Road to the 3D Printed Car: 9 Ways 3D Printing is Changing the Automotive Industry

Although you won’t be able to buy a 3D printed car at the dealership just yet, 3D printing has for many years been a vital part of the development process for automobiles. Recently, however, we’re starting to see 3D printing use cases gain a foothold throughout manufacturing.

3D printing can add enormous value to supply chains, unlocking a broad spectrum of production applications. The technology is growing more workable and affordable, with companies able to bring additive manufacturing in-house to support processes on the factory floor. New, resilient materials are opening opportunities for producing high precision, functional 3D prints that can stand in for final parts and offer (mass) customization opportunities and high performance, but that’s just the beginning.

Read on to find nine key ways 3D printing is powering innovation across the automotive industry, from design to manufacturing and beyond.

3D Printing for Automotive Design and Prototyping

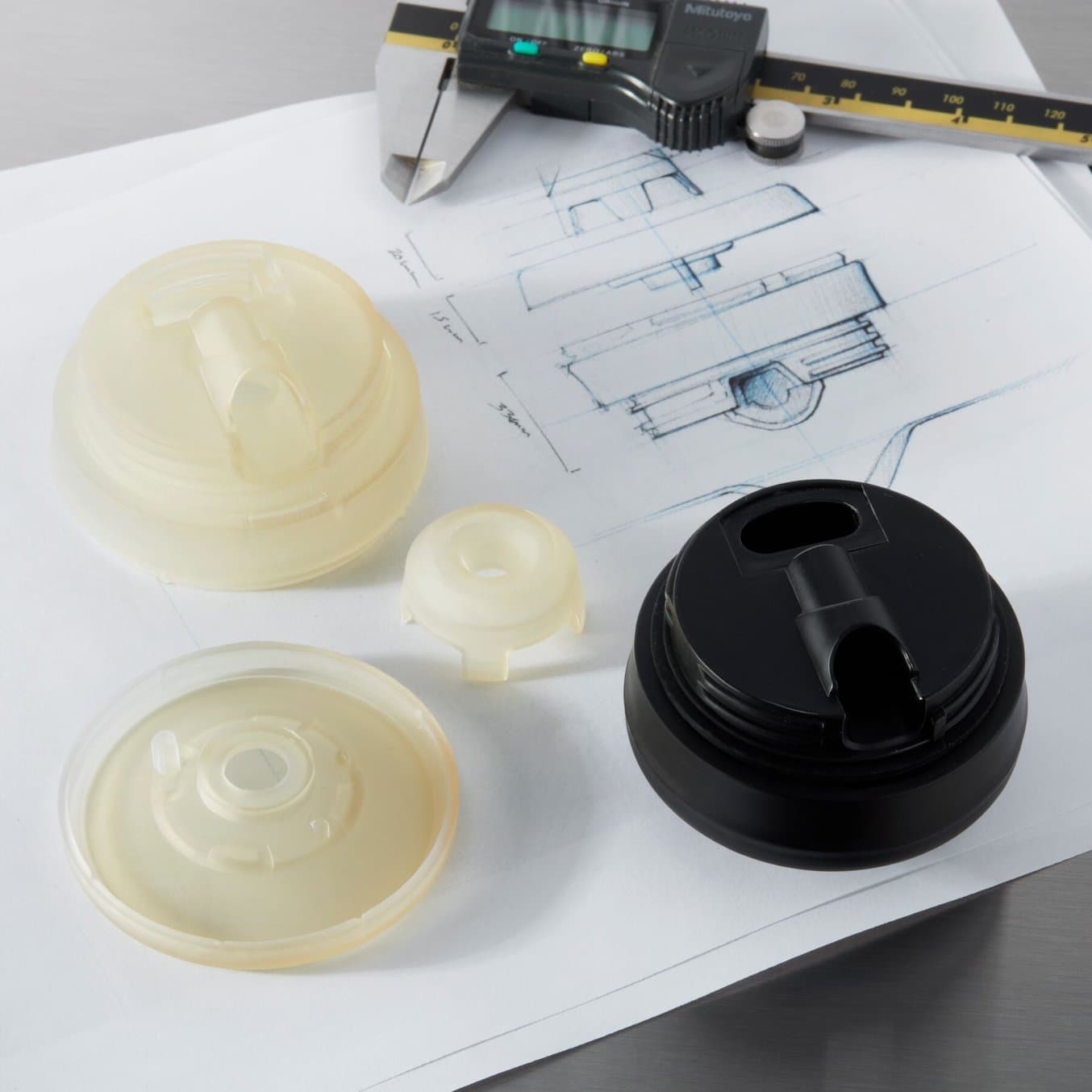

Prototyping has historically been the most common use case for 3D printing in the automotive industry. Thanks to the vastly increased speed at which prototyping can be carried out using 3D printing, rapid prototyping has become virtually synonymous with 3D printing, and the technology has revolutionized the product development process.

With 3D printing, automotive designers can quickly fabricate a prototype of a physical part or assembly, from a simple interior element to a dashboard or even a scale model of an entire car. Rapid prototyping enables companies to turn ideas into convincing proofs of concept. These concepts can then be advanced to high-fidelity prototypes that closely match the end result, and ultimately guide products through a series of validation stages toward mass production.

Prototyping used to be time-consuming and expensive as a product goes through many iterations. With 3D printing, highly convincing, representative, and functional prototypes can be created within a day, at a much lower cost than with traditional manufacturing methods. Desktop 3D printers allow engineering and design teams to bring the technology in-house in order to increase iteration cycles and shorten the distance between idea and final product, strengthening their overall product development workflows.

1. Same-Day Automotive Prototypes With 3D Printing

Ford designers used Formlabs 3D printers to prototype the lettering on the back of the Ford Puma in a matter of hours.

At Ford’s Rapid Technology Center in Merkenich, Germany, many 3D printing technologies are used to create prototypes with short turnaround times. Instead of sending out a job to a shop with a several-week lead time, engineers and designers are able to hold their designs in their hands in a matter of hours.

Designers are able to produce same-day prototypes in the Rapid Technology Center, iterating several designs in just a few hours. Physical prototypes can offer advantages over digital models, says Bruno Alves, additive manufacturing expert at Ford.

For instance, Formlabs 3D printers were used to prototype the lettering on the back of the Ford Puma, allowing designers to see how the lines and shadows would appear in different lighting conditions. “The printer is so fast, and so effective for this kind of lettering, that we could supply the designers the option to iterate,” says Alves. “It’s a thing that you can see it in CATIA or other software, you can simulate lighting, but it’s different to feel, to touch, and to see all the reflections when you put the lettering on the car.”

For more insight on how 3D printing is powering innovation at automotive giants, watch our webinar with Bruno Alves of Ford Motor Co. and Christian Kleylein of Brose.

In Conversation With Ford and Brose: 3D Printing at Scale With Two Automotive Giants

In this webinar, Christian Kleylein, Technologist at Brose, one of the largest family-owned Tier 1 automotive suppliers, and Bruno Alves, Additive Manufacturing Expert at Ford will share how 3D printing is powering innovation across the automotive industry, from design to manufacturing and beyond.

2. Lightweighting Car Parts With 3D Printing

IGESTEK is an automotive supplier in Spain specializing in the development of lightweight solutions using plastics and composite materials. Their team uses 3D printing throughout the product development process, from the conceptual design phase to verify geometries to the detailed design phase for the realization of functional prototypes. They also use 3D printing to manufacture rapid tooling, such as inserts for plastic injection molds or thermoforming tools for composites.

Topology optimization is a hot topic in lightweighting. IGESTEK uses Autodesk Fusion 360 to generate multiple solutions based on a list of parameters.

For one suspension mount, the team developed a multi-material architecture that combines metal 3D printing based on generative geometries and lighter composite materials to offer the best performance, in a 40% lighter package than current solutions on the market. These parts were prototyped on the large format 3D printer Form 3L, which is large enough to prototype multiple designs simultaneously for even faster iteration and testing.

For more details on this application, plus two other ways IGESTEK lightweights automotive parts, read our story with IGESTEK.

An Introduction to Generative Design for Producing Lightweight Parts With 3D Printing

In this webinar, Formlabs Product Marketing Lead Jennifer Milne will provide a simple overview explaining what generative design is, framed in a way that is applicable to mechanical part design, including a step-by-step tutorial of Fusion 360 where she’ll produce a lightweight bracket.

3. Bringing Concept Cars to Life With 3D Printing

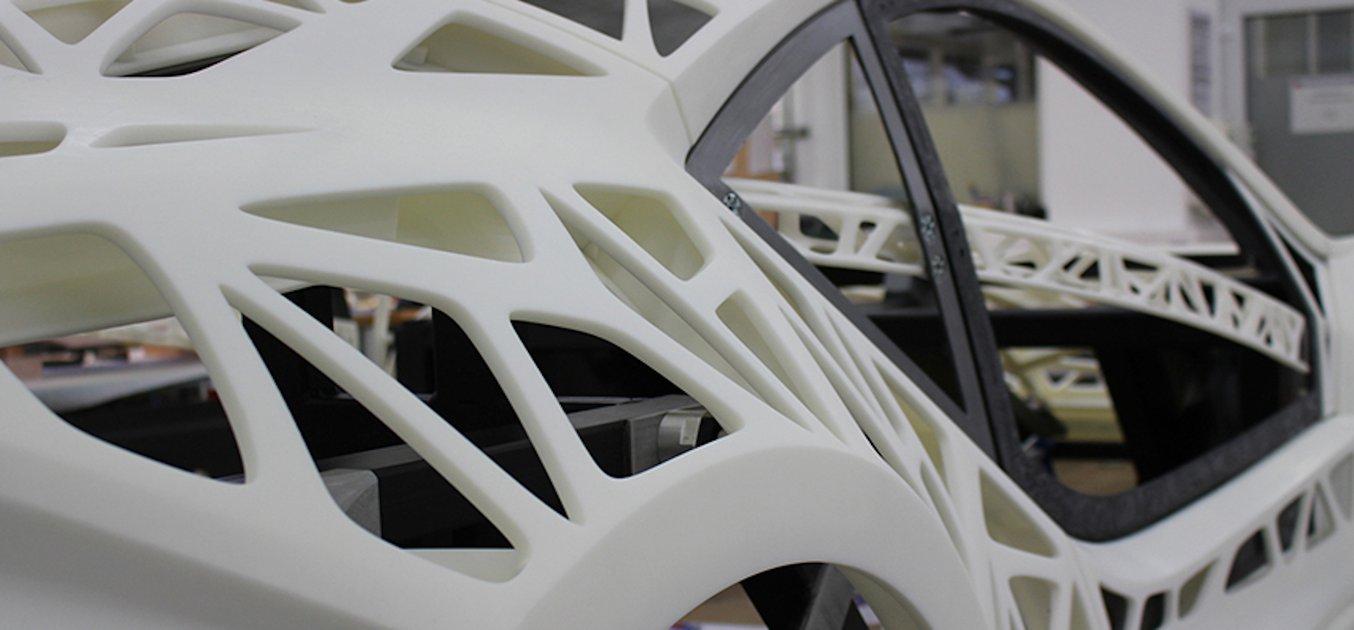

Vital Auto is an industrial design studio in the UK that works with major car brands, such as Volvo, Nissan, Lotus, McLaren, Geely, TATA, and more. When the original equipment manufacturers (OEMs) don't have time for experimentation themselves, they come to Vital to turn ideas, initial sketches, drawings, or technical specifications into a fully realized physical form.

“We've used 3D printing from day one. We wanted to introduce it to our manufacturing processes, not only to reduce costs, but to give the customer more diversity with their designs and their ideas,” said Anthony Barnicott, Design Engineer in charge of additive manufacturing.

Today, Barnicott runs a whole 3D printing department, including 14 large-format fused deposition modeling (FDM) printers, three Formlabs Form 3L large-format stereolithography (SLA) 3D printers, and five Fuse 1 selective laser sintering (SLS) 3D printers. “In terms of capacity, all those printers have run 100%, 24/7, pretty much since day one. We use these printers for all areas of our concepts and designs. Typically, we use the Fuse 1s for our production-based parts and we use our Form 3Ls for our concept-based parts,” said Barnicott.

3D printing not only helps the team create better products faster, but also attracts new business. They found that many of their customers turn to them because they want to have access to the latest technologies and they want to have their components made using the latest cutting-edge materials.

“The progression in technology and 3D printing over the last 10 years is phenomenal. When I first started, producing low volume, niche vehicles, some of the products that we produce today would simply have been inaccessible. And not only am I able to produce these parts today, but I’m also able to produce them very cost-effectively, very quickly,” said Barnicott.

For more insights on specific applications with 3D printed parts, check out our in-depth story with the Vital Auto team.

Guide to Rapid Prototyping for Product Development

In this guide, you’ll learn how rapid prototyping fits into the product development process, its applications, and what rapid prototyping tools are available to today’s product development teams.

3D Printing in Automotive Manufacturing

Thanks to the rapid development of 3D printers and high-performance materials, additive manufacturing can now be used to produce parts that are up to the challenge of extreme environments.

3D printing can be leveraged in manufacturing to reduce overhead and increase efficiency with manufacturing aids like custom jigs and fixtures and produce low-volume rapid tooling for traditional manufacturing processes like injection molding or thermoforming.

3D printed end-use parts are also increasingly common in the automotive industry, especially for applications like aftermarket, custom, or replacement parts, where other means of production would be excessively costly and slow.

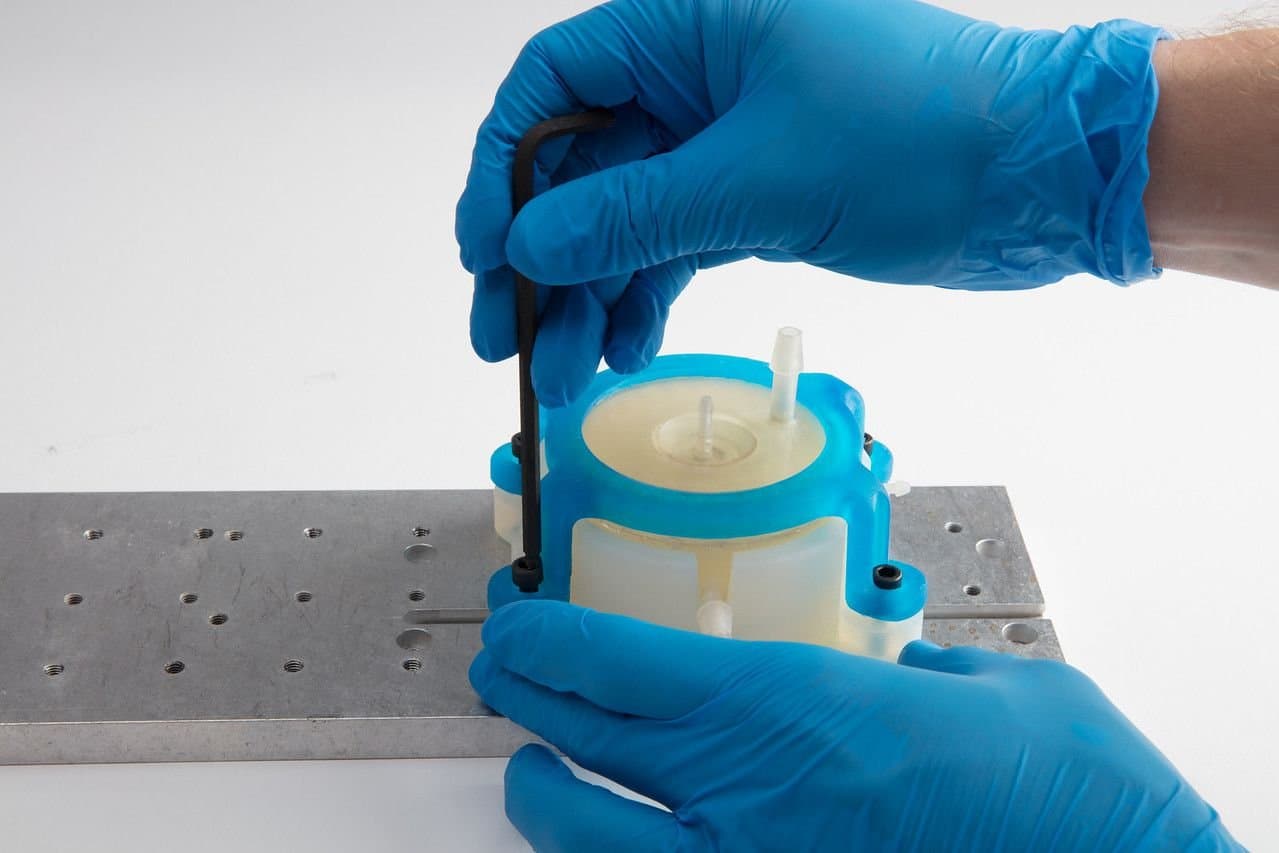

4. 3D Printed Molds and Dies for Car Parts

Makra Pro developed a novel technique for molding leather trim pieces using 3D printed dies.

Makra Pro is an additive manufacturing service provider that has developed a novel process for molding leather, a popular trim material in luxury cars that can be difficult to shape, using 3D printed dies. In partnership with some of their clients, including manufacturers of luxury cars, motorcycles, and motor homes, they have tested a method for shaping and embossing real leather.

Using molds printed on a Form 3, Makra Pro’s technique uses expanding foam to equally distribute pressure across a panel of stretched leather. As the foam hardens, the leather is pressed into the die and takes on its shape.

The finished leather parts can then be, for example, stretched over the door panel in a car or attached to the seat cover in a vehicle. One well-known tuning company of limited-edition luxury automobiles uses these molded leather parts for wall or ceiling panels in vehicle enhancements.

Read our in-depth story with Makra Pro or download our white paper for more rapid tooling applications, including injection molding, thermoforming, and more.

Guide to Rapid Tooling

In this white paper, learn how to combine rapid tooling with traditional manufacturing processes like injection molding, thermoforming, or casting.

5. 3D Printed Manufacturing Aids

Dorman Products produces go/no-go test jigs with Grey Resin that are accurate to +/- 0.05 mm.

Dorman Products designs and manages a database of more than 100,000 parts for hundreds of different vehicles. “Historically we’ve released between 4,000 and 5,000 new parts each year,” says Mechanical Design Team Manager Eric Tryson.

In addition to the sheer logistical challenge of operating as an aftermarket supplier, Dorman’s product design and manufacturing teams need to be particularly agile, says Additive Manufacturing Lead Chris Allebach. “The OEMs have teams of people designing a single part, sometimes starting two years prior to a new car coming out. We need to find ways to ensure our replacements are reliable while also being fast to market.”

Before integrating 3D printers into their workflow, the lack of custom test fixturing was an obstacle to quick development. Machining was prohibitively expensive and time-consuming.

“Now, with the 3D printers, we develop the test fixtures and gauges along with prototyping the product, so when we decide on a final design, we can have the fixture to test it as well. We’re trying to be as proactive as possible,” says Allebach.

Since Dorman acquired their first 3D printer ten years ago, Allebach and Tryson have added more printers steadily, continually maxing out capacity on their existing units, and utilizing the full materials library on their Formlabs SLA printers, including a large-format Form 3L.

“[Our first 3D printer] paid for itself within two months. When we’re doing the cost justification or an ROI for any of the Formlabs printers, we can justify the payoff in months instead of a two-year time frame. That gives our leadership confidence that 3D printing is a worthwhile investment,” says Tryson.

Dorman Products is using 3D printing for several other applications. Read our article to explore them.

Designing Jigs & Fixtures with 3D Printing

For manufacturers, maximizing production speed while maintaining high part quality is critical for success. Jigs and fixtures are used to make manufacturing and assembly processes simpler, more reliable, and more efficient, reducing cycle times and at the same time improving worker safety.

6. End-Use Aftermarket Parts With 3D Printing

BTI Gauges designs telemetry displays for high-performance cars.

Like many successful businesses, BTI Gauges started with a gap in the market. Brandon Talkmitt, founder and owner, was looking for a customizable approach to telemetry display for his high-performance car.

Talkmitt searched, unsuccessfully, for a gauge that contained multiple performance metrics, so his windshield wasn’t littered with multiple screens and distracting read-outs. He then began by prototyping the external casings of the gauges on a 3D printer and testing them out himself, subjecting the casings to high-heat environments inside cars and ovens, and modifying the design to complement multiple car models.

Right away, there was interest in his product from clientele driving 1990’s style Japanese race cars, Lamborghinis, Dodge Vipers, and other high-performance vehicles.

Talkmitt began evaluating other 3D printing options, including expensive plastic powder bed fusion 3D printers, resin 3D printers, and an inexpensive compact SLS option. But between the half a million dollar price tags on some, and the complex materials purchasing process from others, there just weren’t any options available. That is until he heard about the Fuse 1. “When I got the sample I thought, ‘Man, if my parts can look like this.’ So I ran some tests, and figured out what kind of heat it could tolerate. Did the finishing and painting process on it, and everything worked,” says Talkmitt.

During the supply chain issues of the last two years, BTI Gauges faced several shortages of the touchscreen displays, and other components needed for their nine product lines. By bringing 3D printing in-house with the Fuse 1, he was able to pivot immediately to a new design, without having to spend thousands of dollars on new tooling, or dealing with a backlog of now-obsolete products.

“I would have been stuck with all that plastic, but with the Fuse 1, I could make the change on the fly. It was a 30-minute thing for me to change the files. Without it, I would definitely be stuck right now,” says Talkmitt.

Find out more about producing end-use aftermarket parts in our in-depth story with BTI Gauges.

Outsourcing vs. In-House: When Does it Make Sense to Bring SLS 3D Printing In-House?

In this white paper, we evaluate the value proposition of bringing SLS 3D printers in-house, in comparison with outsourcing SLS parts from a service bureau.

3D Printing for Race Cars and Motorcycles

3D printing is a toolless fabrication process that is a great match for motorsports and a powerful tool to achieve low-volume production and custom manufacturing rapidly and cost-efficiently. By eliminating tooling time and costs, it provides the flexibility to revise products quickly and accelerate time to market. It increases design freedom and gives the ability to customize products, and build complex shapes such as lattices without any additional costs.

By using in house 3D printing, motorsport teams can develop faster, keep their IP secure, test more ideas, and ultimately beat their competition.

7. Improving Engine Performance With 3D Printed Iterative Designs

Forge Motorsport’s redesigned duct reduced intake air temperature by 6° C.

Forge Motorsport, which makes aftermarket parts for performance cars, uses 3D printing to prototype their parts. When the Toyota Yaris GR was released, the engineers at Forge noticed a few opportunities to improve the inlet duct design—moving the airbox opening, and increasing the overall size of the part—that would reduce fluctuations in intake air temperature (IAT), which make it hard to anticipate engine performance, while reducing the average temperature overall.

They reverse engineered the OEM part using 3D scanning and made the design changes virtually in SOLIDWORKS, where they were able to simulate airflow. Once they had a workable 3D model, they prototyped it in fast-printing Draft Resin, which they used to confirm that the new location for the airbox opening would work as intended and that the overall increased size of the part wouldn’t interfere with other components or cables. With basic fit confirmed, they reprinted the part in Tough 1500 Resin, a strong and impact-resistant material, painted it black to resemble the final part, and gave it to a customer to test.

The customer used the 3D printed part in his Yaris GR for five months, during which time he collected data on performance under different conditions, including on tracks and uphill climbs. The IAT on the stock part varied between 42-45 °C, with considerable variations observed during the course of a race; with the redesigned part, printed in Tough 1500 Resin, the customer measured IATs between 35-36 °C. As anticipated, the redesigned part had both lower overall IATs and reduced fluctuations. With this data in hand, confident that their part was an improvement over the OEM design, Forge moved forward into manufacturing the final production part with carbon fiber.

For more on the reverse engineering workflow using 3D scanning, watch our webinar with Forge Motorsport and Peel3D.

3D Scanning and 3D Printing in the Automotive Industry with Forge Motorsport

In this webinar brought to you by Formlabs, Solid Print3D, and peel 3d, we talk to Forge Motorsport, who manufacture performance upgrades for the aftermarket automotive industry such as valves, intercoolers, and actuators.

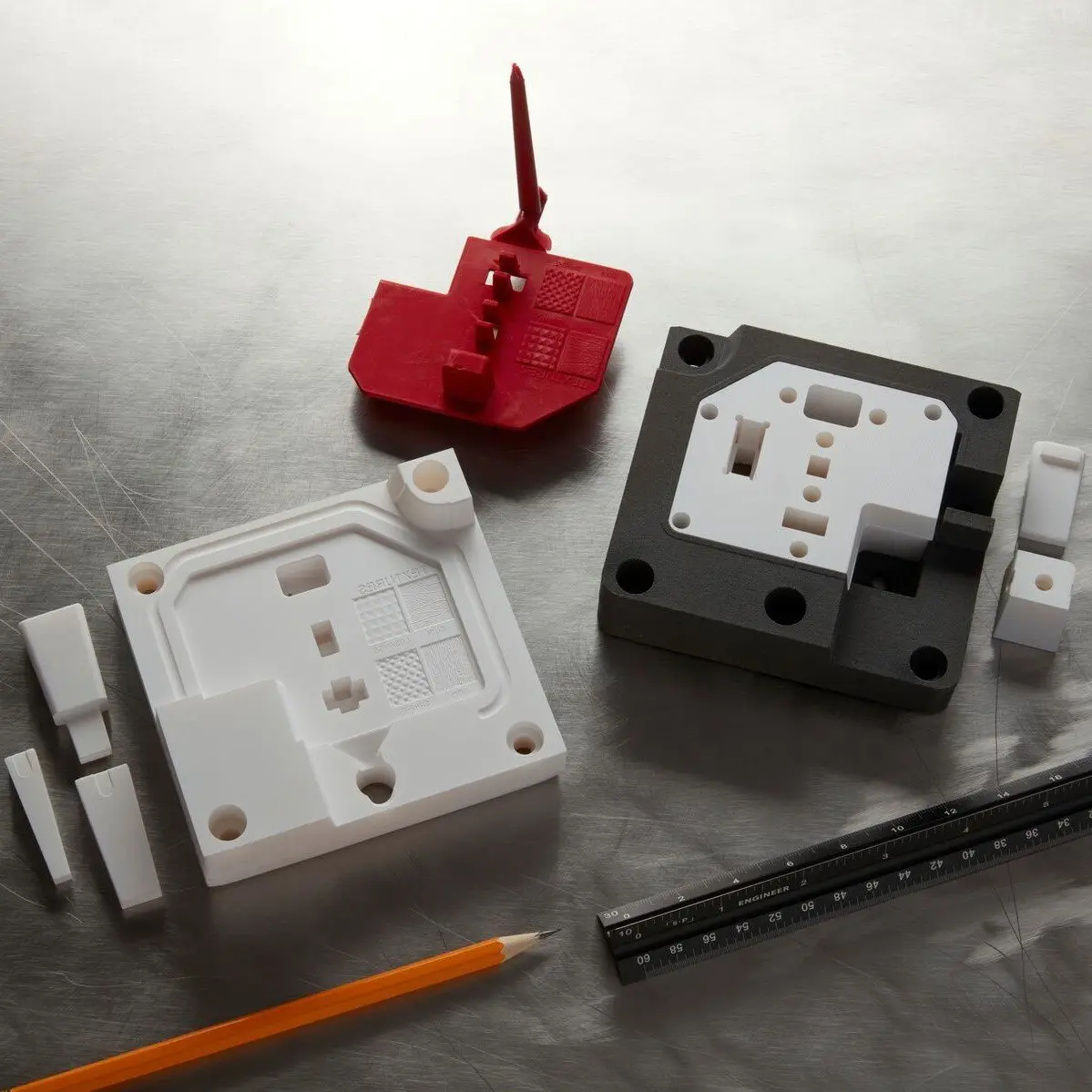

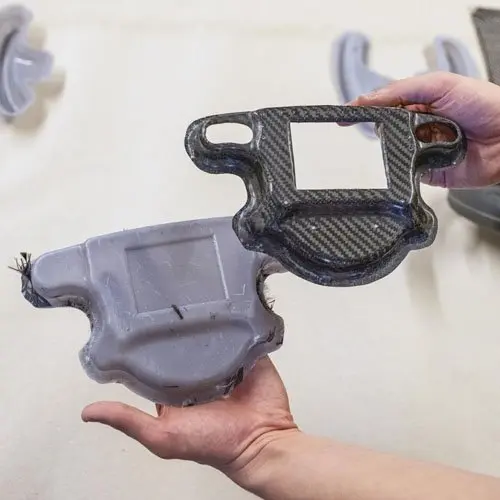

8. Carbon Fiber Molding and 3D Printed End-Use Parts for Formula Cars

By 3D printing molds in-house, TU Berlin’s competition team could drastically cut their costs and lead time for this carbon fiber part.

The Formula Student is a yearly engineering design competition in which student teams from around the world build and race formula-style cars. The Formula Student Team TU Berlin (FaSTTUBe) is one of the largest groups; 80 to 90 students have been developing new racing cars every year since 2005. The team added a Form 3 SLA 3D printer to their toolset that they have used to save time, reduce costs, and create carbon fiber parts that would be prohibitively expensive any other way.

3D printing molds for composites allowed the team much greater flexibility, shorter lead times, and saved costs when designing key parts like the steering wheel chassis. Machining the mold for this part would have required sourcing expensive specialized tools, and outsourcing the molded part would have taken weeks and cost nearly €1000. Instead, 3D printing the mold in-house and laminating it by hand cost only €10 in materials and 1.5 hours of working time.

The team is also using 3D printing to prototype designs, lightweight parts, and even fabricate end-use parts. Read our story with them for more details on these applications.

3D printing has given the FaSTTUBe team new flexibility, design freedom, and cost savings. Additionally, students have gained experience fabricating prototypes, tooling, and even end-use parts for their project. These skills will stay with the students as they enter the workforce, bringing valuable experience to every discipline of engineering.

Carbon Fiber Parts Manufacturing With 3D Printed Molds

Download this white paper for composite mold design guidelines and step-by-step guides to the prepreg and hand laminating methods to create carbon fiber parts.

9. 3D Printed Spare Engine Parts

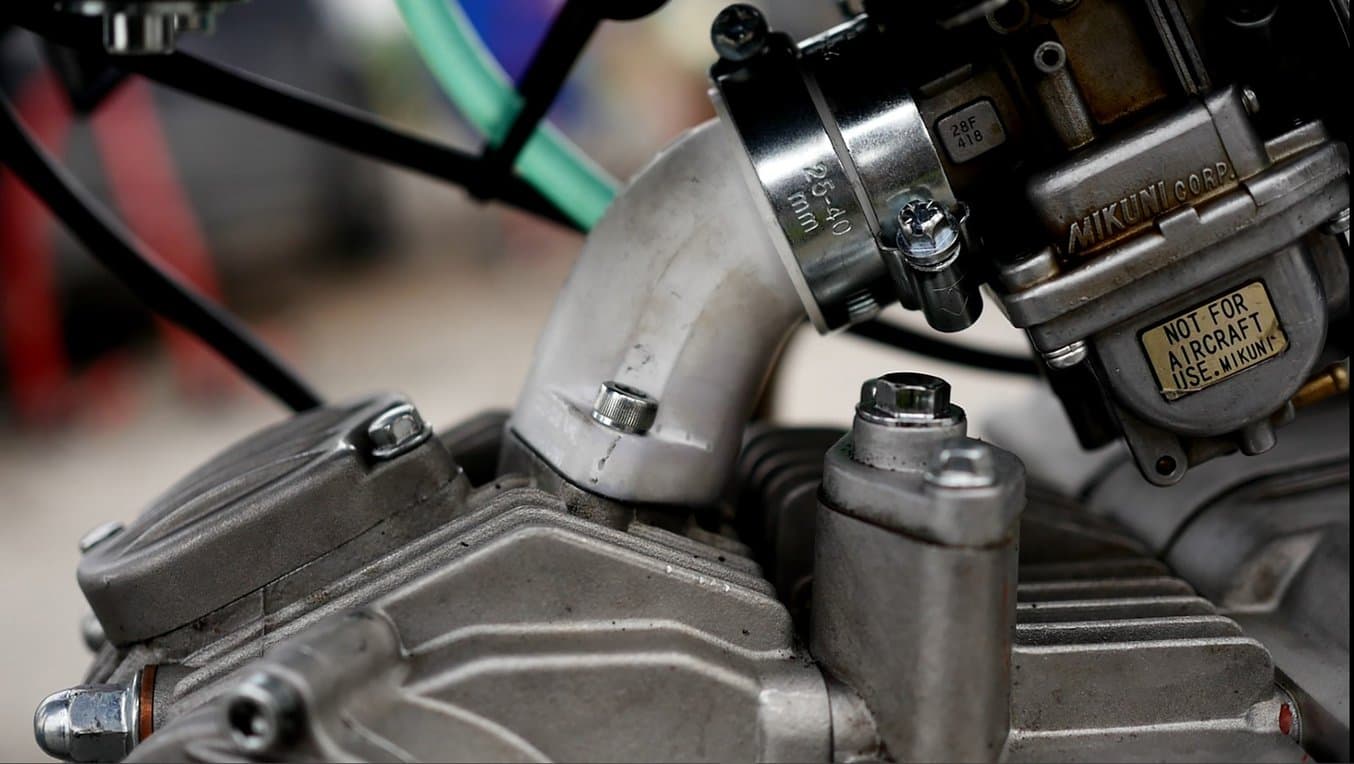

The intake manifold, printed in Rigid 10K Resin, recorded a lower post-race temperature than the original aluminum part.

Andrea Pirazzini has been riding motorcycles since 2012. He wanted to challenge himself to design and fabricate a functional, safe 3D printed intake manifold for his own bike. In the past, he had tried using FDM printing technology, but the result was not what he hoped for, as the part was not airtight and compromised the engine’s function.

To develop the project, Pirazzini used 3D scanning and Autodesk Fusion 360 software to reverse engineer the design. The scan of the four-stroke engine (two-valve) engine with its frame and carburetor helped him to correctly size the manifold and then to position it optimally. With the use of CAD software, it was possible to align the diameter of the head inlet with the carburetor, avoiding steps and any pressure drop or turbulence.

The new manifold design was printed with the Form 3 using the Rigid 10K Resin at a 100 microns layer height, creating a smooth surface without visible layer lines. As for the finish, Pirazzini used classic water-based sandpaper to smooth the surface. Unlike an FDM manifold, which has to be treated externally and internally to be watertight, SLA printing creates solid and waterproof parts.

The manifold that Pirazzini printed with the Form 3 has withstood high and low temperatures perfectly and is still mounted on his pit bike. Thanks to the use of a thermal imaging camera, Pirazzini discovered that Rigid 10K Resin also offered a significantly better thermal performance: The 3D printed manifold with cooling fins recorded a 40-50 degrees Celsius lower temperature compared to a classic aluminum manifold. Moreover, after a race of about 20-25 minutes at an outside temperature of about 33 degrees Celsius, it was possible to touch the manifold without getting burned.

The project not only succeeded, but it even improved the function of the engine. Based on some improvements Pirazzini made to the original design, the engine had more horsepower (about one HP, almost 10% increase) available compared to the standard machined manifold, while remaining within the limits imposed by the rules of the championship.

Find out more about how Pirazzini developed the project in our detailed case study.

3D Scanning and 3D Printing for Reverse Engineering and Other Applications

3D scanning and 3D printing workflows can be applied to replication and restoration, reverse engineering, metrology, and more. Download our white paper to explore these applications and learn how to get started.

Bonus: 3D Printed Cars

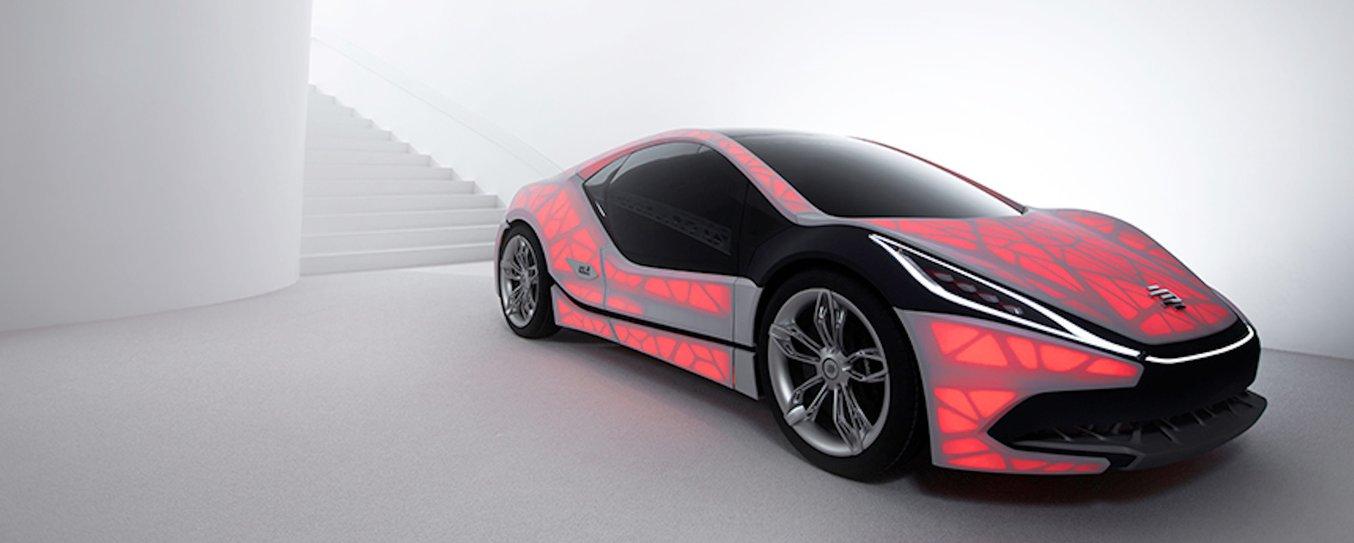

Amid the 3D printing hype of the early 2010s, excitement grew in popular media around 3D printing large-scale, complex assemblies, including entire 3D printed cars. However, even the biggest proponents of “fully” 3D printed cars shifted focus to printing structural and trim components like the chassis, body, and seats, not the engine or other electromechanical assemblies.

Some companies, including Local Motors and EDAG, created full concept cars where the chassis and body were 3D printed, exhibiting them to the public at trade events like SEMA in the mid-2010s. However, none of these projects reached serial production.

Besides weather resistance, the cover on EDAG’s Light Cocoon provides absolute freedom when it comes to design and individualization. (source: EDAG)

Currently, the projects and companies closest to serial production seem to be Divergent 3D and XEV.

Divergent 3D combines generative design and 3D printing to create custom-tailored components for auto parts manufacturers. Once a component is designed, it’s constructed using the company’s metal 3D printers. Their first public project is the Czinger 21C hypercar, while they’re also a supplier of major OEMs, including Aston Martin.

On the other end of the spectrum, the YoYo, developed by the Italian company XEV, might be the first “mass market” 3D printed electric car that is now shipping to customers. Apart from the chassis, the seats, and the windshield, all the visible parts of the YoYo are also 3D printed. Thanks to the extensive use of 3D printing, the company has managed to reduce the number of components from 2,000 to only 57, resulting in a light design that weighs only 450 kilos.

The YoYo is the first “mass market” 3D printed electric car that is now shipping to customers.

Learn More About 3D Printing in Automotive

As we have seen through all these examples, 3D printing has already been proven repeatedly to offer significant advantages to the supplier, the OEM, and the consumer when it’s leveraged creatively to reduce time to market and improve vehicle performance. In some cases, 3D printing technology is pushing boundaries and helping achieve entirely new possibilities in design and production. In others, the technology is lowering production costs and saving time.

As the understanding of the value and realities of 3D printing continues to spread through the industry, and as the technology and available material base grow ever more versatile, additive technology will continue to reshape the way we design, build, and maintain vehicles around the world.