Today, Formlabs is proud to announce a new enterprise focused product offering: Formlabs Factory Solutions. For the first time, in one transparent and comprehensive package, manufacturing firms can bring together everything Formlabs does best: a combination of 3D printing hardware, software, and materials designed to drive additive manufacturing adoption at your business.

Three Solutions, Your Custom Factory

Formlabs 3D printers have become the go-to solution for a wide range of industries because of consistent performance and unparalleled ease of use. Factory Solutions goes much further than a single printer: it’s an ecosystem designed with your business’s products and markets in mind.

Our goal was to offer your business the ability to build an agile factory the way you want it with intuitive tools, transparent pricing, and proven processes. Use additive manufacturing to scale production of new products fast, driving revenue and beating competitors to market. With Formlabs Factory Solutions we’ve reimagined 3D printing to offer a custom manufacturing solution to each and every business.

We’ve achieved this by seamlessly combining three solutions into one offering designed to unlock growth, quickly scale production, and create new product opportunities. The offerings are:

- A Custom Factory Package

- Custom Material Development

- Formlabs Consulting

A Custom Factory Package

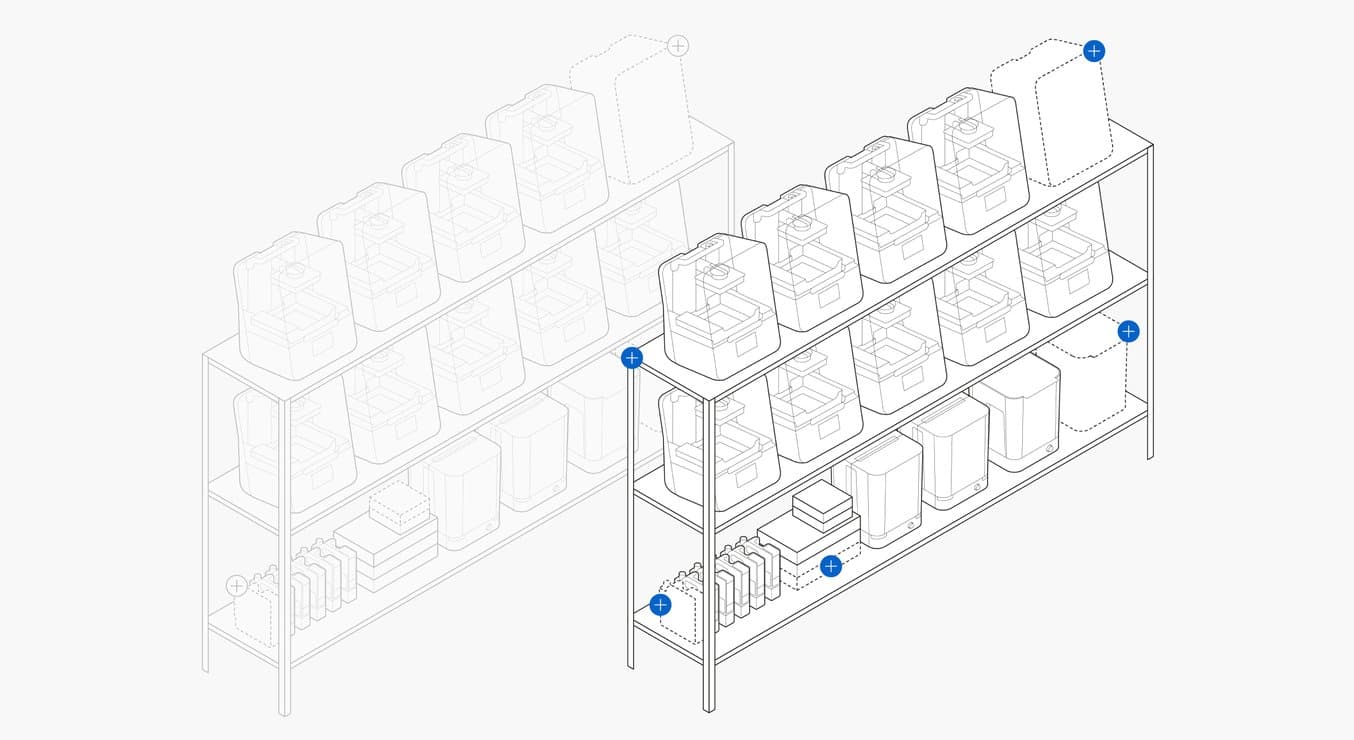

Work with our team to rapidly scale production as your business grows with a modular production station built around the Form 3, an industrial-quality 3D printer that consistently delivers. The Form 3 scales with you, so you can fast-track deployment and implementation of new production infrastructure.

An example of a Custom Factory Package

The backbone of Factory Solutions, 3D printer packages are intended for production of 10,000 or more parts per year. Scaling is easy with the Form 3, from 10 printers in a room to 100 printers spread across your factory, our Factory Solutions Team will guide you every step of the way to tailor the perfect Factory Package for your desired production targets.

Custom Material Development

One of the most powerful advantages of stereolithography (SLA) printing is the wide range of printing materials, all of which can be used interchangeably on the same Formlabs machine.

While our material library addresses a wide range of engineering and manufacturing applications, sometimes your application needs something special. With one of the largest materials science teams in the industry, Formlabs can create a brand new material with properties like tear strength, tensile strength, and elongation tailored for your application.

New Balance’s TripleCell technology is a great example of a high performing and aesthetically striking product made possible by partnering with Formlabs. To meet New Balance’s exacting demands for performance and durability, Formlabs formulated Rebound Resin, a completely new 3D printing material with properties far exceeding the available alternatives.

Formlabs worked closely with New Balance from beginning to end. From preliminary R&D and iteration through hundreds of exploratory material formulations, Formlabs developed brand new production workflows so New Balance could affordably manufacture customized components at scale with Rebound Resin. This included custom software features, on-site support, and dedicated supply chains.

“Where we are now is just a testament to the work we’ve done in-house and the external partnership with Formlabs that have really been able to move our program forward. We’ve demonstrated that we are able to scale up additive manufacturing and have it make sense for a production environment. As far as where we go next, the sky is really the limit.”

Katherine Petrecca, New Balance General Manager of Footwear at the Innovation Design Studio

Formlabs Consulting

Our Factory Solutions team is here to help you build, setup, and launch a tailored 3D printing factory. Our multidisciplinary experts will work alongside your team from product ideation to print optimization and production implementation. We’re here to help you perfect your facility and workflow, become self-sufficient, and take control of your supply chain.

At the beginning of your project, we can deliver an immersive additive manufacturing workshop to inspire your team, and offer examples of additive success stories in your industry. The Formlabs team can also deliver a product development sprint to identify specific product ideas and business cases for 3D printed products.

The scope of our consulting work is up to you and the needs of your business. Our technical team can help you perfect your part file for additive manufacturing or optimize your prints to increase the yield per printer and reduce the cost per part. Or, have Formlabs create a project feasibility & business plan including expected ROI and break even points - with ongoing project management and support.

Formlabs can come on-site for ongoing project management and support.

Formlabs is committed to helping everyone, and every business, make anything. With Formlabs Consulting, make sure you get your agile factory off the ground and produce parts as soon as the printers arrive.

“Formlabs conducted a wonderful onsite additive manufacturing workshop that was both informative and interactive. The use case and product examples helped everyone internally truly understand what is possible in our additive manufacturing future. Thank you Factory Solutions Team!”

Sundaresan Arunachalam

Basic Development Technology at Hirschmann Automotive

The Agile Factory: Additive Manufacturing as a Production Technology

At Formlabs, we have repeatedly seen that in the right applications, additive manufacturing can be much more than “nice to have” or something that vaguely “drives innovation”. Over the years our internal teams have worked with dozens of manufacturing firms, big and small, to hone best practices and create production roadmaps.

Over time, we have arrived at a set of five core advantages of additive manufacturing that are clearly quantifiable and can underpin mission-critical innovation in both products and business models. These core advantages are:

- The ability to customize products.

- No additional cost to produce complex shapes such as lattices.

- Flexibility to quickly change what you are making.

- Faster time to market through avoided tooling and sampling.

- Digitizing inventories that include small quantities of many SKUs.

To launch alongside Formlabs Factory Solutions, our team created a free report on how we evaluate additive manufacturing opportunities. The report includes lessons from a decade of helping manufacturers adopt 3D printing, how to really assess costs associated with additive manufacturing, how to evaluate revenue opportunities, and more.

Introducing Formlabs Factory Solutions

We are launching Factory Solutions to expand access to industrial-quality production with additive manufacturing. Formlabs Factory Solution exists to offer your business a clear, comprehensive, and straightforward package to help you drive growth and revenue with additive manufacturing.

To better understand how a Factory Solutions package can be the tailored solution that unlocks growth at your business, contact us today.