Two techniques have historically defined jewelry making: handcrafting and lost-wax casting. Both techniques require significant technical expertise, are highly time-intensive, and mistakes in the process can prove expensive.

But today, digital design and 3D printing are primed to disrupt these age-old practices in a major way. Supplementing traditional processes with digital techniques such as jewelry 3D printing brings new possibilities in design and production to jewelers, as well as exciting new customization options for customers.

Introduction to Casting for 3D Printed Jewelry Patterns

In this white paper, learn how to cast fine jewelry pieces from 3D printed patterns and how direct investment casting, or lost wax casting, works as a moldmaking technique.

Digital Workflows Augment Traditional Techniques

3D printed jewelry production augments the principles of investment casting, or lost wax casting with the advantages of a digital design and manufacturing process.

With traditional lost-wax casting, jewelry designers hand-carve the original pattern in wax, place the wax pattern in a mold to be burned out, and then pour precious metals like gold or silver into the mold cavity to create the cast piece. To achieve its final appearance, designers polish and finish the cast piece to shine.

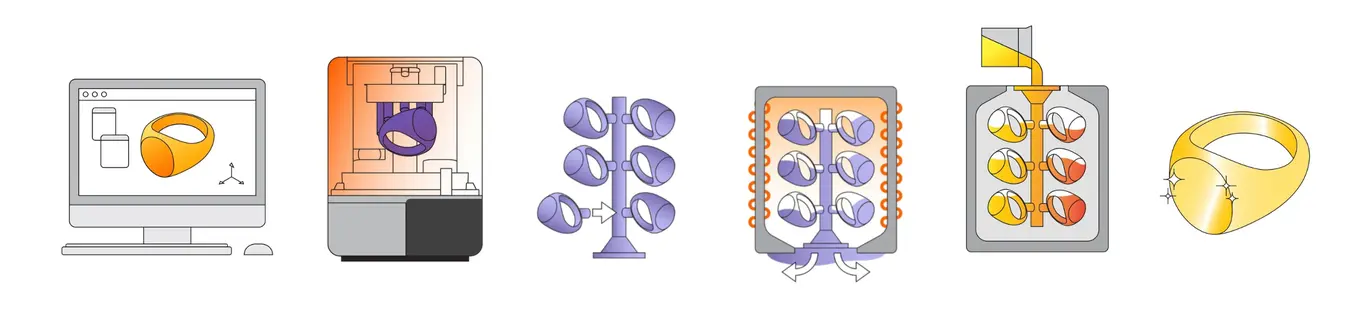

After digitally designing the piece, it is 3D printed and post-processed. Then, the piece is prepared for casting. A mold is made and printed parts are burned out before casting. Once pieces are cast, they are recovered and finished.

With the digital workflow, jewelers use CAD software tools for jewelry design to create the models digitally and a professional 3D printer to produce the 3D printed jewelry patterns that can then be cast in a mold. After burnout of the positive pattern, the process follows the same path as traditional investment casting. Thanks to the digital techniques, the need for time-intensive manual labor is reduced and the design itself is easy to preserve, modify, and recreate when needed.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.

How Jewelers and Customers Benefit

New Frontiers in Customized Jewelry

Until now, the complexity of the design and production process made customized jewelry an expensive privilege. With digital tools, however, jewelers have already started offering personalized creations as part of their basic service or as a value add. If you go to a jeweler today and ask for an engagement ring, often you'll have the option to customize a unique design.

3D printed jewelry try-on pieces drastically shorten the feedback loop between designer and customer.

Jeweller and customer can discuss the design together, and an hour later, the customer can hold and try on a real, physical model of the ring. In jewelry retail, on-site digital design combined with the speed of 3D printing has drastically shortened the feedback loop between designer and customer.

Moving from design to production is easier and faster, as hand carving a precious one-off is no longer a requirement. The try-on pieces can be tailored based on the customer’s requests, 3D printed again, and then manufactured with lost-wax casting, which translates to a considerable reduction in the cost of making customized 3D printed jewelry.

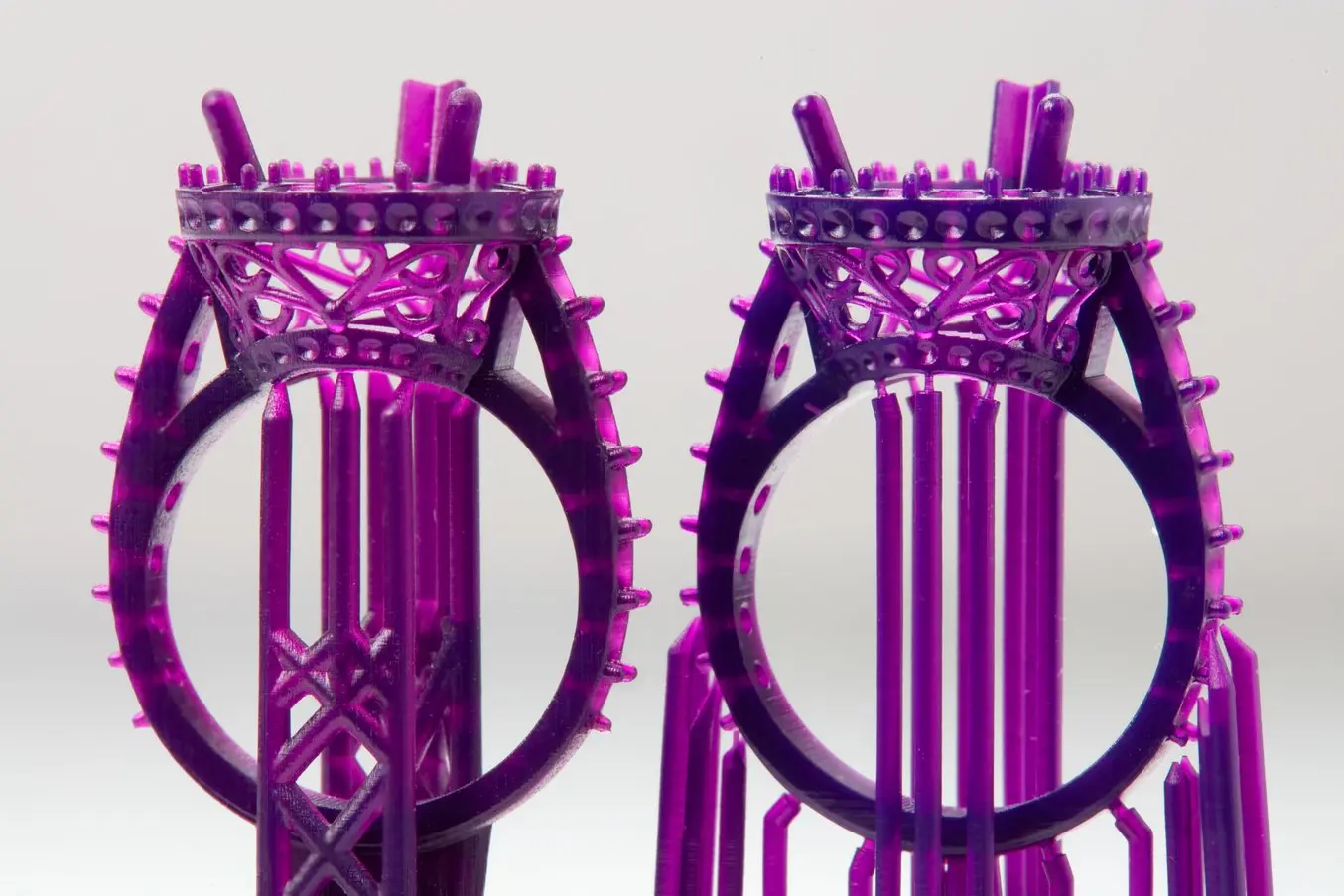

Design Freedom

With 3D printing, jewelry designers are able to produce designs that would be incredibly difficult to hand carve in the traditional manner. Breakthroughs in castable resins are setting new standards for the quality available through an affordable desktop resin 3D printer. Using casting resins with stereolithography (SLA) 3D printing technology results in highly accurate parts with exceptional detail and smooth surfaces.

Both True Cast Resin and Castable Wax Resin can be used to 3D print jewelry patterns. True Cast Resin is a wax-filled material designed for precision casting of intricate jewelry up to 5 mm thick and can be used for delicate filigrees, raised text, and detailed pavé stone settings with consistently excellent casting outcomes. Castable Wax Resin offers high strength and stiffness, making it capable of printing ultrafine structures. The high green strength ensures excellent shape retention for thin patterns such as wire filigree. This material contains 20% wax with zero ash content for clean burnout.

| Castable Wax Resin | Castable Wax 40 Resin | True Cast Resin | Clear Cast Resin | Grey Resin | High Temp Resin | |

|---|---|---|---|---|---|---|

| Applications | Fine filigree, lightweight jewelry, and dental applications | Medium to heavy jewelry and small engineering components | Medium to heavy jewelry, medallions, figurines, and small engineering components up to 5 mm thick | Demanding engineering applications over 3 mm thick | Inexpensive custom fittings | Vulcanized rubber molding |

| Compatibility | Form 2 Form 3/+ Form 4 | Form 2 Form 3/+ | Form 4 | Form 2 Form 3/+ Form 4 | Form 2 Form 3/+ Form 4 | Form 2 Form 3/+ Form 4 |

Stereolithography 3D printing can reproduce complex features that’d be difficult to hand carve.

Ultrafine structures can be 3D printed including for wire filigree.

3D printing enables the creation of fine structures and intricate designs with ease. With long-established design restrictions now removed, we're seeing entirely new genres of design emerging from jewelers who digital capabilities in the US as well as in South Asia and Asia Pacific, and the Middle East.

Product Demo: Form 4

See how Form 4 can enable new levels of productivity and innovation through its unmatched speed, accuracy, and reliability.

Easier Mass Production

Digital tools are not only making jewelry easier to customize, but also simpler to mass-produce designs.

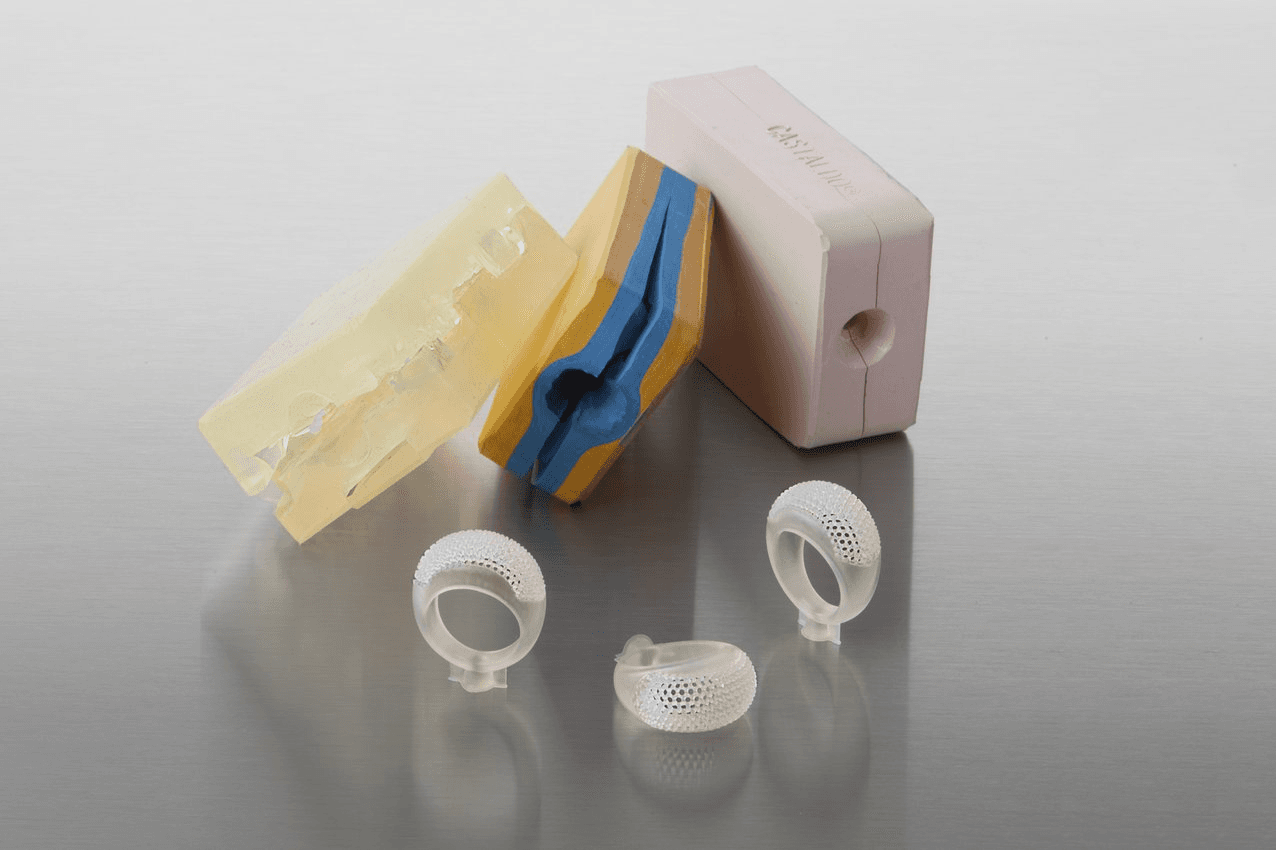

Vulcanized rubber molds are used to produce wax patterns in quantity for lost-wax casting, but the “master” pattern is traditionally made from an investment cast, hand-carved wax pattern.

3D printers can produce master models that are used to form room temperature vulcanization (RTV) molds and even durable high temperature vulcanized rubber molds.

Directly 3D printed jewelry patterns can be used for room temperature vulcanization (RTV) and vulcanization of high temp natural rubber.

“With the quality that you can get with SLA 3D printing for printing these jewelry pieces, you can jump straight from the 3D printed part to a master mold,” said Formlabs' Jewelry Vertical Product Manager Amos Dudley. “The surface finish is already so smooth that it doesn't require very much finishing. You can use that as the rubber mold for creating the final wax parts that go into production.”

Vulcanized Rubber Molding with 3D Printed Masters

3D printing with high-performance materials allows designers and casters to leverage digital technology in their production processes. Read now to learn how 3D printing can be used in the production of small metal parts.

Competitive Independent Jewelers

When new technology is finally made available to the public, it usually comes with a high price tag and a complicated interface, restricting it to users with deep pockets and technical savvy. Previous generations of jewelry 3D printers required both significant maintenance and a skilled operator in addition to thousands of dollars of investment that limited them to the largest jewelry manufacturers and casting houses.

As costs for 3D printers decrease and the technology develops, digital workflows have become an accessible method of manufacturing. Form 4 workflows are intuitive and accessible — anyone can learn to use the printer in 15 minutes. Plus, 99% reliability ensures consistent production without costly troubleshooting.

Thanks to printers like Form 4, small independent jewelers can save time and achieve accurate, consistent production without high overhead costs or a steep learning curve.

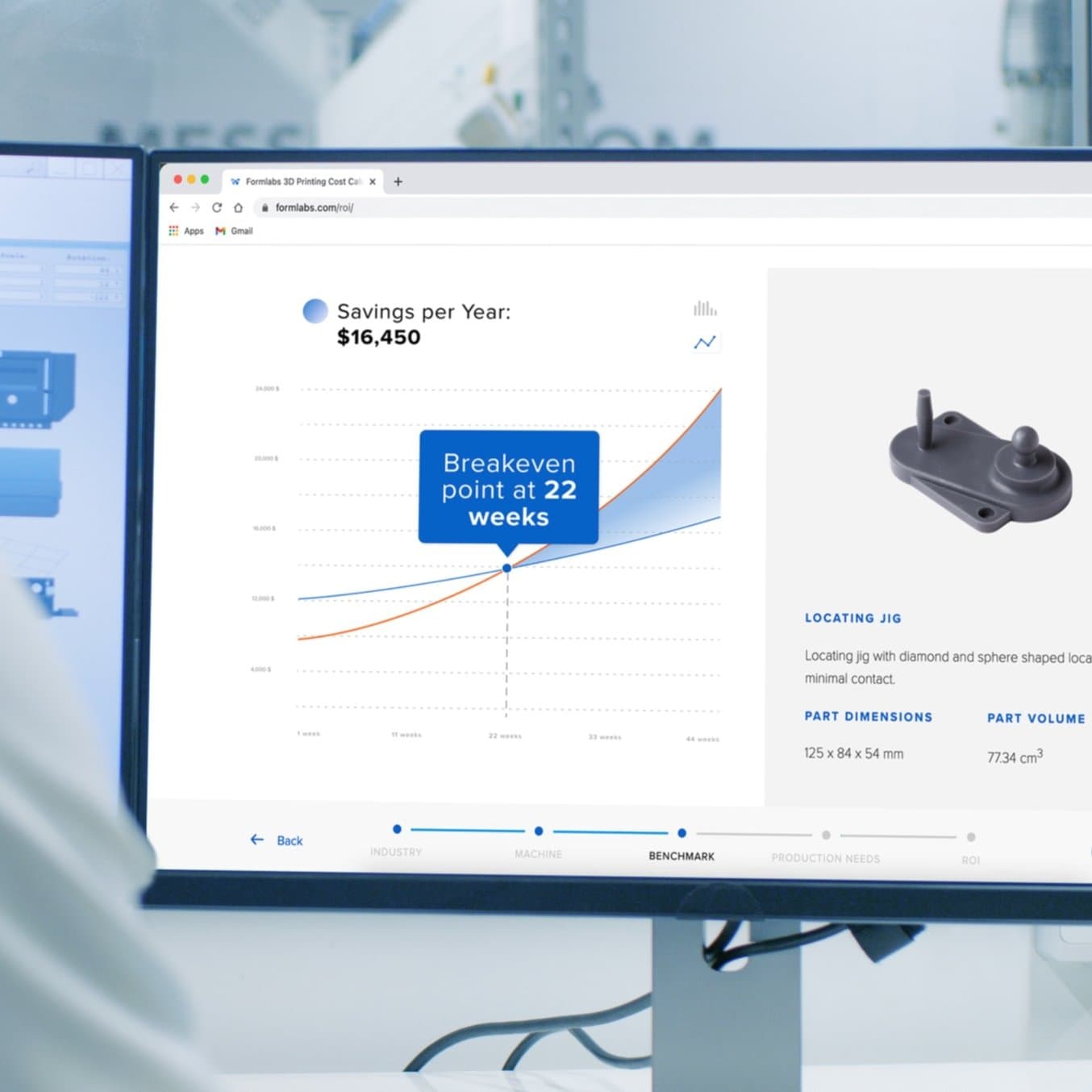

Calculate Your Time and Cost Savings

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Jewelry 3D Printers and Materials

Owing to the formerly high cost of large-scale jewelry 3D printers and the perceived barrier-to-entry of digital jewelry design, 3D printed jewelry, despite its potential, currently represents a relatively small fraction of the market.

Nevertheless, with increasingly easy to use and accessible jewelry 3D printers, the digital workflows in the jewelry market are poised for growth. Desktop stereolithography 3D printers are an important component in this expansion.

Whether you're printing one part or an entire build platform, Form 4 offers fast print speeds and accuracy across the build platform.

3D printing in jewelry has a bright horizon. As education with digital methods continues to increase, digital workflows become even more accessible. Technological advancements, including accurate, intuititve 3D printers like Form 4, make it easy to adopt digital workflows. Meanwhile, developments in materials for casting, like True Cast Resin, empower jewelers to efficiently produce detailed parts.

Request a free sample part to evaluate casting materials for yourself, or contact sales to learn more.