Improve Efficiency With 3D Printed Manufacturing Aids

3D printed manufacturing aids are vital tools for addressing common problems that arise during the manufacturing process. This includes the need for custom jigs, fixtures, tools, and replacement parts. Use in-house 3D printing to improve the efficiency of the manufacturing process, reducing costs and enhancing production.

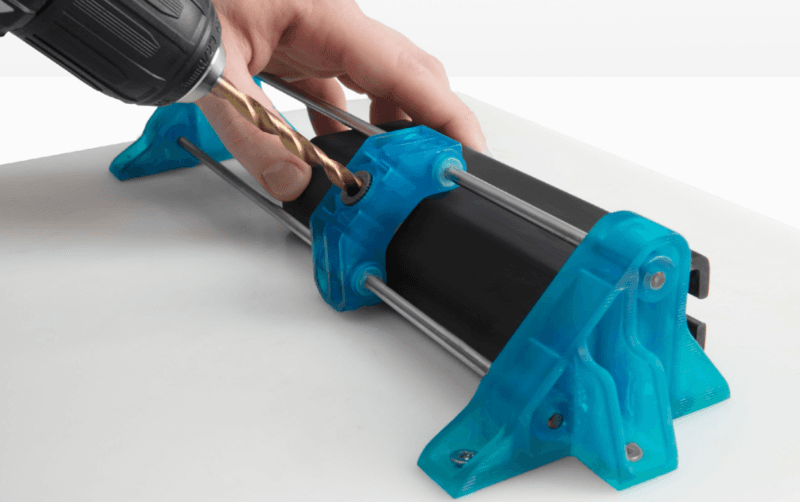

Custom Jigs, Fixtures, and Tools

In-house 3D printing is used by businesses around the world to help solve problems on the shop floor, boosting and streamlining manufacturing efficiency. Reduce machine downtime by creating replacement parts, create custom (lattice, springy, complex) replacement parts that perform better than the originals, and create custom jigs and fixtures to improve production workflows.

Adding 3D Printing to the Machine Shop: Lessons From A&M Tool

Learn why A&M Tools scaled 3D printing applications from prototyping to quick-turn production tools and end-use parts for custom machinery.

Reducing Costs in Manufacturing with 3D Printing

Every single part that Pankl makes requires a series of custom jigs, fixtures, and other tooling that are designed and fabricated specifically for that part. The team turned to 3D printing for custom tooling, and to keep costs under control.

Manufacturing Intricate Gripper Brackets for a Pick and Place Robot

Read how AMRC created a custom springy component and how the team managed to manufacture five iterations of the intricate design in just a few days with 3D printing.

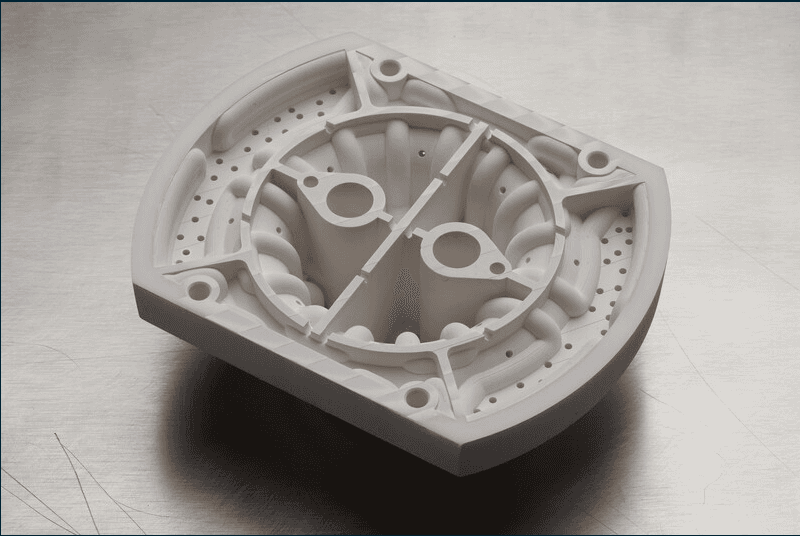

Reverse Engineering: A Powerful Digital Workflow

Reverse engineering with 3D scanning and 3D printing is a powerful digital workflow used to create replacement parts. Instead of replacing an entire machine, scan broken parts and re-print them for a few dollars per part.

3D Scan

Convert To Solid

3D Print

Test and Integrate

Proved ROI in Months

While bringing 3D printing in-house comes with an upfront cost, that investment can pay for itself in a couple of weeks or months compared to the cost of outsourcing or using traditional manufacturing methods.

Understand the costs of 3D printing and how to effectively compare to alternatives: use this interactive tool to calculate your own ROI.

Cost Comparison

Pankl Racing Systems significantly reduced lead time and costs by 3D printing custom jigs.

5 - 9 hours

48x faster

$9 - $28

12x cheaper

2 - 3 weeks

$45 - $340

Create Manufacturing Aids With A Library Of 3D Printing Materials

Formlabs' ecosystem of accessible 3D printers and high-performance materials empowers manufacturing teams to create a wide range of custom manufacturing aids, all in-house, and at an affordable price.

Tools for Manufacturing Aids

Form 4

High Performance SLA 3D Printer

The Form 4 produces precise parts with a high-quality surface finish, ensuring that your manufacturing aids are created fast and true to design with minimal post-processing. Create long-lasting industry-quality parts in-house at an affordable price, enabling your team to print new models in a few hours.

Use the Form 4 at various points of the product development process for a faster ROI. The Formlabs ecosystem was created to easily integrate into any product development process.

Additional Resources About Manufacturing Aids

Check out some additional resources to help you get started using Formlabs 3D printers to make custom manufacturing aids.

Get Started 3D Printing Manufacturing Aids

Contact a Formlabs Solution Specialist to get started 3D printing manufacturing aids.