Resin 3D printers have become vastly popular for their ability to produce highly accurate, isotropic, and watertight parts in a range of advanced materials with fine features and a smooth surface finish. Resin printing is a great option for applications requiring tight tolerances and smooth surfaces, such as rapid prototyping, tooling, manufacturing aids, models, and low-volume end use parts.

Formlabs adapted stereolithography (SLA) 3D printing technology to the desktop in 2011 and has since become the market leader for professionals, selling more than 100,000 desktop and large-format resin printers as of today.

Explore Formlabs Resin 3D Printers

Form 4

Blazing Fast Desktop Resin 3D Printer

Turn your ideas into reality faster than ever with easy workflows, leading reliability, and stunning part quality using the Form 4 resin 3D printer ecosystem. Form 4 is a blazing fast masked SLA 3D printer that combines an industry-leading materials library with a reliable, accurate print engine. With tight tolerances, parts printed in every resin on Form 4 will match your design parameters, every time.

20.0 × 12.5 × 21.0 cm

7.9 × 4.9 × 8.3 in

Ideal for:

Form 4B

Blazing Fast Desktop Resin 3D Printer for Healthcare

Create biocompatible, sterilizable anatomical models and medical devices fast, with easy workflows, leading reliability, versatile materials, and stunning part quality using Form 4B, a blazing fast resin 3D printer that offers the most diverse materials library for healthcare.

20.0 × 12.5 × 21.0 cm

7.9 × 4.9 × 8.3 in

Ideal for:

Form 3+

An Affordable, Industrial-Quality Desktop Resin 3D Printer

Produce functional, high-quality prototypes and end-use parts in record time with the Form 3+, an affordable, industrial-quality resin printer that consistently delivers. The Form 3+ offers reliable print quality and accuracy, easy setup and maintenance, and a wide range of high-performance materials.

14.5 × 14.5 × 19.3 cm

5.7 × 5.7 × 7.6 in

Stereolithography (SLA)

Ideal for:

Form 3B+

An Affordable Desktop Resin 3D Printer for Healthcare

Rapidly print patient-specific parts at the point of care and bring innovative R&D and low-volume commercial production in-house with the Form 3B+, an affordable advanced resin printer for healthcare professionals. The Form 3B+ is compatible with our entire resin library, including biocompatible, sterilizable materials.

14.5 × 14.5 × 19.3 cm

5.7 × 5.7 × 7.6 in

Stereolithography (SLA)

Ideal for:

Form 4L

Blazing Fast Large-Format Resin 3D Printer

Form 4L is a blazing-fast large-format masked SLA 3D printer that combines an industry-leading materials library with a reliable, accurate print engine. Turn your biggest ideas into reality faster than ever with easy workflows, leading reliability, and stunning part quality using the Form 4L large-format resin 3D printer ecosystem.

35.3 x 19.6 x 35.0 cm

13.9 x 7.7 x 14.0 in

Ideal for:

Form 4BL

Blazing Fast Large-Format Resin 3D Printer for Healthcare

Form 4BL is a blazing fast large-format medical 3D printer that offers the most diverse materials library for healthcare. Create biocompatible, sterilizable anatomical models and medical devices fast, with easy workflows, leading reliability, versatile materials, and stunning part quality using the Form 4BL large-format resin 3D printer ecosystem for healthcare.

35.3 x 19.6 x 35.0 cm

13.9 x 7.7 x 14.0 in

Ideal for:

Form 3L

An Affordable Large-Format Resin 3D Printer

Take control of large-format part production and bring your biggest ideas to life with the Form 3L, a cost-effective large-format resin printer that doesn’t compromise on the details.

33.5 × 20 × 32 cm

13.2 × 7.9 × 12.6 in

Stereolithography (SLA)

Ideal for:

Form 3BL

An Affordable Large-Format Resin 3D Printer for Healthcare

3D print adult patient-specific anatomy at full, 1:1 scale or large medical devices with the Form 3BL, a cost-effective large-format resin printer for medical applications, that's compatible with the majority of our materials, including biocompatible, sterilizable resins made in our ISO 13485 certified, FDA-registered facility.

33.5 × 20 × 32 cm

13.2 × 7.9 × 12.6 in

Stereolithography (SLA)

Ideal for:

Automation for Resin 3D Printing

Reach new levels of productivity with a fully-automated Form 3+ printer fleet you can operate from anywhere, at any time. Unlock 24/7 production with Formlabs Automation Ecosystem: Form Auto, Fleet Control, and the Resin Pumping System.

Resin 3D Printing Materials

Explore our 50+ resin 3D printing materials, offering a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

Explore Resin 3D Printing Applications

Rapid Prototyping

Turn your ideas into high-fidelity prototypes that look and work like final products within a day and bring better products to market faster.

- Concept models

- Looks-like prototypes

- Functional prototypes

Compare Formlabs Resin 3D Printers

Technology

Masked Stereolithography (MSLA)

Material Type

Resin

Biocompatible Materials

No (available on Form 4B)

Maximum Part Size

20.0 × 12.5 × 21.0 cm

7.9 × 4.9 × 8.3 in

Layer Thickness

25 – 200 microns

.001 – .008 in

Light Source

Backlight Unit (60 LEDs)

Supports

Auto-generated

Light-touch removal

Materials

23 industry-leading Formlabs materials or third-party materials using Open Material Mode. More exciting new materials are currently in development.

Printing Environment

Ambient conditions. Only PU Resins require a dry cabinet for humidity control.

Printer Dimensions (W × D × H)

39.8 × 36.7 × 55.4 cm

15.7 × 14.5 × 21.9 in

Technology

Masked Stereolithography (MSLA)

Material Type

Resin

Biocompatible Materials

No (available on Form 4BL)

Maximum Part Size

35.3 x 19.6 x 35.0 cm

13.9 x 7.7 x 14.0 in

Layer Thickness

25 – 200 microns

.001 – .008 in

Light Source

Backlight Unit (145 LEDs)

Supports

Auto-generated

Light-touch removal

Materials

19 industry-leading Formlabs materials or third-party materials using Open Material Mode. More exciting new materials are currently in development.

Printing Environment

Ambient conditions. Only PU Resins require a dry cabinet for humidity control.

Printer Dimensions (W × D × H)

66.4 x 52.8 x 79.4 cm

26.1 x 20.8 x 31.3 in

Technology

Masked Stereolithography (MSLA)

Material Type

Resin

Biocompatible Materials

Yes

Maximum Part Size

20.0 × 12.5 × 21.0 cm

7.9 × 4.9 × 8.3 in

Layer Thickness

25 – 200 microns

.001 – .008 in

Light Source

Backlight Unit (60 LEDs)

Supports

Auto-generated

Light-touch removal

Materials

38 industry-leading Formlabs materials, including 15 biocompatible, or third-party materials using Open Material Mode. More exciting new materials are currently in development.

Printing Environment

Ambient conditions. Only PU Resins require a dry cabinet for humidity control.

Printer Dimensions (W × D × H)

39.8 × 36.7 × 55.4 cm

15.7 × 14.5 × 21.9 in

Why Choose Formlabs Resin 3D Printers?

Flawless Prints, Every Time

Our team integrates and optimizes hardware, software, and materials to achieve an industry-leading print success rate of 99%, as tested by an independent lab.

Seamless Workflow

Go from design to finished part in fewer steps than ever with the streamlined, end-to-end ecosystem.

35+ High Performance Materials

Formlabs offers the widest range of advanced resin 3D printing materials with standout mechanical, thermal, or biocompatible properties.

Professional Support

Formlabs Service Plans offer hot-swap replacements, dedicated phone support, training, and more, so you can stay focused on growing your business.

Compare Resin 3D Printers to Other 3D Printing Processes

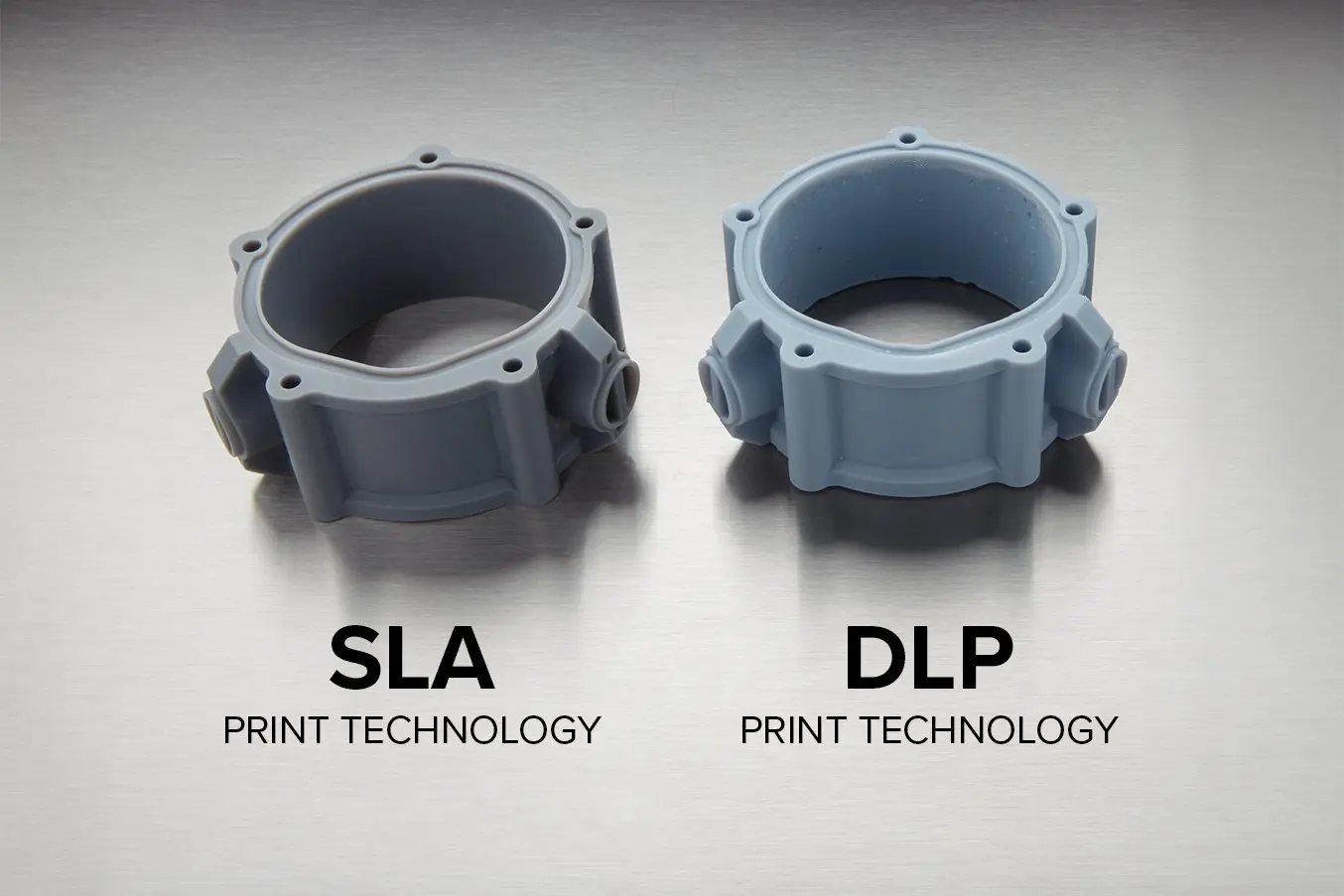

SLA vs. DLP vs. MSLA vs. LCD

Stereolithography (SLA), digital light processing (DLP), and liquid crystal display (LCD) or masked stereolithography (MSLA) 3D printing are the most common processes for resin 3D printing.

FDM vs. SLA vs. SLS

Fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS) are the three most popular types of 3D printers on the market.

FAQ: Resin 3D Printers

What are resin 3D printers?

Resin 3D printing is one of the most popular 3D printing processes. It was the world’s first 3D printing technology, invented in the 1980s. Since then, it has gained widespread adoption and awareness due to more accessible systems, revolutionizing the design and manufacturing processes of hundreds of thousands of professionals across a broad spectrum of industries.

How does a resin printer work?

Resin 3D printers use a light source to cure liquid resin into hardened plastic in a process called photopolymerization. Watch the video below to see the full workflow.

Why choose 3D resin printers?

Resin 3D printed parts have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies. Resin printers are also highly versatile thanks to resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

Resin printing is a great option for highly detailed prototypes requiring tight tolerances and smooth surfaces, such as molds, patterns, and functional parts. Resin 3D printing is widely used in a range of industries from engineering and product design to manufacturing, dentistry, jewelry, model making, and education.

How much do resin 3D printers cost?

A resin printer can cost anywhere from $300 to over $250,000.

- On the lower end, DIY and hobbyist low-cost resin printers offer an attractive entry price point, but with substantial trade-offs in terms of a labor-intensive workflow, lower reliability, and limited material options.

- Mid-range resin 3D printers are more tailored to professionals, with the Form 3+ starting at $2,499 and the large-format resin printer Form 3L at $4,999.

- Traditional large-format industrial resin printers, used predominantly by service bureaus, are available from around $100,000.

Are resin 3D printers suitable for beginners?

Yes. In fact, filament and resin 3D printers are the two most popular processes found also in educational settings. The easy to use end-to-end ecosystem, extensive training resources, and personal support makes Formlabs' solutions the easiest resin printers to get started with.

Are resin or filament 3D printers better?

This depends entirely on your applications and preferences. Read our in-depth guide that compares filament, powder, and resin 3D printers.

Do you need to cure resin prints?

It depends on the material you use, but post-curing enables parts to reach the highest possible strength and become more stable. Achieving optimal properties is especially essential when using functional or specialty resins. For biocompatible materials, post-curing is necessary to achieve the safety standards determined by regulatory agencies. Read more about post-curing resin prints or learn more about the entire workflow for post-processing and finishing resin 3D prints.

Is resin 3D printing strong?

It depends on the material you use, but resin 3D prints can be extremely strong. Resin 3D prints are also isotropic, which means that they offer the same strength in the X, Y, and Z directions.

Explore Formlabs' materials portfolio to find the best strong engineering resin for your application.

Are resin prints waterproof?

Yes, resin 3D printed parts are generally waterproof and airtight, and cured resins have extremely low water absorption. Read our white paper for detailed testing results and clear guidelines on how to affordably 3D print customized watertight enclosures.

Is resin printing safe?

Resin 3D printing in generally safe, but some low-cost resins might have strong odors requiring ventilation and may contain more hazardous chemicals. Formlabs designs its resins to be as safe as or safer to handle than common household chemicals or adhesives. Learn more about resin care for Formlabs materials and always consult the safety data sheets (SDS) for new materials.

Can I use third-party resins in a Formlabs resin printer?

Formlabs offers certified third-party resins and Open Material Mode, an optional one-time lifetime license per printer, that unlocks access any third-party resins. Learn more about Open Platform.