In a global manufacturing network, every component must be traceable by having a unique identifier tracing its path through the manufacturing process and linking it back to its original supplier. Jeil MTech, a Korean manufacturer, makes this tracing process possible. They design and produce dot peen marking machines, industrial devices used to print text, barcodes, and other products.

Their customers, like Hyundai Motor Company and Kia Motors, rely on these machines for their intensive quality control processes: If they find an issue, they need to make sure they can trace the faulty component back through its journey and identify potential issues in their process or with a supplier.

Though traditional dot peen marking machines have been industrial-sized, their evolution has mirrored that of 3D printing — there are accessible, desktop versions available now that are making manufacturing more affordable for small businesses, startups, and individuals.

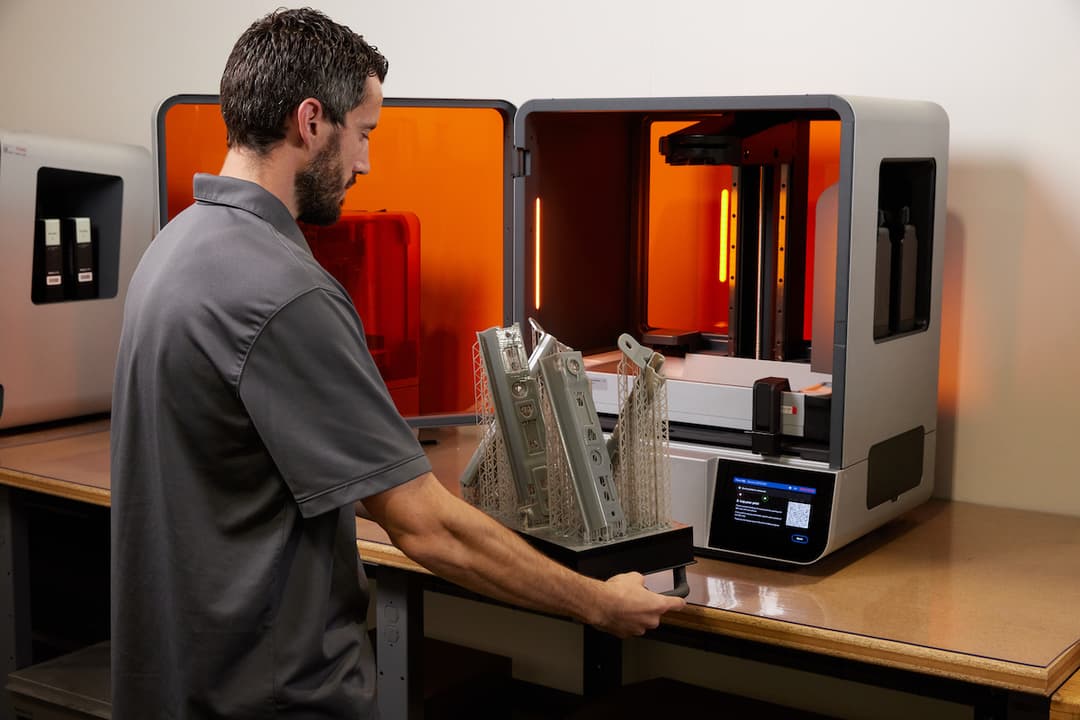

To answer that increased demand, Jeil MTech needed to move away from injection molding for large orders of large-scale products. Jeil MTech tested multiple 3D printers, working with AM Korea to find the right technology. After seeing the Fuse Series selective laser sintering (SLS) 3D printer at a trade show and testing samples, they brought the technology in-house. The Fuse Series has enabled Jiel MTech to expand their product catalog and bring an accessible dot peen marking machine to market.

Testing Technologies

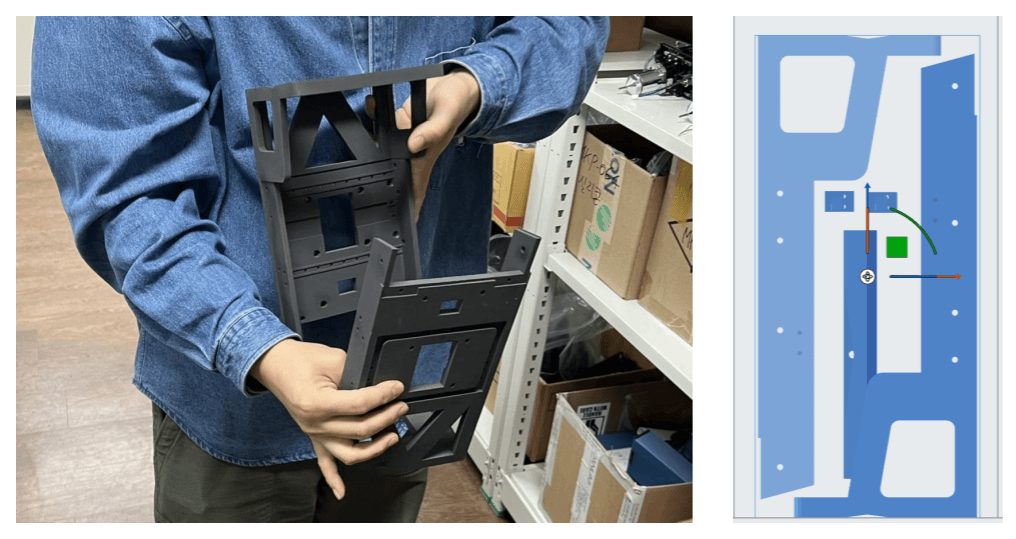

When Jeil MTech realized that developing a new, more accessibly sized and priced dot peen marking machine would require extensive development, they knew that injection molding was too expensive and time-consuming for their needs.

Injection molding typically becomes cost-effective only when volumes are in the thousands or higher — with the high cost of machined tooling for the injection molding shots, new product ideas are often over budget before they even get out of the drafting room. This fabrication method also stymies any possibility of iteration and improvement after the first design is finalized. Changing anything means changing the tooling and waiting weeks or months to get started once more.

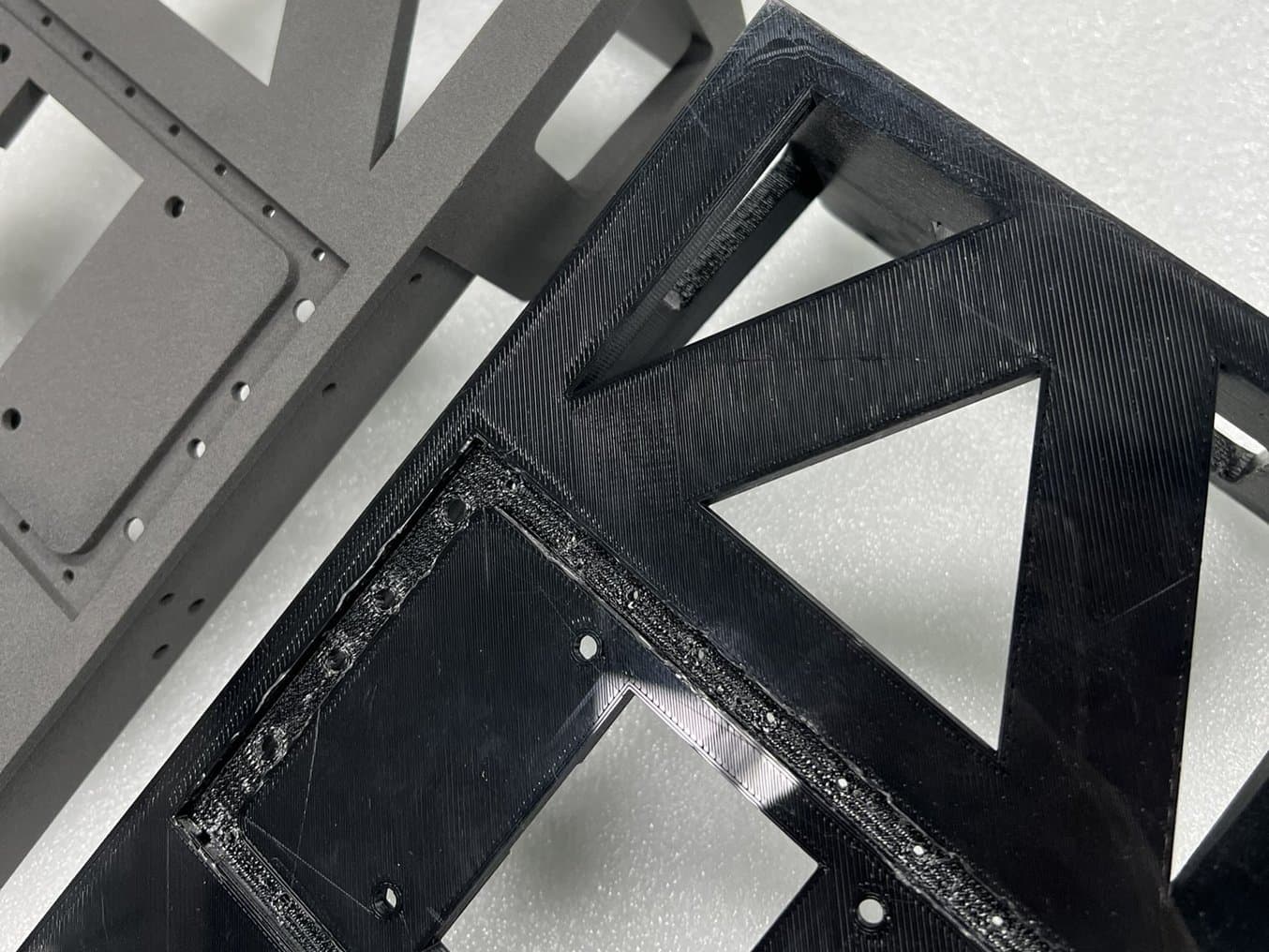

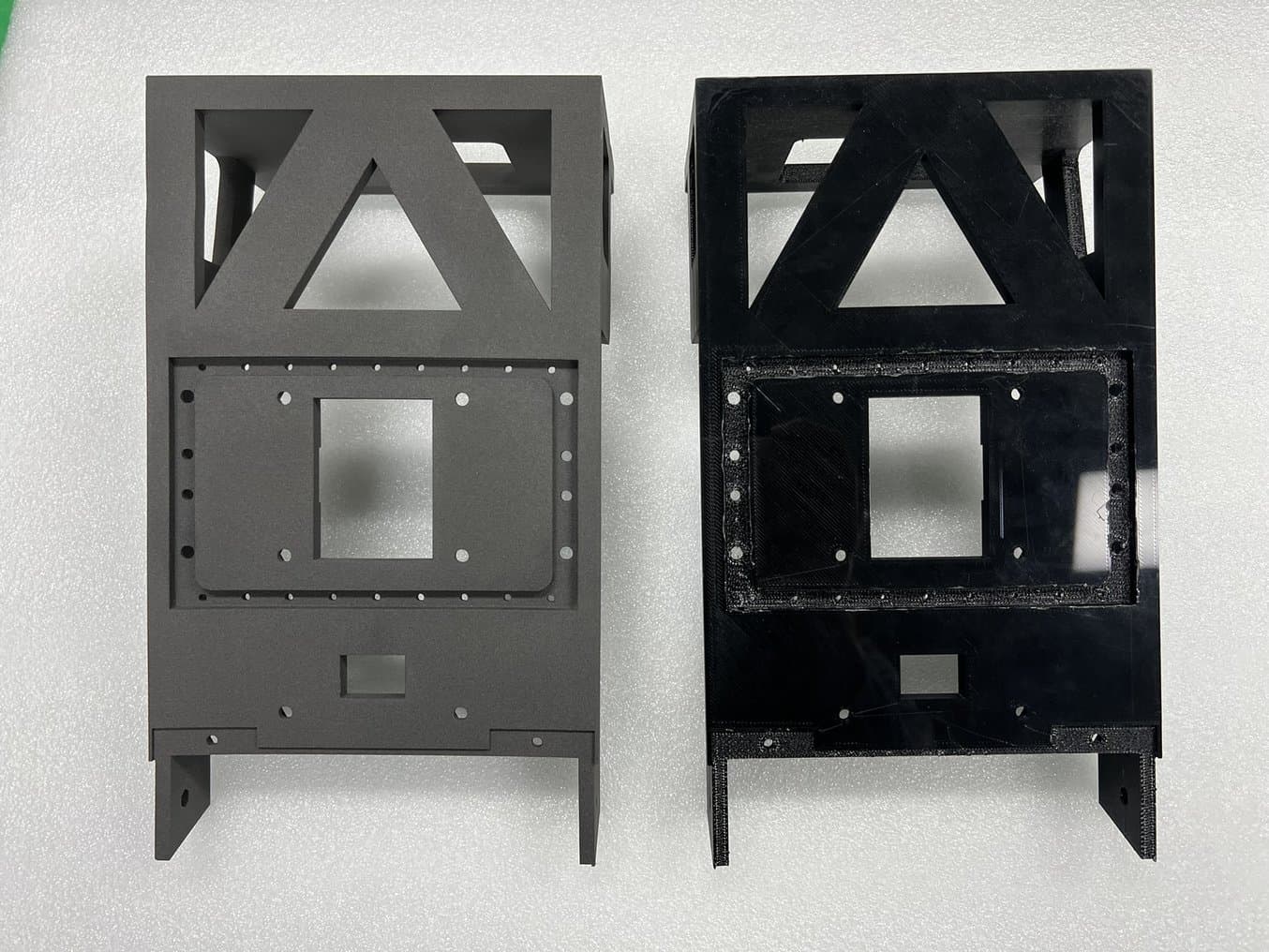

3D printing, especially as printers and materials have advanced and become more capable, has emerged as a cost-effective and time-savvy way of getting new products to market. Jeil MTech first evaluated fused deposition modeling (FDM) 3D printers, which extrude plastic through a heated nozzle, creating a part layer by layer like a hot glue gun would. This technology often produces parts with visible layer lines, and the support structures needed to prop up overhangs can leave imperfections when they’re removed. Jeil MTech realized they needed parts that could be tested functionally and used as end-use components in order to get their new products to market faster.

“Traditional injection-molded products were slow and heavy, and FDM 3D printing posed issues with durability and finish quality. With Formlabs, we solved weight and durability problems and accelerated part production." - Jeil MTech Technical Manager

The mechanical strength of Nylon 12 Powder also played an important role in Jeil MTech’s decision to bring SLS in-house with the Fuse Series. While FDM parts are anisotropic and can break along layer lines, SLS parts are mechanically strong in each direction, so building a functional assembly of SLS 3D printed components is durable enough to withstand everyday use.

Industry Expansion

Adding the Fuse Series in-house has shortened Jeil MTech’s product development timeline, allowed them to try new ideas without risk or wasted investment in tooling, and helped them bring a product to market fast enough to beat the competition.

SLS technology, similarly to dot peen marking machines, used to be the purview of only large, industrial companies with lots of space, thousands of products, and big budgets. By bringing accessible SLS in-house with the Fuse Series, Jeil MTech can develop similarly affordable and easy-to-use dot peen marking machines for the growing number of small and medium-sized businesses. As SLS 3D printing has become more democratized, it in turn can democratize other industries and open up opportunities for products and processes that used to be out of reach for entrepreneurs.

To learn more about the Fuse Series, contact our sales team. To see the quality of Fuse SLS 3D printed powders, request a sample.