New Resin Pumping System and Bulk Pricing Streamline SLA Operations and Lower Cost Per Part

Formlabs is proud to announce that Resin Pumping System and new bulk resin pricing opportunities are now available for the Form 3 Series ecosystem, improving access to professional-quality 3D printing by significantly lowering cost per part. Reduced cost per part makes stereolithography (SLA) 3D printing competitive with other fabrication methods, making it easier to take advantage of the wide range of materials, geometric freedom, and superior surface finish of Formlabs printers.

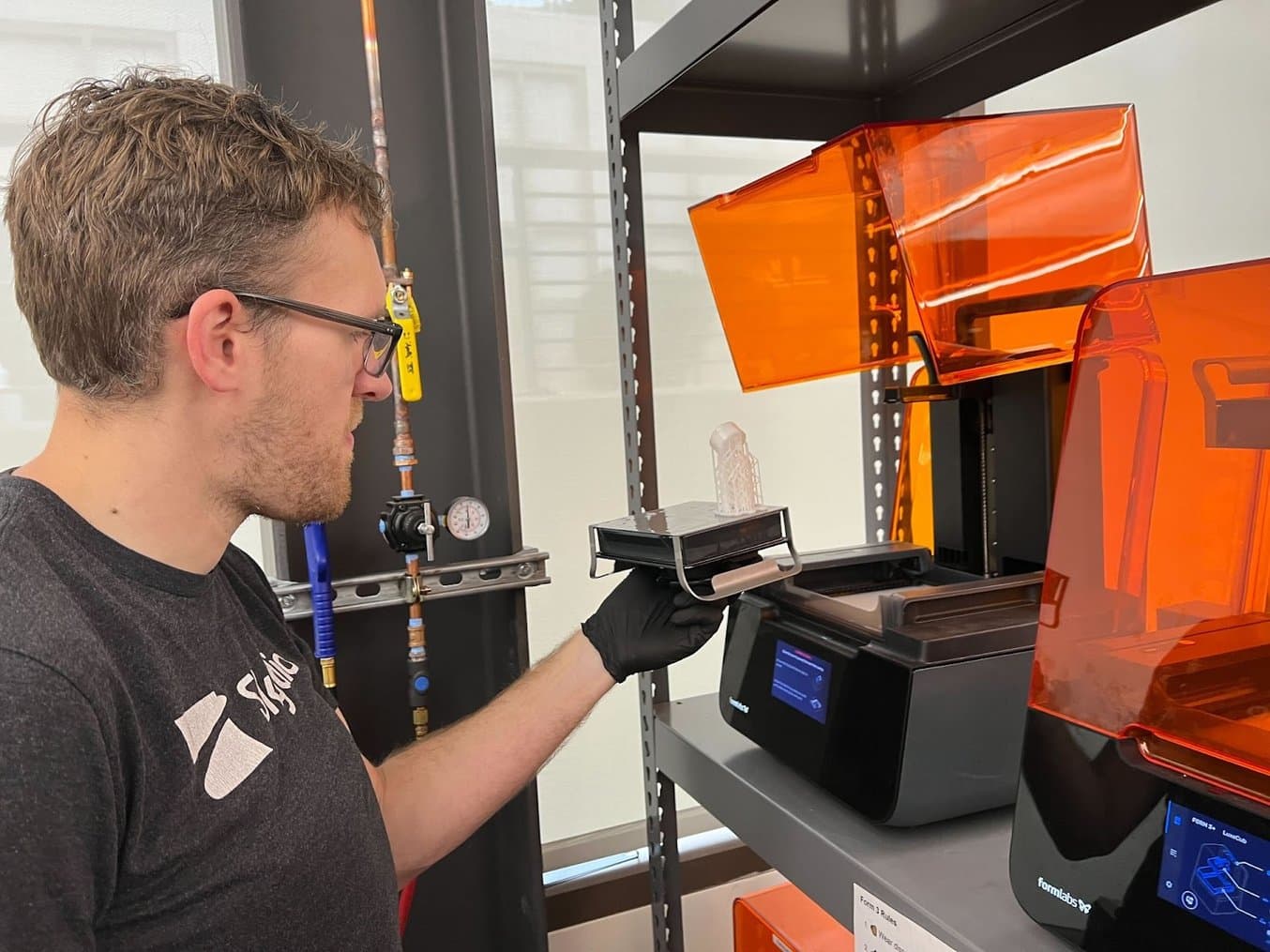

Resin Pumping System, an accessory for the Form 3 Series that delivers 5 L of resin to the printer without cartridge changeover, improves operational efficiency, streamlines the stereolithography (SLA) 3D printing workflow, and reduces waste by 86%. Resin Pumping System enables all Formlabs SLA users to print more parts, more often, with fewer touchpoints, and at a lower cost per liter.

Consumables pricing discounts are now available, both through purchasing 5 L of resin at once with Resin Pumping System as well as speaking with our team about your specific needs. Bulk discounts are available for resin purchased as both 1 L cartridges and 5 L containers. These discounts start at 30 L and scale up with order size, enabling the lowest cost per part possible with Formlabs professional desktop 3D printers.

Both Resin Pumping System and bulk resin discounts lead to lower cost per part, so that your Form 3+ or Form 3L can work continuously to deliver the parts you need, at an even more affordable price.

Visit our materials catalog to choose the best resin for your workflow in a 5 L Resin Container, then purchase Resin Pumping System to get started. To speak with a member of our team and build a custom pricing structure for your needs, contact sales.

How Does Resin Pumping System Work?

The Resin Pumping System consists of a Resin Pump connected to a 5 L Resin Container, tubing, and a unique resin card that tracks material usage and provides low resin warnings.

The Resin Pump sits inside the Form 3/B/+ or Form 3/B/L’s cartridge slot, with the tubing connected to the external 5 L Resin Container. To begin printing with the Resin Pumping System, follow these simple steps:

- Insert the resin card into the slot in the Resin Pump.

- Unscrew the cap on the 5L Resin Container and install the transfer cap.

- Unhook the transfer cap’s silicone plug and connect the tubing between the Resin Pump and Resin Container.

- Twist off the drip cap on the Resin Pump and place it into the printer’s cartridge slot.

The Resin Pumping System will keep the printer’s Resin Tank continuously filled, so that you can print for five times as long before having to change the cartridge and disrupt your workflow.

One major advantage of Formlabs SLA printers has always been the ease of switching between the many advanced materials in our resin library, and that won’t change with Resin Pumping System. For users looking to maintain the ease of switching between materials, tubing for each type of resin can be purchased at an extremely affordable price. The resin itself doesn’t come in contact with the Resin Pump, so there is no cleaning necessary when switching materials.

Why Use Resin Pumping System and the Formlabs Automation Ecosystem

Resin Pumping System completes the Formlabs Automation Ecosystem, helping enable around-the-clock 3D printing.

In early 2023, Formlabs introduced the Automation Ecosystem, a revolutionary new way of 3D printing that enables high-productivity 3D printing at scale, reduces cost per part, and improves fleet management experiences. Resin Pumping System is a key part to making the Automation Ecosystem truly hands-free. After Form Auto removes the print job by leveraging the Quick Release Technology of the Build Platform 2, new prints start automatically. That cycle can now run unattended for five times longer, enabling non-stop, unattended printing for multiple days.

The Form Auto enables a true ‘third shift,’ so that production doesn’t stop when you leave for the day. At Mackart Additive, Managing Director and Founder Steven McCarthy says the Automation Ecosystem helps Mackart increase productivity and enables true production volume. "With the Form Auto, you get that third and weekend shift going, and you don’t have to plan swapovers or any changes of build platforms. It runs nicely and it’s great for small components, and mid-size batch production runs of up to 1000 parts and beyond."

Using Resin Pumping System with Fleet Control gives users a bird’s eye view of their entire operation, but with fewer alerts for consumables changeover. Together, the Resin Pumping System and Automation Ecosystem enable small businesses to build themselves up, large businesses to become more efficient and innovative, educators to engage their students, inventors to bring ideas to life, and so much more.

Reduce Costs

The five most commonly-used resins, Clear Resin, Model Resin, Draft Resin, Grey Resin, and Tough 2000 Resin, will be available immediately, with the rest of the materials library soon to follow.

Since first introducing accessible, industrial-quality desktop 3D printers, Formlabs has continuously improved our product and business strategy to ensure that producing high-quality parts is not only easy, but affordable for all types of professionals.

However, high-quality SLA 3D printing can still be more expensive per part than traditional manufacturing techniques, and the operating costs of resin can deter customers from using SLA materials in every application they’d like to. The bulk pricing of purchasing 5 L at once with Resin Pumping System helps make resin costs more affordable. Additionally, users who are ordering large quantities of resin have the option of using bulk resin discounts on purchases of multiple 5L Resin Containers.

Example: How to Make 1000 3D Printed Rotating Arms (Grey Resin) in Three Days

| Setup | With Automation Ecosystem | Without Automation Ecosystem |

|---|---|---|

| Printers needed | 10 | 28 |

| Number of cartridge changes | 2 | 12 |

| Operators required | 1 | 1 |

| Cost per part* | $1.73 | $2.62 |

*Calculation includes equipment and labor costs, and amortization.

Lower resin costs open up possibilities for using additive manufacturing in new ways. For many products, traditional manufacturing methods are more affordable, but can limit creativity, increase lead times, and create a more complicated supply chain. In-house 3D printing can help solve these issues, especially with a reduced cost per part enabled by 5 L Containers and bulk pricing, which make SLA 3D printing cost-competitive with traditional tools at even higher volumes.

Formlabs printers are tools to help our customers innovate — and just like any tool, they pay for themselves by making your workflow easier and more affordable. That time to ROI will vary depending on print volume, but for users that are printing between two and four liters of resin each month, Resin Pumping System pays for itself in under four months.

Increase Operational Efficiency

Manual replacement of cartridges is a touchpoint that can interrupt the flow of your workday. For customers managing printer fleets or even just one or two printers operating continuously, those printer interactions add up and can present real obstacles to overall efficiency.

Resin Pumping System makes it possible to print five times as long without changing cartridges, enabling continuous uptime for the printer and reducing user touchpoints, so that you can concentrate on higher-value tasks.

Resin storage and inventory footprint become easier with Resin Pumping System, which represents a 58% reduction in footprint compared to printing with individual cartridges. The 5L Resin Containers are easier to store, take up less space, and help customers avoid situations where dozens of partially empty cartridges may sit idle on a rack.

The desktop size of the Form 3 Series is what made it possible for product designers, engineers, and manufacturers to bring industrial-quality 3D printing into their workspace — on their desk within a larger shop floor, in an office setting, or even in home offices. Consumables management can limit the advantage of the desktop workflow. Resin Pumping System can help streamline operational efficiency and ensure that every inch of space is used most efficiently.

Reduce Waste

Efficiency isn’t limited to the pre-print consumables management or the printing touchpoints — disposal processes can be made more efficient as well. Resin Pumping System reduces cartridge and packaging waste by 86%. Single liter cartridges often take up sizable portions of disposal solutions, especially for high volume users, and changing to 5 L Resin Containers is an easy way to cut down on plastic waste and disposal needs.

Case Study: Fewer Touchpoints and Peace of Mind at Skydio Drones

The Skydio 3D printing space is open to multiple members of the hardware team while consumables management is up to Weinhoffer. Resin Pumping System makes things easier and helps him avoid last-minute rush ordering.

Skydio, a manufacturer based in California, creates drones with industry-leading software that enables autonomous flight, tracking, and recording. To match the performance of their software, the Skydio hardware team has to continuously iterate, and they rely on a fleet of FDM and SLA printers to do so.

Eric Weinhoffer is the Senior Hardware Development Specialist, and is in charge of managing their 3D printing fleet. Weinhoffer has to keep track of consumables in each machine, a task made harder by the fact that printers are being used at different frequencies by different people.

“Continually changing resins can be annoying for us because we have a lot of Form 3 users who are aware of the basic printing, washing, and curing process but may not be aware of, or comfortable with, the process for changing resins,” says Weinhoffer. Offering an open prototyping space to engineers is a huge advantage for Skydio’s hardware development cycle, but can lead to confusion around consumables management. Before starting with Resin Pumping System and the new 5L Resin Containers, Weinhoffer had to devote extra time to just staying on top of resin and usage to avoid running out during critical times in the product cycle.

“Not having to interact with the printer as much or worry about running out of 1 L cartridges will free me up to focus on other, more high-value, tasks. This is by far the biggest benefit of moving to 5 L cartridges for us, since I don't have the time to be constantly checking on our 1 L cartridge library. In the past we have run out without me noticing, resulting in a frantic resin order, so having 5L cartridges that last far longer will reduce the mental burden on me.”

Eric Weinhoffer, Senior Hardware Development Specialist, Skydio

Even More Affordable Cost Per Part for Formlabs 3D Printing

New pricing options and Resin Pumping System help reduce the cost and labor associated with 3D printing at scale, so you can leverage the power of the Form 3 Series SLA printers without worrying about consumables management.

The new Resin Pumping System and bulk resin pricing discounts make it easier than ever to choose the Form 3 Series printers for your workflow. Whether evaluating the printers against other fabrication methods, or other 3D printer manufacturers, cost per liter is often the biggest factor to consider.

Both the 5L Resin Containers and customizable tiered discounts create the highest level of savings Formlabs has ever offered, while Resin Pumping System reduces hands-on tasks and frees up your time for higher value activities. These updates to the Form 3 Series workflow help you focus on what you’re making, instead of worrying about costs and printer maintenance. Speak with our sales team to discuss your resin requirements and see if bulk discounts are right for you. To buy Resin Pumping System now and resins in a 5 L Resin Containers, visit our store.