Spare parts management is an endless battle to strike the perfect balance between the demand for spare parts, the minimum order quantities and lead times for producing parts, and the cost of keeping inventories. But does it always have to be that way?

Digital warehousing and digital fabrication of spare parts might sound like buzzwords, but they are increasingly powerful solutions for companies to address challenges around keeping and maintaining a spare parts inventory, while improving their bottom line and optimizing supply chains.

In this guide, we highlight the best practices for spare parts inventory management, compare physical spare part inventory with digital warehousing, and explain how you can use digital fabrication tools like 3D printers to produce spare parts on demand.

Spare Parts Inventory Management Best Practices

The traditional process of managing spare parts inventory involves physically counting inventory and taking stock of the spare part locations within the warehouse or manufacturing shop floor. The manager monitors stock-outs, logistics, and delivery timelines. This physical process is subject to human errors that may lead to unplanned downtime, capital loss, and diverse operational challenges.

Digitalization provides tools to optimize physical inventory management processes and, in some cases, solve the operational challenges those processes face across the warehouse or manufacturing floor.

The successful implementation of an optimized spare parts inventory management framework starts with adopting guidelines or best practices for everyone to follow:

-

Systematically classify components: The first step to optimizing a spare parts inventory is adopting or developing a classification method for the parts. The classification method must take into consideration the components required to maintain or repair critical machinery. Two conventional methods for classifying components are commonly used to implement physical spare parts inventory management processes. These methods are the ABC and XYZ analytical processes.

The ABC analysis approach assigns importance to components with higher consumption values. Here, consumption value refers to the components that are used up at a much higher rate compared to others. For this approach, spare parts categorized as “A” are assigned more consumption value compared to B. Parts designated as C have the lowest consumption value. This valuation empowers inventory managers with the information required to stock up on parts with a higher consumption value.

XYZ analyses are used in classifying spare parts according to the variability of their demand cycles. For example, X parts are items with constant demand throughout production cycles or specific periods. Y parts represent parts with some degree of variation in demand, and the demand for Z parts experiences the most variations, making it difficult to predict the number of Z spare parts to stock. -

Optimize the Bill of Materials (BOM): The BOM refers to a structured list of all the materials and components needed to construct a product. For maintenance and repairs, the conventional BOM identifies the spare parts needed for repairing production equipment. Optimizing the BOM starts with implementing a schedule to continuously update the spare parts inventory in real-time. Optimizing the BOM will reduce inaccuracies and ensure the inventory is stocked with the spare parts required for maintenance and repair activities.

-

Implement a work order process: Work orders play important roles in determining what goes out of the spare parts inventory, stock-outs, and replacement requirements. Scenarios in which human errors occur — such as forgetting to file a formal work order for used parts — may lead to unplanned downtime and maintenance challenges down the line. Implementing a work order process using digitalization solutions such as automated scheduling and reporting reduces human errors and streamlines the work order process.

-

Focus on continuous employee training: Despite best intentions, mistakes happen. These miscalculations and recording errors can be reduced through the adoption of digital spare part inventory management tools and adequate training for inventory management staff. Training programs must take into consideration the use of both physical and digital inventory management processes to ensure employees are well-versed in using either process or a hybrid of both.

-

Make inventory locations accessible: The inventory management process is expected to keep spare parts in stock and ensure they are accessible to employees. A centralized inventory provides a clear overview of the parts in stock and their location, which enhances efficiency in the workplace.

-

Invest in an inventory management system: Embracing digitalized platforms empowers warehouses and manufacturing outfits with intuitive systems that automate the inventory management process. These platforms are equipped with features such as notification systems and data analytics capabilities that implement many of the best-practice solutions highlighted above. The capabilities of an inventory management system can also be enhanced when partnered with IoT solutions for tracking spare parts (including through the supply chain) and forecasting tools that predict future spare parts requirements. This ensures that stock-outs can be predicted and dealt with before they occur.

Digital Warehousing 101

Challenges of Keeping and Maintaining a Physical Spare Parts Inventory

Traditionally, companies manage physical warehouses and storage spaces dedicated to housing and maintaining large inventories of spare parts until they are needed. These inventories of spare parts occupy vast space and require regular maintenance to ensure the spare parts remain in their optimal condition until used. Managing storage space and physical stockpiles of parts locks down considerable financial resources that could be used more productively elsewhere.

Companies that rely on third parties for spare parts also face other challenges associated with keeping an up-to-date inventory. These challenges include increased lead times when the third-party manufacturer deals with increased demand, production downtime, and in extreme cases, bankruptcy. Disruptions to the supply chain caused by a pandemic or political issues may lead to increased delivery timelines for manufactured spare parts. Minimum order quantities also mean that companies often have to order more parts than the forecasted demand.

Digital warehousing and digital fabrication of spare parts offer solutions for dealing with these challenges associated with the physical spare part inventory.

What is a Digital Warehouse?

The digital warehouse is a digital platform that stores digitized spare part designs and blueprints for producing these designs on demand. It’s essentially a digital repository of CAD files, 3D models, and other blueprints necessary to produce parts simply by sending the digital file to a 3D printer or another digital fabrication tool at the company’s own facility or at a service provider.

A digital warehouse can be a simple online storage platform (Google Drive, Microsoft OneDrive, Dropbox, Bynder, etc.) but there are also more sophisticated solutions on the market with more advanced features like categorization, tagging, filtering, advanced search, and links to service providers.

The benefits of digital warehousing and the digital fabrication of spare parts include:

-

Lower costs: By reducing the size of the physical inventory, companies can reduce the capital expenses spent on stocking spare parts and the costs to maintain extensive storage facilities.

-

Lower lead times: Complex and long supply chains to produce parts and components result in parts often taking weeks or months to arrive, rendering the process inflexible and forcing companies to add a substantial buffer to account for the uncertainties around forecasting. In contrast, digital fabrication tools can produce new batches of parts in a few days on demand.

-

Supply chain resilience: The recent COVID-19 pandemic and war in Ukraine have shown that complex supply chains are prone to disruption. Decentralized manufacturing with digital fabrication reduces risks and brings production closer to the end user.

-

No minimum order quantities: Traditional mass manufacturing processes are geared toward producing identical parts in large quantities to achieve economies of scale, which can be an issue when spare parts are only required in lower volumes. Digital fabrication tools have no minimum order quantities and can produce parts on demand.

-

Reduced waste: Parts stocked in warehouses are at risk of becoming obsolete as the product changes, leading to excessive waste. Designs stored in digital warehouses can be versioned, kept always up to date, and produced only on demand, reducing waste, as well as the carbon footprint of the OEM.

Physical Inventory or Digital Warehouse? Both!

When does it make sense to have a physical inventory and when to create a digital warehouse? The answer in most cases is to have both, to maximize the benefits of each approach.

According to Prof. Jeannette Song, having some parts in stock, and 3D printing others on demand optimizes the spare parts inventory management process. The application of analytical solutions to forecast demand also ensures an accurate number of parts are in storage and further demand can be met with digital fabrication.

The hybrid approach reduces costs and waste associated with physical inventories, while balancing the manufacturing limitations associated with digital inventories.

For example, it’s a good best practice to keep an ample inventory of critical spare parts. High-volume parts will probably also be always more cost-effective to produce with traditional manufacturing tools, while digital warehousing and fabrication can yield substantial savings with low-volume spare parts (~1-10,000 units). Material, part dimensions, and other functional specifications also define the best production method and inventory approach for certain parts. OEMs should also calculate ROI based on various factors: obsolescence, risk of supply shortage, room for inventory reduction, etc. Software tools like 3YOURMIND or Spare Parts 3D can help analyze spare part inventories and assess the potential of each part.

Lastly, a hybrid approach also offers an easier path for manufacturers to get started with digitalization while continuing their reliance on time-tested traditional solutions.

SLS 3D Printing vs. Injection Molding: When to Replace Molded Parts With 3D Printing?

This white paper showcases the cost-dynamics for real-life use cases, and presents guidelines for using SLS 3D printing, injection molding, or both.

How to Set Up a Digital Warehouse

Parts in the digital warehouse have to be represented with digital files. If your part or product was designed using CAD software, then the digital file should be readily available.

For older spare parts, reverse engineering with 3D scanning and 3D modeling are the tools used in building the digital spare parts inventory.

Reverse engineering is a powerful method for recreating older spare parts.

To get started, companies can use a simple online storage platform, use a digital warehouse software solution or develop a fully proprietary solution. For those planning to order parts from demand, some 3D printing service providers also offer digital warehousing solutions.

3D Scan to 3D Print: Rapid Reverse Engineering for Machine Restoration, Assembly Jigs, and Aftermarket Products

Watch this webinar for a detailed look at how to start using 3D scanning to improve part design and production when paired with reverse engineering CAD and 3D printing.

Digital Fabrication of Spare or Replacement Parts

Additive Manufacturing (3D Printing)

3D printing or additive manufacturing (AM) technologies create three-dimensional parts from computer-aided design (CAD) models by successively adding material layer by layer until a physical part is created.

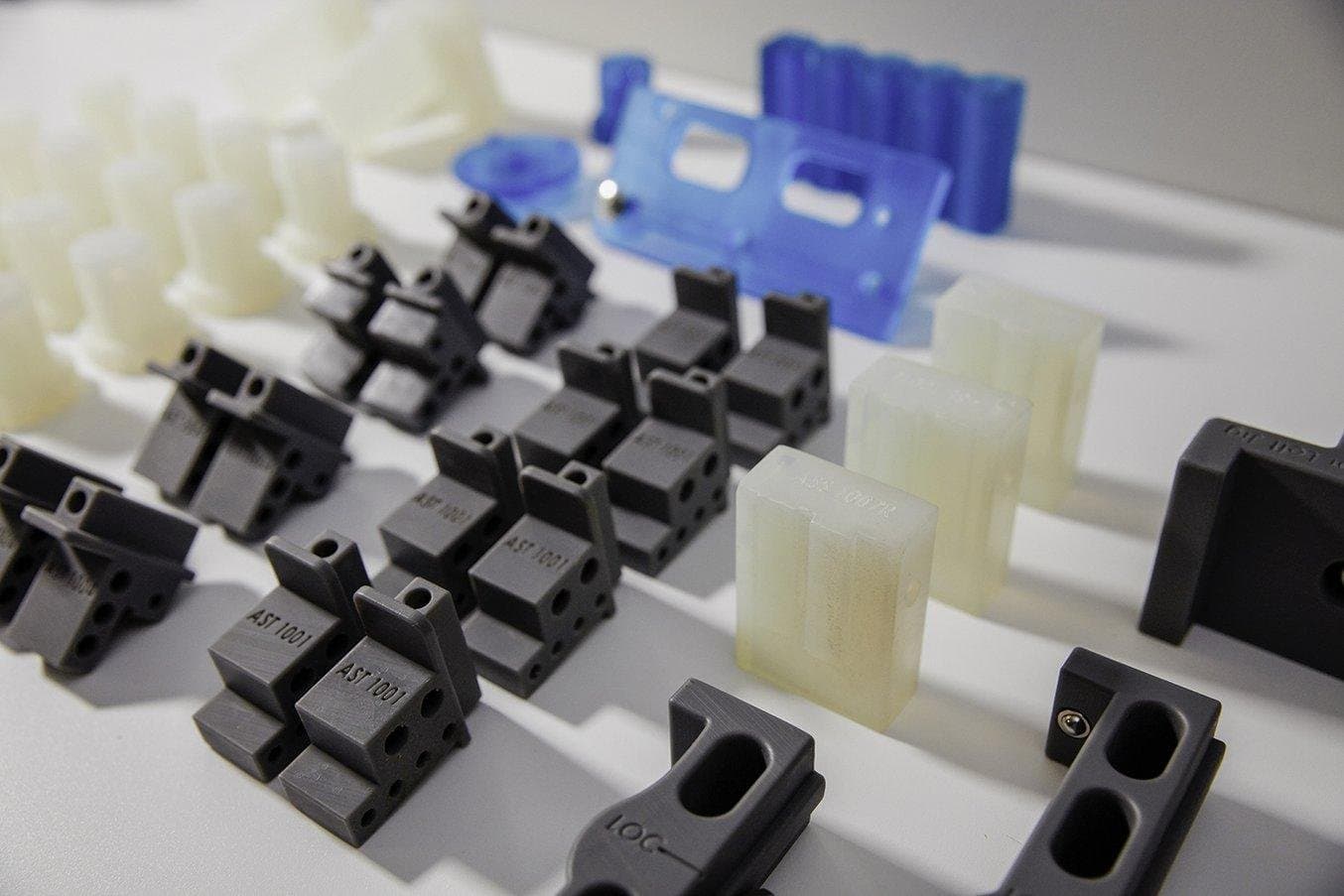

3D printing has been ubiquitous in prototyping and product development for decades. Now, this maturing technology is entering widespread use in manufacturing. In the product development process, manufacturers are already leveraging the flexibility of 3D printing for producing internal tools, such as jigs, fixtures, and other manufacturing aids, or even rapid tooling such as molds for injection molding or thermoforming.

Recent advances in machinery, materials, and software open opportunities for producing high-precision, functional 3D prints that can stand in for end-use parts—parts that are sold to and used by the final customer—empowering businesses to bring innovative products to market and make small and mid-scale manufacturing finally accessible.

Stress Testing 3D Printed Parts for End-Use Applications

This white paper presents Formlabs 3D printing hardware and material solutions for end-use part production. It documents various users' case studies and includes stress testing results to verify the suitability of 3D printing materials for end-use applications.

3D printers are most commonly used to produce plastic parts—metal 3D printers are also available, but at a substantially higher cost. There are many different types of 3D printers, the most common processes for producing plastic parts being: selective laser sintering (SLS), stereolithography (SLA), and fused deposition modeling (FDM).

While most traditional manufacturing processes require expensive industrial machinery, dedicated facilities, and skilled operators, 3D printing also allows companies to bring production in house. Compact desktop or benchtop 3D printing systems for creating plastic parts are affordable and require very little space and no special skills, enabling professional engineers, designers, and manufacturers to speed up iteration and production cycles from months to just a few days.

Award-winning custom car shop Ringbrothers initially brought SLA 3D printing in-house as a prototyping tool to iterate faster and more cost-effectively. Since adopting the technology, they’ve found ways to use 3D printing to push the quality and creativity of their work with end-use parts, including spare parts for classic cars.

For a mirror project, the team used 3D printed parts as part of the final assembly; the part acted as a permanent assembly fixture bonded inside a carbon shell that additional parts are bolted onto. In another case, the team used a castable 3D printing material to create a metal emblem for a custom car project.

“That next level detail wouldn't have been possible had we not been able to 3D print the wax and have [our local jeweler] cast it in-house, ” said product development specialist, Matt Moseman.

Ashley Furniture, the world’s largest furniture manufacturer, integrates new technologies into its factories, from 3D printing to robotics. There are 700 3D printed parts at work on Ashley Furniture’s factory floor in Arcadia, Wisconsin, right alongside industrial robots and CNC milling workhorses, from assembly to fabrication.

Besides manufacturing aids, some of their most practical applications are replacement parts for the manufacturing floor. When a vacuum retainer ring for a point-to-point drilling machine couldn’t be purchased on its own, the only option was to purchase the whole assembly, which was costly.

“The company wouldn’t sell just the ring, we would have to buy the whole pod for $700,” said production engineer Brian Konkel. “Instead, we were able to 3D scan the part to capture the geometry, and print a replacement part for $1 to keep our drilling equipment running, without having to buy the complete assembly.”

Instead of purchasing a complete new assembly pod for $700, the company 3D printed the part that needed replacement for just $1.

Machine shop A&M Tool and Design has scaled to use 3D printing to produce functional parts like fixtures and several end-use parts. For example, when a spider coupling for one of their large lens polishing machines arrived in the wrong size two days before a big trade show, Little quickly designed and 3D printed a correctly-sized replacement on an SLA 3D printer. The printed coupling was used to drive a two-horsepower motor on a grinding machine.

When an outsourced spider coupling for a lens polishing machine arrived in the wrong size, Little 3D printed a replacement in Durable Resin for a quick fix ahead of a big trade show.

Tessy Plastics, a contract manufacturer of plastic parts for the healthcare industry, utilized the Fuse Series SLS 3D printer to manufacture a spare timing-belt pulley system on demand. In this scenario, a last-minute change in the customer’s requirements would have delayed production for days if conventional manufacturing processes were used. With 3D printing, Tessy Plastics was able to quickly 3D print the replacement system, and the end part was used for weeks.

How to Unlock Low Volume Production and Custom Manufacturing with 3D Printed End-Use Parts

Watch this webinar to learn how to achieve custom manufacturing and low volume production of end-use parts quickly and cost-effectively with 3D printing.

CNC Tools

Computer numerical control (CNC) tools are subtractive manufacturing processes. They start with solid blocks, bars, or rods of plastic, metal, or other materials that are shaped by removing material through cutting, boring, drilling, and grinding.

CNC tools include CNC machining, which removes material with either a spinning tool and fixed part (milling) or a spinning part with a fixed tool (lathe). Laser cutters use a laser to engrave or cut through a wide range of materials with high precision. Water jet cutters use water mixed with abrasive and high pressure to cut through practically any material. CNC milling machines and lathes can have multiple axes, which allows them to manage more complex designs. Laser and water jet cutters are more suited for flat parts.

CNC tools can shape parts from plastics, soft metals, hard metals (industrial machines), wood, acrylic, stone, glass, and composites. They’re ideal for producing custom or low-volume end-use parts, structural parts, and tooling for a wide range of industries.

Compared to additive manufacturing tools, CNC tools are more complicated to set up and operate, while some materials and designs might require special tooling, handling, positioning, and processing. This makes them costly for one-off parts compared to additive processes and better suited for small production runs. Machining is ideal for low-volume manufacturing applications that require tight tolerances and geometries that are difficult to mold, such as pulleys, gears, and bushings.

Machining processes have more part geometry restrictions than 3D printing. With machining, the cost per part increases with part complexity. Undercuts, pass-throughs, and features on multiple part faces all increase costs. Machining processes require allowances for tool access and certain geometries, like curved internal channels, are difficult or impossible to produce with conventional subtractive methods.

Comparison: Digital Fabrication Tools for Spare or Replacement Parts

| 3D Printing | CNC Tools | |||

|---|---|---|---|---|

| Technologies | Selective laser sintering (SLS), stereolithography (SLA), fused deposition modeling (FDM), metal 3D printing | CNC machining (mill or lathe), laser cutting, water jet cutting | ||

| Materials | Plastics, metals (limited), silicone and rubber-like parts | Plastics, metals, wood, acrylic, stone, glass, and composites | ||

| Form | High degree of freedom | Medium degree of freedom | ||

| Lead time to final parts (in house) | One to two days | One day to a week | ||

| Cycle time | < 1 hour to multiple hours, depending on part size | < 1 hour to multiple hours, depending on part size, design, and complexity | ||

| Setup cost | $ | $$ | ||

| Cost per part | $$-$$$ | $$$$ |

Get Started Digital Warehousing and 3D Printing Spare or Replacement Parts

Setting up a digital spare parts inventory is a cost-effective way to reduce inventory management costs. Pairing this system with an in-house digital fabrication tool like 3D printing supports on-demand strategies, and enables manufacturers to reduce costs and lead times, improve resiliency, and reduce downtime.

Formlabs offers cutting-edge SLA and SLS 3D printers and industrial-grade materials for manufacturing spare and replacement parts. Explore our 3D printers or get in touch with a specialist to discuss how you can piece together an ideal workflow.