Biomedical Modeling Inc. (BMI) has always been at the forefront of new technology. Since 1997, the anatomical engineering service bureau has been using digital fabrication methods to create models for education, guides, and demonstration purposes.

Some of their most famous projects include models for the successful surgical separation of the conjoined twins from Guatemala and the reconstruction of King Tutankhamun’s skull and face.

BMI was one of Formlabs’ Kickstarter backers, and among the earliest to use the machines.

Watch the video to learn more about how BMI uses the Form 1+.“We have used a lot of big, more expensive stereolithography machines that were a lot harder to use. That’s why we were excited when the Form 1 3D printer came out,” said Crispin Weinberg, president of BMI.

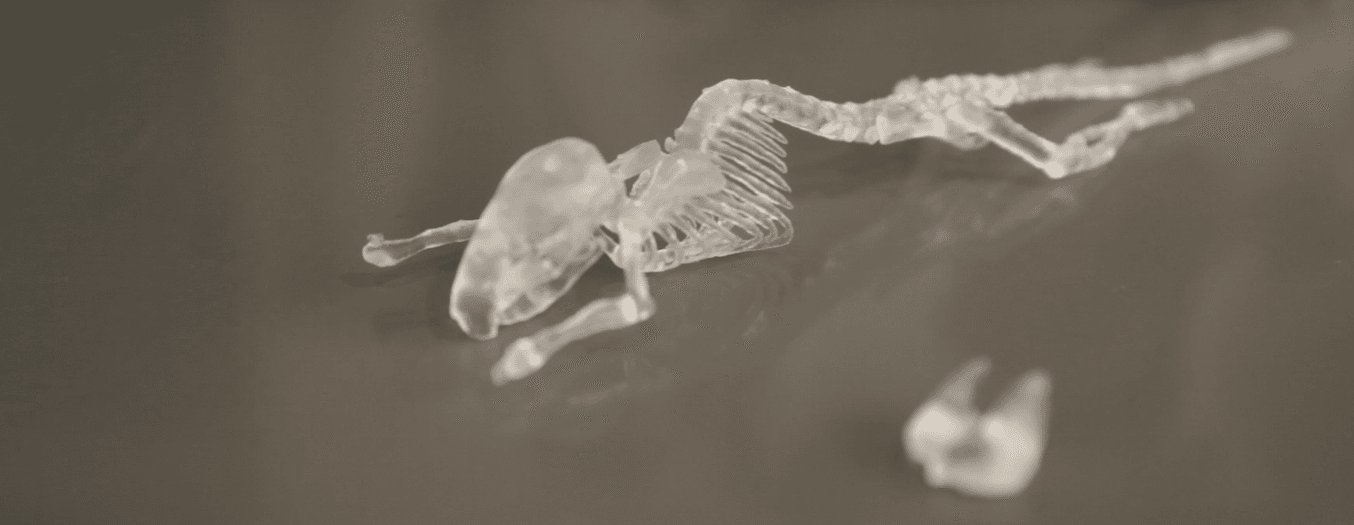

“We use it to print small parts and capture detail in high resolution. It’s convenient to have a small, readily-available desktop stereolithography printer for that purpose.”

The smooth surface finish of the Form 1+ parts also makes them ideal for moldmaking. One such project was an education model for pediatric neurosurgeons, who were learning on operation procedures for spina bifida, a congenital disorder.

Learn more about SLA technology in our free white paper, and request a free sample part below.