Bring Products to Market Faster by 3D Printing Prototypes In House

Rapid prototyping with affordable in-house 3D printers empowers you to 3D print prototypes within a day and carry out multiple iterations of design, size, shape, or assembly based on results of real-life testing and analysis, helping you to bring better products to market faster. Turn your ideas into realistic proofs of concept, advance these concepts to high-fidelity prototypes that look and work like final products, and guide products through a series of validation stages toward mass production.

Concept Exploration

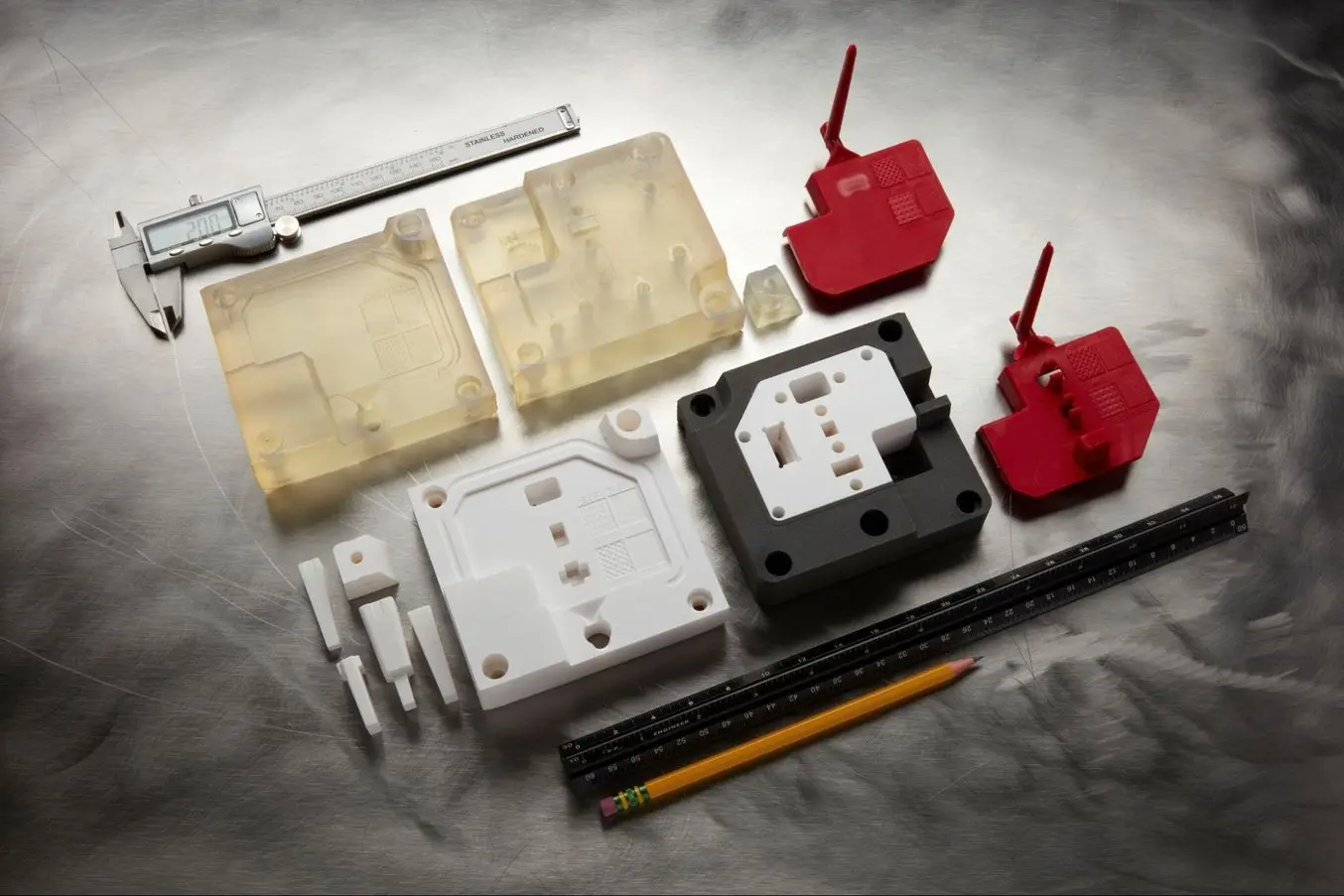

Elevate initial ideas with low-risk concept models, proof-of-concept (POC) prototypes, and looks-like prototypes. 3D printing empowers you to go from CAD to physical object in no time, and rapidly develop, evaluate, and iterate a range of designs in-house.

Watch the video: How Ford Developed the New Explorer Using Formlabs SLA and SLS 3D Printers

See Also

How Ford Developed the New Explorer Using Formlabs SLA and SLS 3D Printers

How Black Diamond Reduced Costs by 84% With Rapid Prototyping on the Form 3L

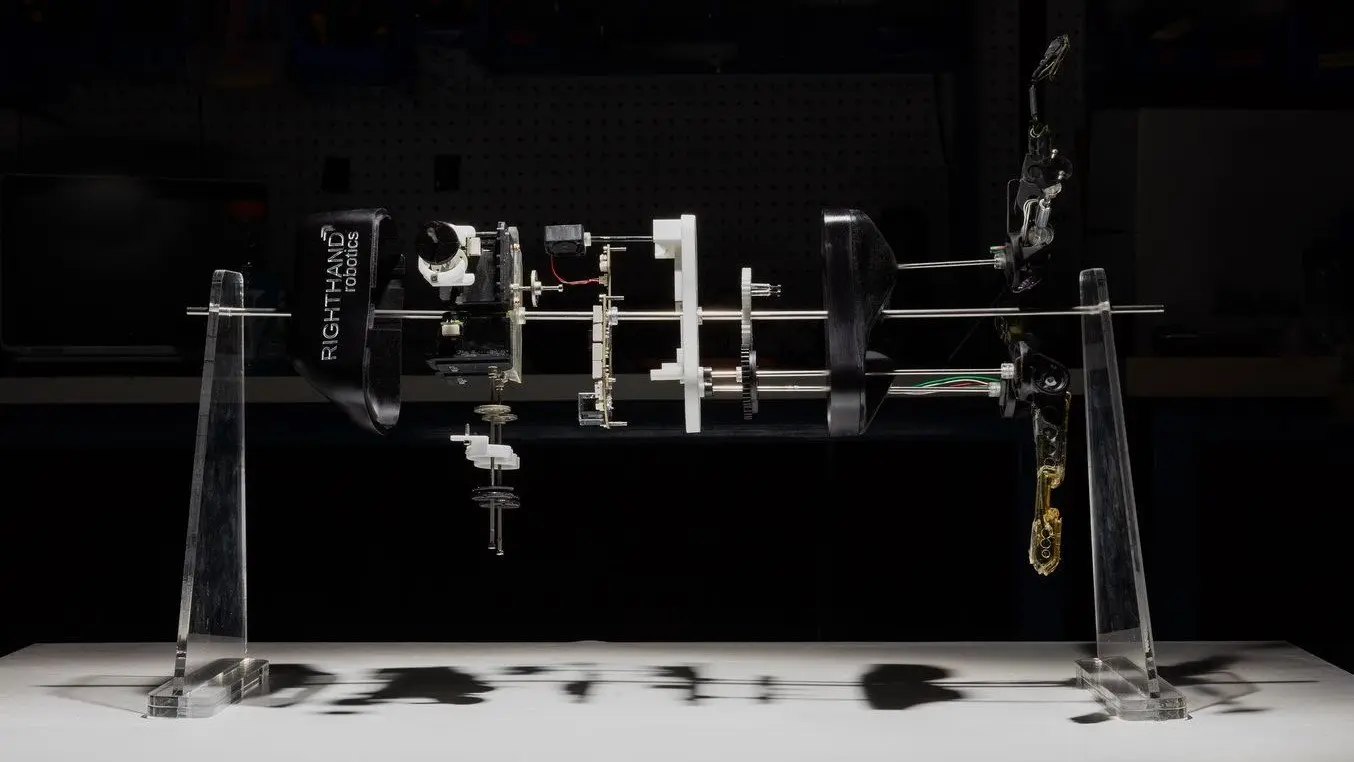

Producing High-Precision Prototypes for Mechanical Watches Using 3D Printing

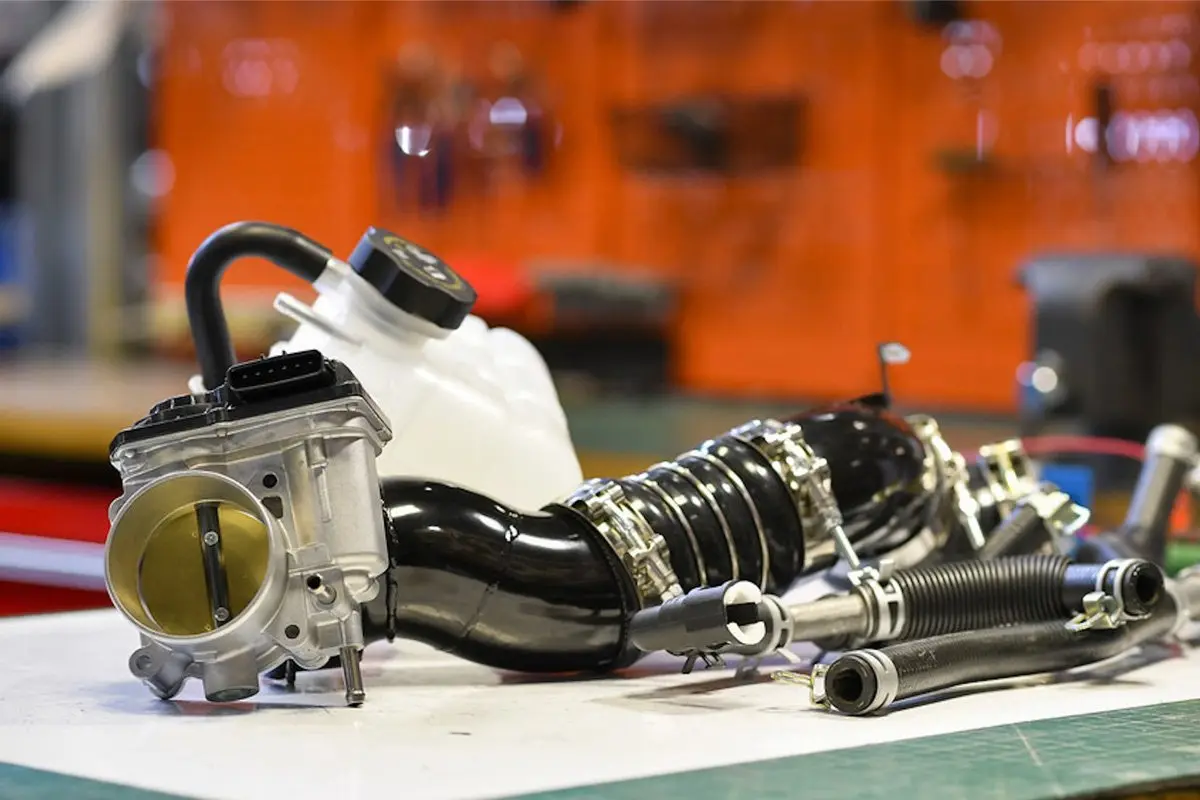

Functional Prototyping

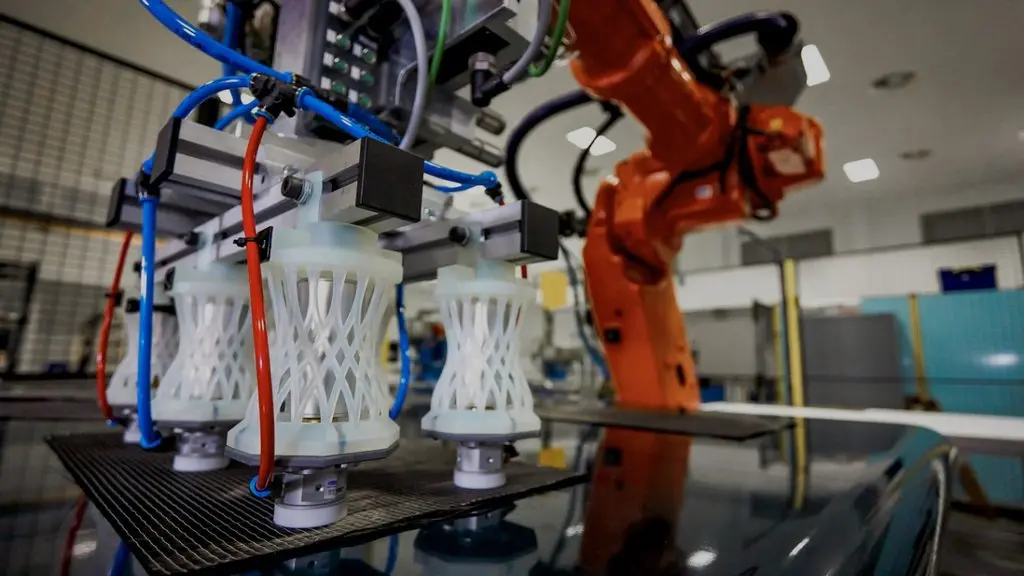

Produce functional prototypes with material properties closely matching common injection-molded plastics to test concepts, communicate requirements, and validate designs for manufacturability. Create small-batch runs or one-off custom solutions for comprehensive field and in-house testing before investing in expensive tooling for production.

Watch the video: How a 3D Printing Station Supports Hundreds of Engineers at the AMRC

See Also

Prototyping an Optically Clear Airlock for Homebrewing With 3D Printing

How Lush Cosmetics Take Ideas From Concept to Reality in Under 24 Hours with 3D Printing

Rome Snowboards Accelerates Product Development With SLS 3D Printing

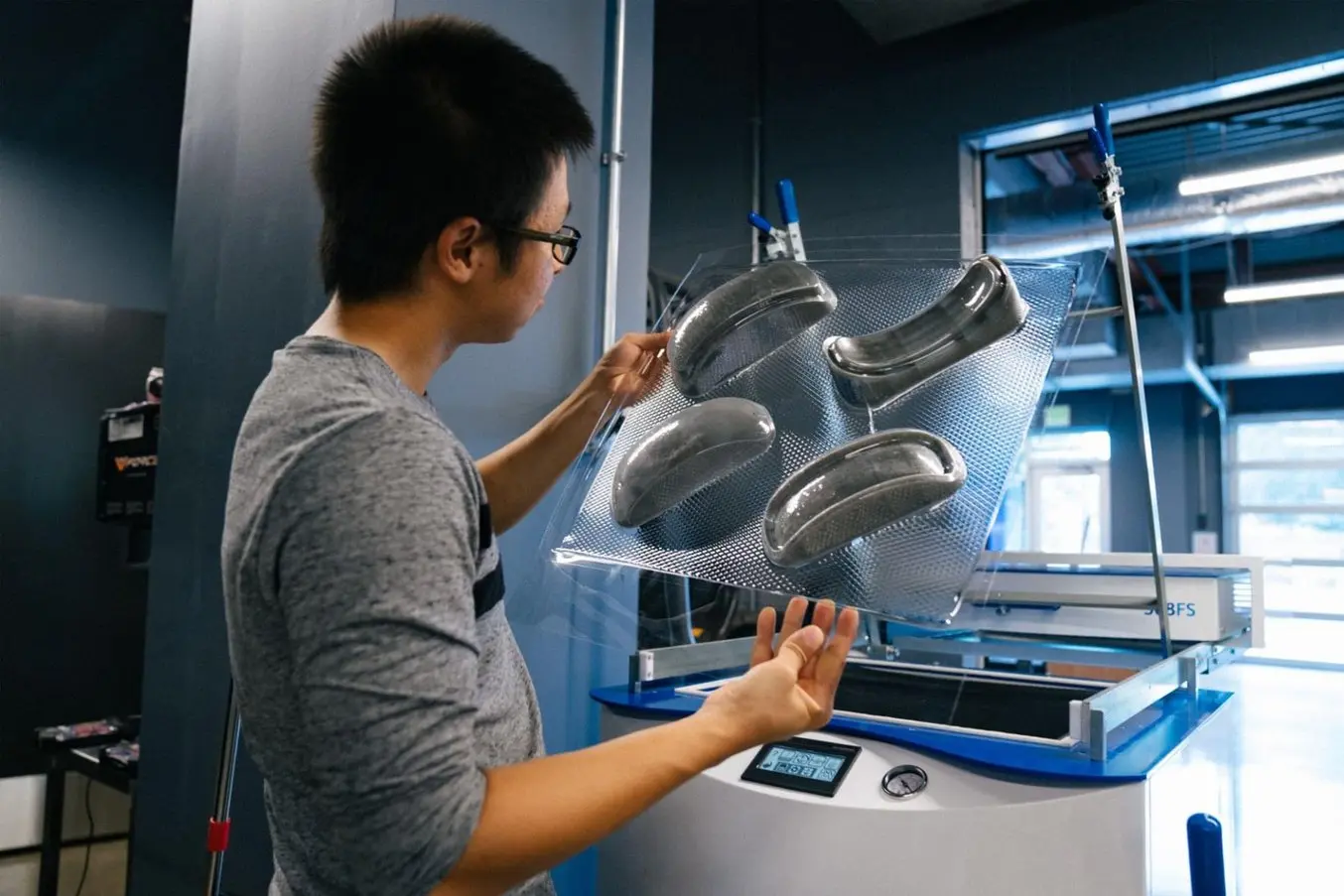

Product Validation

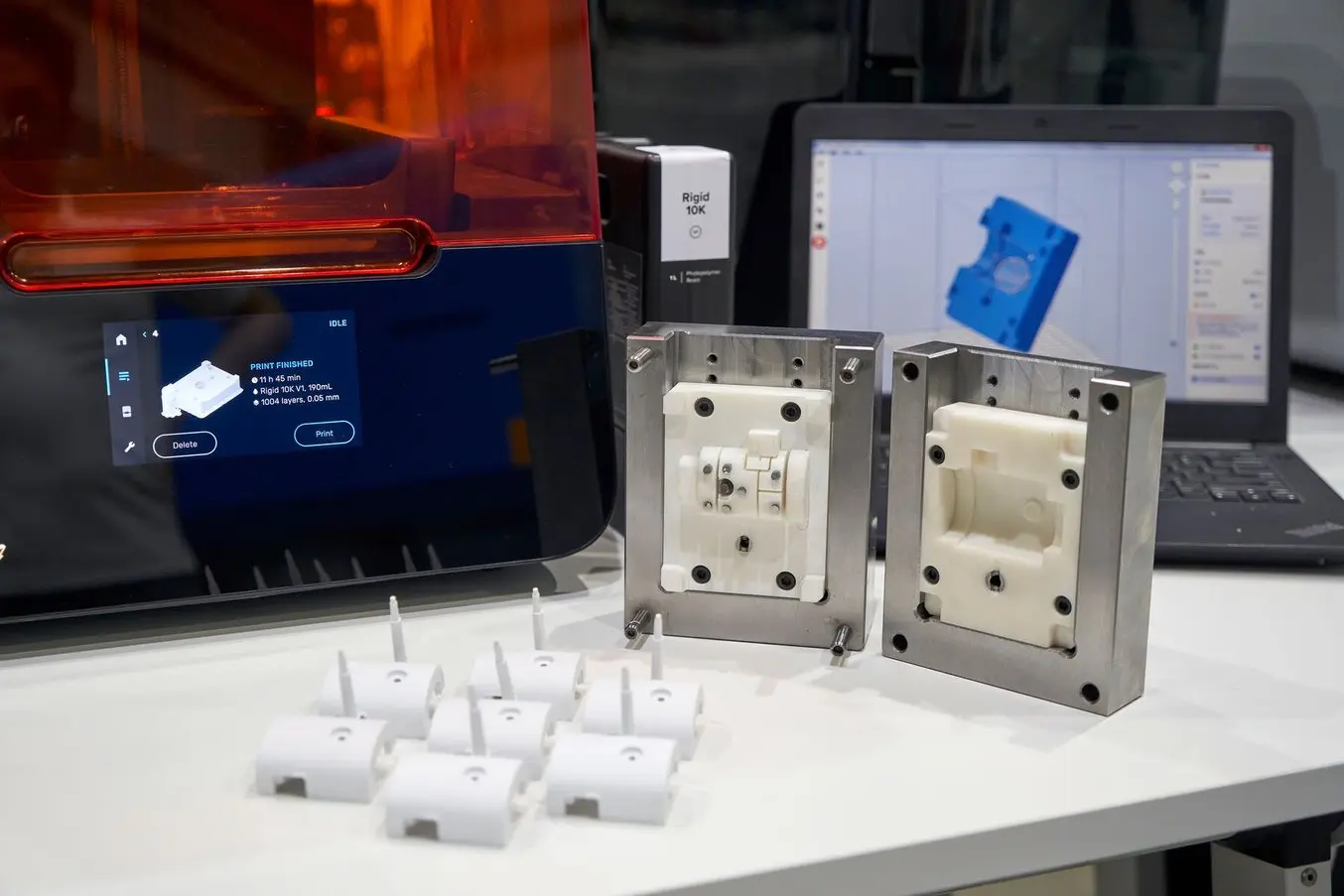

Test tolerances with the actual manufacturing process in mind and conduct comprehensive in-house and field testing before moving into mass production. Combine 3D printed rapid tooling with traditional manufacturing processes like injection molding, thermoforming, or silicone molding. Create custom test jigs and fixtures to simplify functional testing and certification by gathering consistent data.

Watch the video: Inside Google ATAP: Bridging Pre-Production Challenges With 3D Printing

See Also

How a Contract Manufacturer Uses 3D Printed Molds for Low-Volume Production

A Product Development Company Using 3D Printing To Do It All

Save Time and Money

Your printer pays for itself in a matter of weeks or months, accelerating the pace of work along the way.

| In-House 3D Printing | Outsourcing | |

| Time | 2 h 37 min | 7 days |

| Cost | $45 | $1000 |

Curious to see how much you can save? Try our interactive ROI tool to calculate cost per part and lead time when 3D printing on Formlabs 3D printers.

Seat Prototype

Printed on Form 4L

Cut Your Prototyping Cycle to 24 hours

Never again wait weeks for prototypes to arrive from a service provider. With in-house 3D printing, you can create rapid prototypes within a day, run tests, tweak your design, and print again.

Design

3D Print

Test

Iterate

A Full Suite of 3D Printers For Rapid Prototyping

Turn ideas into high-fidelity 3D printed rapid prototypes with Formlabs' SLA and SLS 3D printers for prototyping.

Form 4

Small to mid-size prototypes

Quick drafts and concept models

Prototypes in a wide variety of materials

Form 4L

Mid-size to large prototypes

Quick drafts and concept models

Prototypes in a wide variety of materials

Fuse 1+ 30W

Functional prototypes

Prototypes for in-field customer feedback

Rigorous functional testing of products

High-Performance Materials for Rapid Prototyping

Formlabs has an extensive library of proprietary 3D printing materials suitable for even the most demanding applications.

Fast Model Resin

Tough Resins

SLS Powders

Flexible and Elastic Resins

Color Prototyping

Print parts in your preferred color for accurate prototypes in a wide variety of colors to match your brand, product line, or creative vision. Make parts that blend in or stand out with the freedom to customize from subtle neutrals to bold statement colors. Color Resin can be directly printed on Formlabs resin 3D printers, saving time and labor while achieving consistent, repeatable results.

Color Resin is currently only available in the USA, with expansion to other regions coming in the near future.

Get Started 3D Printing for Rapid Prototyping

Contact a Formlabs Solution Specialist to get started with rapid prototyping powered by 3D printing.