Formlabs

is Open

Maximize Your 3D Printer’s Potential with Developer Platform

Unlock Custom Applications for More Versatility on Your Formlabs 3D Printer

Open Material Mode

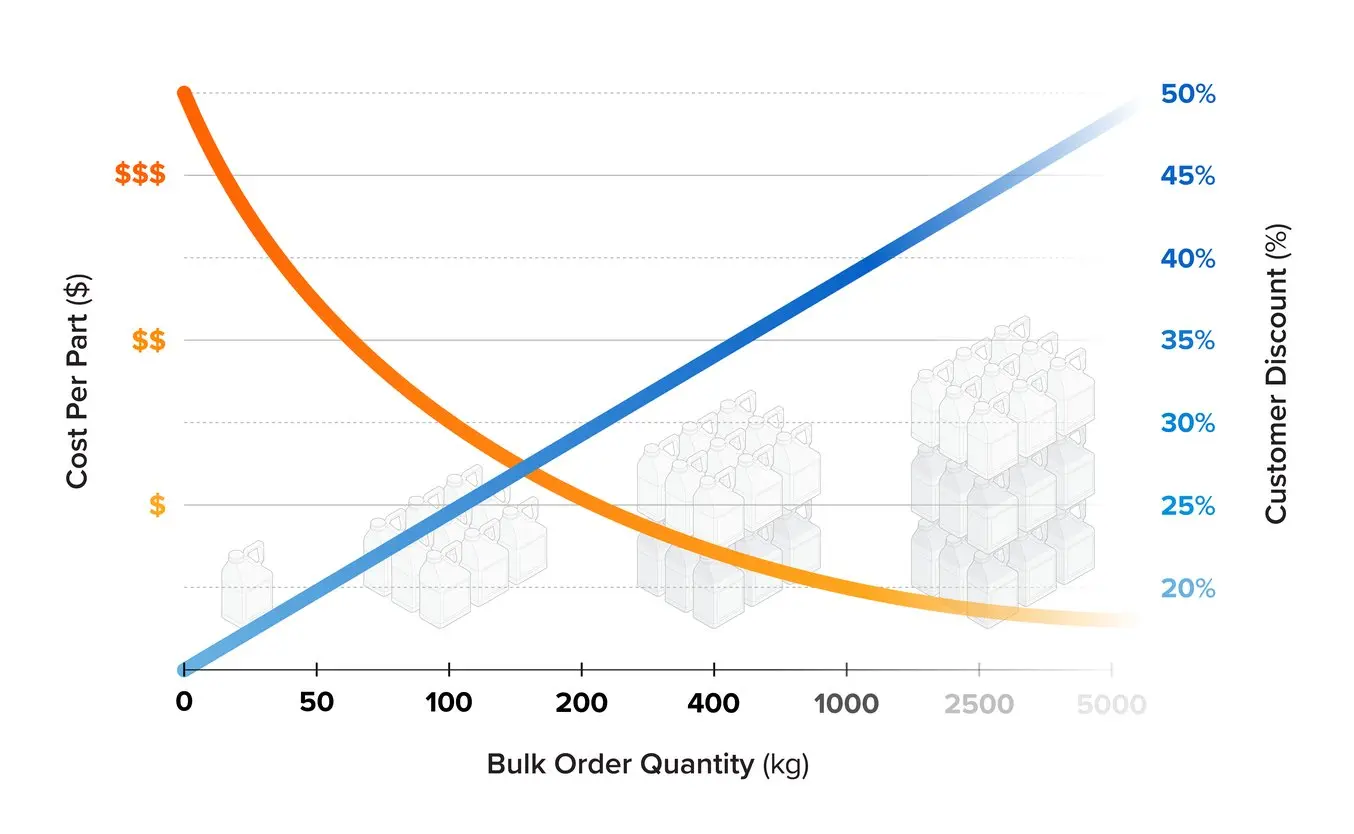

Unlock the possibility to print with any 405 nm photopolymer resin or 1064 nm powder on Formlabs 3D printers, empowering researchers and expert users to unlock new applications and explore endless new possibilities in 3D printing on the most reliable and accessible professional 3D printers on the market.

SLA: All Form 3 & Form 4 Series printers

SLS: Fuse 1 & Fuse 1+ 30W printers

Optional, one-time purchase per printer for lifetime access.

“If R&D is interested in the capability of a new material for a specific application that we're wanting to explore, having open material settings allows us to vet it out and see if it's something that we can consistently replicate in a production setting.”

Elena Tercheria, Additive Manufacturing Manager

“We started off with FDM and we got a lot of requests for that, but a lot of people want finer resolution. Being able to have the resorbable material with the finer resolution of SLA, it's not cost prohibitive and it’s where we really see the market going.”

Aaron Vaughn, Manager of Material Science and Technology, Poly-Med

“Our work wouldn’t have been possible without Open Material Mode. It’s actually changed the way we think about new projects moving forward. This will not be the last 3D printing material we make. We’re working with other DoD departments and even commercial, private airlines. Open Material Mode is our path to getting those opportunities.”

Jonathon McDaniels, Co-Founder, Figure Engineering

For materials suppliers: If you are interested in marketing your material’s compatibility with a Formlabs printer through Open Material Mode, please view messaging guidance here.

Print Settings Editor

Tailor print performance with Formlabs materials and third-party materials by customizing a range of print settings such as exposure, layer height, heating for SLA, or layer thickness, XYZ correction factors, and exposure for SLS. Easily share print settings files with others.

SLA: All Form 3 & Form 4 Series printers

SLS: Fuse 1 & Fuse 1+ 30W printers

Free access to anyone with a compatible Formlabs 3D printer.

“Settings Editor definitely opens up a lot. It allows us to reach the printer's full potential.”

Perry Derenoncourt, Additive Manufacturing Technician, restor3d

“We really like how there are so many options for putting energy dosing into the different parts of the print. You can have the outside cured differently than the inside, and the support structure can be cured differently. This is really advantageous for us.”

Aaron Vaughn, Manager of Material Science and Technology, PolyMed, Inc.

Formlabs API

Build integrations into the Formlabs software ecosystem with the powerful new Formlabs API. Automate design-to-print workflows with CAD integrations, automate batch production, and connect printers to MES and other software. The Formlabs API gives you access to powerful infrastructure to build better integrations in other applications and automate workflows to go from design to printed part effortlessly. Design, develop, support, and launch your feature or integration with Formlabs API.

Build Native CAD Integrations

Unlock the ability to print on Formlabs printers from your CAD application.

Use the API to prepare models for printing, slicing, and uploading jobs to a printer.

Automated Batch Production

Prepare hundreds of parts for printing with automated batch processing.

Automate print preparation — orientation, layout, support generation — and send jobs to printers automatically.

Connect Printers to Other Software

Monitor print progress, and printer status by connecting Formlabs printers to MES and other software.

Upcoming integrations using the Formlabs API:

-Materialise CO-AM

Why Choose the Formlabs Ecosystem?

Our industry-leading SLA and SLS 3D printers are trusted by tens of thousands of professionals around the world and offer best-in-class reliability, ease of use, and part performance.