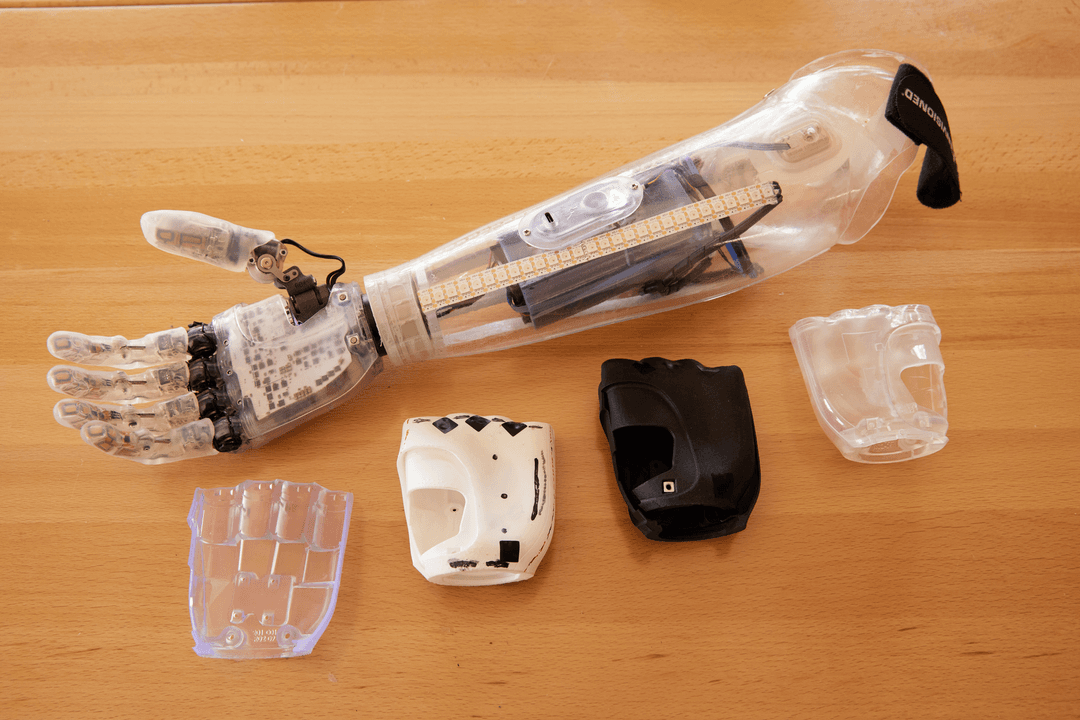

(Photo copyright Care Center Deutschland GmbH)

Care Center Deutschland GmbH is well over 100, but they are still on the cutting edge of orthopedic technology, using an in-house Fuse Series selective laser sintering (SLS) ecosystem to decrease manufacturing timelines and innovate on new products.

“My task is to provide technicians with innovative products and processes in their daily work so that they can carry out their tasks with higher quality, more individuality, and more cost-effectively. As digital manufacturing aims to enhance traditional craftsmanship through digital processes, production with the Fuse integrates seamlessly with our existing production steps.”

Lukas Schubert, Head of Department, Digital Manufacturing

Care Center Deutschland GmbH was founded over 100 years ago, in 1918, and offers innovative, patient-oriented aid solutions in the fields of orthopedic technology, orthopedic shoe technology, rehabilitation technology, medical technology, and homecare. Today, traditional craftsmanship is enhanced by digital manufacturing, enabling 200 staff members at seven locations to help over 5,000 individuals a month access medical aids including custom orthoses and prosthesis for fingers, hands, wrists, forearms, lower legs, ankles, feet, and necks, as well as masks for facial bone fractures.

By embracing traditional techniques alongside digital manufacturing, Care Center Deutschland GmbH can provide higher-quality customized solutions more cost-effectively, and bring innovative new products to market faster for improved patient care.

Talk to Our Medical Sales Team

Whether you need to make patient-matched surgical tools or are prototyping for a cardiac medical device, we’re here to help. Formlabs Medical team are dedicated specialists who know exactly how to support you and your company's needs.

The Time-Savings of Digital Production

From 2020 to 2023, Care Center Deutschland GmbH was a part of a study on the feasibility of 3D printed wrist orthosis. In addition to material and design considerations, quality and speed of production were a key part of the study.

Wrist orthotics are 3D printed in Polypropylene Powder. (Photo copyright Care Center Deutschland GmbH)

Time to produce a wrist orthosis

| Traditional production | Digital workflow | |

|---|---|---|

| Measuring the patient | 6 min | 15 min |

| Taking an impression | 20 min | - |

| Modeling | 2 h | 45 min |

| Material selection | 6 min | - |

| Production | 4 h | 1.5 h |

| Total time | 6 h 32 min | 2.5 h |

The findings showed a time savings of 60% in a fully digital workflow for producing a wrist orthosis.

Substantial time savings come from the initial measurement and modeling process, which is done with Artec Eva, Shining3D EinScan H, and Revopoint Miraco Pro scanners. Care Center Deutschland GmbH then uses Geomagic Freeform and Autodesk Fusion for design.

Bringing the Fuse Series Ecosystem In-House

For the past five years, Care Center Deutschland GmbH has used fused deposition modeling (FDM) 3D printers to prototype or to help with intermediate production steps. During this time, they worked with service providers (e.g. 3D Werk Black Forest GmbH) who produced their final products using selective laser sintering (SLS) or multi-jet fusion (MJF) 3D printing.

Schubert uses the Fuse Series ecosystem, including the Fuse 1+ 30W, Fuse Sift, and Fuse Blast, for the production of orthotics. (Photo copyright Care Center Deutschland GmbH)

As the business grew, it became apparent that bringing 3D printing in-house would save costs and shorten timelines. Care Center Deutschland GmbH worked with Formlabs reseller 3D-Werk Black Forest GmbH to do process demonstrations and hands-on testing of potential printers.

“When we were looking for a suitable SLS system, we also considered printers from other companies. However, the unpacking and post-processing procedures were significantly more labor-intensive, which is why we chose the Fuse Series ecosystem.”

Lukas Schubert, Head of Department, Digital Manufacturing

Overcoming the Post-Processing Challenge

An orthotic for a child produced on the Fuse Series ecosystem. (Photo copyright Care Center Deutschland GmbH)

One of the greatest challenges to orthotic production is post-processing. Schubert explains, “Handcrafted medical aids require significant effort after thermoforming or casting to smooth edges, add closures or joints, or integrate padding.” This is often eliminated by moving to digital workflows.

Part of the post-processing time savings come from the design possibilities that 3D printing enables. Including fittings, closures, and added padding on CAD designs eliminates the post-processing steps of traditionally manufactured orthoses. Additionally, post-processing solutions Fuse Sift and Fuse Blast help to save time and material. Fuse Sift extracts parts and collects unsintered powder, mixing it with fresh powder to prepare for future print runs, saving on material costs.

“The post-printing processes are perfectly coordinated. The Fuse Sift and Fuse Blast provide us with tremendous added value in terms of time efficiency and ease of use. With the Fuse Sift, we always achieve the correct mixing ratios and do not have to worry about material storage.”

Lukas Schubert, Head of Department, Digital Manufacturing

While thermoformed orthotics require sanding and padding, SLS 3D printed orthotics are cleaned and polished in Fuse Blast, attaining a semi-gloss surface finish that can be worn against the skin without needing additional sanding or padding.

Request Your 3D Printed Insole Shell Sample Part

Discover the power of Nylon 11 Powder and revolutionize your insole game. Experience excellent energy return and durability, independently tested to exceed four million steps.

The Fuse Series Ecosystem Fuels New Treatment Concepts

“Formlabs provides us with an excellent opportunity to turn our products from theoretical designs into physical components in a very short time. The entire manufacturing process is perfectly coordinated and fully meets our quality requirements — dimensional accuracy, precision, and biocompatibility.”

Lukas Schubert, Head of Department, Digital Manufacturing

Traditionally, ankle injuries are treated with a custom shoe, which takes four to six weeks to produce. To reduce delivery time and labor, Care Center Deutschland GmbH developed the SLS 3D printed CCD.3D Ankle Orthosis, which reduces lead time by 50% and production costs by 20% thanks to SLS 3D printing.

The CCD.3D Ankle Orthosis was developed by Care Center Deutschland GmbH and is produced on the Fuse Series ecosystem. (Photo copyright Care Center Deutschland GmbH)

The CCD.3D Ankle Orthosis weighs 50% less than a traditional orthosis, making it more comfortable to wear. (Photo copyright Care Center Deutschland GmbH)

Printing on Fuse 1+ 30W takes less than a day, enabling quick turnaround of prototypes during product development. Holes, lattice, and padding can be included in designs for SLS 3D printing, all without worrying about supporting the print, for smooth surfaces and complex geometries.

Due to design and materials, the CCD.3D Ankle Orthosis weighs 50% less than a traditional orthosis, making it more comfortable to wear. By halving lead time, patients receive their orthotics faster, enabling faster treatment.

The CCD.3D Ankle Orthosis is just the first of a series of new, SLS 3D printed products Care Center Deutschland GmbH is developing. As they continue to expand their Digital Manufacturing division, the Fuse Series ecosystem is powering development and production of new products and processes to improve patient experience.

Explore the Fuse Series ecosystem to learn more or request a free SLS 3D printed sample insole to evaluate Formabs materials for yourself.