3D Printing for Medical Devices

Accelerate medical device development timelines by 3D printing multiple iterations a day, produce customized medical devices, or increase your speed to manufacturing. 3D printing enables agile, on-demand production for optimized inventory, so you can deliver injection molded quality at lower costs.

Why 3D Print Medical Devices With Formlabs?

Accelerate Product Development

Eliminate outsourcing costs by prototyping in hours instead of days. Leverage functional, medical-grade materials for clinical validation.

Increase Speed to Manufacturing

Achieve the quality of injection molding without costly tooling or long lead times. Produce biocompatible, sterilizable devices for end-use production.

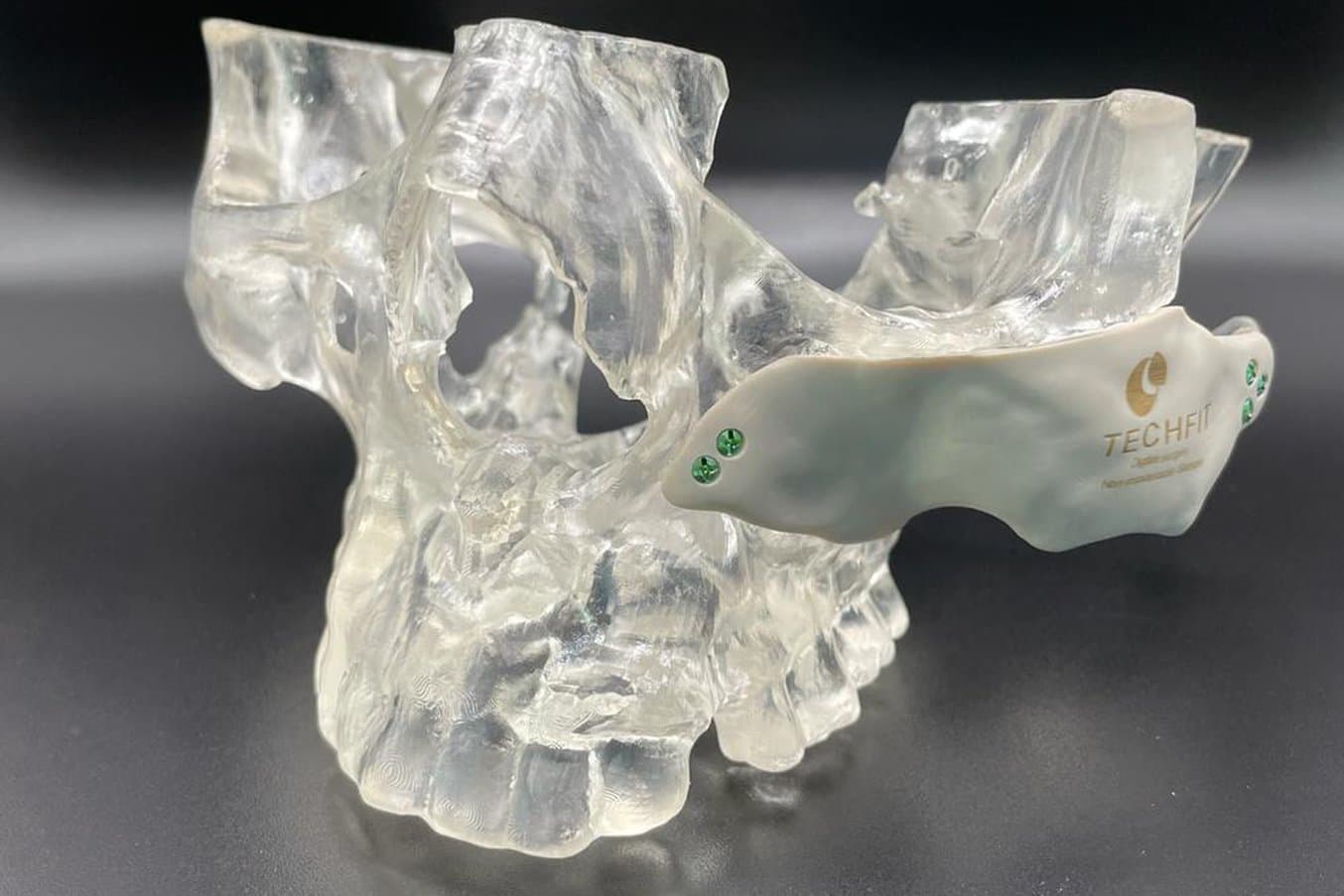

Deliver Patient-Matched Devices

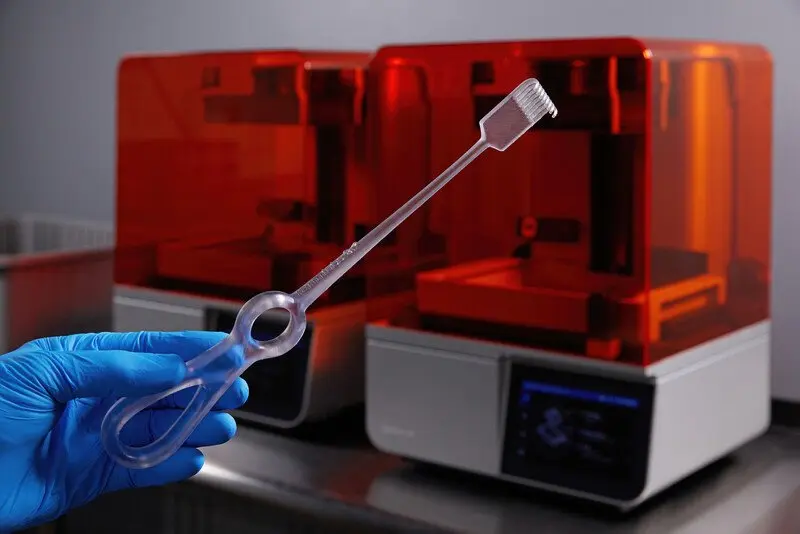

Print affordable, patient-matched surgical tools, reducing costs and improving patient outcomes.

Optimize Inventory Costs

Reduce inventory costs and streamline supply chains with on-demand, cost-effective surgical tool production.

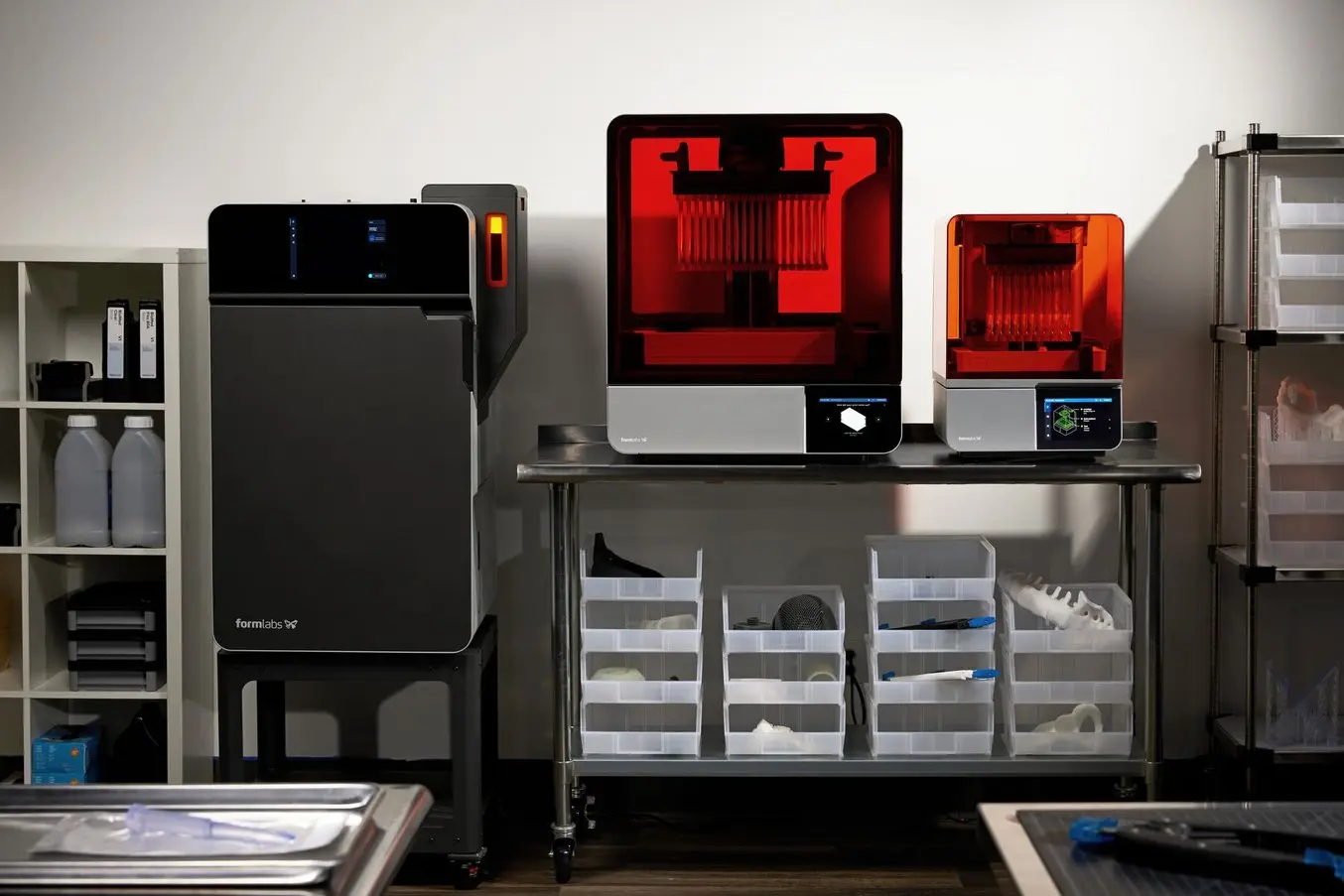

A Full Suite of 3D Printing Solutions

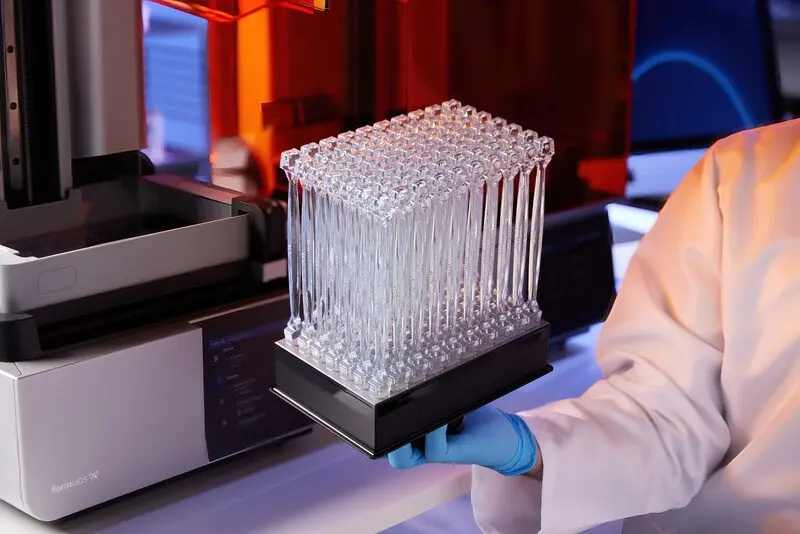

Form 4B

Industry-leading print speeds enable high-throughput production capabilities.

Precise, accurate prints across the build platform.

99% reliability with unmatched print success.

Form 4BL

Same-day turnaround for large prints.

Produce parts with exceptional tolerances and quality, rivaling injection molding.

Achieve high-throughput production with more parts per build and fewer user interactions.

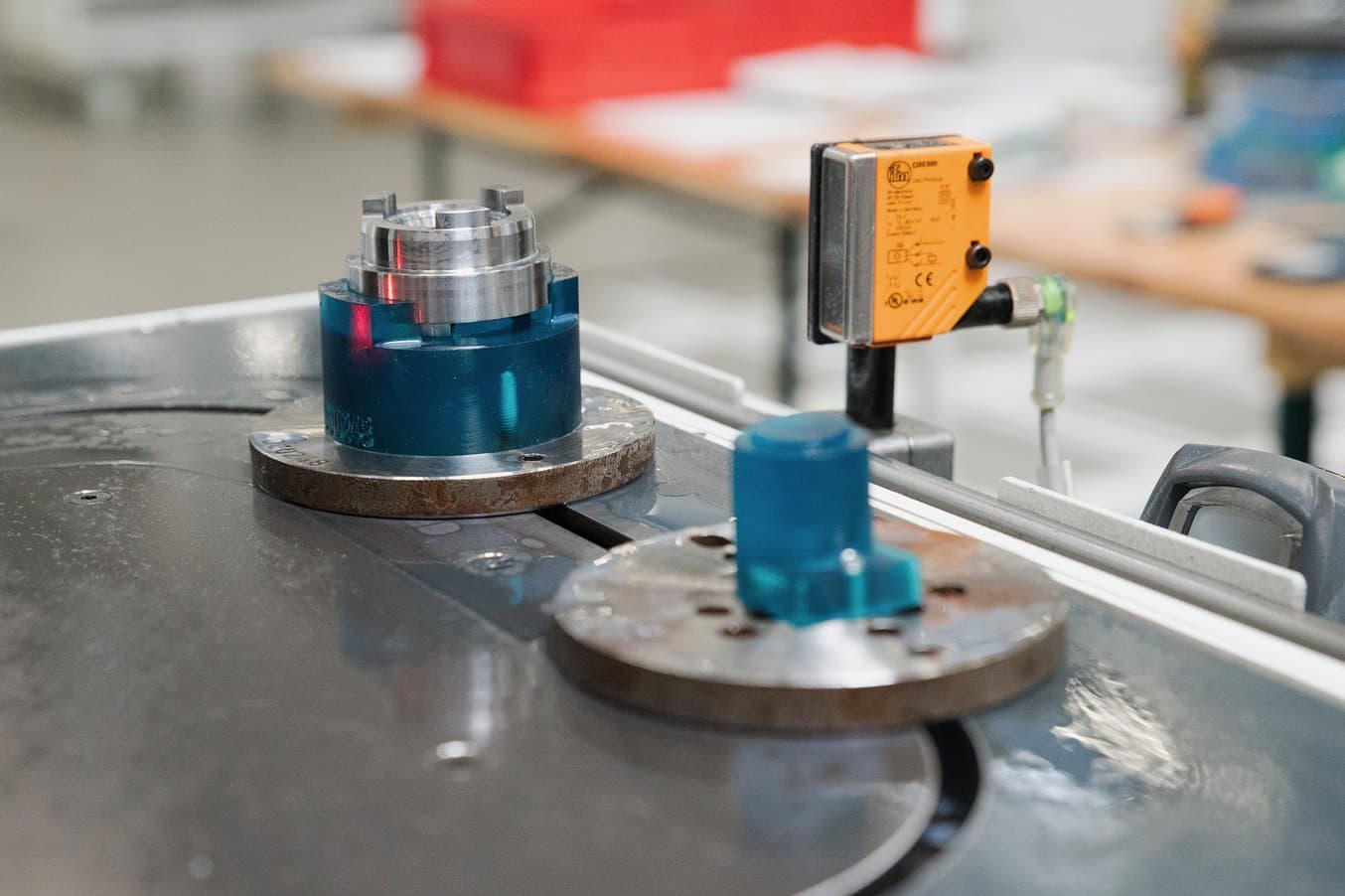

Fuse 1+ 30W

Automated ecosystem for streamlined, end-to-end workflows with fewer touchpoints.

Unlock a broad range of industry-standard materials including nylon, polypropylene, and TPU.

Customer-ready parts in under a day.

High-Performance 3D Printing Materials for Medical Device Production

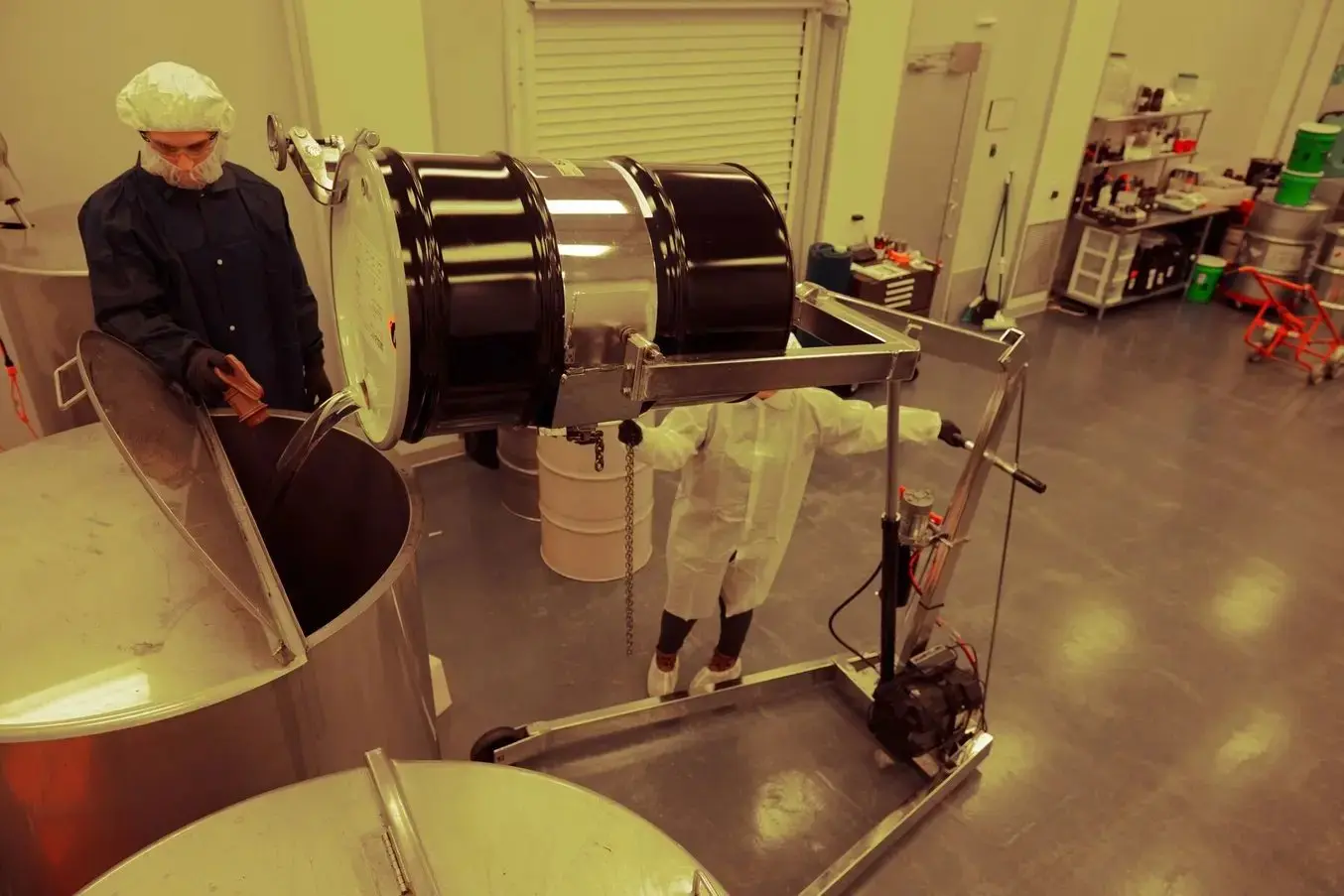

Access 45+ Formlabs materials, including 25+ biocompatible resins for healthcare, supported by an ISO 13485 and EU MDR-certified Quality Management System in our FDA-registered facility, or experiment with any 405 nm photopolymer or 1064 nm powder using Open Material Mode.

BioMed Resins for SLA 3D Printing

Formlabs biomedical and medical device resins are designed and manufactured within our robust Quality Management System that is ISO 13485 and EU MDR certified in our certified FDA-registered facility. Formlabs Medical Device Resins are made in a certified ISO Class 8 Clean Room and registered with the FDA and CE marked according to the EU MDR.

Powders for SLS 3D Printing

3D print production-ready, end-use parts on our SLS printers with our family of SLS Powders. Our materials, hardware, and software are developed and validated together to deliver peak performance while optimizing cost per part. Plus, make the most of your material with simple, efficient powder recycling.

See Also

Material Mastery for 3D Printing Medical Devices: Choosing the Right Fit for Your Application

Formlabs Biocompatible Resins: A Comprehensive Guide To Choosing the Right Material

High Quality Parts, Quickly and Affordably

228

Form 4BL

7 h 46 min

BioMed Durable Resin

Leverage 3D Printing From Prototyping To Manufacturing

Rapid Prototyping

Clinical & Usability Trials

Manufacturing

Accelerate Product Development

Contact a healthcare specialist to discuss your unique needs and see how much you can save.

See Also

Concept to Commercialization in Four Months: How Arbutus Medical Utilized 3D Printing for Rapid Device Development

Innovative, Low-Cost Inhalers Enable Access for Millions: 3D Printing Powers Lean R&D for Medical Devices

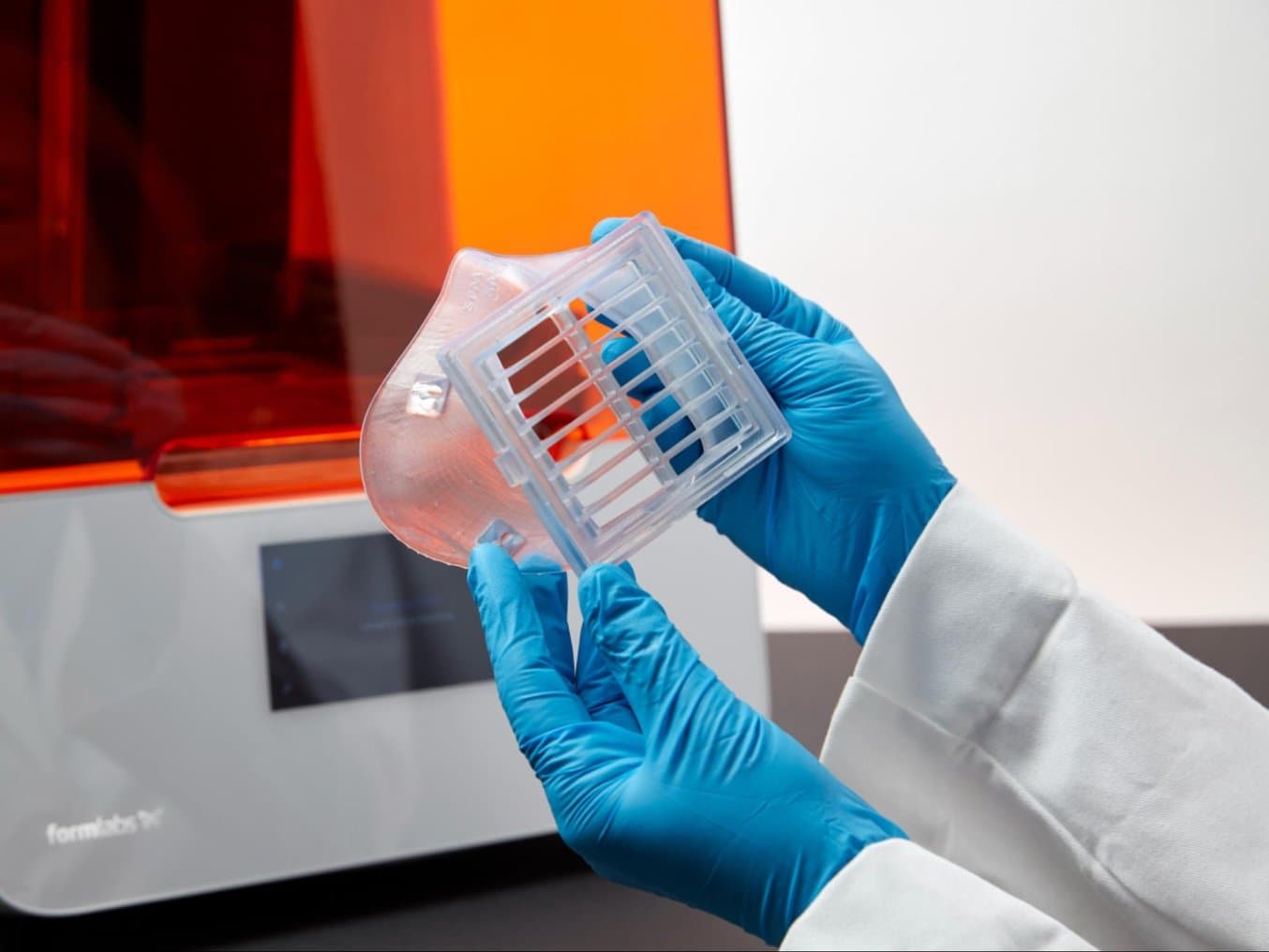

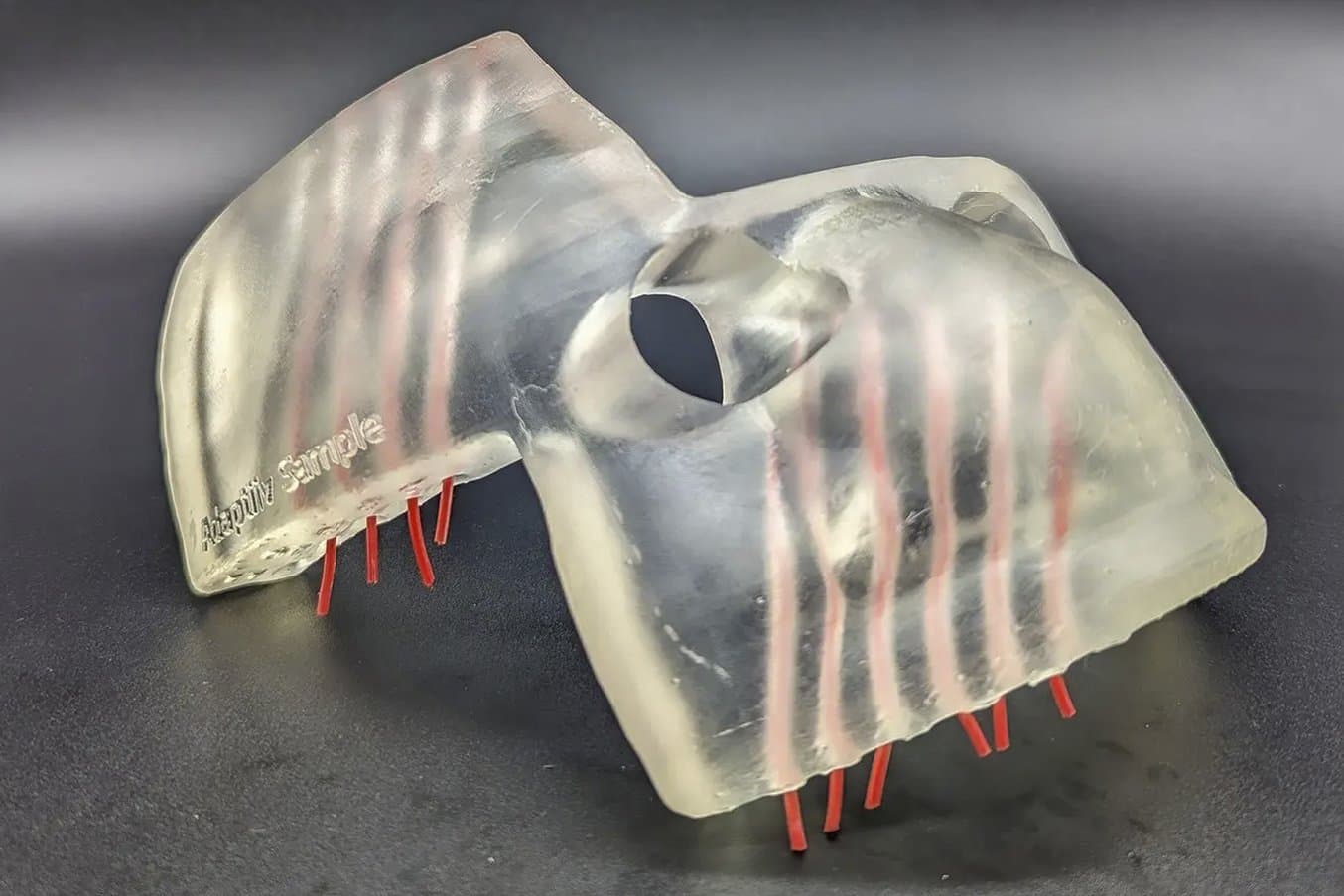

3D Print Biocompatible End-Use Parts Without Tooling

See Also

Unlock Patient-Specific Solutions for Radiation Therapy Using Formlabs 3D Printing

In-House Production of Manufacturing Aids

See Also

3D Printing The Next Generation Of Metabolic Analyzers

Streamlined Workflows for Patient-Matched Orthotic Production

Optimize Inventory Costs and Supply Chain Management

Minimize Costs

Replace expensive surgical trays with single-use 3D printed sizing instruments for precise implant fitting and reduced overhead.

Optimize Efficiency

Streamline inventory and alleviate the burden on sterile processing with single-use instruments, improving workflow and resource allocation.

On-Demand Manufacturing

Reduce product inventory and costs with rapid, commercial-quality 3D printing for just-in-time manufacturing of end-use devices.

Your Cutting Edge Partner

Agile, scalable production puts the tools in your hands, on your timeline. Top medical device companies have used the Formlabs ecosystem to build and scale their businesses. Get started now or expand your in-house production with Formlabs, a proven, cutting-edge partner in medical 3D printing, ready to help you build your business.

Utilize the Expert Knowledge of Our Regulatory Affairs and Quality Assurance Team

Access Information on Regulatory Affairs and Quality Assurance (RAQA) including access to specialists to help speed your device to market.

See Also

Formlabs x TÜV SÜD: Exploring Additive Manufacturing and Regulatory Requirements in the EU

How Formlabs Develops and Ensures Compliance for Over 25 Biocompatible Materials

Biocompatibility, Materials, and Strategies for Medical Additive Manufacturing

Start 3D Printing Medical Devices

Explore our 3D printers or contact a 3D printing expert today to find the solution to meet your business goals.

Disclaimer: Formlabs is an industry-leading provider of 3D printers and materials that are used by healthcare providers to support the practice of medicine. Please consider local regulations, material data sheets, PHI, and institutional requirements before 3D printing and/or using anatomical models.