Thunder, an MSU veterinary orthopedic patient, during a check-up.

At the Michigan State University College of Veterinary Medicine, patients of all shapes, sizes, and species can come through the door. For Dr. Danielle Marturello, DVM, MS, DACVS an Assistant Professor of Small Animal Orthopedic Surgery, that means that every day is different. Some days she might be in the clinic, seeing dogs and cats brought with bone fractures, skeletal deformities, or ligament tears. On another, she is in the operating room, helping to fix these patients and get them on the road to recovery.

Different Patients, Different Challenges

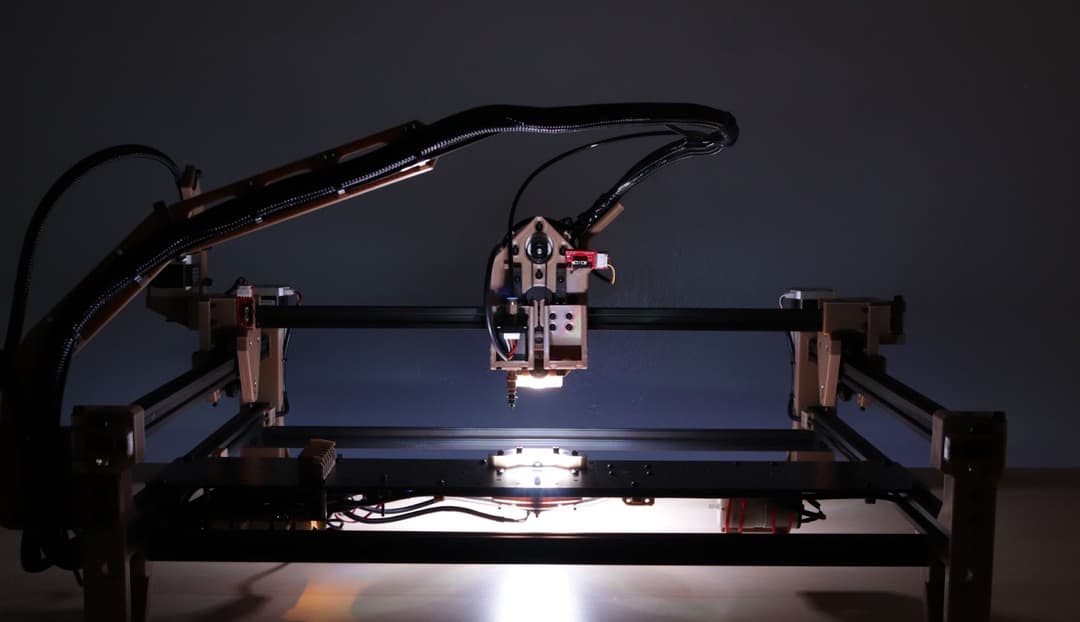

In veterinary orthopedics, doctors have to memorize the makeup and structure of not just one skeletal system, but many. To help her team visualize, plan, and execute complex surgeries, Dr. Marturello creates detailed 3D models and surgical guides from imaging data using a fleet of Formlabs stereolithography (SLA) printers. The variety of materials available also means that the printers can create teaching aids for veterinary students, interns, and residents, improving surgical outcomes and the educational experience MSU can provide.

Solving Complex Cases With High Quality Imaging

As with human medicine, veterinary orthopedics relies heavily on quality imaging. When seeing a patient, Dr. Marturello will always order an X-ray at the minimum. Then depending on the case complexity and whether or not a 3D model is needed, possibly an additional CT scan. Unlike in human medicine however, patients are unable to communicate their level or location of pain, so high-resolution imaging and modeling is even more integral to both diagnosis and treatment, along with a thorough physical exam.

“Imaging is paramount to our career and work. When we need to plan a surgery, when we’re done with surgery and need to see if an implant is in the right spot, honestly, we really cannot do our job without it,” says Marturello.

Scooby, a patient being treated for an angular deformity.

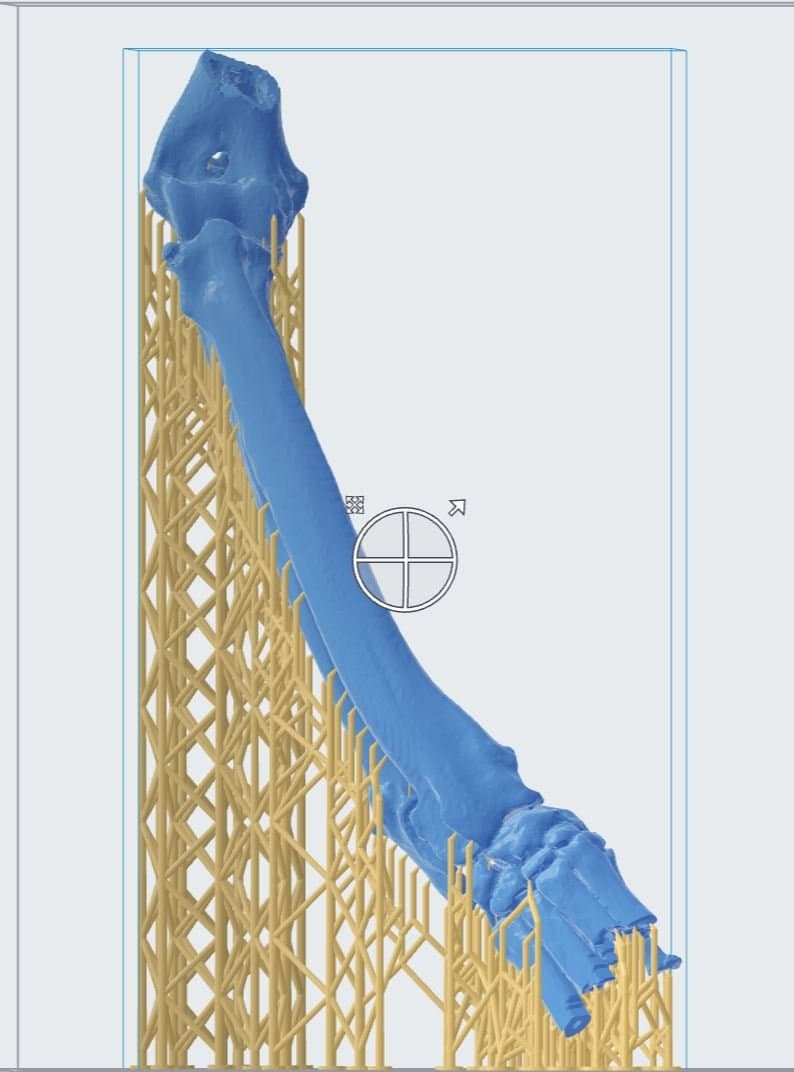

Scooby's affected joint shown in PreForm before being printed.

These images and models are used to look at several different pathologies, such as fractures caused by car accidents, or growth deformities where two bones have grown incorrectly and are hampering range of motion or normal function. Dr. Marturello’s team will print models of the bones in White Resin on the Form 3 or Form 3L printers to study the pathology and rehearse surgery ahead of time.

“We need to make sure that we’re planning ahead—is what we thought would work, actually going to work? We can also use it to pre-contour our implants to that model bone, sterilize it, and then use the pre-contoured implant in surgery which saves time for the patient under anesthesia,” says Maturello.

In one particularly complicated case, a dog was brought in with a shattered tibia, very close to the knee. Because the break was so close to the joint, it was difficult to see on an X-ray the full extent of the damage. Dr. Marturello printed the fractured tibia using White Resin on the Form 3, sterilized the models and made them safe to bring into an operating environment.

Dr. Marturello told us, “We were able to spin around the bone in surgery to help us to have a more tangible three dimensional idea of the fracture pattern. This is important because we only see one side of it with our surgical approach. Having that printed bone, because of the angle of the fracture, was super helpful and though it was a really challenging case, the dog did fabulous. It really helps take that surgery to the next level.”

In another case, a fracture on a dog had not healed correctly, creating a ‘non-union’ fracture, and the dog wasn’t able to walk well. Because it was so close to a joint, Dr. Marturello needed to use an implant called an External Fixator, but due to the location of the fracture, the typical pins used to affix the implant to the bone didn’t fit. The solution was to include a ring component, and Dr. Marturello practiced first on a printed bone, placing the hybrid construct on the model before the dog even came in.

The hybrid external fixator used to plan the non-union fracture revision surgery.

“Once I made the fixator on the printed bone, everything went faster. I was able to take that construct and study it ahead of time, then during the surgery just replicate what I did on the model, which was much easier,” says Maturello.

Helping Reassure Worried Pet Owners

A common use of 3D printed models in human medicine is to educate patients about their specific pathology or procedure, improving their understanding and lowering anxiety about complicated operations. Dr. Marturello’s team can’t explain to their patients what is about to happen, but 3D printed models are very useful in demonstrating to pet owners the details of their pets’ needs.

“For one angular deformity surgery, we got a saw, brought it into the room, and just did the surgery on the printed model to show the owner. This helped us to gain their trust as well as facilitate their understanding, resulting in consent for the procedure.”

The education component also applies to the residents and veterinary students who are assisting and observing clinical work and surgeries. Dr. Marturello models bones and surgeries for her students, interns, and residents to allow them to practice and gain technical skills.

“Models are expensive and get worn out, and it’s hard to get cadavers, but a 3D image of a complex or complicated case lasts forever. So when one printed model gets used for practice, we can just print another and have it whenever we need it.”

As one of only a few people in the veterinary school who uses 3D printing, Dr. Marturello also gets called upon by other departments when a particular pathology presents an imaging or operational challenge. Using her Form 3, Form 3B, and Form 3L printers, she can print models of tumors and organs in Clear Resin or White Resin to help other surgeons envision the path to removing the pathology.

“We like the reliability—I never have a failed print. SLA printers produce nicer looking models than FDM, so especially when we’re using them to talk to the pet owners, that’s great because we want the models to look nice. We started with the Form 2, and now the Form 3, Form 3B, and Form 3L. We’ve been really happy with their accuracy.”

Dr. Maturello with Otis, four weeks after his successful operation.

Guide to 3D Printing In Education

In this guide, we’ll discuss the benefits of 3D printing in education, from improved student collaboration to workforce development and empowered creativity.