Drones, also known as unmanned or uncrewed aerial systems (UASs), unmanned/uncrewed aerial systems (UAVs), or unmanned/uncrewed underwater systems or vehicles (UUSs or UUVs), were first introduced decades ago for defense applications, and were, at first, slightly scaled-down, fixed-wing planes that flew with a remote operator. But in the past three decades, new technological advances have led to an explosion in growth for the drone industry, and now, drones can be found in all different shapes, sizes, and capacities.

New radio and communication technologies have led to drones with longer ranges and better real-time data. Material science innovation has created new ways of fabricating strong, lightweight drone frames. Battery technology and chip computing technologies have improved exponentially, and advances in camera lenses and transmission components mean drone operators can see the effects of all of these advances from farther away. Not to mention, the artificial intelligence boom is giving new meaning to the term ‘unmanned mission.’

These advances have created sub-industries within the drone design, manufacturing, and operation umbrella. Drones as a service (DaaS), drone racing, drone photography, drone delivery and logistics, and remote monitoring applications are all thriving industries built on the proliferation of new types of affordable, accessible drones.

Each of these sub-applications have their own requirements. Professional drone racers require speed and frame flexibility, but don’t typically require long battery life. Drones built for agricultural surveying can be slow flying and relatively inflexible, but must be able to complete long flights and resist a range of weather conditions.

Any drone, whether it’s used for tactical surveillance missions or Hollywood photography, requires a range of lightweight, strong, and reliable components, most likely made from several different materials. Choosing the right drone prototyping and manufacturing technology is critical. Many hobbyist drone components are mass-produced with injection molded or carbon-fiber cut components, which the pilots then customize with 3D printed additions or accessories they print or purchase inexpensively. Large manufacturers will nearly always use 3D printing for much of their R&D work before moving to more traditional methods, though some drone manufacturers are now 3D printing end-use drone components.

This guide presents the best 3D printers for drones, comparing fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS) 3D printing technologies to find the right manufacturing solution for engineering functional, flight-ready UAV components.

Talk to Our Sales Team

Whether you need to prototype at speed, or are producing end-use parts, we’re here to help. The Formlabs Sales team is composed of dedicated specialists who know exactly how to support you and your company's needs.

Why 3D Print Drone Parts?

For manufacturers like DJI or Skydio — those producing hundreds of thousands of the same drone models for a primarily hobbyist/consumer audience — injection molding and CNC machining carbon fiber sheets make sense as primary manufacturing methods. However, even with a drone mass-produced by injection molding, end-users like drone pilots are very often making their own small tweaks to accommodate their personal preferences for cameras, motors, mounts, and other components.

For mid-volume manufacturers like Vector, ORQA, or Nextech, 3D printing is an integral part of the initial design process as well as the end-use manufacturing process for certain components.

At ORQA, SLS 3D printers are used for prototyping and product development as well as manufacturing some end-use components.

SLS 3D printed TPU drone parts are ideal for stop-gap manufacturing vibration-dampening components.

At ORQA, one vibration-dampening component needed to be changed close to final production deadlines. The change would have delayed the delivery timelines and cost a significant amount to change the injection molded tooling.

Instead, the ORQA team decided to go with SLS 3D printed TPU for end-use production. They needed several hundred TPU parts, and printed them on the Formlabs Fuse 1+ 30W SLS 3D printer in just a few days in TPU 90A powder. “With the Fuse 1+, we can get prints the same day. We don’t need to wait for changes in tooling,” says Antonio Kovac, ORQA’s Mechanical Designer.

3D printing offers three distinct advantages for UAV manufacturing:

-

Rapid customization: Engineers can rapidly iterate on frames, camera mounts, and protective guards, testing multiple designs in a single day.

-

End-use quality materials: From carbon fiber reinforced nylon powders to variable durometer TPU and a range of unique, durable plastics, the range of 3D printing materials helps enable end-use drone manufacturing.

-

Manufacturing agility: The high cost and lead times of tooling make any design change prohibitively expensive and time-consuming. 3D printing enables manufacturing resilience, responsiveness, and agility for a better market fit.

-

Weight optimization: Additive manufacturing enables topology optimization and complex geometries, such as internal lattice structures, which reduce weight without sacrificing strength.

-

Aftermarket changes and customization: Drone pilots and operators (both hobbyist and professional) frequently need to make changes to their models — 3D printing makes it possible for anyone to customize their kit.

How to Build a 3D Printed Drone

Read our free white paper to 3D print and assemble your own SLS 3D printed quadcopter-style drone, including a list of what extra components to purchase and step-by-step instructions for assembly.

Comparing 3D Printing Technologies for Drones: FDM vs. SLA vs. SLS

When looking for the best 3D printer for drone parts, the answer depends entirely on the mechanical requirements. This section compares the best 3D printing technology options to find the right fit for your drone application.

FDM: Best Entry Point, Weakest for Structural Drone Parts

FDM drones built for target practice and training exercises, like the orange drone on the right, don't need to have end-use material properties, because they're designed to be destroyed after a single use.

Fused deposition modeling (FDM) works by extruding melted plastic filament layer by layer. This makes FDM parts anisotropic, which means they will split along layer lines under stress, unlike SLA (fully isotropic) and SLS (mostly isotropic) parts.

Currently, in the drone industry, FDM parts are used by nearly everyone for aftermarket customization. Hobbyists and pilots will typically have FDM printers at home for quick components like soft TPU camera or GPS mounts, or harder ABS enclosures.

-

Pros: Low entry cost and approachable workflow.

-

Cons: FDM parts suffer from isotropic weakness, meaning layers often split during crashes (delamination). Anisotropy also means FDM parts are not watertight, so humidity and rain when flying outdoors can cause warping and damage. FDM prints generally have lower dimensional accuracy, and heavy vibration during flight can loosen layer adhesion. Significant post-processing and finishing are often required to achieve a smooth finish.

-

Best for: Early prototyping, disposable or target and defense drones, hobbyist projects, and non-structural cosmetic parts.

Best FDM 3D Printer for Beginners or Hobbyist Drones: Prusa or Bambu Lab

While professional engineers are switching to SLA and SLS, FDM printers such as those from Prusa or Bambu Lab remain a viable option for beginner or hobbyist drone makers. They are cost-effective for learning the basics of flight dynamics before investing in industrial-grade hardware.

FDM materials for drone needs:

-

PLA filament for rapid prototyping, initial fit-checks, and low-stress cosmetic components, in parts such as display stands, non-structural fairings, and cable clips

-

ABS filament for durable, impact-resistant parts with moderate heat tolerance, in parts such as protective casings, canopies, and structural frames (requires UV coating for long-term outdoor exposure)

SLA: Best for Precision Drone Components and Smooth Surfaces

SLA 3D printed drones, like this one from Marble Aero, are excellent at minimizing wind-resistance and optimizing for aerodynamic performance.

Stereolithography (SLA) uses a laser to cure liquid resin into hardened plastic. SLA parts are fully isotropic, highly dimensionally accurate, watertight, and come with a wide variety of mechanical properties.

-

Pros: SLA 3D printing offers isotropic strength, meaning parts do not snap along layer lines. There is a wide variety of material properties available, from high rigidity to impact-resistance, heat-resistance, or high tear-strength and elongation at break.

-

Cons: Parts require support structures and post-processing, and are thus not suitable for higher production volumes.

-

Best for: Aerodynamic shells, intricate FPV camera mounts, precision brackets, payload housings, waterproof or airtight housings, customized gaskets and seals (with soft materials like Formlabs Silicone 40A Resin).

Best SLA 3D Printer for Drones: Formlabs Form 4

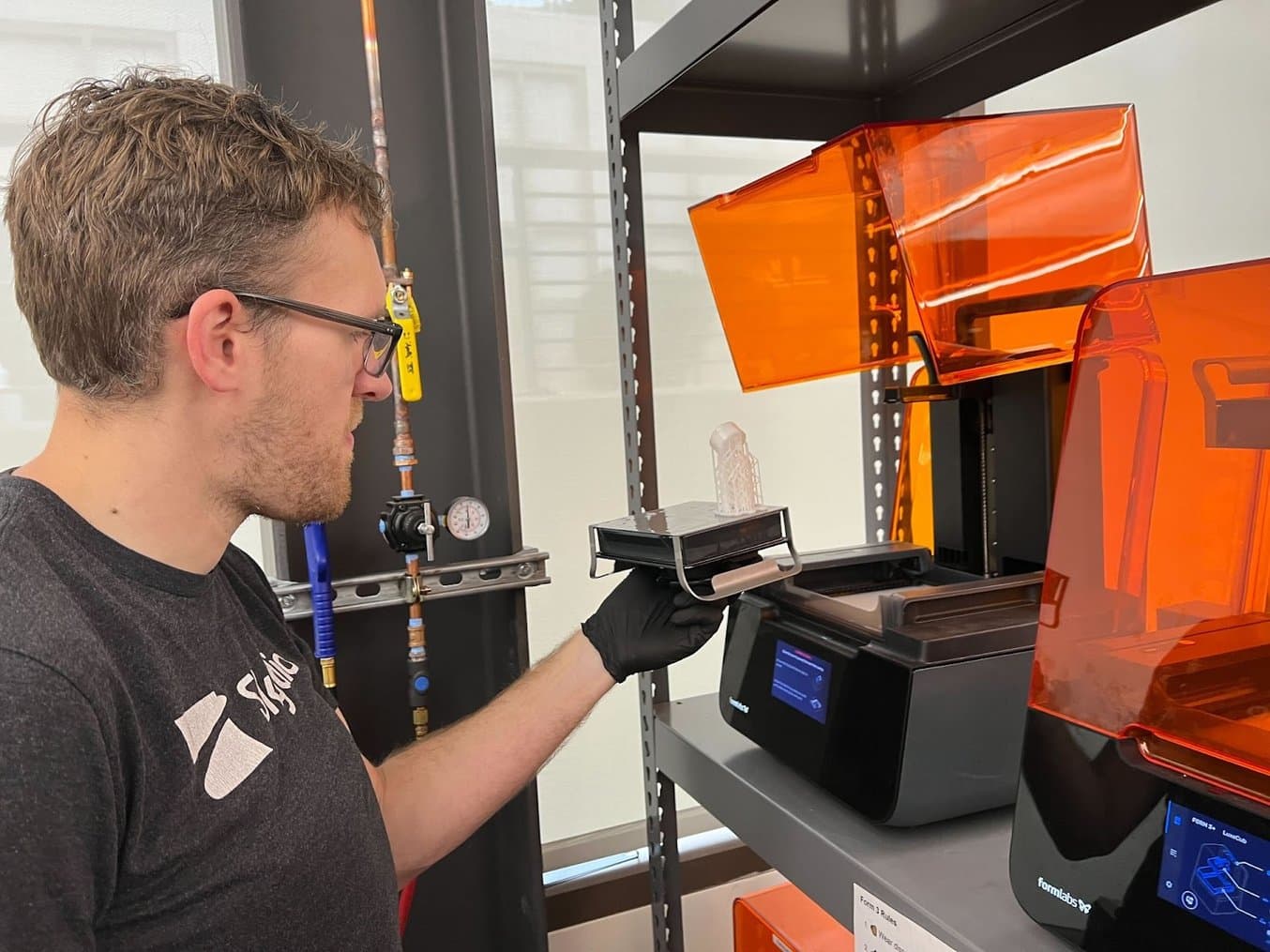

At Skydio, SLA 3D printers are used for everything from prototyping fuselage and external components to jigs and testing fixtures.

For drones that depend on precision, repeatability, and surface finish, Form 4 is an excellent choice. Form 4 enables access to a materials library of over 40 resins, each particularly suited for a specific application. For drones that need maximum aerodynamic performance, SLA resins like Rigid 10K Resin are perfect for extremely smooth exterior parts. For all resins, the watertight, airtight nature of SLA parts means long-term use, even in harsh conditions like the Arctic Circle, is possible.

Why Form 4 is a strong 3D printer for drone parts:

-

Speed: Form 4 can produce most prints in under two hours, which supports multiple iterations per day for brackets, housings, and mounts. Drone manufacturers can iterate faster than ever to get their products to market first.

-

Range of mechanical properties available: Formlabs’ materials library includes over 40 unique resins that can satisfy the wide range of requirements for different drone components.

-

Build volume: Form 4 has a build volume of 20.0 × 12.5 × 21.0 cm, which covers many drone brackets, mounts, and enclosures.

-

Accuracy and reliability: Independent tests show that Form 4 has a 99% reliability rate.

Form 4 applications: Best for prototyping, for fixed-wing fuselage components, for underwater applications.

-

Components in harsh environments (underwater, extreme cold, extreme heat)

-

Antenna and GPS mounts that need a consistent fit

-

Electronics housings, clips, and brackets that require tight tolerances

-

Aerodynamic covers, where smooth surfaces reduce drag and noise

SLA materials for drone needs:

-

Tough resins, such as Tough 2000 Resin or Tough 1500 Resin, for impact-prone mounts and brackets

-

Heat-resistant resins like High Temp Resin, for parts near motors or heat sources (choose based on your thermal requirements)

-

High-pressure-capable resins, such as Rigid 10K Resin, for molds and tooling to produce propellers and other advanced components

-

Pliable, flexible resins like Silicone 40A Resin, Flexible 80A Resin, or Elastic 50A Resin for spacers, gaskets, seals

-

Super-smooth and highly rigid materials like Rigid 10K Resin, for fuselage components on long-flight drones

Best SLA Large-Format 3D Printer for Drones: Form 4L

Form 4L offers the same speed and precision as Form 4 but with a 4.6 times larger build volume. This allows manufacturers to print single-piece drone fuselages or large batches of smaller components simultaneously.

Large-format 3D printing eliminates the need to assemble smaller frame sections, increasing the overall structural integrity of the drones.

Marble Aero’s MRB5 aircraft performing test flights under arctic conditions (Spring) in Illulissat, Greenland. The aircraft is almost completely printed on Form 4L in Rigid 10K Resin, which provides an extremely smooth, rigid surface for the fuselage and helps improve aerodynamics.

Why Form 4L is a strong 3D printer for large drone parts:

-

Large-format build volume: Form 4L has a build volume of 35.3 × 19.6 × 35.0 cm, which supports bigger housings and larger structural shells, as well as higher production volumes for smaller parts.

-

Speed: Form 4L can complete large prints in under six hours without compromising on accuracy or reliability.

Form 4L applications: Best for large drone components

-

Payload housings and protective shells

-

Molds for propellers

-

Larger aero fairings and covers

-

Full-body fuselages for fixed-wing drones and large quadcopter frames

-

Bigger custom enclosures for mapping, thermal, or inspection payloads

SLS: Best for Durable Nylon Drone Parts and Low-Volume Production

SLS 3D printed drone frames, like this one from ION Mobility, are rugged, strong, and durable. SLS materials like carbon fiber nylon, Nylon 12 Tough Powder from Formlabs, and TPU are ideal for different drone components.

Selective laser sintering (SLS) uses a high-power laser to sinter polymer powder, such as nylon or TPU, into solid parts. SLS technology produces strong, lightweight parts in industry-familiar materials that are durable enough to withstand wear and tear and more rugged, outdoor conditions as end-use parts.

Furthermore, SLS 3D printer build chambers are self-supporting, meaning that each part is held up by the powder surrounding it as it’s being sintered. This enables nearly complete design freedom and geometric flexibility, as well as the possibility of higher production volumes by stacking or nesting several components together at once. SLS production like this can lower the overall cost per part and improve drone manufacturing efficiency.

-

Pros: SLS parts are durable and flexible, making them ideal for snap-fit joints and impact resistance. SLS materials (like nylon and TPU) are familiar to manufacturers and can serve as a bridge manufacturing solution. SLS offers complete design flexibility and higher production volumes.

-

Cons: Higher initial system cost

-

Best For: Professional UAV manufacturing, TPU mounts, bumpers, enclosures, and vibration-dampening components. Rigid nylon frames, covers, and enclosures.

Request a Free Nylon Powder Sample Part

Formlabs offers seven SLS powders with a range of mechanical and visual properties. Choose a free sample printed on the Fuse 1+ 30W to see them for yourself.

Best SLS 3D Printer for Drones: Fuse Series

The Formlabs Fuse Series SLS 3D printers are affordable, accessible, and easy to use. Drone startups can go from early concept to manufacturing with one printer, then scale as demand grows. Large manufacturers can either scale in-house production with a Fuse Series print farm or prototype in three different materials on three industrial-quality printers, without breaking the bank or laboriously switching materials.

The Fuse 1 and Fuse 1+ 30W 3D printers (the Fuse Series) enable small and medium-sized drone businesses to bring the full design to production workflow in-house, and large manufacturers to have as an alternative and bridge solution when traditional tooling is too time-consuming or costly to change. It can deliver minimum feature sizes of 0.2 mm consistently, and create complex, organic shapes without any supports, making post-processing easier while enabling new geometries. The materials available, from Nylon 12 Tough Powder to TPU 90A Powder, are ideal for end-use drone applications.

Why Fuse 1+ 30W is a top choice for UAV manufacturing:

-

Manufacturing agility and scalability: Small and medium-sized businesses can afford to bring the entire drone design-to-manufacturing workflow in-house with one or multiple Fuse Series printers, shortening time to market and keeping them competitive in a fast-changing industry.

-

Advanced, industrial materials: Carbon-fiber reinforced nylon, variable durometer TPU, and strong, tough nylon parts are ideal for drone production.

-

Production volumes: Manufacturers can print hundreds of small drone components at once, or larger parts like fuselages and covers, in the Fuse Series build chamber or by stacking parts in the self-supporting powder bed.

-

Lowest cost per part: The Fuse Series printers bring the lowest cost per part for up to tens of thousands of parts, faster than with any traditional manufacturing method.

SLS materials for drone needs:

-

Nylon 12 Powder for general-purpose, impact-resistant frames, enclosures, jigs, fixtures, housings

-

Nylon 12 Tough Powder for impact resistance and durability in parts such as rugged frames, rotor arms, enclosures, jigs, fixtures, and housings

-

Nylon 11 CF Powder for stiff, strong, lightweight structures, in parts such as rotor arms, brackets, frames, and structural interfaces

-

TPU 90A Powder (and variable durometer TPU with Open Material Mode) for rubbery, vibration-damping parts such as mounts, spacers, and gaskets

Fuse Series applications: Best for professional UAV manufacturing and end-use parts:

-

Defense drone prototyping and production

-

Drone customization

-

Rubbery TPU drone parts like mounts, spacers, and vibration-damping

-

Heavy-lift drone arms

-

Impact-resistant bumpers

Key Material Properties for Drone Components

Selecting the right 3D printing material is as important as the printer itself. Drone parts must withstand specific environmental and mechanical stressors. Some important elements to consider include:

-

Impact Resistance: Drones can crash. Materials like Nylon 12 Tough Powder (SLS) or Tough 2000 Resin (SLA) can absorb energy without shattering, unlike standard brittle plastics.

-

Stiffness-to-Weight Ratio: Weight is a relevant metric in flight. Nylon 11 CF Powder (SLS) offers stiffness comparable to traditional carbon fiber molding but allows for complex, optimized shapes that shave off unnecessary weight, while Rigid 10K Resin (SLA) can provide extremely smooth surface finishes for gliders and fixed-wing drones flying long-range.

-

Heat Resistance: Motor mounts and battery housings generate significant heat. Standard PLA (FDM) often warps or melts under these conditions. Temperature-resistant SLA resins such as Rigid 10K Resin or High Temp Resin, or SLS Nylon powders, maintain dimensional accuracy even under heavy thermal load.

Real-Life Use Cases: Selecting the Best 3D Printer for Your Drone Needs

See below how industry leaders use Formlabs printers to solve drone engineering challenges.

Marble Aero

Marble Aero designs and manufactures long-range surveillance drones currently monitoring the Arctic ice sheet in Greenland. They print the entire drone fuselage on their two Form 4L printers in Rigid 10K Resin, which they love for its rigidity, thermal stability, and smooth surface finish.

Skydio

As one of the largest drone manufacturers in the world, Skydio’s product development team moves fast to stay ahead of the pack. They iterate and functionally test their drone designs using their Form 4 SLA and Fuse 1+ 30W SLS 3D printers.

Nextech

Nextech utilizes a combination of FDM, SLA, SLS, and CNC machining to manufacture their low-volume, highly customized drones used for agricultural monitoring.

Ion Mobility

SLS 3D printing has enabled Ion Mobility to manufacture medium volumes of end-use drones that are nearly entirely 3D printed. Certain components, like propellers, they buy off the shelf, and customize the rest of the build with Nylon 12 Powder parts from the Fuse 1+ 30W printer.

Vector

With years of experience in military operations, Vector builds drones for the defense industry that can be modified and adapted to the situation at hand. They SLS 3D print drone components in Nylon 12 Powder and TPU 90A Powder.

ORQA

ORQA leverages their two Fuse Series printers to create SLS prototypes of their small quad-copter style drones, and their Form 4 3D printer to make tooling for injection moldingother components.

Nakai Robotics

Nakai Robotics is an Israeli robotics startup 3D prints over 3,000 individual parts for its ship-cleaning robots. The parts are often Cerakoted to better withstand deep-sea pressure.

SoSub

SoSub’s unmanned underwater vehicles (UUVs) repair fishing nets and underwater infrastructure, saving businesses thousands of dollars and making a difficult process more efficient. The UUVs are prototyped and manufactured with SLA 3D printed parts.

Boresight

An Australian defense contractor, Boresight, designs and produces thousands of target drones as well as defensive drones for the Australian military. Though their target drones are made for crash and target testing and are thus printed cheaply on FDM printers, their end-use drones are SLS 3D printed on the Fuse Series.

heliguy

heliguy was able to streamline its product development process and bring manufacturing in-house — improving lead times, reducing costs, and gaining more control over its workflows with SLA and SLS 3D printers from Formlabs.

FAQ: 3D Printing Drones

What is the best 3D printer for drones?

For professional manufacturing and high-performance parts, the Fuse 1+ 30W SLS 3D printer is the top choice due to its ability to print durable, lightweight nylon, carbon-fiber reinforced nylon, and TPU parts. For smooth fuselage parts and glider or fixed-wing drones, an SLA printer like Form 4 with Rigid 10K Resin is relied upon by some of the industry’s leading manufacturers.

-

Best for low to mid-volume end-use manufacturing of strong, durable components: Fuse 1+ 30W and Nylon 12 Tough Powder

-

Best for soft mounts, spacers, and vibration-dampening components: Fuse 1+ 30W and TPU 90A Powder

-

Best for fuselage components and smooth surfaces: Form 4 and Rigid 10K Resin

-

Best for larger housings and big parts: Form 4L

Can you 3D print drone propellers?

You can, but for long-term performance and durability, you should probably 3D print a propeller mold instead. Propellers have extremely thin and precisely calibrated geometries. Even highly accurate printers like the Form Series or the Fuse Series can struggle to produce parts that thin without any warp or creep over time — especially under the extreme forces generated during flight. Prototyping propeller designs will definitely work, but end-use propellers are still best made by injection molding.

Companies like ORQA are designing new drone propellers and using Form 4 and Rigid 10K Resin to create end-use injection molding tooling for the final propeller.

This video from ORQA shows their injection molding process using 3D printed injection molds for drone antennae, but the same process can be used to 3D print injection molds for propellers as well.

What is the best 3D printer type for strong and lightweight drone parts?

SLS printers, such as Fuse 1+ 30W, particularly using Nylon 12 Tough Powder, offer the best strength-to-weight ratio. FDM printers using reinforced filaments are a secondary option for hobbyists, though they lack the geometric freedom of SLS.

Where does 3D printing add the most value in UAV manufacturing?

The benefits of 3D printing for UAV manufacturing are faster design iteration, customization for mission requirements, and cost efficiency for lower-volume production.

Getting Started with Drone 3D Printers

The best 3D printer for drones ultimately depends on your goals. For hobbyists learning to fly, FDM remains an accessible entry point. However, for those focused on performance, aerodynamics, and UAV manufacturing, SLA and SLS are the industry standards.

-

Choose FDM as a starting point for prototypes or hobbyists, but keep in mind that it often falls short for flight-critical parts due to anisotropic strength.

-

Choose SLA – Form 4, for drones that require precision, smooth surfaces, and assemblies that fit reliably.

-

Choose SLA – Form 4L, for large drone components.

-

Choose SLS – Fuse 1+ 30 W, for durable nylon parts and low-volume UAV manufacturing.

-

Combine SLA and SLS — Fuse 1+ 30W SLS and Form 4 SLA, for a full prototyping-to-end-use-manufacturing workflow and the broadest range of options of material properties

Are you ready to 3D print drones?

Explore Formlabs 3D printers and materials to find the optimal fit, or request a free sample part to feel the quality for yourself.

Still unsure? If you need help choosing the optimal 3D printer for your application, our team can help you find your optimal solution.