Formlabs reseller BTech Innovation has printed 13,000 anatomically accurate teaching aids.

Hands-on teaching aids are helpful in any classroom, and they are absolutely essential in educational settings like labs and pre-clinical instruction. In these environments, handling a tangible model enhances a student’s understanding of theory, permits repeated practice of techniques, and allows instructors to observe and make corrections.

Sourcing high-quality, effective, budget-friendly teaching aids can be a challenge for instructors and administrators. 3D printing offers an alternative with more flexibility and control for schools of any size.

Assoc. Dr. Gülşah Uslu, an instructor in the dental school at Canakkale Onsekiz Mart University in Turkey, and Dt. Halit Yosunçığır, dental product manager at Formlabs reseller BTech Innovation, have found a unique way 3D printing can augment hands-on instruction. Together, the team used Formlabs 3D printers to produce more than 13,000 anatomically accurate artificial teeth models that students could use when first learning certain procedures.

The 3D printed teaching aids turned out to have several advantages over traditionally manufactured teaching aids, including some benefits Dr. Uslu and her team didn’t expect. Read on to find out what these advantages are and how other programs can benefit from their learnings.

Replicable Practice on Real-Life Cases With 3D Printed Teaching Aids

Dental students typically go through a hands-on training program before they treat their first patient under supervision in the clinic. This training is either conducted on artificial anatomical models or on extracted teeth.

Plastic anatomical models, called typodonts, are ubiquitous in dental schools. They help students visualize concepts taught in the classroom and are used in hands-on exams to evaluate the students’ technique. Training on typodonts allows students to practice on familiar tools, but they are expensive. Additionally, because they are optimized for mass production and ease of assembly rather than anatomical accuracy, they don’t realistically simulate varied clinical situations.

Working with real extracted teeth allows students to practice on real-life cases, but there are risks associated with this option. Access to a steady supply of quality, safe, and ethically extracted teeth depends on voluntary donations from local clinicians. Additionally, they carry some risk of cross-infection, and can vary in quality and complexity, which lowers uniformity standards in student learning and assessment.

As Dr. Uslu and her students have learned, 3D printed teeth provide the best of both worlds: accurate and realistic learning experiences based on real patient cases, while giving every student the opportunity to practice on the same exact case—and all without the risk of cross-infection.

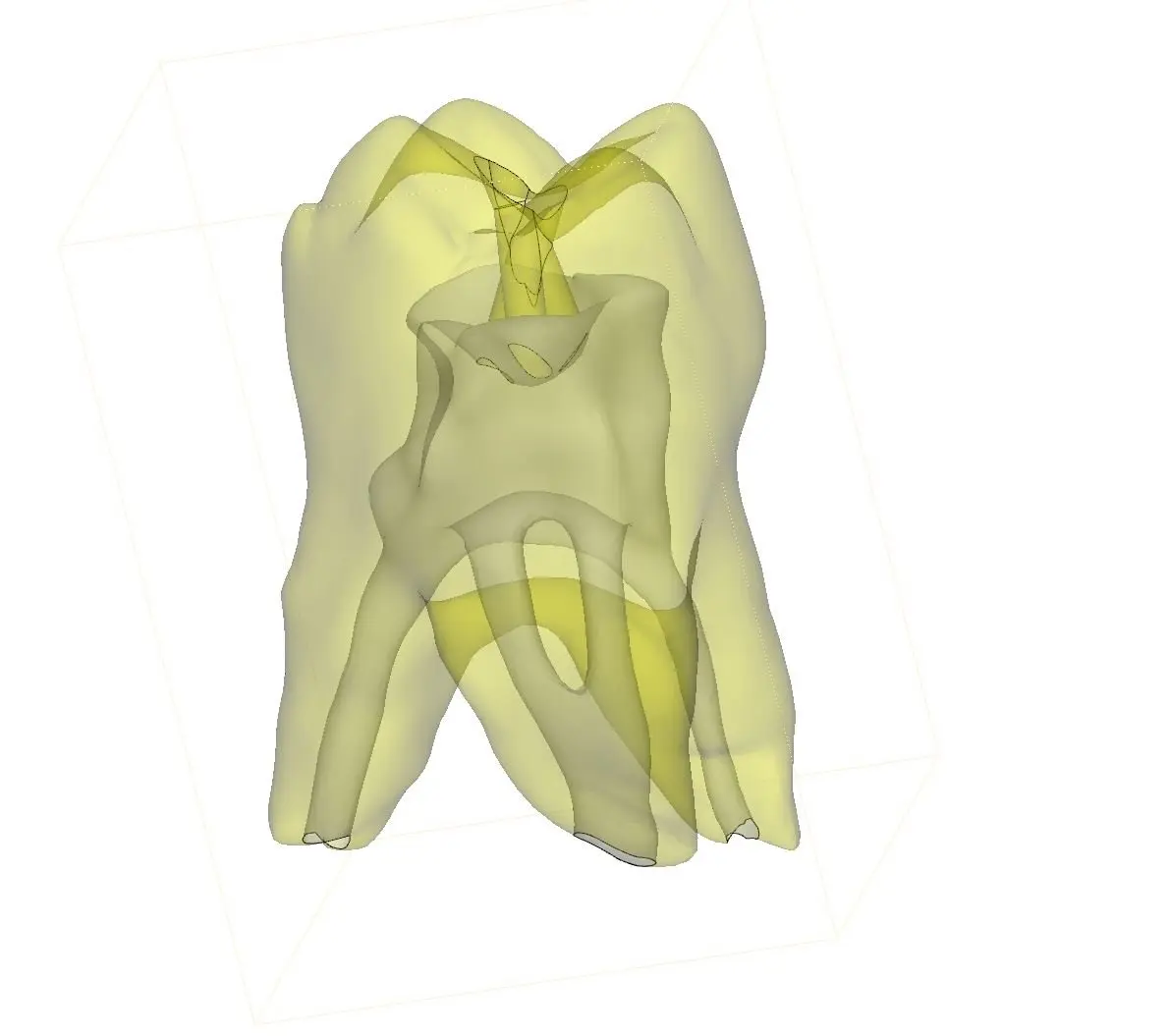

Printing in Clear Resin permits students and instructors to view work without an X-ray, which wasn’t possible with either of the traditional types of teaching aids.

More Advantages of 3D Printing Teaching Aids

The team at COMU and Btech were pleasantly surprised to identify three further advantages to the 3D printed teaching aids.

Visual Transparency

Thanks to the transparency of Clear Resin, students and instructors can visualize the entire tooth, which is particularly beneficial in a training environment. Students can continuously monitor every angle of the procedure as they go, and errors can be detected and corrected by an instructor without an X-ray.

Flexibility in the COVID Era

Dr. Uslu began this project when her university transitioned to fully remote instruction in 2020. Dental education relies heavily on experiential learning, so the faculty got creative to give students remote hands-on training. Using 3D printed teeth for pre-clinical procedure instruction permitted instructors to stay flexible and continue to deliver quality education under adverse circumstances.

Price Per Unit

Whether students buy their own or the university supplies them for students, typodonts are expensive. Lower-end typodonts, made with lower quality materials, cost between $50 and $100 USD, but it’s not uncommon to spend more than $300 for a quality model. On the other hand, the 3D printed teeth cost just $2 each to produce.

The Form 3B’s build platform is larger than that of other dental 3D printers, which meant the BTech team could print more units in a single batch.

3D Printed Teaching Aids In More Disciplines

3D printing may be a useful way to create teaching aids in other disciplines. It’s important to consider how a design is chosen and sourced, how many copies are needed, and, of course, cost.

Sourcing a 3D Model

3D printing is only useful once you have a 3D computer file of the object you want to print. There are multiple ways to obtain a 3D model, including designing it from scratch, adapting it from a 3D scan, and downloading it from an online 3D model repository.

The BTech team adapted their teeth designs from real patient scans. They used the Mimics Innovation Suite of software from Materialise to analyze computed tomography (CT) images taken from the head and neck region of a patient. Using Mimics, they isolated individual teeth, including roots, made adjustments, and exported each model as a 3D file.

Scale of Production

It’s important to consider how many units are needed, and over what timescale. BTech’s production team was able to produce up to 110 molar teeth per print on the Form 3B. Each print took about eight hours, and using three Form 3B printers, they produced 13,000 units in 13 months, or approximately 1,000 units each month.

Cost

To calculate the cost to 3D print any item, consider the upfront cost of the 3D printer and accessories, the material use per unit, and the cost of labor. This can be tricky to calculate on your own. Try our interactive ROI calculator to estimate the cost of producing a variable number of items.

As for what types of teaching aids could be 3D printed—the possibilities are endless. See how Formlabs customers in industry are using 3D printing for more inspiration.