The Form 4 Ecosystem

Complete Your 3D Printing Experience

Looking for a 3D printer? Compare Formlabs Form 4 with the Bambu Lab X1 Series side by side.

Formlabs Form 4

Cost

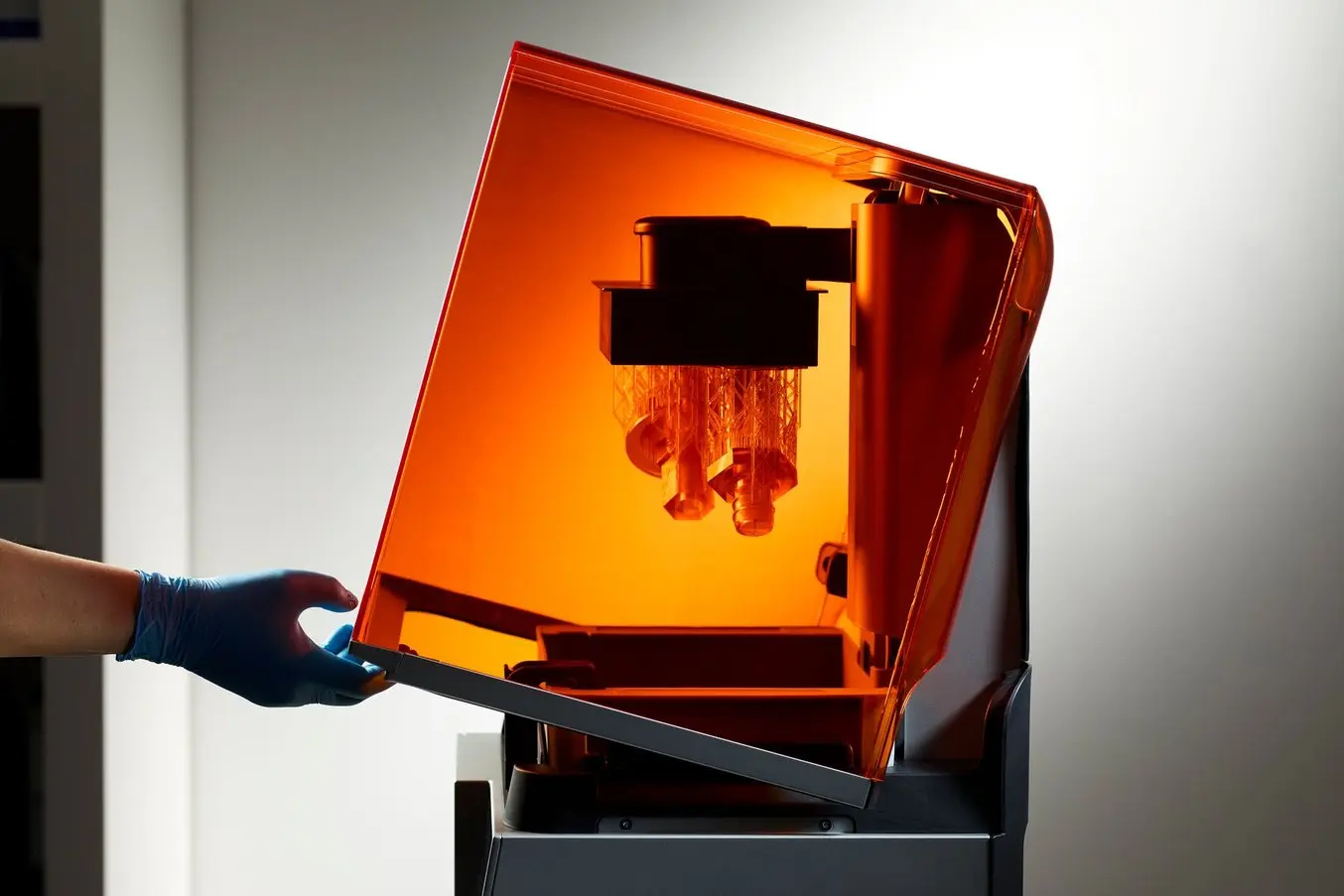

Low Force Display™ (LFD) is a new generation of masked stereolithography (MSLA) 3D printing where reduced peel forces lead to incredible speed, surface finish, and unmatched accuracy. Resin 3D printing creates 100% solid parts with a smooth surface finish and fine details. This makes it possible to produce clear, watertight, and isotropic parts.

BENEFITS

APPLICATIONS

* Use Form 4B for biocompatible printing

Print Speed

Time to print one assembly on Form 4 in Grey Resin, 100 microns layer height.

Time to print 50 assemblies (100 parts) on Form 4 in Grey Resin, 100 microns layer height.

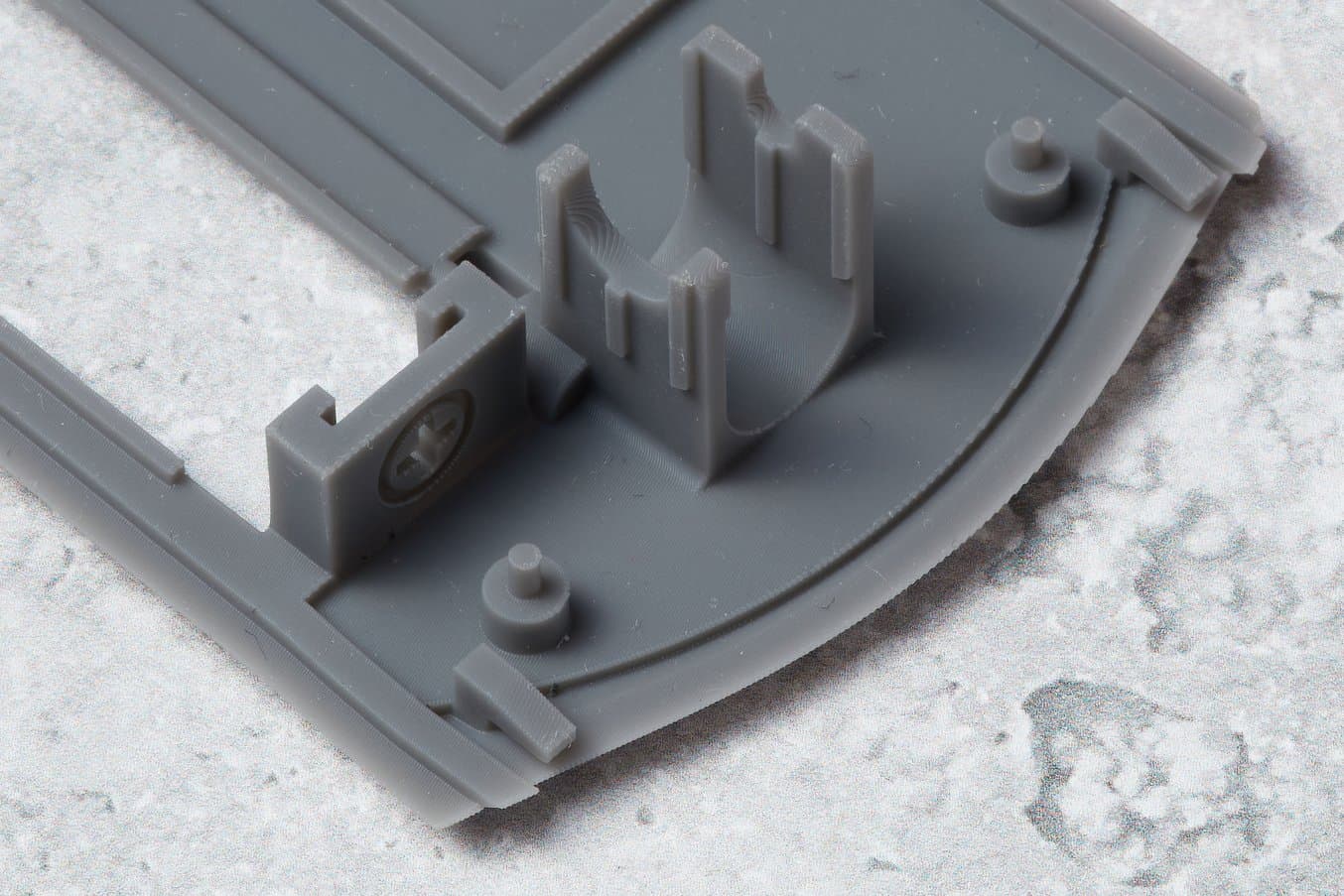

Surface Finish

SLA 3D printers create parts that are nearly indistinguishable from injection molded plastics.

Resolution

XY RESOLUTION

50 μm

Pretuned anti-aliasing for subpixel resolution resulting in superior fine and sharp feature performance.

MINIMUM WALL THICKNESS

0.2 mm

MINIMUM EMBOSSED AND ENGRAVED DETAILS

0.1 mm

Build Volume

Materials

Formlabs resins are designed for a range of high-performance applications including underwater parts, wind tunnel test models, welding jigs, and threaded parts.

Engineering materials are designed with specific mechanical properties from soft silicone to flexible, tough, durable, and rigid varieties. Materials include polyurethanes for end-use parts, and specialty materials for high-temperature applications.

A comprehensive library of resins for dental and medical applications is available on Form 4B, including 15+ materials for biocompatible parts including materials for bone, tissue, dentin, and mucosal membrane contact.

Formlabs resins are designed with user safety and minimum odor in mind.

Reliability

Form 4 was measured to have a 98.7% print success rate by an independent global leader in product testing. Read a complete description of the test methodology and see the results in our white paper.

A new Release Texture and a durable Flexible Film Resin Tank minimize peel forces during printing. Plus, the built-in Resin Level Sensor and Z-Axis Force Sensor ensure consistency and performance.

In the event of an issue, error messages display QR codes that lead to support articles to get you back up and running as quickly as possible.

TYPICAL DIMENSIONAL TOLERANCES

1-30 mm features: ±0.15% (lower limit: ±0.02 mm)

31-80 mm features: ±0.2% (lower limit: ±0.06 mm)

81-150 mm features: ±0.3% (lower limit: ±0.15 mm)

Software

Formlabs' free print preparation software, PreForm, has validated print settings for all Formlabs resins for easy, optimized printing, and the option to fine-tune settings for peak performance.

You can also use the online Dashboard to manage a fleet of printers, monitor prints, track materials and consumables, and work with your team.

Support

All Formlabs hardware comes with one-year warranty and email support provided by a dedicated staff. Purchase a Pro Service Plan to extend your coverage further and get access to additional benefits like hot-swap replacements, dedicated phone support, training, and more, so you can stay focused on growing your business.

Cost

The $3,499 starting price includes all the essential tools required to start printing and access to the powerful software and online Dashboard. The Form 4 complete package for $5,849 also includes custom-developed automated post-processing tools and a premier service plan for a turnkey solution.

Buy from Formlabs via sales or the online store, or purchase through one of our distribution partners.

Company

Formlabs brought SLA 3D printing to the desktop in 2011 and SLS printing to the benchtop in 2021, and has become the market leader in both technologies, selling more than 130,000 printers. The Form 4 is a 4th generation product, powered by a proven technology that has been used to print over 400 million performance parts.

Bambu Lab X1 Series

Cost

Fused deposition modeling (FDM) 3D printers extrude thermoplastic filaments, creating lightweight, low-cost parts, but the process lacks the ability to reproduce fine details and parts often have visible layer lines on the surface. FDM prints also have voids, which makes them anisotropic, meaning they are weaker in the Z direction than the XY plane.

BENEFITS

APPLICATIONS

Print Speed

Time to print one assembly in PLA Basic on Bambu Lab X1, 120 microns layer height.

Time to print 50 assemblies (100 parts) in PLA Basic on Bambu Lab X1, 120 microns layer height.

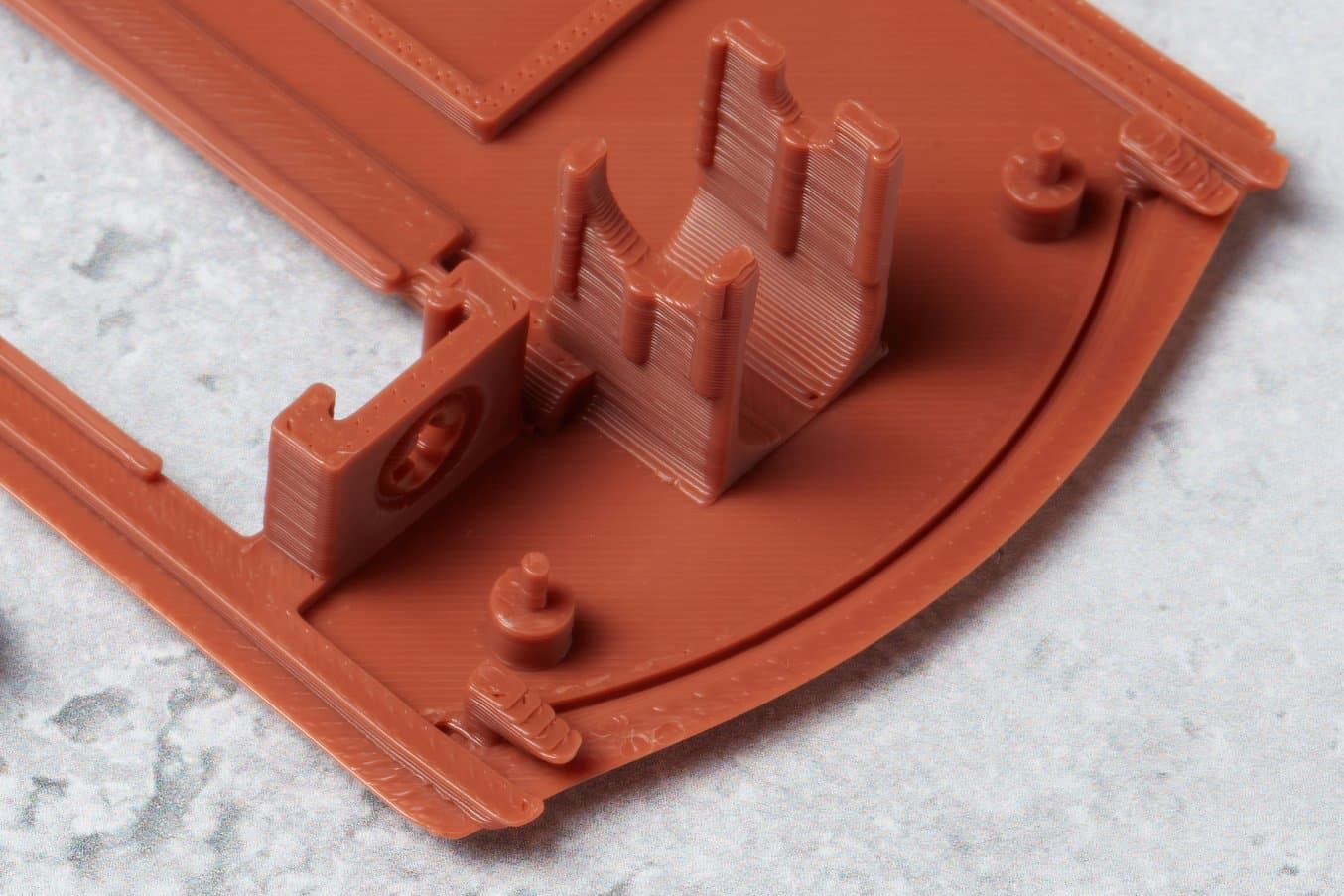

Surface Finish

FDM printers create parts with visible layer lines and a slightly rough surface, requiring additional post-processing for higher quality results.

Resolution

XY RESOLUTION

N/A

The resolution of FDM 3D printed parts is dependent on the nozzle’s size, the material properties of the molten material, and the control with which the motor can move the nozzle.

MINIMUM WALL THICKNESS

0.8 mm

MINIMUM EMBOSSED AND ENGRAVED DETAILS

0.6 mm wide, 2 mm high

Build Volume

Materials

Bambu Lab provides a wide range of filaments and printers can be used with third-party materials. Filaments are budget-friendly, with a range of colors and finishes, including gloss, matte, glow-in-the-dark, and glitter, and the option to include up to 16 materials in one print.

FDM parts can be hollow to save material and print time, but they cannot be printed fully dense, even with 100% infill. Parts are anisotropic, not watertight, and lack clarity and smoothness. As a thermoplastic, FDM parts will soften at high temperatures.

Skin-safe filaments are available, but other biocompatible options are not available, limiting applications.

FDM parts can be handled directly after printing and the process is clean and low-odor.

Reliability

TYPICAL DIMENSIONAL TOLERANCES

N/A

Software

Bambu Lab’s free print preparation software, Bambu Studio, has print settings for their own filament, plus generic presets for third-party materials. Print settings can be imported or edited with trial and error.

Third-party slicers such as Superslicer, Prusaslicer, and Cura are compatible with Bambu Lab printers, but some advanced features are not supported.

Support

The warranty is limited to one year and does not extend to any printer parts which are considered consumables. Support is available via an online portal.

Cost

The Bambu Lab X1C starts at $1,199, while the X1E starts at $2,499. The X1C Combo, which includes one AMS material management system, enabling the printing of four different colors, is $1449. Additional AMS is available for $349 and also requires the AMS Hub for $48.99, to print 5-16 colors. Free slicer software from Bambu Lab is available, as well as third-party offerings. There is no option for professional service.

Software

Bambu Lab is a consumer tech company founded in 2020 based in Shenzhen, China. They launched with a massive Kickstarter campaign and since then have become one of the market leaders for desktop FDM 3D printers.

Do you have more questions about the differences between these solutions?

See and feel Formlabs quality firsthand. We’ll ship a free sample part printed on Form 4 to your office.

Experience the new standard for professional 3D printing with a demonstration of the end-to-end Form 4 workflow plus a comprehensive Q&A session addressing the new technology, workflow, applications, and more.

In this white paper, learn how SLA technologies work, why thousands of professionals use this process today, and what you need to know to explore how SLA 3D printing can benefit your work.

Get more done with most prints in under 2 hours.1

A Wide Range of Applications To Help You Excel in Your Work

Forge Motorsport reverse-engineered an underperforming part, 3D printed a new design, and tested it on a vehicle for five months before committing to tooling.

Forge Motorsport reverse-engineered an underperforming part, 3D printed a new design, and tested it on a vehicle for five months before committing to tooling.

The Form 4 Ecosystem

Complete Your 3D Printing Experience