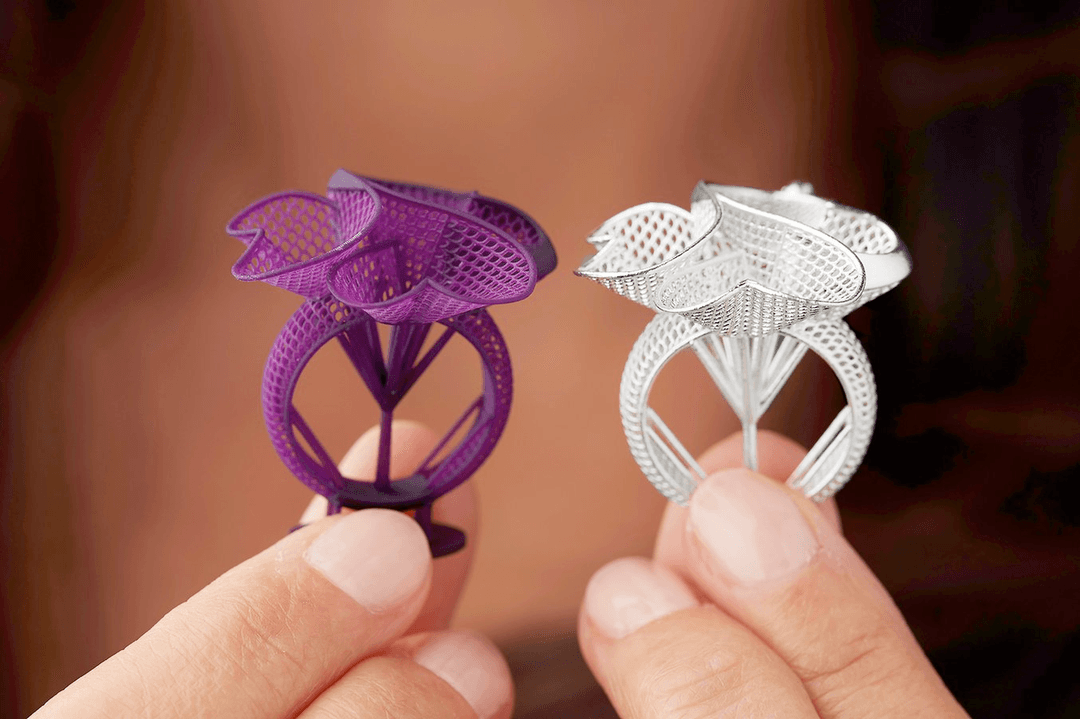

3D printed jewelry patterns and cast metal rings.

Lost-wax casting is a metal casting technique for creating objects, from simple to complex, in a variety of metals (such as gold, silver, brass, or bronze) by casting an original model or pattern.

It is one of the oldest known metal-forming techniques dating back 6,000 years, but it is still widely used for producing jewelry, dentistry, and art. Its industrial form, investment casting, is a common way to create precision metal parts in engineering and manufacturing.

While traditionally associated with artisanal handcraft, creators can now transform the lost-wax casting process with digital design and 3D printing to simplify the workflow, save time, lower costs, and reshape the process for the 21st century.

Read on to learn how digital technologies have revitalized the lost-wax casting method and what it means for professionals from jewelers to dentists and volume producers.

Book a Free Consultation

Get in touch with our 3D printing experts for a 1:1 consultation to find the right solution for your business, receive ROI analyses, test prints, and more.

Lost-Wax Casting Process

Patterns sprued to a casting tree.

Molten metal poured into the investment.

The lost-wax casting process can differ depending on the industry and application, but it generally consists of the following steps. Cast parts can be made from a wax model itself, called the direct method, or from replicas of the original wax model, called the indirect method. The direct method jumps from step one straight to step four.

-

Model-making: The artist carves a design out of wax. The size and complexity of the wax model are limited to the wax carver’s skill and the capacity of their casting equipment.

-

Creating a mold: A caster then casts this model and polishes the casting to produce a “master” pattern. The master model is used to make a wax mold out of rubber, which is heated and “vulcanized” around the master casting to make a flexible wax mold.

-

Producing wax patterns: Molten wax is injected or sometimes poured into the rubber mold. This can be done over and over to make copies of the original design.

-

Assembling the wax pattern: Sprues are added to the wax copies and they’re connected to create a tree-like structure, which provides paths for the molten wax to flow out and molten metal to later fill the cavity.

-

Applying investment materials: The wax tree is either dipped into a slurry of silica, or put into a flask and surrounded by the liquid investment plaster.

-

Burnout: After the investment material dries, the flask is placed upside down into a kiln, which melts the wax leaving a negative cavity in the shape of the original model.

-

Pouring: The investment mold is further heated in a kiln to reduce the temperature difference with the molten metal. Metal is melted and then poured, using gravity or vacuum pressure to pull the metal into the cavity.

-

Devesting: Once the molten metal has cooled somewhat, the investment mold is quenched in water to dissolve the refractory plaster and release the rough casting. The sprues are cut off and recycled, while the cast parts are cleaned up to remove signs of the casting process.

-

Finishing: The cast parts are filed, ground, machined, or sandblasted to achieve final geometry and surface finish. Where necessary, the cast parts are also heat-treated to enhance the mechanical properties of the material.

The cast tree after divesting.

The cast part finished by filing, grounding, and machining.

A Short Summary of the Long History of Lost-Wax Casting

It’s no exaggeration to state that lost-wax casting is as old as civilization itself. Artifacts like scepters, sculptures, and furniture made through lost-wax casting have been discovered as far afield as Israel, Vietnam, Nigeria, Nicaragua, and the Indus Valley. The very oldest known lost-wax-cast object, an amulet created by a society in the Indus Valley, is over 6,000 years old.

After centuries of use in the production of sculptural ornaments and in textile relief, lost-wax casting began to be supplanted by piece molding in 18th-century Europe. Parts of the process were adapted for investment casting to meet the needs of the growing industry in the 19th century.

In dentistry, lost-wax methods are used widely to create gold crowns, inlays, and onlays. The legacy of lost-wax casting, as such, remains well in evidence today.

Moving Lost-Wax Casting into the 21st Century with Digital Design and 3D Printing

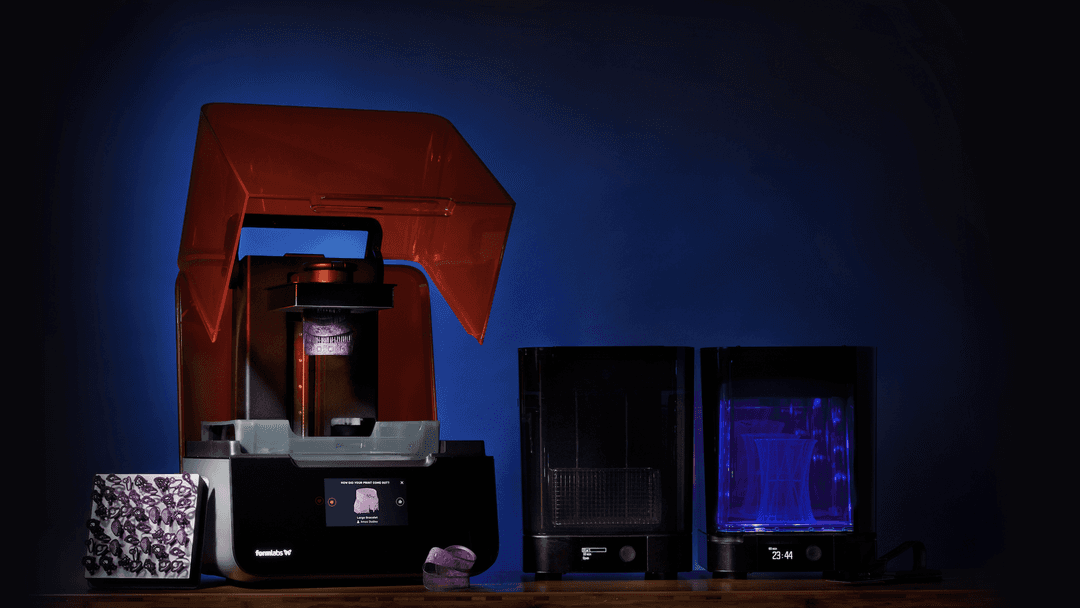

Today, digital software tools and 3D printing augment lost-wax casting with the advantages of a digital design and manufacturing process.

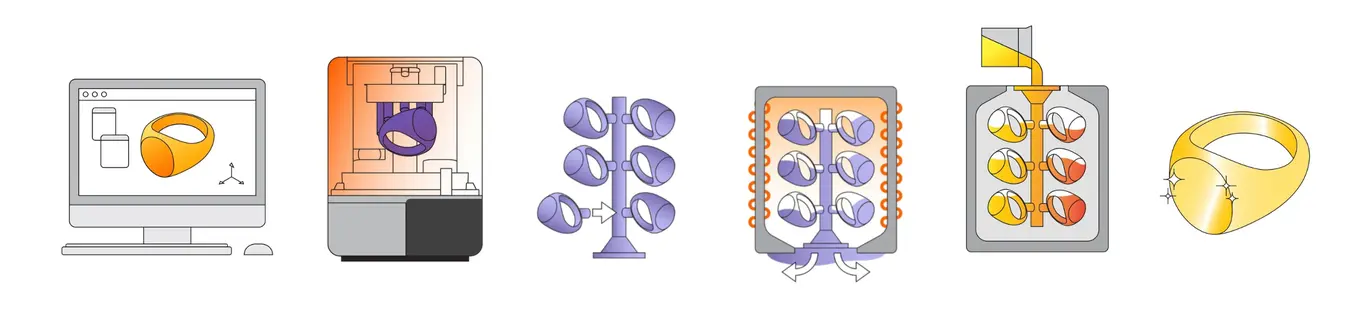

The digital workflow begins with digitally designing the pattern. The pattern is 3D printed and prepared for casting. The mold is then made and the printed parts burned out. Once the pattern is cast, parts are polished and finished.

With the digital workflow, designers use CAD software tools to create designs digitally and a professional 3D printer to produce 3D printed patterns that can then be cast in the mold. After burnout of the positive pattern, the process follows the same path as traditional investment casting.

Thanks to digital techniques, the need for time-intensive manual labor is greatly reduced and the design itself is easy to preserve, modify, and recreate when needed.

Applications of Lost-Wax Casting With Digital Technologies

From engineers to jewelry makers, various professional fields are taking advantage of the new possibilities enabled by digital technologies for lost-wax casting.

Jewelry

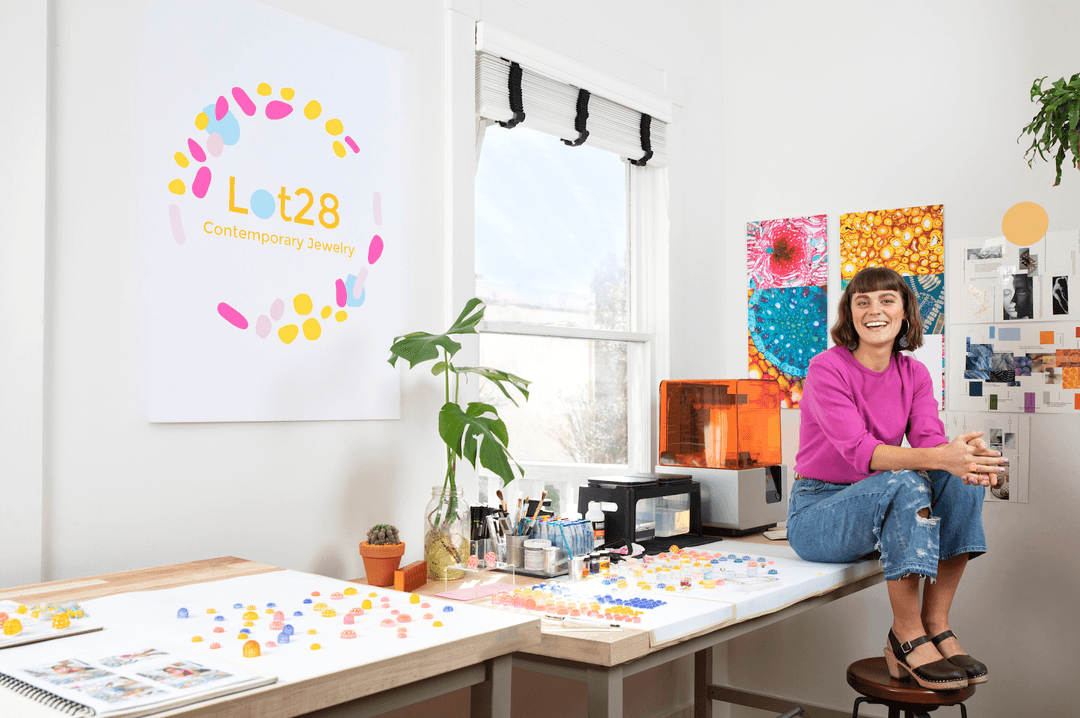

One of lost-wax casting’s first use cases was for producing jewelry and fine ornaments. But wax patterns for intricate jewelry are complicated to produce by hand, and in a world driven by high demand and fast fashion, it can be difficult for hand-crafted pieces to keep pace.

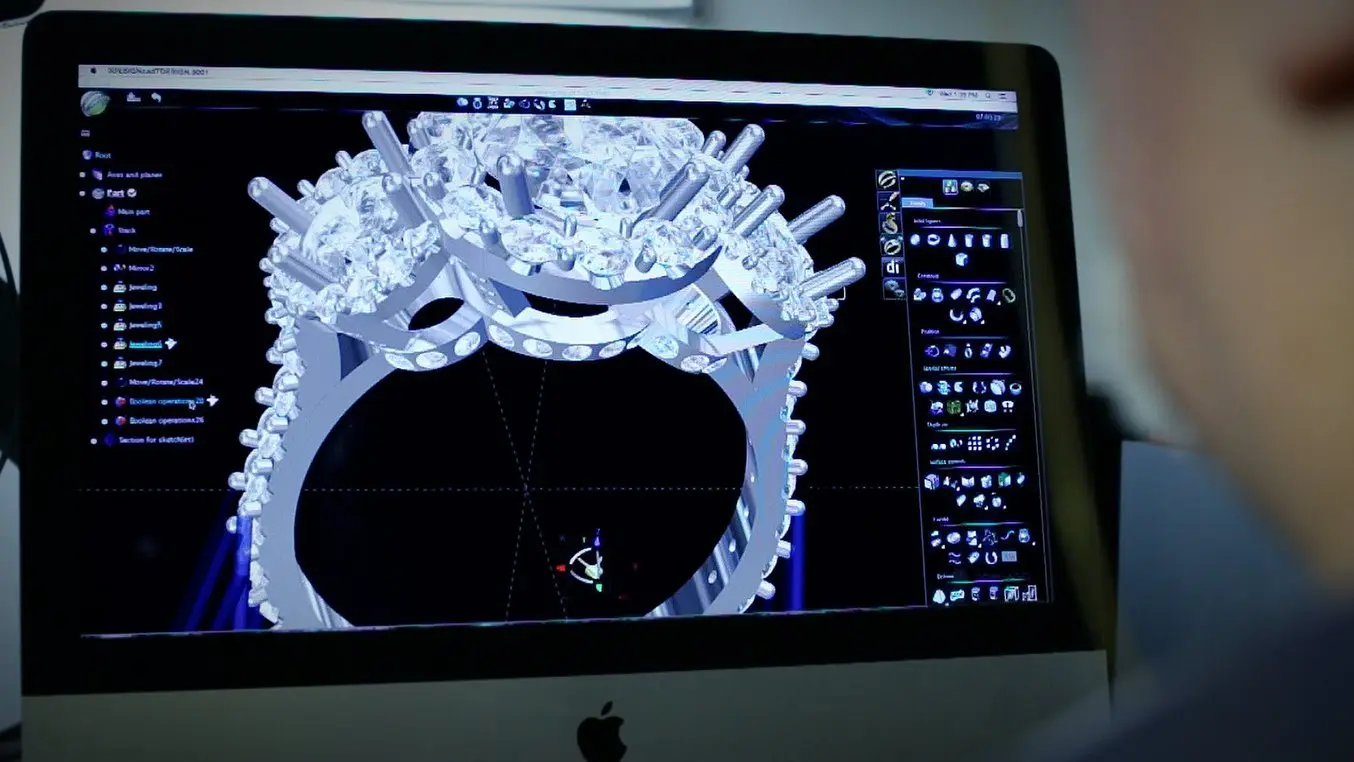

Jewelry designers can use jewelry CAD software tools to design jewelry pieces, making it easier to produce and fit complicated geometries that once required hours of meticulous labor to carve from wax.

Digital design, advanced materials, and affordable in-house resin 3D printers are now changing the way jewelry manufacturers and designers work in terms of concepting, prototyping, and producing.

Stereolithography 3D printing can reproduce complex features that’d be difficult to hand carve.

Jewelry designers can use jewelry CAD software tools to design jewelry pieces, making it easier to produce and fit complicated geometries that once required hours of meticulous labor to carve from wax.

Affordable industrial-quality 3D printers can create patterns rapidly that can be cast just like traditional wax. 3D printing offers an almost unlimited scope for geometric creativity in design. Thanks to a precisely controlled laser, extraordinary design details — delicate filigrees, raised text, and detailed pavé stone settings — can be captured with incredible sharpness.

The biggest barriers to adopting a digital workflow in jewelry are often digital design skills and training. However, newer cohorts of jewelry designers entering the industry are taught the foundations of traditional design along with jewelry CAD software and training on 3D printers, preparing them for the inevitable transition.

Introduction to Casting for 3D Printed Jewelry Patterns

In this white paper, learn how to cast fine jewelry pieces from 3D printed patterns and how direct investment casting, or lost wax casting, works as a moldmaking technique.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Dentistry

Lost-wax casting and pressing restorations have been standard practice in dentistry for decades to fabricate inlays, onlays, crowns, ceramic–alloy crowns, all-ceramic crowns, partial denture frameworks, and other implant restorations.

Wax patterns are traditionally formed by hand on a working die of the tooth or an arch model that is based on a manual impression from the patient. The patterns are then sprued to a tree and burned out, following the traditional lost-wax casting workflow.

With digital technologies, dentists collect the patients’ anatomy digitally using an intraoral scanner, or a lab scans a physical model or impression using a desktop scanner. The scan data gets imported into CAD software and the dental technician designs the desired restorations. The patterns can then be 3D printed out of a wax-like material, and cast or pressed using the traditional workflow.

Patterns for dental crowns, inlays, partial denture frameworks, and more can then be 3D printed out of a wax-like material, and cast or pressed using the traditional workflow.

In dentistry, digital design is also not much of a limitation, since the patient's anatomy comes from an impression. Dental CAD software tools make the design process simple, while 3D printing automates the manufacturing process of the patterns that traditionally requires an experienced technician and many manual steps.

Digital technologies with lost-wax casting combine the best of the analog and digital worlds and empower dental labs to produce highly accurate patterns, with a consistent and reliable digital workflow and easy-to-use machinery.

New Castable Wax Resin for Dental: Efficient, Cost-Effective Production

Learn how to produce fixed restorations in-house, and hear shares practical tips for building digital production workflows for casting and pressing crowns, bridges, and removable partial dentures (RPDs).

Manufacturing

For industries requiring mass-produced metal parts with a high level of dimensional accuracy, casting remains a cost-effective and highly capable manufacturing process, producing critical components for aerospace, automotive, and medical applications.

Traditionally, patterns for direct investment casting, the industrial form of lost-wax casting, are carved by hand or machined if the part doesn’t need to be mass-produced. With 3D printing, engineers and foundries can directly create patterns to achieve shorter lead times and geometric freedom that exceeds the design for manufacturability (DFM) constraints of molding processes.

Precision and Cost-Efficiency in Casting: Leveraging 3D Printing for Metal Parts

This webinar will walk you through the methods by which several established foundries were able to cast metal parts using patterns 3D printed on Formlabs’ 3D printers. Learn how foundries are cutting costs, reducing lead times, and improving the quality of their metal parts by integrating Formlabs’ Clear Cast Resin and Materialise Magics’ Lattice with traditional casting methods.

Industrial Investment Casting With 3D Printed Patterns Using Formlabs Clear Cast Resin

This white paper presents the methods by which several established foundries were able to cast metal parts using 3D printed patterns produced by Formlabs’ stereolithography (SLA) 3D printers.

A Revolution in Tradition

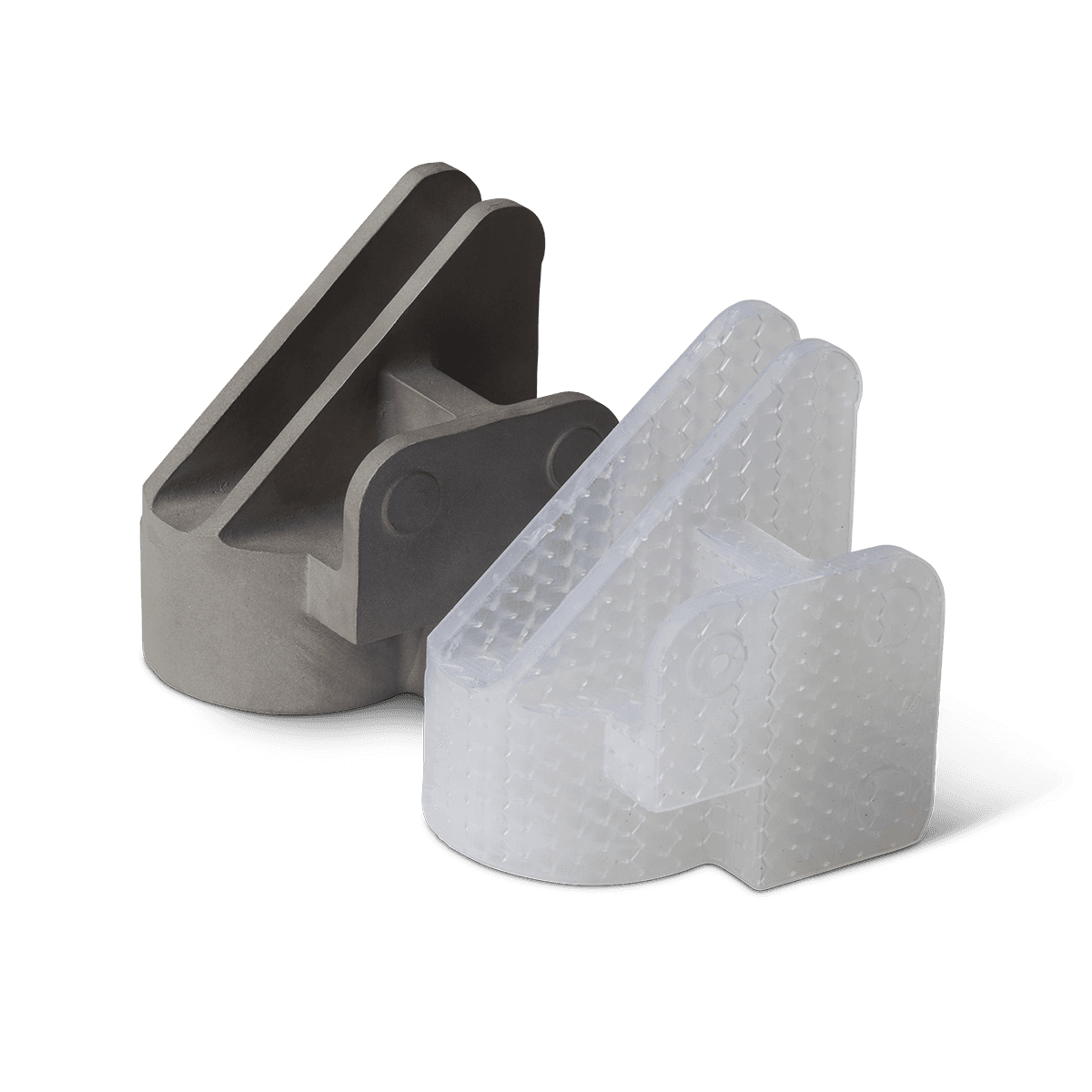

True Cast Resin can be 3D printed and integrated into casting workflows to create jewelry and engineering parts up to 5 mm thick.

The evolution of the lost-wax casting process with digital tools proves that technology doesn’t need to alienate us from the past. Employed correctly, these techniques can produce high-quality parts at scale — from bespoke custom jewelry to mass-produced automotive parts. The result is a remarkable new degree of production efficiency and design freedom.

Learn more about Formlabs resin 3D printers or contact our 3D printing experts if you have any questions.

Not sure which 3D printing solution fits your business best? Book a 1:1 consultation to compare options, evaluate ROI, try out test prints, and more.