2022 3D Printing Research Report: Using 3D Printing to Meet Customer Demands

At Formlabs, we constantly hear about amazing 3D printing applications. Our customers are continually pushing the envelope of what’s possible with additive manufacturing, inspiring us to improve our materials and 3D printers. And while we know that for every industry, there are different applications and reasons to invest, we were curious to hear why businesses are investing in 3D printing, many for the first time in 2022.

That’s why Formlabs created our first ever state of the industry report, called “The 2022 3D Printing Applications Report”. Filled with key insights on what is driving current and future investment in additive manufacturing, this report is based on survey data from 400 businesses in a multitude of industries around the world.

In our previous blog post, we covered one of the central findings of the report: the rapid rise of end-use part creation as a use-case of 3D printing. In this post, we will look at what has been driving recent investments in 3D printing.

New 3D Benefits Emerge: Investing in Sustainability

As businesses re-evaluate their sustainability initiatives and analyze the impact their products are having on the environment, a growing number of them are viewing in-house 3D printing as a major solution to address sustainability concerns. 70% of recent adopters (those who invested in the technology in the past two years) cite sustainability as a significant or very significant benefit of 3D printing, which is more than double that of early adopters of 3D printing.

While SLA 3D printing does produce waste, such as post-processing water mixed with IPA, it can often be used to eliminate the shipping of parts from outsourcing firms. Additionally, traditional manufacturing processes such as injection molding create waste, which is completely eliminated when using in-house 3D printing processes such as SLS. Oftentimes, in order to reduce the amortized cost of an injection molding order, firms will purchase in large quantities, with some parts going unused and later thrown out. With in-house production, supply can be created to perfectly match demand, reducing excess waste.

Finally, Formlabs strengthened its own supply chain by purchasing resin maker Spectra, making sure we had control over resin production for Formlabs prints. This further strengthens our customers' supply chains, removing the need for businesses to rely on third party suppliers and knowing exactly when and for how long different materials will be supported.

A Customer First Design Process

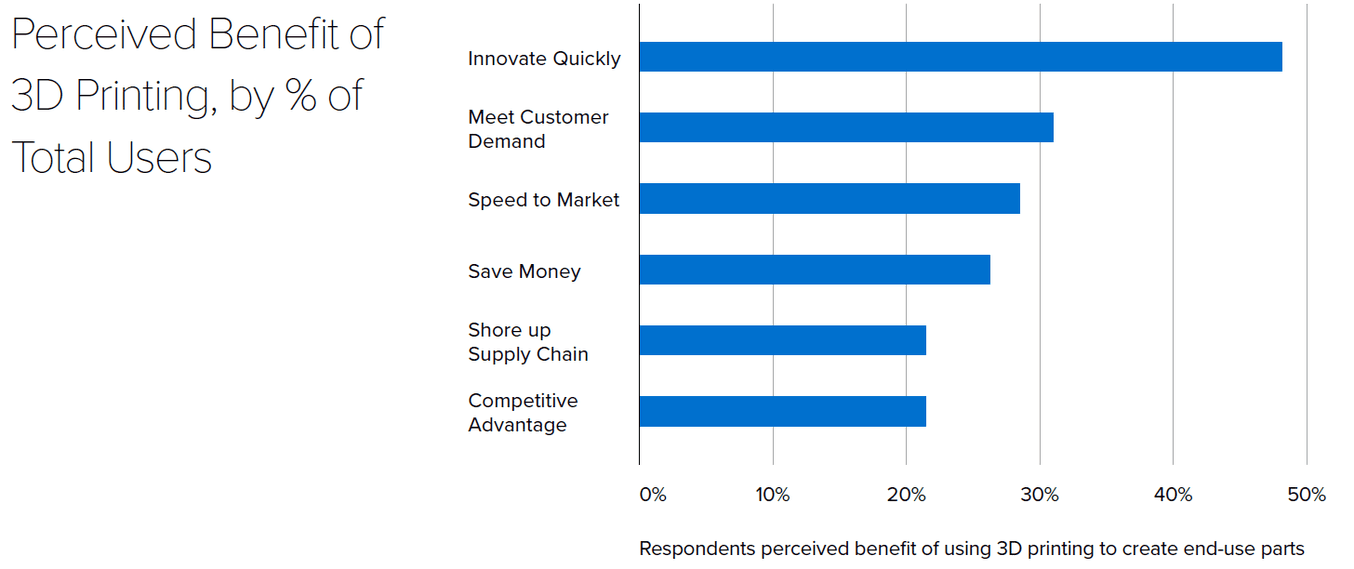

There are many reasons why businesses across a range of industries invest in 3D printing for end-use part production. When examining the top three reasons given in the 2022 3D Printing Applications Report, we see a common theme: innovate quickly, meet customer demand, and speed to market. These three are inextricably linked; innovating products quickly and getting them to market before competitors is incredibly important for every business, allowing brands to establish themselves as market leaders. But shipping a bad product quickly is counterproductive, which is why using 3D printing as a tool to meet customer demand is critical. The report highlights how 3D printing is increasingly being deployed across modern workflows, from rapid prototyping, to the creation of rapid tooling, to the use of end-use parts to create better products for customers faster than ever before.

Curious to See the Answers For All the Other Questions? Read the Full Report

3D printing is unleashing new possibilities and business opportunities. What used to be too complex, prohibitively expensive, or impractical to produce with traditional methods is now available in-house at a fraction of the cost, giving full control to designers and manufacturers, and opening the door for fully customizable products to become a reality. The increased adoption of end-use parts as a major application of 3D printing doesn’t replace, but supplements, other use cases such as rapid prototyping. While 3D printing will never fully replace traditional manufacturing methods, it has become an integral part of the engineering toolbox.

The 2022 3D Printing Applications Report is packed full of information on the current state of the 3D printing industry. It covers changes in perceived benefits (such as addressing supply chain shocks) of 3D printing, to adoption of new applications, and more.

The entire report is available below, free to download. Let us know what you think of the report on LinkedIn.