win for both the patient and the hospital that serves the patient,” explains Dr. Shah. “We can reduce radiation to the patient by decreasing use of fluoroscopy in the operating room. At the same time, we can cut down surgical time by as much as three hours per case. This allows the hospital to perform more surgeries every day while at the same time decreasing patient operative risk from anesthesia, risk of infection, and blood loss.”

“ImmersiveTouch technology has been implemented in over 132 hospitals. We’ve received four FDA clearances for our mixed reality surgical simulators and surgical planning process with 3D printing.”

Jay Banerjee, CEO and Co-Founder, ImmersiveTouch

Medical 3D Printing Quality Management for Healthcare Innovators

From patient-specific anatomical models, to surgical guides, boluses, orthotic devices, and more, the adoption of 3D printing in healthcare is on the rise. It’s more important than ever that the quality of 3D printed parts meets the same quality standards as traditional manufacturing methods across applications.

ImmersiveTouch and Formlabs Team Up for the Regulatory Process

With good reason, medical care is highly regulated in the United States. Any medical technology like ImmersiveTouch that seeks to disrupt current processes — especially one so essential to a critical mode of care — will be thoroughly and comprehensively evaluated before it is granted FDA clearance. This can often place smaller companies, who have fewer resources, at a disadvantage when it comes to managing regulatory affairs.

Nonetheless, FDA clearance is absolutely essential for ImmersiveTouch. “Without it,” says Banerjee, “we’re not even able to have conversations with potential users.”

Namratha Kumara, product quality and regulatory specialist at ImmersiveTouch, says that among the four FDA clearances, their application for a 510 (k) to cover the 3D printing process was examined especially closely. “By far, the 3D printing FDA clearance has been the most elaborate one,” says Kumara. “That is why the supporting documentation provided by Formlabs and outside testing was so useful.”

ImmersiveTouch runs lean — it employs approximately 40 people — and needed to submit complex applications for four separate FDA clearances that covered the use of multiple advanced technologies. In order to help with the regulatory process as it pertained to 3D printing, they partnered with the Formlabs Regulatory Affairs and Quality Assurance (RAQA) team to access documentation on biocompatibility, sterility, stabilization time, strength, durability, accuracy, and other factors. Because of the complexity of the ImmersiveTouch use case, the FDA required that they use a third-party testing group to validate Formlabs documentation, a process that costs tens of thousands of dollars and can take more than a year.

“The proof that Formlabs had was very helpful to expedite the process. But the FDA asked for further validation, too, which is why we had to seek a third party,” explains Kumara. “It turns out that the numbers we got from both were exactly the same.”

“When the FDA needed external validation, we were able to show that the external numbers exactly matched the Formlabs numbers and it solidified our case. Formlabs definitely helped expedite the process.”

Namratha Kumara, Product Quality and Regulatory Specialist, ImmersiveTouch

Any small hiccup in the regulatory application process can trigger re-testing or further evaluation, which can drive up expenses and delay product timelines. Despite intense scrutiny, Kumara says, ImmersiveTouch managed to avoid these costly hurdles. “With supporting documentation to match the outsourced testing, the FDA deemed that we had valid proof and asked no more questions,” she says.

Creating Bone Simulation Models for Cutting and Drilling

3D printed bone-simulation models are revolutionizing medical training, surgical planning, research, and medical device development. This application guide walks through the bone-simulation material options for stereolithography (SLA) 3D printing and the entire in-house manufacturing process for bone-like anatomical models intended for cutting and drilling.

How to 3D Print Anatomical Models for Preoperative Planning and Enhanced Patient Consent

This white paper offers a practical walkthrough for physicians and technologists to get started creating 3D printed anatomical models from patient scans, reviewing best practices for setting up a CT/MRI scan, segmenting datasets, and converting files to a 3D-printable format.

Form 3B+: The Ideal Partner for Point of Care

Banerjee points out that the small footprint, cost-effectiveness, and ease of use make Formlabs SLA 3D printers ideal for the ImmersiveTouch surgical planning workflow. “Having 3D printing at the point of care is essential for this process to work,” he says.

ImmersiveTouch uses the Form 3B+ 3D printer to print parts that are used for patient teaching, resident training, and in the operating room.

Dr. Patel emphasizes the importance of a seamless transition from virtual planning to having a physical model. “For the first time, the surgeons and residents in training have an intuitive virtual environment that gives them depth perception and a sense of 'touch' as if they could manipulate the fracture segments as close to the real world as possible. The reduced fractures in the virtual environment can then be 3D printed in the real world,” he says. “The physical 3D models can be used for patient teaching, for resident training and, importantly, used in the operating room as a surgical instrument for skeletal fixation.”

Because many 3D printers with the materials capability and accuracy required for medical 3D printing are large, expensive, and require dedicated maintenance procedures and personnel, the printers are often installed at separate locations from the hospital. The process of obtaining a 3D printed model for preoperative planning can involve many different people and departments. Sometimes, it requires shipment of the 3D printed part, creating a timeline that would be unacceptable for trauma surgeries.

However, the Form 3B+ is compact and easy enough to use that it can often be located at the point of care.

“As soon as the fractures are fixed in the virtual environment, they get exported as an STL file to the printer,” explains Banerjee. “A lot of hospitals that have Formlabs printers also have trauma centers.”

“With a Form 3B+ at point of care, surgeons can take a finished 3D printed bone model and use it to match the pre-bent plate right in the operating room,” says Kumara.

Despite the Form 3B+’s compact size, its build volume is still large enough to accommodate almost any print a craniofacial trauma surgery would require.

Formlabs Biocompatible Resins: A Comprehensive Guide To Choosing the Right Material

Formlabs currently offers more than 40 unique materials for stereolithography (SLA) 3D printing. This paper helps users compare and contrast our biocompatible offerings, and determine the best fit for their medical applications.

Transforming Trauma Surgery

ImmersiveTouch offers an integrated workflow that harnesses AI, Mixed Reality, and 3D printing. ImmersiveTouch collaborates with Formlabs to leverage 3D printing technology to bring revolutionary ideas to market, exemplifying how the transformative potential of technology in medicine is realized. Banerjee says that this collaboration has the potential to enhance the lives of millions of trauma surgery patients, with ongoing efforts indicating a commitment to further advancements in the field.

“There’s a huge opportunity in improving the quality of care for trauma patients,” says Banerjee.