Last year, the Motion Picture Academy Museum commissioned KNB EFX with a project to celebrate the 50th anniversary of “Jaws:” creating an interactive, quarter-scale replica of the iconic shark — accurate to the original, mechanically robust, and ready for exhibition. In less than one month.

The timeline alone was daunting. But the real complexity lay in the exhibit’s interactivity. This wasn’t a static display; the animatronic shark needed to withstand repeated use as visitors manipulated levers, all without sacrificing the distinctive details that made the original Bruce shark so memorable on screen.

Even a few years ago, delivering a piece of this scale and precision on such a compressed schedule might not have been possible. But by integrating modern digital fabrication tools alongside traditional techniques, KNB EFX was able to meet the deadline with a result that met the Academy’s standards, and their own.

“A week later we had a full-size piece,” says Greg Nicotero, Founder and Owner of KNB EFX. “It’s pretty astounding, and the best thing about it is it matches the shark perfectly. There’s no room for error.”

A key part of that process was the Formlabs Form 4L stereolithography (SLA) 3D printer. By combining 3D scanning, modeling, and high-speed resin printing, the team moved from concept to physical artifact with unprecedented speed and without compromising the artistry that defines their work.

“I'm thrilled with how Formlabs was able to really push this project to a whole other level, especially for us because of all the projects that we're doing now, there's always an opportunity to say, ‘let's print that.’”

Greg Nicotero, Founder and Owner, KNB EFX

The “Jaws” shark is just one example. Today, modern fabrication tools like Form 4L sit comfortably next to traditional tools like clay modeling. These tools enable the team to meet relentless production schedules while preserving the craftsmanship that has made them one of the most respected effects houses in the industry.

A 3D printed model was used to mold this interactive “Jaws” shark. Internal parts, including the palettes, were also 3D printed. Image: Greg Nicotero

KNB EFX founder and owner, Greg Nicotero, holding a baby skeleton the team delivered to a set across the country in under four days.

Pulling off a one-month build for a museum-quality, interactive replica is extraordinary. But at KNB EFX, the pressures that shaped the “Jaws” project are the norm, not the exception.

“When you're dealing with a television schedule, you have seven days to prep an episode, and while you're shooting that one, they're prepping the next one; it's literally this domino effect. So this technology, the ability to 3D print assets, allows us to stay on schedule.”

Greg Nicotero, Founder and Owner, KNB EFX

In television especially, production moves at a relentless pace. Episodes overlap, schedules compress, and physical props are often needed with little margin for delay. For a studio responsible for delivering highly detailed, tactile assets under constant deadlines, speed isn’t a luxury, it’s a prerequisite.

“The biggest benefit to having 3D printing as part of our workflow is the simplicity and the amount of detail that we can get. If a director comes in and has changes, you can go click, click, click. Sometimes you could even print out a smaller version and take it to the director and he can actually look at it. Filmmakers are a tactile bunch. They want to hold things, they want to look at things.”

Greg Nicotero, Founder and Owner, KNB EFX

Talk to Our Sales Team

Whether you need to prototype at speed, or are producing end-use parts, we’re here to help. The Formlabs Sales team is composed of dedicated specialists who know exactly how to support you and your company's needs.

The Value of Embracing New Technologies

Form 4L is not the first modern tool Nicotero and the KNB EFX team have embraced. In the mid-nineties, when computer generated effects hit the industry, Nicotero says, “We were one of the few companies that really embraced that technology and said, look, this is the way that it works. Any painter will not use just one tool to create a painting.”

Traditional methods like sculpting sit comfortably beside newer processes like 3D modeling.

Actor models — both cast and 3D printed — mingle on shelves.

Eight years ago, KNB EFX added 3D printing to their tools, starting with fused deposition modeling (FDM) 3D printers. Derrick Childers, a mechanical engineer in the 3D printing department, found that FDM parts broke easily and that bed leveling, nozzle cleaning, and enclosure temperature requirements were annoying and stalled timelines. This resulted in using machined aluminium for some parts, which was strong, but took time — a problem in a fast-moving industry where time is money.

KNB EFX then added resin printing, including Form 3L. With 3D printing and scanning, a sculptor can make a miniature or maquette in a few days, which can be scanned and output at whatever size is required, versus making a full-size sculpt, which can take four weeks.

“In our situation, time is money. If we're spending days with the Form 3L, then that's only probably eight hours with the Form 4L. The difference in time is just impeccable.”

Derrick Childers, Mechanical Engineer, 3D Print Department, KNB EFX

In an industry where turnaround time is front of mind, speed and reliability are key. When Form 4L was released, Childers saw a solution that could provide the strong parts he needed with the speed, reliability, and build volume he required.

Form 4L: Fast and Reliable

“Using the Form 4L, you don't have to do anything, which is a great stress relief because you can take it straight out of the box, plug it in, and it's going to work every time.”

Derrick Childers, Mechanical Engineer, 3D Print Department, KNB EFX

Tight timelines means Childers doesn’t have time to fiddle with print settings or reprint parts. With Form 4L, he could plug in the printer and immediately start printing. The speed of Form 4L immediately made a difference, and has been a key part of projects from an interactive “Jaws” shark replica to a skeleton prop to dioramas, animatronics, and more.

“I love the speed, accuracy, detail, curing times, support removal…just the fact that Formlabs is constantly coming out with new things every year: new materials, the Flex Build Platform. It has definitely increased our capacity to do what we do.”

Derrick Childers, Mechanical Engineer, 3D Print Department, KNB EFX

GREY RESIN

Childers mostly uses Grey Resin to print parts that are going to be molded, such as stunt masks, as he can achieve fast print times while maintaining the level of detail required for pores or wrinkles.

Rather than putting an actor through multiple face casts, a digital scan of the face is done, and then the face is printed on Form 4L. This is used to make a mold for a silicone stunt mask that a double can simply strap on.

“KNB has always been the innovator, pushing the limit. Formlabs has definitely helped us improve our workflow, improve our quality, and I think it will be a mainstay here in our company.”

Derrick Childers, Mechanical Engineer, 3D Print Department, KNB EFX

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.

Behind the “Jaws” Build

For the “Jaws” anniversary exhibit, accuracy and durability were non-negotiable.

Creating a replica that matches the original was important to Nicotero, as the shark has distinctive features, including the shape of the fin. Image: Greg Nicotero

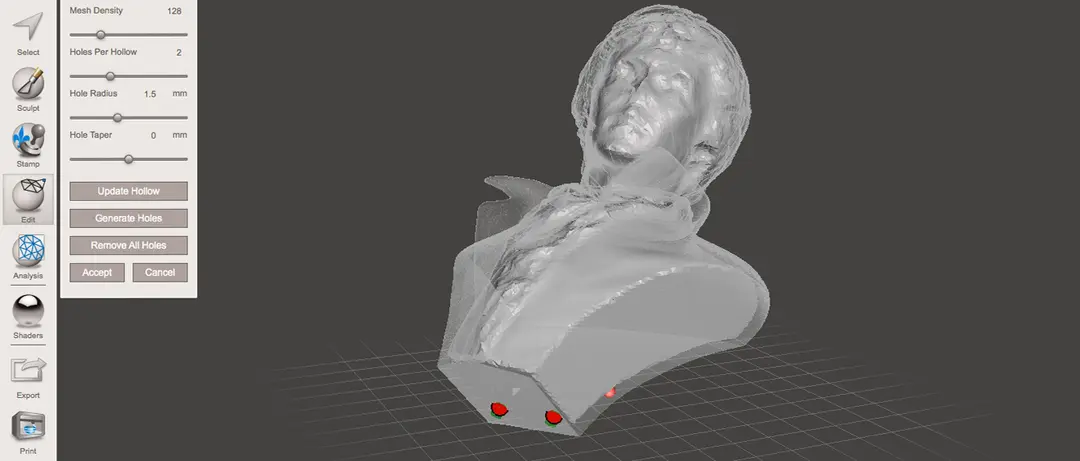

The shark was scanned, digitally altered to match the shark as seen in the movie, and then scaled down.

The 3D model was separated into keyed parts for printing on Form 4L. Once printed, the parts were assembled into a model.

A mold and running core was made from the model to cast the skin. A second core was also made for the mechanical department, to design the internal components.

Once cast and partially assembled, including internal mechanical components, the shark was painted to match the original.

The palettes are some of the end-use parts that are 3D printed.

Final assembly included installing the 3D printed and painted palettes, and painting the internal mechanical components.

Nicotero putting the final touches on the shark.

The shark exhibit in the Motion Picture Academy Museum. Image: Greg Nicotero

Next-Day Props for “Guts and Glory”

Nicotero’s “Guts and Glory” is a 2025 reality competition show with horror elements. While Nicotero was scouting in Georgia for the show, he realized he wanted a creepy skeleton that could be put in the lake for contestants to find. The challenge? It was a Thursday and he needed the prop by Monday for the shoot.

Back in LA, the team had less than three days to create the prop, which would have to be sent across the country to the set. Due to the details of the bones of the prop, the toes alone would take two days to sculpt, making the turnaround time impossible for traditional modeling. But with 3D modeling and printing, it took less than four days total to model, print, paint, and ship, with Childers printing the model overnight.

Props for “Guts and Glory” printed on Form 4L include idols and an intricate baby skeleton produced and delivered to set in four days.

“By Monday it was printed and painted and in a box within four days, and we're talking about a skeleton. The detail on the model that we had and the complexity of how you would've had to break it down to mold it, we could have never done it ever in a million years, but now with the technology, we were able to put that on the printer and print it and it looks magnificent.”

Greg Nicotero, Founder and Owner, KNB EFX

The fast print times of Form 4L meant Childers could print the skeleton overnight while the 99% reliability of Form 4 Series 3D printers gave him the confidence that the print would be complete and ready for painting the next morning.

Creatures at Any Size: Making a Godzilla Diorama

Digital artist Dave Grasso made 3D models of Godzilla and King Ghidorah. Maquettes were 3D printed as well as the heads of each monster at the required scale.

KNB EFX takes on a variety of projects related to film and television. A recent project is a large, detailed diorama for the lobby of a children’s hospital featuring a battle between Godzilla and Kind Ghidorah. The scene features multiple end-use parts printed on Form 4L:

-

LED-illuminated Clear Resin parts, including building windows and Godzilla’s spines

-

The detailed heads and tails of the characters, printed in Grey Resin

-

Tapped flanges holding up the buildings

The build volume of Form 4L enables the printing of large parts like Godzilla’s head overnight or in less than a day while also achieving fine finishes and intricate details like scales.

Childers assembles King Ghidorah’s heads, which are 3D printed and then painted.

CLEAR RESIN

Clear Resin is used for translucent parts, like eyeballs, or clear parts on props that will be illuminated by LEDs, such as the spines on Godzilla.

Innovative Animatronics

Animatronics give actors a physical prop to react to on set. Childers has begun 3D printing internal components.

Multiple parts for an animatronic head are set up with one-click in PreForm print preparation software and then printed in one Form 4L build.

Animatronics are one of the many props KNB EFX produces. Each time Childers makes a new mechanical head, he tries to improve it, most recently by 3D printing parts. Each piece has to fit perfectly together. Childers says that, “With the Form 4L, I can print parts with really great accuracy — all the holes are going to be perfectly fit and snug. I think that our heads are only going to keep getting better because of this — we can bring them to life a lot easier.”

Childers printed parts for an animatronic head in ESD Resin on Form 4L.

ESD RESIN

“I’m a big fan of the ESD Resin because it's strong, reliable, and heat resistant,” says Childers. “ESD is great for tapping. The structural integrity of it is better than any of the other resins from any other printers that I've ever tried.”

Childers did a test where he 3D printed a skeleton hand in ESD resin and put it in the foam oven, which reaches ~300 ℉, for five days, with no deformation.

A Tool for Artists

“This technology has allowed us to improve our work. The amount of detail that we can put into something and print it — and it looks exactly like the model. With 3D printing, every pore, every fang, every little nuance that you put into that sculpture is perfectly reproduced — and that's game changing for us.”

Greg Nicotero, Founder and Owner, KNB EFX

Finely detailed props in short timelines and at reasonable costs is asking for good, fast, and cheap, but by embracing all the tools available — and knowing how and when to use them — KNB EFX delivers.

“This technology does allow us to be more affordable because it cuts off manufacturer time. You have a 3D model and you print it if you don't need to mold it, and you can take the print and paint it. The accelerated schedule saves days.”

Greg Nicotero, Founder and Owner, KNB EFX

To start printing, explore Form 4L or contact sales to learn more. To evaluate the quality of parts for yourself, request a free sample part.